Navigating the complexities of tire inflation solutions is critical for international B2B buyers, particularly those sourcing products in regions such as Africa, South America, the Middle East, and Europe. The challenge of ensuring optimal tire performance while balancing cost and quality can be daunting. Inadequate tire pressure not only leads to increased fuel consumption and reduced tire lifespan but can also compromise vehicle safety. This guide on tire inflation will comprehensively explore various types of tire inflation equipment, their applications, and the essential factors for supplier vetting.

In the pages that follow, you’ll discover insights into the latest tire inflation technologies, including traditional air compressors and nitrogen inflation systems, and their respective advantages. We will also provide actionable strategies for evaluating suppliers, understanding pricing structures, and identifying the best options for your specific needs.

By equipping yourself with the knowledge presented in this guide, you will be empowered to make informed purchasing decisions that not only enhance operational efficiency but also contribute to sustainability goals. As a result, your organization can minimize risks associated with improper tire inflation while maximizing vehicle performance and safety across diverse markets.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Compressed Air Inflation | Utilizes air compressors to inflate tires; widely available. | Automotive service centers, fleets | Плюсы: Easy access, cost-effective. Конс: Air pressure fluctuates with temperature. |

| Nitrogen Inflation | Tires filled with nitrogen instead of air; retains pressure longer. | Luxury vehicles, racing teams | Плюсы: Reduced pressure loss, improved fuel efficiency. Конс: Higher initial cost, limited availability. |

| Portable Tire Inflators | Compact devices for on-the-go inflation; often battery-operated. | Small businesses, delivery services | Плюсы: Convenient, useful for emergencies. Конс: Limited air capacity, may require frequent recharging. |

| CO2 Tire Inflation | Uses carbon dioxide for inflation; less common. | Specialty applications, racing | Плюсы: Consistent pressure, quick inflation. Конс: More expensive than air, requires specialized equipment. |

| Manual Pump Inflation | Hand-operated pumps; no power source needed. | Remote areas, off-road vehicles | Плюсы: Portable, low cost. Конс: Labor-intensive, slower inflation process. |

Compressed air inflation is the most prevalent method for tire inflation, especially in automotive service centers and for fleet management. This method relies on air compressors, which are readily available at gas stations and service shops. B2B buyers appreciate its cost-effectiveness and ease of access. However, it is crucial to note that air pressure can fluctuate with temperature changes, potentially leading to under or over-inflation if not monitored regularly.

Nitrogen inflation is increasingly popular among businesses operating luxury vehicles or those involved in motorsports. This method reduces the rate of air loss due to the larger nitrogen molecules compared to oxygen. B2B buyers benefit from improved fuel efficiency and extended tire life, which can lead to lower operational costs. However, the higher initial investment and limited availability can be drawbacks for some businesses.

Portable tire inflators are compact, battery-operated devices ideal for businesses that require mobility, such as delivery services or small fleets. They provide convenience for quick, on-the-spot inflation, which is especially useful in emergencies. While they are advantageous for their portability, buyers should consider the limited air capacity and the need for frequent recharging, which may hinder operations in high-demand situations.

Illustrative image related to inflate a tire

CO2 tire inflation is a specialized method used primarily in racing and other high-performance applications where consistent tire pressure is critical. This method allows for rapid inflation and maintains stable pressure, which can enhance performance. However, the cost of CO2 systems and the need for specialized equipment may limit its use for many businesses.

Manual pump inflation remains a viable option in remote areas or for off-road vehicles where access to power sources is limited. While these hand-operated pumps are affordable and portable, they require physical effort and take longer to inflate tires compared to powered methods. B2B buyers may find them beneficial in specific contexts where convenience and cost are prioritized over speed.

| Промышленность/сектор | Specific Application of inflate a tire | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Manufacturing | Quality control in tire production | Ensures tires meet safety and performance standards | Supplier reliability, compliance with international standards |

| Transportation & Logistics | Fleet maintenance and management | Reduces operational costs through improved fuel efficiency | Availability of portable inflators, service contracts |

| Строительство | Heavy machinery tire inflation | Enhances safety and productivity on job sites | Heavy-duty inflation equipment, local service availability |

| Сельское хозяйство | Inflation of agricultural vehicle tires | Maximizes crop yield through reliable machinery operation | Access to specialized tire inflation equipment |

| Mining | Tire maintenance for mining vehicles | Increases tire lifespan and reduces downtime | Durable inflation solutions, local support infrastructure |

In automotive manufacturing, inflating tires is a critical part of the quality control process. Ensuring that tires are inflated to the correct pressure is essential for meeting safety and performance standards. Manufacturers must invest in reliable tire inflation systems that can maintain precise pressures throughout the production process. For international buyers, sourcing equipment that complies with regional safety regulations and standards is crucial, as is ensuring that suppliers can provide consistent support and maintenance services.

In the transportation and logistics industry, maintaining proper tire pressure in fleet vehicles is vital for operational efficiency. Under-inflated tires can lead to increased fuel consumption and reduced vehicle safety, significantly impacting the bottom line. Companies often seek portable tire inflators to facilitate on-site maintenance. When sourcing these solutions, buyers must consider the reliability of the equipment and the availability of service contracts to ensure ongoing support, especially in remote areas of Africa or South America.

In the construction sector, proper tire inflation for heavy machinery is paramount for safety and productivity. Well-inflated tires reduce the risk of accidents and ensure that machinery operates efficiently on rugged job sites. Construction firms require heavy-duty tire inflation equipment that can withstand harsh conditions. Buyers should prioritize sourcing durable solutions that can be serviced locally to minimize downtime, particularly in regions with limited access to specialized maintenance services.

Agricultural vehicles rely on proper tire inflation to maximize crop yield and ensure reliable operation. Farmers need to maintain tire pressure to avoid costly delays during planting and harvesting seasons. This necessitates access to specialized tire inflation solutions that can handle various vehicle types. For international buyers, understanding the local availability of inflation equipment and the ability to source replacement parts is essential to ensure uninterrupted operations during critical agricultural periods.

In the mining industry, tire maintenance, including inflation, is crucial for the longevity of vehicles operating in harsh environments. Properly inflated tires prevent excessive wear and tear, reducing downtime and maintenance costs. Companies must invest in durable tire inflation solutions capable of withstanding the demands of mining operations. When sourcing these products, buyers should consider the local infrastructure for support and service, ensuring that they can maintain their fleets effectively in remote mining locations.

Проблема: Many businesses operating fleets of vehicles, such as delivery services or transportation companies, face the challenge of managing operational costs. One common issue arises from underinflated tires, which can significantly increase fuel consumption and tire wear. For instance, tires that are underinflated by just 20% can lead to a reduction in tire lifespan by up to 20%, resulting in more frequent replacements and higher fuel expenses. In regions with fluctuating temperatures, such as Africa and the Middle East, maintaining optimal tire pressure can become even more difficult, further compounding these costs.

Решение: To combat the effects of underinflation, businesses should implement a regular tire maintenance schedule. This can include monthly tire pressure checks and pre-trip inspections to ensure all tires are inflated to the manufacturer’s recommended PSI. Investing in a fleet of portable tire inflators allows drivers to quickly address any pressure discrepancies on-site, reducing downtime. Additionally, companies should consider using nitrogen inflation instead of regular air. Nitrogen helps maintain tire pressure longer due to its larger molecular size, leading to fewer adjustments and extended tire life. Training drivers on the importance of tire pressure and how to check it correctly can further minimize risks and costs.

Проблема: Businesses in remote or underserved areas often struggle to access reliable tire inflation equipment. This challenge can be particularly acute in regions like South America and parts of Africa, where gas stations may be scarce or their inflation machines poorly maintained. When tire pressure is low, it can lead to hazardous driving conditions, reduced fuel efficiency, and increased vehicle maintenance costs, ultimately impacting service delivery and customer satisfaction.

Решение: To address this issue, businesses should consider investing in portable air compressors for their fleets. These devices can be easily stored in vehicles and used at any location, ensuring that drivers can maintain tire pressure without needing to find a gas station. When selecting an air compressor, businesses should look for models with built-in pressure gauges and automatic shut-off features to prevent over-inflation. Additionally, creating partnerships with local tire service providers can ensure that support is readily available when needed. Training drivers on how to properly use these compressors will empower them to take proactive steps in tire maintenance, ensuring vehicle safety and efficiency.

Проблема: A common pain point for B2B buyers, particularly in the automotive industry, is the misunderstanding of tire pressure specifications. Many drivers mistakenly rely on the tire sidewall markings for pressure recommendations, which can lead to incorrect inflation levels. This confusion can result in either underinflation or overinflation, both of which compromise safety, increase operational costs, and reduce the lifespan of the tires. Companies operating in Europe, where regulations are stringent, may face legal repercussions for not adhering to proper safety standards.

Решение: To mitigate this issue, businesses should establish clear protocols for tire maintenance that emphasize the importance of consulting the vehicle’s user manual or door jamb specifications for the correct PSI. Regular training sessions for drivers can reinforce this knowledge and highlight the consequences of improper inflation. Additionally, businesses should implement a system for monitoring tire pressure that includes regular checks and the use of calibrated tire gauges. Leveraging technology, such as tire pressure monitoring systems (TPMS), can provide real-time data on tire pressure, alerting drivers when adjustments are needed. By fostering a culture of safety and adherence to specifications, companies can ensure better vehicle performance and compliance with regulations.

When selecting materials for inflating tires, it’s essential to consider various factors such as performance, durability, and compliance with international standards. Here, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Rubber is the most common material used in tire construction and inflation systems. It offers excellent flexibility and resilience, making it ideal for tires that need to withstand varying temperatures and pressures. Rubber can handle pressure ratings typically up to 44 PSI, depending on the specific formulation and design. Additionally, it has good resistance to wear and aging, which is crucial for maintaining tire integrity over time.

Плюсы: Rubber is cost-effective, easy to manufacture, and provides excellent grip and shock absorption. It also complies with various international standards, such as ASTM and ISO, making it suitable for global markets.

Cons: However, rubber can degrade under extreme temperatures and UV exposure, leading to a reduced lifespan. Moreover, it may require additives to enhance its resistance to ozone and other environmental factors.

Steel is often used in tire valves and rims due to its high tensile strength and durability. It can withstand high pressures and extreme conditions, making it a reliable choice for tire inflation systems. Steel components typically have a pressure rating well above 60 PSI, ensuring safety during operation.

Плюсы: The main advantage of steel is its strength and longevity. It is also recyclable, which aligns with sustainability practices increasingly valued by businesses.

Cons: On the downside, steel is susceptible to corrosion, especially in humid or saline environments, which can lead to failure. Additionally, steel components can be heavier than alternatives, potentially affecting vehicle performance.

Aluminum is another material used for tire rims and valve stems. It is lightweight, corrosion-resistant, and can handle moderate pressure levels, typically up to 50 PSI. Aluminum’s thermal conductivity also helps dissipate heat, which is beneficial for tire performance.

Плюсы: The primary advantage of aluminum is its lightweight nature, which can improve fuel efficiency and handling. Its resistance to corrosion makes it suitable for various climates, particularly in coastal regions.

Cons: However, aluminum can be more expensive than steel, and its lower tensile strength may not be suitable for all applications. Additionally, it may require protective coatings to enhance its durability.

Composite materials, which combine different substances to enhance performance, are increasingly being used in advanced tire technologies. These materials can be engineered to provide specific properties, such as enhanced pressure resistance and reduced weight.

Плюсы: Composites can offer superior performance characteristics, including flexibility, strength, and resistance to environmental factors. They are also customizable, allowing manufacturers to tailor them for specific applications.

Cons: The main limitation is the higher manufacturing complexity and cost associated with composites. Additionally, not all composites meet international standards, which can complicate compliance for B2B buyers.

| Материал | Typical Use Case for inflate a tire | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire construction and inflation | Cost-effective and flexible | Degrades under extreme conditions | Низкий |

| Сталь | Valves and rims | Высокая прочность и долговечность | Susceptible to corrosion | Мед |

| Алюминий | Lightweight rims and valve stems | Легкий и устойчивый к коррозии | Higher cost and lower tensile strength | Высокий |

| Композит | Advanced tire technologies | Superior performance and customization | Higher manufacturing complexity and cost | Высокий |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in tire inflation systems. Understanding the properties, advantages, and limitations of each material will help in making informed decisions that align with operational needs and compliance requirements in various international markets.

Illustrative image related to inflate a tire

The manufacturing process for tire inflation equipment involves several critical stages that ensure both efficiency and safety. Understanding these stages is essential for B2B buyers looking to source reliable tire inflation solutions.

Подготовка материалов

The first step involves sourcing high-quality materials, which typically include rubber compounds, steel belts, and composite materials for tire inflation systems. Manufacturers often perform chemical analyses to ensure material specifications meet industry standards. Additionally, suppliers must ensure that materials are sourced from certified vendors to guarantee consistency and reliability.

Формирование

During the forming stage, the materials are shaped into the necessary components. This might involve molding rubber into tire shapes, manufacturing valve stems, and creating air compressor units. Techniques such as injection molding and extrusion are commonly employed. Advanced technologies, like computer numerical control (CNC) machining, may also be utilized for precision parts, ensuring that all components fit together seamlessly.

Сборка

The assembly process involves bringing together all components to create the final product. This may include assembling the tire inflation unit, integrating air compressors, and attaching pressure gauges. Manufacturers often use automated assembly lines to enhance productivity and ensure consistency. Skilled technicians are also essential in this stage for quality checks and to handle complex assemblies that require manual intervention.

Отделка

The finishing stage includes processes like surface treatment, painting, and quality inspection. This ensures that the products not only function well but also have a desirable appearance. Techniques like powder coating are commonly used to enhance durability and resistance to environmental factors. Final assembly checks are performed to ensure that all components are correctly installed and functioning.

Quality assurance (QA) is a critical aspect of the manufacturing process for tire inflation equipment. Implementing robust QA measures helps ensure that the final products meet international standards and customer expectations.

Соответствующие международные стандарты

Compliance with international standards such as ISO 9001 is essential for manufacturers aiming to export their products. ISO 9001 outlines the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas sectors may be applicable, depending on the target market.

Контрольные точки контроля качества

Manufacturers typically implement various checkpoints throughout the production process:

B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, need to have a clear understanding of how to verify the quality control practices of their suppliers.

Проведение аудита поставщиков

Regular audits are an effective way to assess a supplier’s manufacturing processes and quality assurance practices. Buyers should request access to audit reports and certifications to verify compliance with international standards. On-site audits can also be beneficial to gain firsthand knowledge of the production environment.

Просмотр отчетов о контроле качества

Suppliers should provide comprehensive quality control reports that detail their processes, testing results, and any corrective actions taken. B2B buyers should scrutinize these reports to ensure that the supplier consistently meets quality standards and addresses any issues promptly.

Привлечение сторонних инспекторов

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can perform random checks during production and at the final inspection stage, ensuring that the products meet the required specifications before shipment.

Understanding the nuances of quality control and certification is crucial for B2B buyers, particularly those operating in international markets.

Illustrative image related to inflate a tire

Regional Compliance Requirements

Different regions may have specific compliance requirements for tire inflation equipment. For instance, products sold in Europe must meet CE marking requirements, while those entering the Middle Eastern markets may need to comply with local regulations. B2B buyers should be aware of these requirements to avoid regulatory issues.

Documentation and Traceability

Maintaining proper documentation is vital for quality assurance. B2B buyers should ensure that suppliers provide traceability documentation for materials and components. This is particularly important in industries where product recalls may occur, as it allows for quick identification of affected products.

Cultural and Language Considerations

When dealing with suppliers from diverse regions, B2B buyers should consider cultural and language differences that may affect communication. Clear communication regarding quality expectations and standards is essential to avoid misunderstandings that could impact product quality.

In summary, B2B buyers looking to source tire inflation equipment must have a comprehensive understanding of the manufacturing processes and quality assurance practices involved. By focusing on quality control measures, compliance with international standards, and thorough supplier verification, buyers can ensure that they are procuring reliable and safe products for their operations.

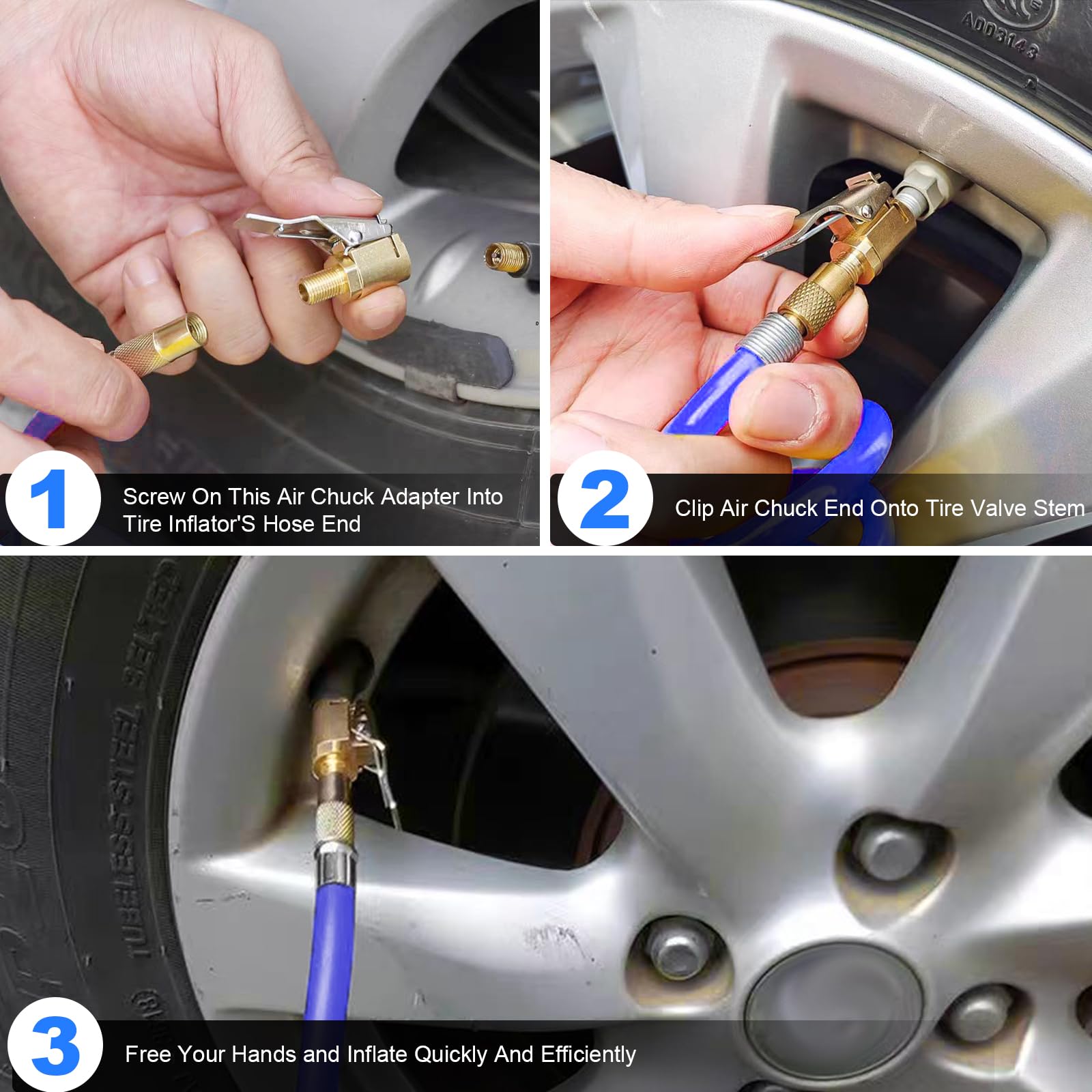

In the fast-paced world of automotive maintenance, ensuring that tires are properly inflated is essential for safety, fuel efficiency, and overall vehicle performance. This guide provides a step-by-step checklist for B2B buyers looking to procure the necessary equipment and services to inflate tires effectively.

Understanding the specific requirements for tire inflation is crucial. Consider the types of vehicles you service and the typical tire sizes you encounter. This will help you select the appropriate tools and equipment, such as air compressors or portable inflation devices, that cater to your operational needs.

Conduct thorough research to identify suppliers that specialize in tire inflation equipment and services. Look for companies with a strong reputation in the industry and positive customer reviews.

Once you have a list of potential suppliers, assess the range of tire inflation equipment they offer. Choose products that align with your operational requirements and budget.

Before making a purchase, request demonstrations of the tire inflation equipment. This step is vital to ensure the products meet your expectations and operational standards.

Assess the warranty terms and support services offered by the suppliers. A solid warranty and reliable customer service can significantly impact your operational continuity.

Gather pricing information from different suppliers and compare it against the features and benefits offered. Consider not only the initial purchase price but also long-term costs associated with maintenance and operation.

After evaluating all factors, finalize your procurement strategy. Ensure that your decision aligns with your business goals and operational capabilities.

By following this structured checklist, B2B buyers can ensure they procure the right tire inflation equipment and services, ultimately enhancing safety, efficiency, and customer satisfaction in their automotive operations.

Illustrative image related to inflate a tire

When sourcing tire inflation solutions, understanding the cost structure is crucial for B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Материалы: The cost of materials encompasses the components required for tire inflation systems, such as hoses, gauges, compressors, and valves. The choice between standard and premium materials can significantly impact overall costs. For instance, high-quality rubber or corrosion-resistant metals may enhance durability but will also lead to higher material costs.

Труд: Labor costs involve both direct and indirect labor. Direct labor relates to the assembly of tire inflation systems, while indirect labor includes management and administrative tasks. In regions with varying wage standards, like Africa and South America, labor costs can fluctuate, impacting total expenses.

Производственные накладные расходы: This includes costs associated with facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, thus influencing pricing strategies.

Инструментальная оснастка: Initial investments in tooling can be significant, particularly for customized or specialized tire inflation solutions. Buyers should consider whether the supplier has existing tooling that can accommodate their needs to avoid additional costs.

Контроль качества (QC): QC processes are essential to ensure that tire inflation systems meet safety and performance standards. Implementing stringent QC measures can increase upfront costs but may reduce long-term liabilities.

Логистика: Transportation and shipping costs are critical, particularly for international buyers. Factors such as distance, shipping method, and customs duties can add to the total cost. Efficient logistics management can help mitigate these expenses.

Маржа: Suppliers will typically add a markup to cover their costs and generate profit. Understanding the competitive landscape and market rates can aid buyers in negotiating better prices.

Several factors can influence pricing beyond the basic cost structure:

Объем/МОК: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and meeting these thresholds can provide better pricing per unit.

Технические характеристики/настройка: Customized tire inflation solutions can incur additional costs. Buyers should weigh the benefits of bespoke features against their budget constraints.

Материалы: The choice of materials significantly affects pricing. For example, opting for nitrogen inflation instead of standard air may incur higher initial costs but can lead to savings over time through reduced tire wear and improved fuel efficiency.

Качество/сертификация: Suppliers with recognized quality certifications (e.g., ISO) may charge a premium. However, certified products often offer better reliability and safety, which can justify the higher cost.

Факторы поставщика: The supplier’s reputation, reliability, and service offerings can impact pricing. Established suppliers may charge more for their proven track record and customer support.

Инкотермс: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Understanding these terms can help buyers make informed decisions regarding total landed costs.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing can lead to cost savings:

Вести переговоры: Always engage in negotiations. Suppliers may have flexibility in pricing, particularly for larger orders or long-term partnerships.

Ориентируйтесь на общую стоимость владения (TCO): Consider not just the initial purchase price but also the long-term costs associated with tire maintenance, fuel efficiency, and potential downtime.

Research Pricing Nuances: Understand regional pricing trends and market conditions. For instance, economic factors in Brazil or Saudi Arabia may influence supplier pricing strategies.

Leverage Relationships: Building strong relationships with suppliers can lead to better terms and priority service, which is invaluable during peak demand periods.

Request Quotes from Multiple Suppliers: Obtaining quotes from various suppliers can provide insights into competitive pricing and help identify the best value for your needs.

Prices mentioned in this analysis are indicative and may vary based on specific circumstances, market conditions, and regional factors. Always consult with suppliers for the most accurate and current pricing information.

When it comes to maintaining optimal vehicle performance, the method of inflating tires is crucial. However, there are various approaches available that can enhance or serve as alternatives to traditional tire inflation. This section analyzes some of these alternatives, helping B2B buyers understand their options and make informed decisions.

| Сравнительный аспект | Inflate A Tire | Портативный воздушный компрессор | Nitrogen Tire Inflation |

|---|---|---|---|

| Производительность | Provides immediate pressure adjustment | Quick inflation, varies by model | Maintains pressure longer |

| Стоимость | Minimal (cost of air at stations) | Moderate (typically $30-$100) | Higher initial cost (service fees) |

| Простота реализации | Requires access to a station | Simple to use, requires electric source | Requires professional service |

| Техническое обслуживание | Low, just periodic checks | Low, but needs power source | Moderate, needs periodic checks |

| Лучший пример использования | Routine maintenance for personal vehicles | Ideal for emergency situations | Best for fleet vehicles and long-term use |

A portable air compressor offers a convenient solution for tire inflation, especially in emergency situations. These devices can be plugged into a vehicle’s power outlet and provide quick inflation of tires without needing to visit a gas station. The primary advantage is the ease of use and accessibility, allowing users to inflate tires anywhere. However, the initial cost of purchasing a quality compressor can be moderate, and users must ensure they have a power source available. Additionally, the performance may vary based on the model, with some compressors taking longer to inflate tires compared to traditional methods.

Nitrogen tire inflation is a method that replaces standard air with nitrogen, which is less prone to leakage and helps maintain tire pressure for a longer duration. This method can significantly benefit fleet vehicles and long-distance travel, where consistent tire pressure is critical for safety and fuel efficiency. The advantage of nitrogen is its ability to reduce the frequency of inflation, thus saving time and enhancing performance. However, the service can be more expensive initially, and access may be limited to specialized tire service shops. Regular checks are still necessary to monitor pressure, as other factors can lead to leaks.

When selecting the appropriate tire inflation method for your business needs, consider factors such as the scale of operations, frequency of tire usage, and budget constraints. For businesses with a fleet or high tire turnover, nitrogen inflation may offer long-term benefits in performance and safety. Conversely, for smaller operations or individual vehicle owners, investing in a portable air compressor could provide the necessary flexibility and cost-effectiveness. Ultimately, understanding the specific requirements of your vehicles and operations will guide you in choosing the most effective tire inflation solution.

When it comes to inflating tires, understanding the technical specifications of the equipment and materials used is crucial for B2B buyers. Here are some essential properties to consider:

Номинальное давление

The pressure rating indicates the maximum air pressure a tire can safely hold, typically measured in PSI (pounds per square inch) or bar. This specification is vital for ensuring safety and performance; over-inflating tires can lead to blowouts, while under-inflation can cause uneven tire wear and increased fuel consumption. For B2B buyers, selecting equipment with the appropriate pressure rating ensures compliance with manufacturer standards and enhances vehicle safety.

Класс материала

The materials used in tire inflation equipment, such as hoses, valves, and compressors, are often graded based on durability and heat resistance. For example, rubber hoses must withstand high temperatures and pressures without degrading. Understanding material grades helps buyers select reliable and long-lasting products, reducing maintenance costs and downtime in operations.

Calibration Tolerance

Calibration tolerance refers to the acceptable deviation in pressure readings for gauges and compressors. Typically expressed in PSI or bar, a lower tolerance ensures more accurate measurements, which is essential for maintaining optimal tire pressure. For B2B operations, using calibrated equipment minimizes the risk of operational errors that could lead to safety hazards or increased costs.

Flow Rate

The flow rate measures the volume of air delivered by an inflator or compressor, usually expressed in liters per minute (L/min). A higher flow rate can significantly reduce the time required to inflate tires, which is crucial for businesses with a fleet of vehicles needing quick turnaround times. Choosing the right flow rate enhances operational efficiency and productivity.

Temperature Range

Tire inflation equipment must operate effectively across a range of temperatures. Equipment rated for extreme conditions ensures consistent performance, whether in hot, arid climates or cooler environments. For businesses in diverse regions, understanding the temperature range of products helps avoid equipment failure due to environmental conditions.

Familiarity with industry jargon is essential for effective communication and decision-making. Here are some commonly used terms in the tire inflation industry:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that can be sold under another company’s brand. In the context of tire inflation, OEM parts may guarantee compatibility and reliability with specific vehicle models. B2B buyers often prefer OEM products to ensure quality and maintain warranties.

MOQ (минимальное количество заказа)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cash flow. Suppliers may have different MOQs for tire inflation equipment, impacting purchasing decisions based on demand forecasts.

RFQ (запрос котировок)

An RFQ is a document sent by potential buyers to suppliers requesting price estimates for specific products or services. In tire inflation, an RFQ can help businesses compare costs and negotiate better terms with suppliers, streamlining the procurement process.

Инкотермс

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers in different regions, understanding Incoterms ensures compliance with international trade regulations and minimizes risk during logistics.

Calibration

Calibration refers to the process of adjusting the accuracy of measuring equipment, such as tire pressure gauges. Regular calibration is essential to ensure precise tire pressure readings, which directly affect vehicle performance and safety. B2B buyers should prioritize calibrated equipment to ensure operational reliability.

Tread Depth

Although not directly related to inflation, tread depth is a critical parameter for tire performance. It affects grip, handling, and safety. Understanding tread depth can help businesses make informed decisions about tire maintenance and replacement, enhancing overall fleet safety and efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding tire inflation equipment and services, ultimately leading to safer and more efficient operations.

The global tire inflation market is witnessing significant shifts driven by advancements in technology, regulatory changes, and growing awareness about vehicle safety and environmental impact. One of the primary drivers is the increasing focus on fuel efficiency, as properly inflated tires can enhance fuel economy by reducing rolling resistance. This is particularly important for B2B buyers in regions like Africa and South America, where fuel costs can heavily impact operational expenses.

Emerging technologies, such as smart tire monitoring systems, are becoming prevalent. These systems provide real-time data on tire pressure and health, enabling businesses to perform proactive maintenance. Additionally, the rise of e-commerce has made sourcing tire inflation equipment and accessories more accessible for international buyers, facilitating competitive pricing and broader options.

Moreover, regulatory frameworks in various regions are pushing for better vehicle safety standards, which indirectly boosts the demand for tire maintenance products. B2B buyers should stay informed about local regulations to ensure compliance and capitalize on market opportunities.

Sustainability is becoming a critical concern for B2B buyers in the tire inflation sector. The environmental impact of tire production and disposal is significant, as tires contribute to landfill waste and can release harmful chemicals. To address this, many manufacturers are adopting sustainable practices, including the use of eco-friendly materials and processes.

Illustrative image related to inflate a tire

For B2B buyers, sourcing from companies that prioritize ethical supply chains is essential. This includes selecting suppliers who demonstrate transparency in their sourcing practices, utilize sustainable materials, and have certifications such as ISO 14001 for environmental management. Additionally, buyers should consider the lifecycle of products, opting for those that promote recycling or are made from recycled materials.

Investing in “green” certifications and sustainable products not only enhances brand reputation but also meets the increasing consumer demand for environmentally responsible practices. As a result, B2B buyers can differentiate themselves in competitive markets by aligning with sustainability goals.

The tire inflation market has undergone substantial evolution, reflecting broader technological and economic changes. Initially, tire inflation was a manual process, relying on simple hand pumps and gauges. However, with the advent of automotive technology in the mid-20th century, air compressors and automatic inflation systems emerged, improving efficiency and accuracy.

Illustrative image related to inflate a tire

The late 20th and early 21st centuries saw further advancements, including the development of nitrogen tire inflation, which offers benefits such as reduced air loss and improved performance. The integration of digital technology has revolutionized tire maintenance, with smart sensors and mobile applications facilitating real-time monitoring.

As global awareness of environmental issues has grown, the market has also shifted toward more sustainable practices, leading to innovations in materials and manufacturing processes. This evolution highlights the importance for B2B buyers to stay abreast of technological advancements and sustainability trends in the tire inflation sector, ensuring they remain competitive and responsible in their sourcing decisions.

How do I ensure the correct tire pressure for my fleet vehicles?

To maintain optimal tire pressure for your fleet, regularly check the pressure using a calibrated tire gauge. Refer to the manufacturer’s specifications, usually found in the vehicle’s manual or a sticker inside the driver’s door. Implement a routine where tire pressure is checked at least once a month and before long trips. Additionally, consider using a centralized tire inflation system for efficiency, especially if managing a large fleet, as it can automate pressure checks and inflations.

What is the best method for inflating tires in different climates?

Inflating tires in varying climates requires adjustments. In colder regions, tire pressure decreases with temperature; thus, checking and adjusting pressure regularly is crucial. Conversely, in hot climates, tire pressure can increase, so it’s essential to check when tires are cold. Utilizing nitrogen instead of air can help maintain pressure more consistently across temperature changes, providing a more stable tire performance in extreme conditions.

What are the key factors to consider when sourcing tire inflation equipment?

When sourcing tire inflation equipment, consider factors such as reliability, ease of use, and compatibility with your existing systems. Look for suppliers with a proven track record in quality and service. Additionally, assess the availability of parts and support for maintenance. Certifications that meet international safety and quality standards can also be a significant indicator of the equipment’s reliability.

How can I vet suppliers for tire inflation products?

To vet suppliers, start by checking their industry reputation through reviews and testimonials from other B2B buyers. Request samples of their products to evaluate quality firsthand. Verify their certifications and compliance with international standards. Additionally, consider their logistical capabilities and responsiveness to inquiries, as this can indicate their reliability as a partner.

What are the minimum order quantities (MOQ) for tire inflation products?

Minimum order quantities for tire inflation products can vary significantly by supplier. Generally, MOQs are set based on production costs and inventory management strategies. It’s advisable to negotiate terms that suit your purchasing capacity. Some suppliers may offer flexibility in MOQs for first-time buyers or larger contracts, so it’s worth discussing your specific needs directly with potential suppliers.

What payment terms are typical in international tire inflation equipment transactions?

Payment terms in international transactions often include options like advance payment, letters of credit, or payment upon delivery. Terms can vary based on the supplier’s policies and your business relationship. Establishing a good rapport with suppliers can lead to more favorable terms. It’s also crucial to clarify currency exchange rates and any potential fees associated with international transactions to avoid unexpected costs.

How do I ensure quality assurance for tire inflation equipment?

To ensure quality assurance, request documentation of the supplier’s quality control processes and certifications. Conduct regular inspections and audits of the products upon delivery. Implement a testing protocol for all equipment before use to confirm they meet safety and performance standards. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations.

What logistics considerations should I keep in mind when importing tire inflation products?

When importing tire inflation products, consider shipping times, customs regulations, and potential tariffs. Work with logistics providers experienced in international shipping to navigate these complexities. Ensure that all necessary documentation is prepared in advance to avoid delays at customs. Additionally, assess the supplier’s ability to provide reliable shipping options and support for tracking shipments, as this can significantly impact your supply chain efficiency.

Домен: michelinman.com

Зарегистрирован: 2001 (24 года)

Введение: Michelin offers a complete range of tires for various mobility needs including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. The tire selection includes categories such as durability, confidence, sport, winter, and efficiency. Michelin’s product families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and Prem…

Домен: lowes.com

Зарегистрирован: 1995 (30 лет)

Введение: Portable air compressors and tire inflators are essential for maintaining proper tire pressure, improving fuel efficiency, and ensuring safety. Key features include:

– Types: Tire inflators (compact, direct-drive, tankless) and air compressors (with reservoir tanks, more powerful).

– Power Sources: Can be powered by household outlets, 12-volt car plugs, or cordless batteries.

– PSI Range: Recomme…

In today’s competitive landscape, effective tire inflation management is essential for ensuring vehicle safety, optimizing fuel efficiency, and prolonging tire lifespan. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality tire inflation equipment and services can significantly enhance operational efficiency. Companies must prioritize reliable suppliers who offer calibrated inflation tools and maintenance solutions, as these can mitigate risks associated with improper tire pressure, such as increased fuel consumption and reduced tire longevity.

Moreover, understanding the nuances of tire inflation—such as the importance of checking pressure regularly and the benefits of nitrogen inflation—can lead to substantial cost savings and environmental benefits. As the market evolves, embracing innovative technologies and sustainable practices will be key to maintaining a competitive edge.

Illustrative image related to inflate a tire

As you look to the future, consider how strategic sourcing in tire management can empower your business to achieve operational excellence. By investing in reliable tire inflation solutions, you not only ensure the safety of your fleet but also contribute to sustainability efforts, ultimately positioning your business for long-term success in a rapidly changing global market.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.