In the dynamic realm of logistics and transportation, sourcing the right tire pump for trucks can be a pivotal challenge for international B2B buyers. With increasing demands for efficiency and safety, having reliable tire inflation solutions is essential for maintaining fleet performance and minimizing downtime. This comprehensive guide delves into the diverse types of tire pumps available, their specific applications across various truck models, and the critical factors to consider when evaluating suppliers.

From understanding the nuances of portable inflators to identifying heavy-duty options tailored for larger vehicles, this guide equips buyers with the knowledge needed to make informed purchasing decisions. We also cover vital aspects such as cost analysis, supplier vetting processes, and the importance of after-sales support, ensuring that you select a product that meets both operational needs and budget constraints.

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—this resource empowers you to navigate the complexities of the global market with confidence. By leveraging the insights and recommendations within this guide, you can enhance your procurement strategy and secure tire pumps that will keep your fleet running smoothly and efficiently.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Cordless Tire Inflators | Battery-operated, portable, often with built-in pressure gauge | Fleet maintenance, emergency roadside assistance | Плюсы: High portability, ease of use; Конс: Limited battery life, may not handle high pressures well. |

| 12V Powered Inflators | Connects to vehicle’s 12V power outlet, typically compact | Automotive workshops, on-the-go repairs | Плюсы: Convenient for vehicles, generally fast; Конс: Dependent on vehicle power, limited range. |

| Heavy-Duty Air Compressors | High PSI capabilities, often with multiple attachments | Trucking companies, heavy machinery repairs | Плюсы: High power, suitable for large tires; Конс: Bulky, requires more storage space. |

| Portable Air Pumps | Lightweight, often includes various adapters for inflating other items | Construction sites, outdoor events | Плюсы: Versatile, can inflate various items; Конс: Lower durability for heavy-duty use. |

| Digital Tire Inflators | Digital pressure gauge, automatic shut-off features | Fleet management, tire shops | Плюсы: Accurate readings, user-friendly; Конс: May be more expensive, can require batteries or charging. |

Cordless tire inflators are compact, battery-operated devices ideal for quick tire inflation without needing a power source. They are particularly suitable for fleet maintenance and emergency roadside assistance, where portability and ease of use are paramount. When purchasing, B2B buyers should consider battery life and the maximum PSI capability to ensure the inflator meets the demands of various truck types.

12V powered inflators connect directly to a vehicle’s power outlet, making them convenient for automotive workshops and on-the-go repairs. Their compact design allows for easy storage in vehicles, which is beneficial for businesses that rely on quick tire servicing. Buyers should assess the inflator’s speed and durability, as well as its compatibility with different tire sizes to maximize its utility.

Heavy-duty air compressors are designed for high PSI applications, making them essential for trucking companies and heavy machinery repairs. These compressors can handle larger tires and more demanding inflation needs, which is critical for businesses operating in rugged environments. However, buyers should be aware of their bulkiness and storage requirements, as well as the need for a stable power source.

Portable air pumps are lightweight and versatile, often coming with various adapters to inflate items beyond tires, such as sports equipment and air mattresses. They are particularly useful on construction sites or during outdoor events where quick inflation is necessary. B2B buyers should consider the durability and overall capacity of these pumps, as they may not withstand heavy-duty usage as effectively as other options.

Digital tire inflators feature advanced technology, including digital pressure gauges and automatic shut-off capabilities, ensuring accurate inflation and preventing over-inflation. They are ideal for fleet management and tire shops where precision is crucial. When considering a digital tire inflator, B2B buyers should evaluate the cost-benefit ratio, as these models can be more expensive but offer enhanced functionality and reliability.

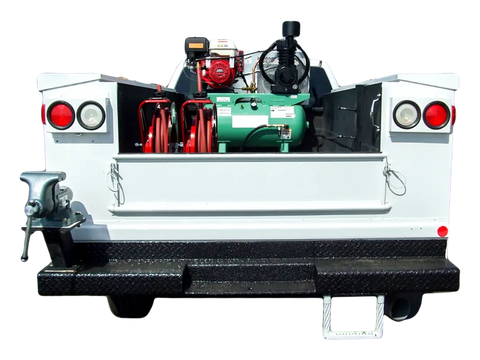

Illustrative image related to tire pump for trucks

| Промышленность/сектор | Specific Application of tire pump for trucks | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Logistics and Freight | On-site tire inflation for delivery trucks | Reduces downtime and enhances operational efficiency | Durability, portability, and compatibility with truck models |

| Строительство | Tire maintenance for heavy machinery and trucks | Ensures safety and prevents costly equipment failures | High-pressure capabilities and robust design |

| Сельское хозяйство | Inflation of agricultural vehicles and trailers | Improves productivity and reduces tire wear | Ability to handle varying tire sizes and conditions |

| Mining | Tire inflation for heavy mining trucks | Enhances vehicle reliability in harsh environments | Resistance to dust and moisture, high PSI performance |

| Transportation | Emergency tire inflation for passenger and freight vehicles | Minimizes road-side assistance costs and delays | Quick inflation time and ease of use |

In the logistics and freight industry, tire pumps are essential for maintaining the optimal performance of delivery trucks. On-site tire inflation enables drivers to quickly address low tire pressure issues, reducing downtime and preventing delays in the supply chain. Businesses must consider pumps that are durable and portable, ensuring they can withstand the rigors of daily use and are compatible with various truck models.

In construction, tire pumps are vital for the upkeep of heavy machinery and trucks, where tire pressure directly affects safety and operational efficiency. Regular inflation helps prevent equipment failures, which can lead to costly project delays. Buyers in this sector should prioritize high-pressure capabilities and robust designs to handle the demanding conditions typical on construction sites.

Agricultural vehicles and trailers often operate in diverse terrains, making tire maintenance critical for productivity. A reliable tire pump can help farmers maintain proper tire pressure, reducing wear and tear, which ultimately extends the lifespan of the tires. When sourcing pumps, farmers should look for units that can accommodate varying tire sizes and conditions, ensuring versatility and reliability.

Illustrative image related to tire pump for trucks

Mining operations require heavy trucks that can endure harsh environments, making tire maintenance crucial for vehicle reliability. Tire pumps allow for quick inflation of large tires, ensuring that vehicles remain operational even in challenging conditions. Buyers should focus on pumps that offer resistance to dust and moisture and can deliver high PSI performance to meet the demands of mining activities.

In the transportation sector, tire pumps serve a critical role in emergency situations, allowing quick inflation of tires for passenger and freight vehicles. This capability minimizes the need for roadside assistance, saving businesses time and money. When selecting a tire pump, transportation companies should consider factors like quick inflation times and ease of use to ensure efficiency during emergencies.

Проблема: Many B2B buyers, particularly those managing fleets of trucks, face the challenge of maintaining optimal tire pressure. Inconsistent tire pressure can lead to decreased fuel efficiency, increased tire wear, and potential safety hazards. When tire pumps are unable to accurately gauge or maintain the desired pressure, it creates frustration and operational inefficiencies. A flat tire can halt operations, leading to delays and increased costs, especially in industries reliant on timely deliveries.

Решение: To overcome this issue, B2B buyers should prioritize tire pumps equipped with high-quality, built-in pressure gauges that offer accurate readings. When sourcing tire pumps for trucks, look for models that provide digital pressure displays and automatic shut-off features. These pumps will not only inflate tires quickly but will also ensure that they reach the correct pressure without the risk of overinflation. Regular training on how to use these devices effectively can also enhance their utility, allowing staff to quickly identify and rectify pressure discrepancies before they become problematic.

Проблема: For businesses operating in remote locations or in industries like construction and agriculture, having a portable tire pump is essential. However, many conventional tire pumps are bulky and require a power source that may not always be available on-site. This limitation can lead to prolonged downtime when a truck’s tire goes flat, impacting productivity and profitability.

Illustrative image related to tire pump for trucks

Решение: B2B buyers should invest in compact, cordless tire pumps that are specifically designed for heavy-duty vehicles. When evaluating options, look for pumps that feature robust battery life and can inflate tires to high pressures, ideally accommodating the needs of trucks with larger tires. Additionally, consider models that come with multiple charging options, such as USB charging or 12-volt adapters for vehicle use. These features will enable quick and efficient repairs, minimizing downtime and enhancing operational efficiency.

Проблема: Trucks come in various sizes and tire specifications, making it challenging for fleet managers to select a single tire pump that meets all needs. Some pumps may struggle with the high pressures required for larger truck tires, while others may not have the necessary adaptability to accommodate different valve types. This inconsistency can lead to operational delays and increased expenses from needing multiple pumps.

Решение: To effectively address this challenge, B2B buyers should select tire pumps with versatile specifications, capable of accommodating a wide range of tire sizes and pressures. Pumps like the Viair 88P are an excellent choice due to their ability to handle larger tires and provide quick inflation. When sourcing these pumps, ensure that they include multiple nozzle adapters to fit various valve types. Additionally, consider establishing a standardized maintenance schedule for the pumps to ensure they remain in optimal working condition, capable of addressing the diverse needs of the fleet efficiently.

When selecting a tire pump for trucks, the choice of materials is critical to ensure durability, performance, and compliance with international standards. Below, we analyze four common materials used in the construction of tire pumps, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum is a lightweight and corrosion-resistant material commonly used in tire pump construction. Its excellent thermal conductivity allows for efficient heat dissipation during operation, which is crucial for maintaining performance under high-pressure conditions. Aluminum pumps typically have a temperature rating of up to 150°C and can handle pressures exceeding 100 psi.

Плюсы: Aluminum is durable yet lightweight, making it easy to transport. It is also relatively inexpensive compared to other metals, which can help keep manufacturing costs low.

Конс: While aluminum is resistant to corrosion, it can be susceptible to dents and scratches, potentially affecting the pump’s longevity. Additionally, the manufacturing process can be more complex, requiring specialized techniques like anodizing for enhanced corrosion resistance.

Влияние на применение: Aluminum is compatible with various media, including air and nitrogen, making it suitable for tire inflation. However, it may not be ideal for environments with extreme temperatures or corrosive substances.

Соображения для международных покупателей: Compliance with standards such as ASTM or DIN is essential. Buyers should ensure that the aluminum used meets the required specifications for strength and corrosion resistance, particularly in regions with high humidity or salt exposure, such as coastal areas in Africa or South America.

Steel, particularly stainless steel, is another popular material for tire pumps due to its strength and durability. It has a higher temperature rating than aluminum, often exceeding 200°C, and can handle high pressures (up to 150 psi) without deforming.

Плюсы: Steel is incredibly robust and resistant to wear, making it ideal for heavy-duty applications. Its longevity can result in lower replacement costs over time.

Illustrative image related to tire pump for trucks

Конс: Steel is heavier than aluminum, which can affect portability. Additionally, the cost of stainless steel can be significantly higher, impacting the overall price point of the tire pump.

Влияние на применение: Steel is compatible with air and other gases but may not be suitable for corrosive environments unless properly treated. Its strength makes it ideal for pumps designed for larger vehicles or frequent use.

Соображения для международных покупателей: Buyers in regions with stringent regulations, such as Germany, should verify that the steel meets relevant standards for strength and corrosion resistance. Certifications like ISO or CE may be required for compliance.

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in tire pump construction due to their lightweight and corrosion-resistant properties. These materials can handle pressures up to 80 psi and are resistant to a wide range of chemicals.

Illustrative image related to tire pump for trucks

Плюсы: Plastic is cost-effective and lightweight, making it easy to manufacture and transport. It is also resistant to corrosion, which is beneficial in humid or chemically aggressive environments.

Конс: While plastic is durable, it may not withstand high temperatures as effectively as metals, limiting its use in high-pressure applications. Additionally, it may not be suitable for heavy-duty pumps designed for trucks.

Влияние на применение: Plastic pumps are generally suitable for light-duty applications and can be used for inflating smaller tires or recreational vehicles. However, they may not perform well under extreme conditions.

Соображения для международных покупателей: Buyers should ensure that the plastic materials used comply with international standards for durability and safety. In regions like the Middle East, where temperatures can soar, heat resistance becomes a critical factor.

Rubber is often used for seals and hoses in tire pumps due to its flexibility and resilience. It can handle pressures up to 100 psi and is resistant to wear and tear.

Плюсы: Rubber provides excellent sealing capabilities, ensuring no air leaks during inflation. Its flexibility allows for easy handling and maneuverability.

Конс: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. This can lead to cracks and loss of functionality.

Влияние на применение: Rubber is essential for ensuring airtight connections, making it suitable for various tire inflation applications. However, it may require more frequent replacement compared to metal components.

Соображения для международных покупателей: Buyers should look for rubber that meets international standards for durability and UV resistance, particularly in regions with high sun exposure, such as parts of Africa and South America.

Illustrative image related to tire pump for trucks

| Материал | Typical Use Case for tire pump for trucks | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Lightweight tire pumps | Corrosion-resistant and lightweight | Susceptible to dents and scratches | Низкий |

| Сталь | Heavy-duty tire pumps | Extremely durable and long-lasting | Более тяжелые и дорогие | Высокий |

| Пластик | Light-duty or portable tire pumps | Экономичный и легкий | Limited high-temperature resistance | Низкий |

| Резина | Seals and hoses in tire pumps | Excellent sealing capabilities | Can degrade over time | Средний |

This analysis provides B2B buyers with valuable insights into material selection for tire pumps, enabling informed decisions that align with operational needs and regional considerations.

The manufacturing of tire pumps designed specifically for trucks involves several critical stages, each aimed at ensuring the final product meets both performance and durability standards. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundational stage where raw materials are selected based on specifications for durability and performance. Common materials include high-grade plastics for the casing, aluminum or steel for structural components, and rubber for seals and hoses. Suppliers often conduct material testing to ensure that these components can withstand high pressures and varying environmental conditions.

The forming stage encompasses various techniques, including injection molding for plastic components, die-casting for metal parts, and extrusion for hoses. Injection molding allows for precise shaping of complex designs, which is vital for ensuring airtight seals in tire pumps. Die-casting is particularly useful for components that require strength and resilience, such as the pump housing.

Assembly involves integrating all the formed components into a cohesive unit. This may include manual assembly or automated processes, depending on the scale of production. Quality checks are often performed during assembly to ensure that all parts fit correctly and function as intended. For instance, ensuring that the hose connectors are leak-proof is critical for performance.

Finishing processes can include surface treatment, painting, and packaging. Surface treatments may involve coatings that enhance resistance to corrosion and wear, essential for pumps that will be used in rugged environments. Packaging is designed not only for aesthetics but also for protection during shipping, ensuring that the pumps arrive at their destination in optimal condition.

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that tire pumps meet international and industry-specific standards.

International standards such as ISO 9001 are essential benchmarks that manufacturers should adhere to. ISO 9001 outlines the criteria for a quality management system, focusing on consistent quality and customer satisfaction. Other relevant certifications include CE marking for compliance with European safety standards and API (American Petroleum Institute) standards for pumps that may be used in oil and gas applications.

Quality control (QC) checkpoints play a crucial role in maintaining product integrity. Common QC checkpoints include:

Входящий контроль качества (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

Внутрипроцессный контроль качества (IPQC): This step includes monitoring the manufacturing process to identify defects early, allowing for immediate corrective actions.

Окончательный контроль качества (ОКК): Conducted after assembly, this stage involves comprehensive testing of the finished product to verify that it meets performance criteria and safety standards.

Various testing methods are employed to ensure that tire pumps function correctly under different conditions. Common tests include:

Illustrative image related to tire pump for trucks

Pressure Testing: Pumps are subjected to high-pressure conditions to ensure they can handle the required PSI for truck tires without failure.

Испытания на долговечность: This involves simulating real-world usage conditions, such as continuous operation and exposure to extreme temperatures, to assess the pump’s longevity.

Leak Testing: Ensuring that there are no leaks in the system is vital for functionality. This is often done using specialized equipment to detect air loss.

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers.

Conducting supplier audits is an effective way to evaluate manufacturing practices and QA systems. During an audit, buyers can assess compliance with international standards and review documentation related to quality checks and test results.

Requesting detailed quality reports from suppliers can provide insights into their QA processes. Additionally, third-party inspections can offer an unbiased evaluation of manufacturing practices and product quality. Engaging an independent inspection service can help verify that the supplier meets both local and international standards.

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control can be critical.

Different regions may have specific standards that affect the manufacturing and importation of tire pumps. For instance, CE marking is required for products sold in the European Union, while compliance with local regulations is crucial in African and South American markets. Buyers should familiarize themselves with these regional requirements to avoid compliance issues.

Illustrative image related to tire pump for trucks

Supply chain logistics can also impact quality assurance. Delays in shipping can lead to products being stored improperly, affecting their performance upon arrival. Buyers should work closely with suppliers to ensure that products are packaged and handled correctly throughout the shipping process.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing tire pumps for trucks, ultimately ensuring they receive high-quality products that meet their operational needs.

This guide provides a comprehensive checklist for B2B buyers looking to procure tire pumps specifically designed for trucks. Given the diverse conditions and requirements in international markets, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the key factors in selecting the right tire pump is essential for ensuring operational efficiency and reliability.

Illustrative image related to tire pump for trucks

Before initiating the sourcing process, it’s vital to establish clear technical specifications for the tire pumps you require. Consider factors such as the maximum PSI needed, compatibility with different tire sizes, and whether you need a cordless or corded model. Understanding these specifications will help narrow down your options and ensure you select a pump that meets your operational needs.

Verify the credentials of potential suppliers to ensure they meet industry standards and regulations. Look for certifications such as ISO or CE, which can indicate adherence to quality management and safety standards. Additionally, assess their experience in the industry, particularly with products suited for the trucking sector.

When comparing different tire pumps, focus on essential features that enhance usability and efficiency. Look for pumps with built-in pressure gauges for accuracy, fast inflation capabilities, and durable construction to withstand tough conditions. Additional features like LED lights or USB charging ports can also add value, especially for emergency use in low-light situations.

A robust warranty and reliable customer support are crucial when purchasing equipment like tire pumps. Check the warranty period offered and what it covers—this can vary significantly between suppliers. Good after-sales support, including access to technical assistance and spare parts, is essential to minimize downtime in case of equipment failure.

Whenever possible, request samples or demonstrations of the tire pumps from potential suppliers. This allows you to evaluate the product’s performance in real-world conditions and ensures it meets your expectations. Testing the pump’s functionality, ease of use, and speed of inflation can significantly influence your purchasing decision.

Analyze the pricing structures of different suppliers, ensuring you understand the total cost of ownership, including shipping and potential import duties. Negotiate payment terms that align with your cash flow requirements, considering options such as deferred payments or bulk purchase discounts. This step is vital for maintaining budgetary control and optimizing your procurement strategy.

Finally, gather and review customer feedback and testimonials about the tire pumps you’re considering. Insights from other B2B buyers can provide valuable information about product performance, reliability, and supplier integrity. Platforms like industry forums or direct references can offer a clearer picture of what to expect from both the product and supplier.

Illustrative image related to tire pump for trucks

By following this checklist, B2B buyers can make informed decisions when sourcing tire pumps for trucks, ensuring they select products that enhance efficiency and reliability in their operations.

When sourcing tire pumps specifically designed for trucks, understanding the cost structure is crucial for B2B buyers. The primary components of cost include:

Материалы: High-quality materials are essential for durability and performance, particularly in harsh environments. Common materials include reinforced plastics, metals for the pump casing, and rubber for hoses and seals. The choice of materials can significantly influence both the initial cost and the longevity of the product.

Труд: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing; however, this may sometimes come at the expense of quality. Skilled labor is required for assembly and quality assurance, impacting the overall labor cost.

Производственные накладные расходы: This includes utilities, rent, and equipment depreciation associated with the manufacturing process. Efficient production methods and facilities can reduce overhead costs, benefiting the buyer through lower pricing.

Инструментальная оснастка: Custom tooling for specific pump designs can be a significant upfront cost. However, investing in specialized tooling can lead to better quality and efficiency, which can justify higher initial prices.

Контроль качества (QC): A robust QC process ensures that the tire pumps meet safety and performance standards. While this adds to the cost, it mitigates risks associated with product failures, which can be particularly costly for truck operators.

Логистика: Shipping costs, including freight and insurance, vary based on the distance from the manufacturer to the buyer. Incoterms, which define responsibilities for shipping, can also affect pricing. Buyers should consider both the shipping method and delivery time when assessing logistics costs.

Маржа: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the margin expectations can help buyers negotiate better prices.

Several factors influence the pricing of tire pumps for trucks, particularly for international buyers:

Объем и минимальное количество заказа (MOQ): Larger orders often lead to reduced per-unit costs. Negotiating favorable MOQs can help lower overall expenses.

Технические характеристики и персонализация: Custom features or higher specifications typically lead to increased costs. Buyers should weigh the benefits of customization against the potential price increase.

Сертификация материалов и качества: Higher-quality materials and compliance with international quality certifications can increase costs but may provide better long-term value and reliability.

Факторы поставщика: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market entry.

Инкотермс: Understanding the responsibilities outlined in Incoterms can help buyers manage costs effectively. For instance, FOB (Free on Board) terms may lead to lower shipping costs compared to CIF (Cost, Insurance, and Freight), where the seller assumes more responsibility.

B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

Повышение совокупной стоимости владения (TCO): Evaluate not just the purchase price, but also the long-term costs associated with maintenance, durability, and potential downtime. This approach can justify a higher upfront cost if it leads to savings over time.

Understand Pricing Nuances: Familiarize yourself with regional pricing variations and market conditions. For instance, tariffs, taxes, and currency fluctuations can affect overall costs and should be factored into negotiations.

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, priority service, and improved terms. Suppliers are often more willing to negotiate with trusted partners.

Request Multiple Quotes: Gathering quotes from various suppliers can provide a clearer picture of the market and empower buyers to negotiate better deals.

Be Transparent About Needs: Clearly communicate your requirements and expected volumes to suppliers. Transparency can foster trust and potentially lead to more favorable pricing.

While this analysis provides a general framework for understanding the costs and pricing of tire pumps for trucks, actual prices can vary widely based on specific supplier offerings, market conditions, and buyer negotiations. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

In the realm of tire maintenance for trucks, selecting the right solution can significantly impact operational efficiency and costs. While tire pumps designed specifically for trucks are a popular choice, alternative methods and technologies may also offer effective solutions for maintaining optimal tire pressure. This analysis compares tire pumps for trucks against two viable alternatives: portable air compressors and tire maintenance services.

| Сравнительный аспект | Tire Pump For Trucks | Портативный воздушный компрессор | Tire Maintenance Services |

|---|---|---|---|

| Производительность | High-pressure capability, suitable for heavy-duty tires | Versatile, can handle various tire sizes | Comprehensive service, includes inspection and repairs |

| Стоимость | Moderate ($60-$100) | Variable ($30-$150) | Higher (typically $100+ per service) |

| Простота реализации | User-friendly, requires minimal setup | Requires some knowledge for effective use | Convenient, no user involvement needed |

| Техническое обслуживание | Low, mainly cleaning and occasional battery checks | Moderate, may need filter changes and oil checks | Low, service provider handles all maintenance |

| Лучший пример использования | On-the-road emergencies and routine tire pressure checks | Home or workshop use, versatile for different vehicles | Regular fleet maintenance and comprehensive checks |

Portable air compressors are a popular alternative due to their versatility and ability to handle various tire sizes, including those for trucks, cars, and even bicycles. They often come with multiple attachments for different inflation needs. However, they can require a certain level of technical knowledge to operate efficiently, which may not be ideal for all users. Additionally, while they offer a good performance-to-cost ratio, their portability can be limited by size and weight compared to dedicated tire pumps.

Illustrative image related to tire pump for trucks

Tire maintenance services provide a comprehensive approach to tire care, including pressure checks, rotations, and repairs. These services are particularly beneficial for businesses that rely on a fleet of vehicles, as they ensure that tires are always in optimal condition without requiring user intervention. However, the cost can be significantly higher compared to purchasing a tire pump or compressor, and they may not be as readily available in remote areas. This makes them less practical for on-the-road emergencies but invaluable for routine fleet management.

When determining the best tire maintenance solution, B2B buyers should consider their specific operational needs, budget constraints, and the frequency of tire issues. Tire pumps for trucks are excellent for immediate, on-the-spot inflation needs, especially in remote locations. Portable air compressors offer flexibility and can handle various tasks but may require more knowledge and effort to use effectively. Tire maintenance services, while more expensive, provide a thorough solution for businesses looking to ensure their fleet’s longevity without direct involvement. By weighing these factors, buyers can select the most suitable option that aligns with their operational strategies and financial considerations.

When selecting a tire pump for trucks, certain technical properties are essential to ensure reliability and efficiency. Here are some critical specifications:

The maximum pressure rating indicates how much air pressure the pump can deliver, typically measured in pounds per square inch (PSI). For heavy-duty trucks, pumps should handle pressures of up to 80 PSI or more. This capability is crucial for maintaining optimal tire performance, enhancing fuel efficiency, and ensuring safety during operation. Understanding PSI ratings helps buyers select pumps that meet the demands of larger tires.

The duty cycle refers to the amount of time a pump can operate continuously before requiring a cooldown period. For instance, a 25% duty cycle means the pump can run for 25 minutes but will need a 75-minute rest. This specification is vital for B2B buyers, as it affects how quickly and efficiently tire maintenance can be performed, especially in commercial settings where downtime can lead to lost revenue.

Illustrative image related to tire pump for trucks

Tire pumps can be powered by various sources, including battery, 12-volt outlets, or alligator clamps connected to the vehicle’s battery. Each power source has its advantages; for example, battery-powered pumps offer portability, while those using vehicle batteries may provide more consistent power. Understanding the power source helps businesses choose pumps that align with their operational needs and vehicle types.

This property measures how quickly a tire pump can inflate a tire from a specific PSI to the desired level. For example, a pump that can inflate a tire from flat (0 PSI) to 35 PSI in under seven minutes is considered efficient. Fast inflation speeds are crucial for B2B operations, particularly in logistics and transportation, where time is a critical factor.

The accuracy of the pressure gauge is paramount, as it ensures that tires are inflated to the correct pressure. Gauges can be digital or analog, with digital gauges typically offering more precise readings. A reliable pressure gauge prevents overinflation or underinflation, contributing to better tire health and performance.

The length of the hose determines the ease of access to all tires, especially for larger trucks. A longer hose allows for more flexibility in positioning the pump without needing to reposition it frequently. This consideration is especially important for fleet managers who need to ensure quick and efficient tire maintenance.

Illustrative image related to tire pump for trucks

Understanding industry jargon is vital for effective communication in B2B transactions. Here are some common trade terms:

This term refers to companies that manufacture products that are sold under another company’s brand name. In the context of tire pumps, an OEM might produce pumps that are rebranded by a larger automotive company. B2B buyers should consider OEM products for quality assurance and compatibility with existing equipment.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for procurement, as it affects inventory management and cost-efficiency. Buyers should negotiate MOQs that align with their operational needs without overcommitting resources.

Illustrative image related to tire pump for trucks

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This is a crucial step for B2B transactions, as it allows companies to compare offers and make informed purchasing decisions. Crafting a clear RFQ can streamline the procurement process.

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaging in global trade, as they clarify costs and responsibilities, minimizing disputes.

Lead time refers to the period between placing an order and receiving the product. For tire pumps, understanding lead times is critical for planning maintenance schedules and ensuring that equipment is available when needed.

Illustrative image related to tire pump for trucks

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance their operations and maximize efficiency in tire maintenance for trucks.

The tire pump for trucks sector is witnessing significant transformation, driven by a confluence of global trends and technological advancements. Key market drivers include the increasing demand for efficient and reliable tire maintenance solutions among fleet operators and logistics companies. As vehicle safety regulations tighten globally, there is a heightened focus on ensuring optimal tire pressure, which directly influences fuel efficiency and extends tire life.

Emerging technologies, such as smart tire inflators equipped with IoT capabilities, are revolutionizing the market. These devices can monitor tire pressure in real-time, send alerts to drivers, and automatically adjust pressure as needed. This trend aligns with the growing adoption of telematics in commercial vehicles, facilitating better fleet management and operational efficiency.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is critical. Buyers must consider factors such as varying regional regulations, the availability of reliable supply chains, and the need for products that can withstand diverse climatic conditions. Additionally, as sustainability becomes a priority, there is a noticeable shift towards sourcing eco-friendly tire pumps, which is reshaping procurement strategies.

The environmental impact of manufacturing processes and the importance of ethical sourcing are increasingly shaping purchasing decisions in the tire pump sector. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainability, including responsible sourcing of materials and minimizing waste throughout the production cycle.

Incorporating ‘green’ certifications and materials into product offerings is becoming essential. For instance, suppliers that use recycled components or eco-friendly manufacturing processes can distinguish themselves in a competitive market. Certifications like ISO 14001 for environmental management and the use of materials compliant with RoHS (Restriction of Hazardous Substances) are becoming key considerations for B2B buyers.

Furthermore, buyers are recognizing the long-term benefits of sustainable sourcing, such as reduced operational costs and enhanced brand reputation. As businesses increasingly align their procurement strategies with sustainability goals, the tire pump for trucks sector will likely see a surge in demand for innovative, environmentally-friendly products.

Illustrative image related to tire pump for trucks

The evolution of tire pumps for trucks can be traced back to the early 20th century when manual pumps were the norm. These simple devices required considerable physical effort and were often inefficient. As the automotive industry progressed, so did tire pump technology, leading to the introduction of electric and portable inflators in the late 20th century.

The focus on convenience and efficiency paved the way for modern tire inflators, which now feature advanced functionalities such as digital pressure gauges, automatic shut-off mechanisms, and rapid inflation capabilities. Today, the market is increasingly influenced by technological advancements and a growing emphasis on sustainability, reflecting the changing needs of B2B buyers and the broader transportation industry.

Understanding this historical context helps international buyers appreciate the ongoing innovations and the importance of selecting tire pumps that not only meet current operational needs but also align with future trends in sustainability and technology.

How do I choose the right tire pump for my truck?

Selecting the right tire pump involves evaluating several factors, including the pump’s PSI capacity, power source, and portability. For trucks, especially those with larger tires, look for models that can inflate to at least 80 PSI. Assess whether you need a cordless model for convenience or a corded one for continuous power. Additionally, consider features like built-in pressure gauges, speed of inflation, and additional functionalities like USB ports or integrated lights. Reading user reviews and conducting product comparisons can also help you make an informed decision.

What are the best tire pumps for heavy-duty trucks?

For heavy-duty trucks, the Viair 88P is often recommended due to its high inflation capacity and speed, making it suitable for larger tires. The AstroAI Cordless Tire Inflator is another excellent choice, praised for its portability and ability to inflate multiple tires on a single charge. When selecting a pump, ensure it can handle your truck’s specific tire size and pressure requirements. Researching the latest models and comparing features can help you find the best match for your needs.

What customization options are available for tire pumps?

Many manufacturers offer customization options for tire pumps, including branding, color choices, and additional features. You can request specific PSI ratings, hose lengths, or attachments to suit your operational needs. Customization can enhance product visibility and align the pump with your brand identity. When negotiating with suppliers, clearly communicate your requirements and inquire about their capabilities to deliver bespoke solutions.

What is the minimum order quantity (MOQ) for tire pumps?

Minimum order quantities (MOQ) for tire pumps can vary significantly depending on the supplier and the model. Typically, MOQs can range from 50 to several hundred units. It’s essential to discuss MOQs directly with potential suppliers, as they may offer flexibility based on your business needs or the potential for long-term partnerships. Understanding your demand can help you negotiate better terms and avoid excess inventory.

How can I vet suppliers for tire pumps?

Vetting suppliers requires a multi-step approach. Start by checking their industry reputation through online reviews and testimonials. Verify their certifications and compliance with international quality standards. Request product samples to assess quality firsthand. It’s also beneficial to inquire about their production capabilities, lead times, and after-sales support. Engaging in direct communication can provide insights into their reliability and responsiveness, essential for a successful partnership.

What payment terms are common for international purchases of tire pumps?

Payment terms for international purchases can vary widely but typically include options like upfront payment, partial payments, or payment upon delivery. Common methods include wire transfers, letters of credit, and PayPal. It’s crucial to establish clear terms before finalizing any agreements to mitigate risks. Discussing payment terms openly with suppliers can lead to mutually beneficial arrangements, especially if you have a long-term relationship.

What quality assurance (QA) measures should I expect from tire pump suppliers?

Quality assurance measures vary by supplier but should include rigorous testing protocols for performance, durability, and safety standards. Expect suppliers to provide certifications that demonstrate compliance with international regulations. Many reputable manufacturers conduct pre-shipment inspections and offer warranties to ensure product reliability. Request detailed QA processes to ensure the pumps meet your operational standards and reduce the risk of defects.

What logistics considerations should I keep in mind when sourcing tire pumps?

When sourcing tire pumps internationally, logistics is a critical factor. Consider shipping methods, lead times, and customs clearance processes that may affect delivery. Ensure that the supplier can handle logistics efficiently, including packaging that protects products during transit. It’s also wise to understand potential tariffs and duties that may apply to your shipments. Establishing a clear logistics plan with your supplier can help ensure timely and cost-effective delivery of your order.

Домен: fanttik.com

Зарегистрирован: 2020 (5 лет)

Введение: 2X Faster Electric Tire Inflators, Various Models: X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Sale prices range from $48.99 to $199.97 with discounts up to 50%. Regular prices vary from $59.97 to $129.99. Customer ratings average 4.8. Black Friday Sale from 11.20-12.7.

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: 1. ETENWOLF Tire Inflator: Runs off truck battery clamps, inflates to 95 psi, compact size fits behind the seat, praised customer service. 2. Milwaukee Inflator: Recommended by users for air up after trips, specific model mentioned is 2848-20.

In conclusion, the strategic sourcing of tire pumps for trucks is not just about selecting a reliable product; it involves understanding the specific needs of your operations, the regional market conditions, and the technological advancements shaping the industry. Buyers should prioritize inflators that demonstrate efficiency, accuracy, and versatility, such as the AstroAI Cordless Tire Inflator and Viair 88P, which cater to the demands of heavy-duty vehicles.

Investing in high-quality tire inflators can lead to significant cost savings by extending tire lifespan, improving fuel efficiency, and ensuring safety on the road. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, establishing strong supplier relationships can enhance supply chain resilience and provide access to innovative solutions tailored to local market needs.

As we look to the future, the demand for advanced tire inflators will continue to grow, driven by the increasing focus on operational efficiency and safety. Now is the time to evaluate your sourcing strategies and consider aligning with suppliers who can provide cutting-edge technology and exceptional service. Embrace the opportunity to elevate your fleet’s maintenance capabilities and drive your business forward.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.