In the fast-paced world of automotive maintenance, sourcing the right air compressor nozzle for tires can be a daunting task for international B2B buyers. With an increasing demand for efficient and reliable tire inflation solutions, businesses must navigate a complex landscape of products, suppliers, and market trends. This guide offers a comprehensive overview of air compressor nozzles specifically designed for tire applications, helping you understand the various types available, their specific uses, and the essential factors to consider when vetting suppliers.

Throughout this guide, we delve into the nuances of air compressor nozzles, exploring options such as self-locking nozzles, quick-release adapters, and traditional connectors. We also provide insights into pricing structures, enabling you to make informed budgetary decisions without sacrificing quality. For businesses operating in diverse regions, including Africa, South America, the Middle East, and Europe, we highlight key market trends and regional preferences that may influence your purchasing strategy.

By empowering you with actionable insights and expert recommendations, this guide aims to streamline your sourcing process, ensuring that you select the best air compressor nozzle for your specific needs. Whether you are in Nigeria, Saudi Arabia, or any other market, our goal is to equip you with the knowledge necessary to enhance your operations and drive success in your tire maintenance endeavors.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Screw-On Nozzle | Secure attachment, often used with standard tire valves | Automotive repair shops, fleet maintenance | Pros: Secure fit; Cons: Slower to attach/detach. |

| Clip-On Nozzle | Quick connection, often spring-loaded for easy use | Tire service centers, mobile repair units | Pros: Fast attachment; Cons: May leak if not secured. |

| Lock-On Nozzle | Self-locking mechanism, allows hands-free operation | High-volume tire inflation operations | Pros: Hands-free use; Cons: More expensive. |

| Thumb-Lock Nozzle | Manual locking mechanism, simple design | Small automotive shops, DIY enthusiasts | Pros: User-friendly; Cons: Less secure than others. |

| Extension Nozzle | Longer reach, ideal for hard-to-reach valve locations | Commercial fleets, agricultural equipment | Pros: Versatile; Cons: May require additional storage. |

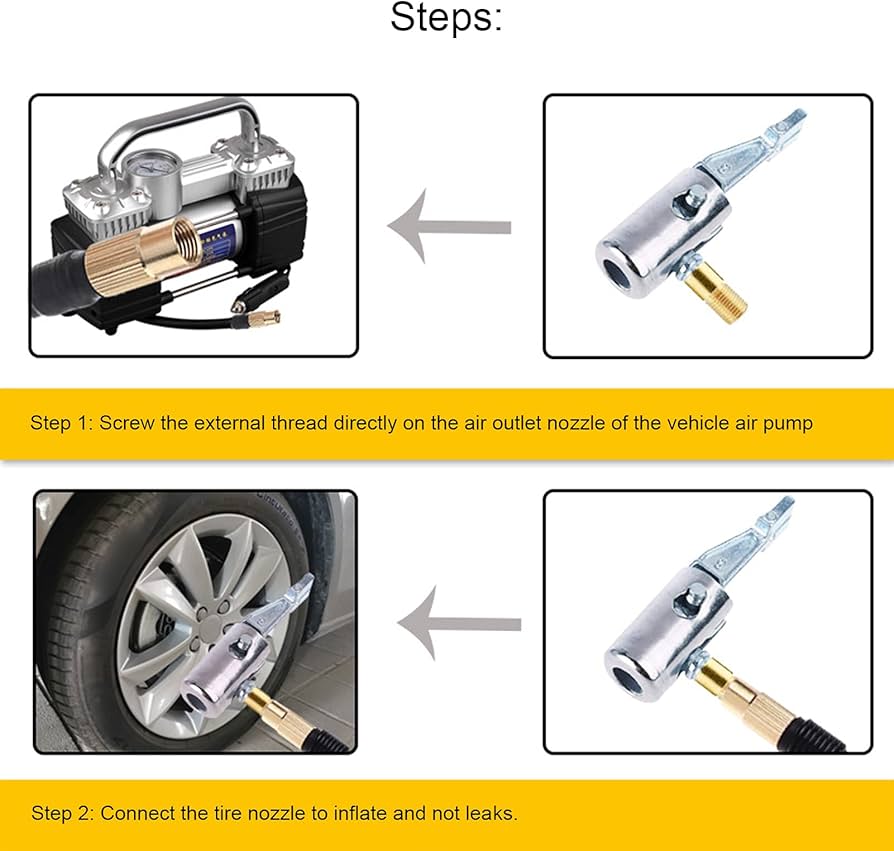

Screw-on nozzles are characterized by their threaded connection, which ensures a secure fit with standard tire valves. This type is commonly utilized in automotive repair shops and fleet maintenance operations where reliability is paramount. Buyers should consider the durability of the material and the ease of use, as these factors can affect the overall efficiency of tire inflation processes. While they provide a stable connection, the time taken to attach and detach can be a drawback in high-volume settings.

Illustrative image related to air compressor nozzle for tires

Clip-on nozzles feature a spring-loaded design that allows for quick and easy attachment to tire valves. This makes them ideal for tire service centers and mobile repair units where speed is essential. The main advantage is the rapid connection, which minimizes downtime. However, buyers should be cautious about potential air leaks if the nozzle is not securely attached, which can affect inflation accuracy and efficiency.

Lock-on nozzles are designed with a self-locking mechanism that allows for hands-free operation, making them particularly beneficial in high-volume tire inflation operations. They enable technicians to focus on other tasks while the tire inflates, improving workflow efficiency. Although they tend to be more expensive than traditional nozzles, the investment can be justified by the increased productivity they offer in busy environments.

Thumb-lock nozzles utilize a manual locking mechanism that simplifies the attachment process. Their straightforward design makes them popular among small automotive shops and DIY enthusiasts. While they are user-friendly and generally affordable, buyers should consider that their locking mechanism may not provide the same level of security as other types, which could lead to air loss during inflation.

Extension nozzles are designed to provide a longer reach, making them particularly useful for hard-to-reach valve locations. This feature is advantageous for commercial fleets and agricultural equipment, where accessibility can be an issue. Buyers should evaluate the length and flexibility of the nozzle to ensure it meets their specific needs. While they offer great versatility, the need for additional storage space can be a consideration for some businesses.

Illustrative image related to air compressor nozzle for tires

| Промышленность/сектор | Specific Application of air compressor nozzle for tires | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Ремонт автомобилей | Tire inflation during vehicle servicing | Ensures optimal tire pressure for safety and performance, reducing wear on tires. | Compatibility with various tire valves and ease of use. |

| Transportation & Logistics | Fleet maintenance and tire management | Enhances operational efficiency by reducing downtime from flat tires. | Durability and reliability under high-frequency usage. |

| Строительство | Heavy equipment tire inflation | Maintains performance of machinery, minimizing delays in construction projects. | Pressure ratings suitable for heavy machinery tires. |

| Aviation | Aircraft tire maintenance | Critical for safety, ensuring proper tire pressure for takeoff and landing. | Compliance with aviation standards and safety regulations. |

| Сельское хозяйство | Farm vehicle tire maintenance | Ensures equipment efficiency, reducing the risk of crop damage from equipment failure. | Ability to handle various tire sizes and pressures. |

In the automotive repair sector, air compressor nozzles are vital for tire inflation during routine servicing. Proper tire pressure is crucial for vehicle safety and performance, as under-inflated tires can lead to increased fuel consumption and reduced handling. B2B buyers in this sector must consider compatibility with different tire valve types and ease of use, ensuring that technicians can quickly and efficiently inflate tires. Reliable nozzles can significantly enhance customer satisfaction by reducing wait times and improving service quality.

In transportation and logistics, air compressor nozzles are essential for maintaining fleet vehicles’ tires. Regular tire inflation minimizes the risk of flats and blowouts, which can lead to costly delays and loss of productivity. Buyers in this industry should prioritize sourcing durable and reliable nozzles capable of withstanding frequent use in various environments. Ensuring that nozzles can accommodate different tire sizes and pressures is also critical for optimal fleet management.

For the construction industry, air compressor nozzles are used to inflate the tires of heavy machinery, ensuring that equipment operates efficiently. Properly inflated tires enhance traction and stability, reducing the risk of accidents and project delays. B2B buyers should focus on nozzles with high-pressure ratings that can accommodate the specific needs of construction equipment. Additionally, sourcing durable nozzles that can withstand rough job site conditions is essential for maintaining operational continuity.

In aviation, air compressor nozzles are crucial for maintaining aircraft tire pressure, which is vital for safe takeoff and landing. Ensuring that tires are inflated to the correct specifications helps prevent accidents and enhances the overall safety of flight operations. Buyers in the aviation sector must consider compliance with industry regulations and standards when sourcing these nozzles. Additionally, nozzles must be capable of handling the specific pressure requirements of various aircraft types.

Illustrative image related to air compressor nozzle for tires

In agriculture, air compressor nozzles are used for maintaining the tires of farm vehicles, ensuring that equipment operates effectively during critical planting and harvesting seasons. Proper tire inflation prevents equipment malfunctions that could damage crops or delay operations. B2B buyers should look for nozzles that can handle a range of tire sizes and pressures, as agricultural equipment varies widely. Durability and ease of use are also key factors to consider, particularly in rugged farming environments.

Проблема: Many B2B buyers experience frustration when attempting to connect air compressor nozzles to tires. A common issue is the incompatibility between the nozzle type and tire valve, which can lead to air leaks and inefficient inflation. This problem is exacerbated in regions with varied valve standards, such as in Africa and the Middle East, where both Schrader and Presta valves may be in use. Buyers often waste time and resources trying to find a compatible nozzle that can securely attach to different tire valves, leading to delays in service delivery and increased operational costs.

Решение: To overcome this challenge, B2B buyers should invest in universal air compressor nozzles that are designed to fit multiple valve types. When sourcing nozzles, prioritize those that feature a self-locking mechanism to ensure a secure connection and prevent air leaks during inflation. Additionally, conducting thorough market research on the specific tire valve types prevalent in the target region can inform purchasing decisions. Buyers should also consider creating a standardized toolkit that includes multiple nozzle types to accommodate various customer needs, thus streamlining operations and enhancing service efficiency.

Проблема: Inconsistent air pressure delivery is a prevalent issue for B2B buyers utilizing air compressor nozzles for tire inflation. This inconsistency can stem from subpar nozzle design or insufficient compatibility with the compressor’s output pressure. Such discrepancies can lead to under-inflated tires, increasing the risk of blowouts and affecting vehicle safety. Buyers in industries reliant on transportation, such as logistics and construction, face heightened risks and potential liability when their equipment does not perform reliably.

Illustrative image related to air compressor nozzle for tires

Решение: To ensure consistent air pressure delivery, buyers should select high-quality, industrial-grade air compressor nozzles specifically designed to handle the required pressure ratings. It is crucial to verify that the nozzle is compatible with the air compressor’s specifications, particularly regarding PSI ratings. Investing in nozzles with built-in pressure gauges can also provide real-time feedback on inflation levels, allowing users to make adjustments as necessary. Moreover, regular maintenance and inspections of both the air compressor and nozzle should be performed to prevent wear and tear that can lead to inconsistent performance.

Проблема: For businesses operating in remote areas or regions with limited infrastructure, accessing reliable tire inflation solutions can be a significant pain point. B2B buyers may struggle with transporting standard air compressors and nozzles, especially in markets across South America and Africa where road conditions can be poor. This limitation can hinder timely service and repair operations, ultimately impacting customer satisfaction and business reputation.

Решение: To address the issue of accessibility, buyers should explore portable and lightweight air compressor nozzles specifically designed for easy transport. Products that are compact and equipped with battery or solar-powered options can greatly enhance mobility and usability in remote locations. Buyers should also consider establishing partnerships with local distributors to ensure a steady supply of necessary components, reducing lead times and enhancing service capabilities. Additionally, training staff on efficient usage and maintenance of portable equipment can empower teams to manage tire inflation effectively, regardless of location.

When selecting materials for air compressor nozzles designed for tire inflation, it is essential to consider various factors including performance characteristics, cost, and regional compliance standards. The following analysis covers four common materials used in the manufacturing of these nozzles: brass, aluminum, plastic, and stainless steel.

Brass is an alloy primarily composed of copper and zinc, known for its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for tire inflation applications. Brass nozzles typically have a temperature rating of up to 200°C and can handle pressures exceeding 300 PSI.

Illustrative image related to air compressor nozzle for tires

Плюсы: Brass nozzles are highly durable and resistant to corrosion, which is particularly beneficial in humid or saline environments. They provide a reliable seal and are less likely to fail under pressure.

Конс: The primary downside is the cost; brass is more expensive than some alternatives. Additionally, the manufacturing process for brass can be complex, requiring specialized machining.

Влияние на применение: Brass is compatible with a wide range of media, including air and various gases, making it versatile for different tire inflation scenarios.

Соображения для международных покупателей: Compliance with ASTM standards is crucial, especially in regions like Europe and the Middle East. Buyers should ensure that the brass used meets specific alloy compositions to avoid issues with quality and performance.

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for air compressor nozzles. It typically has a pressure rating of around 150 PSI and can operate effectively at temperatures up to 120°C.

Плюсы: The lightweight nature of aluminum makes it easy to handle and reduces the overall weight of the inflation equipment. It is also less expensive than brass, making it an attractive option for cost-sensitive buyers.

Конс: Aluminum is less durable than brass and may not withstand extreme conditions as effectively. It can also be prone to wear and tear over time, especially in high-use environments.

Влияние на применение: Aluminum nozzles are suitable for air and non-corrosive gases, but caution should be exercised when using them with certain chemicals that may degrade the material.

Соображения для международных покупателей: Buyers should verify that aluminum nozzles comply with relevant standards such as DIN or JIS, particularly in regions like Africa and South America, where quality assurance is critical.

Plastic nozzles are often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC). They are lightweight and can be molded into complex shapes, providing flexibility in design.

Плюсы: The primary advantage of plastic nozzles is their low cost and ease of manufacturing. They are also resistant to corrosion and can be produced in various colors and designs.

Конс: However, plastic nozzles generally have lower pressure ratings (up to 100 PSI) and can become brittle over time, especially when exposed to UV light or extreme temperatures.

Illustrative image related to air compressor nozzle for tires

Влияние на применение: Plastic nozzles are best suited for low-pressure applications and should not be used with high-temperature gases. They are ideal for basic tire inflation tasks.

Соображения для международных покупателей: Compliance with environmental regulations is essential, particularly in Europe, where restrictions on certain plastics are in place. Buyers should confirm that the materials used are compliant with REACH regulations.

Stainless steel is known for its exceptional strength and resistance to corrosion, making it a premium choice for high-performance applications. It can handle pressures well above 300 PSI and operates effectively at temperatures exceeding 200°C.

Плюсы: The durability and longevity of stainless steel nozzles make them ideal for heavy-duty applications. They are also resistant to rust and can withstand harsh environmental conditions.

Конс: The main drawback is the higher cost associated with stainless steel compared to other materials. Additionally, the manufacturing process can be more complex, requiring advanced techniques.

Влияние на применение: Stainless steel is compatible with air and various gases, making it suitable for industrial applications where reliability is paramount.

Соображения для международных покупателей: Buyers in regions like the Middle East and Europe should ensure compliance with both ASTM and ISO standards for material quality and performance.

| Материал | Typical Use Case for air compressor nozzle for tires | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Brass | General tire inflation in various environments | Excellent corrosion resistance and durability | Более высокая стоимость и сложность производства | Высокий |

| Алюминий | Lightweight applications and portable inflators | Легкий и экономичный | Less durable and lower pressure rating | Средний |

| Пластик | Low-pressure tire inflation | Низкая стоимость и простота изготовления | Brittle over time and lower pressure rating | Низкий |

| Нержавеющая сталь | Heavy-duty industrial applications | Исключительная прочность и коррозионная стойкость | Более высокая стоимость и сложность производства | Высокий |

This guide provides a comprehensive overview of material selection for air compressor nozzles, allowing B2B buyers to make informed decisions based on their specific needs and regional requirements.

Illustrative image related to air compressor nozzle for tires

The manufacturing process of air compressor nozzles for tires involves several critical stages, each designed to ensure the final product meets high standards of performance and reliability. These stages include material preparation, forming, assembly, and finishing.

Подготовка материалов

The first step involves selecting appropriate raw materials, typically aluminum or high-strength plastic, known for their durability and resistance to wear. These materials are then subjected to stringent quality checks to ensure they meet the required specifications. Suppliers often utilize techniques like spectrometry to analyze the chemical composition and mechanical properties of the materials before production begins.

Техника формовки

Once the materials are prepared, forming techniques such as injection molding or CNC machining come into play. Injection molding allows for the creation of complex shapes with high precision, making it ideal for nozzles that require intricate designs for optimal airflow. CNC machining, on the other hand, is used for parts that require tight tolerances. Both methods are complemented by computer-aided design (CAD) software, which helps in optimizing the design for manufacturability.

Процесс сборки

After forming, the components undergo an assembly process where parts are fitted together. This stage may involve manual assembly or automated processes, depending on the production scale. The use of jigs and fixtures ensures that each component is assembled correctly, reducing the potential for defects. Quality assurance is integrated into this stage through the use of standardized assembly protocols.

Завершающие штрихи

The finishing stage includes surface treatment processes such as anodizing or painting, which not only enhance the aesthetic appeal but also improve corrosion resistance. This is particularly important for nozzles exposed to varying environmental conditions, especially in regions with high humidity or salt exposure. Final inspections are performed to ensure that the finish meets industry standards before the products are packaged for shipment.

Illustrative image related to air compressor nozzle for tires

Quality assurance (QA) is a crucial aspect of the manufacturing process for air compressor nozzles. Implementing robust QA measures ensures that products meet international standards and customer expectations.

What International Standards Guide Quality Control?

International standards such as ISO 9001 play a significant role in establishing a quality management system (QMS) within manufacturing facilities. Compliance with ISO 9001 ensures that manufacturers consistently produce products that meet customer and regulatory requirements. Additionally, region-specific certifications such as CE marking in Europe or API standards in the oil and gas industry may apply, depending on the application of the nozzles.

Каковы ключевые контрольные точки контроля качества в производственном процессе?

Quality control checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) checks materials as they arrive at the facility. In-Process Quality Control (IPQC) monitors production at various stages to catch defects early, while Final Quality Control (FQC) ensures that the finished products meet all specifications before shipping.

What Common Testing Methods Are Employed?

Testing methods commonly used include pressure testing, flow rate testing, and dimensional accuracy checks. Pressure testing ensures that the nozzles can withstand operational pressures without leaking, while flow rate testing assesses the efficiency of air delivery. Dimensional checks using calipers and gauges verify that the nozzles meet specified tolerances.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to ensure product reliability and safety.

Каковы лучшие практики проведения аудита поставщиков?

Conducting supplier audits is a proactive approach to verifying quality control processes. Buyers should look for manufacturers that are open to audits, providing access to their production facilities and documentation. During an audit, buyers can assess compliance with international standards, review quality assurance processes, and evaluate the overall production environment.

How Can Buyers Leverage Quality Reports and Certifications?

Requesting quality reports and certifications from suppliers is another effective way to verify quality control. Manufacturers should provide documentation that outlines their quality assurance processes, including results from any third-party inspections. Certifications from recognized bodies can serve as validation of a manufacturer’s commitment to quality.

Каковы нюансы контроля качества и сертификации для иностранных покупателей?

International buyers should also be aware of specific nuances related to quality control and certification. Different regions may have varying regulatory requirements, which can impact product compliance. Buyers should ensure that their suppliers are knowledgeable about the regulations in their target markets. For example, CE marking is crucial for products sold in Europe, while compliance with local standards may be necessary for markets in Africa and South America.

Understanding the manufacturing processes and quality assurance measures for air compressor nozzles for tires is vital for B2B buyers seeking reliable suppliers. By focusing on key manufacturing stages and implementing rigorous quality control practices, manufacturers can deliver products that meet the high expectations of international markets. B2B buyers can enhance their procurement strategies by actively engaging in supplier audits, reviewing quality documentation, and ensuring compliance with relevant international standards. This proactive approach not only mitigates risks but also fosters stronger supplier relationships, ultimately leading to improved product performance and customer satisfaction.

The purpose of this guide is to provide B2B buyers with a comprehensive checklist for sourcing air compressor nozzles for tires. These nozzles are critical components for tire maintenance, and selecting the right supplier can significantly impact operational efficiency and product quality.

Identify the requirements of your air compressor nozzle. This includes understanding the compatibility with various tire valve types, pressure ratings, and materials used in manufacturing. Clearly defined specifications ensure that you procure products that meet your operational needs and enhance efficiency.

Conduct thorough research to identify reliable suppliers. Utilize online platforms, trade shows, and industry publications to compile a list of potential manufacturers or distributors. This step is crucial to ensure that you are sourcing from reputable sources that can meet your volume and quality needs.

Verify the certifications and compliance of potential suppliers. Certifications such as ISO 9001 or industry-specific standards indicate that the supplier adheres to quality management principles. This step is important for ensuring product reliability and minimizing risks associated with inferior products.

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality, durability, and performance of the nozzles firsthand. This step can help prevent costly mistakes associated with ordering large quantities of unsatisfactory products.

Illustrative image related to air compressor nozzle for tires

Analyze pricing structures and payment terms from different suppliers. While cost is an important factor, the cheapest option may not always provide the best value. Consider the total cost of ownership, which includes quality, reliability, and after-sales support.

Evaluate the after-sales support and warranty offered by the supplier. A strong after-sales service can be invaluable for resolving issues and ensuring that you receive ongoing support. Understanding warranty terms will also protect your investment.

Consolidate all gathered information and make an informed purchasing decision. Weigh the pros and cons of each supplier based on your findings in previous steps. An informed decision will enhance your supply chain efficiency and ensure long-term satisfaction with your procurement.

By following this checklist, B2B buyers can streamline the sourcing process for air compressor nozzles, ensuring they find the best products and suppliers to meet their needs.

Illustrative image related to air compressor nozzle for tires

When sourcing air compressor nozzles for tires, it is essential to understand the various cost components that contribute to the overall pricing structure. The primary components include:

Материалы: The quality and type of materials used significantly impact the cost. Common materials include brass, aluminum, and high-grade plastics. Premium materials not only enhance durability but may also come with certifications for safety and performance, affecting the final price.

Труд: Labor costs vary based on the region of production. Countries with lower labor costs may offer competitive pricing but could compromise on quality. Understanding the labor market in the supplier’s location is crucial for cost analysis.

Производственные накладные расходы: This encompasses the indirect costs associated with production, such as utilities, rent, and maintenance of equipment. Efficient manufacturing processes can reduce overhead costs, thus lowering the price for buyers.

Инструментальная оснастка: Custom tooling is often necessary for specialized nozzles. This upfront investment can be significant and is usually amortized over the production volume, which means that larger orders may benefit from reduced per-unit tooling costs.

Контроль качества (QC): Implementing rigorous QC processes ensures that the nozzles meet industry standards. This can add to the cost, but it is a necessary investment to avoid potential liabilities from substandard products.

Логистика: Transportation and handling costs vary significantly based on the shipping method and distance. International buyers should factor in tariffs, duties, and shipping insurance, especially for larger shipments.

Маржа: Suppliers generally apply a markup to cover their costs and achieve a profit margin. This can fluctuate based on the supplier’s pricing strategy and market conditions.

Several factors influence the pricing of air compressor nozzles, which B2B buyers should consider:

Объем и минимальное количество заказа (MOQ): Larger orders typically lead to lower prices per unit due to economies of scale. Buyers should negotiate MOQs to optimize their costs.

Технические характеристики и персонализация: Customized nozzles tailored to specific applications may incur additional costs. Buyers should assess whether the added functionality justifies the higher price.

Качество материалов и сертификаты: Nozzles that meet international quality standards or have specific certifications may be priced higher. Buyers should weigh the benefits of certified products against their budget constraints.

Факторы поставщика: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants may offer lower prices to build market share.

Инкотермс: Understanding the terms of delivery is crucial. Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Buyers should clarify these terms to avoid unexpected expenses.

To achieve cost-efficiency in sourcing air compressor nozzles, buyers should consider the following strategies:

Переговоры о ценах и условиях: Engage in discussions with suppliers to negotiate better pricing, especially for larger orders. Leveraging competition among suppliers can also yield favorable terms.

Оцените общую стоимость владения (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. A higher upfront cost may lead to lower TCO if the product lasts longer.

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import regulations, and local market conditions that may affect pricing.

Request Samples Before Committing: Before placing large orders, request samples to evaluate the quality. This can prevent costly mistakes and ensure that the product meets your specifications.

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better pricing, priority in production schedules, and improved service.

Prices for air compressor nozzles can fluctuate based on market conditions, material availability, and supplier pricing strategies. The figures mentioned in this analysis are indicative and may vary depending on the specific requirements and negotiation outcomes. Always conduct thorough market research and supplier assessments to obtain accurate and current pricing.

In the world of tire maintenance, the air compressor nozzle for tires is a popular choice, known for its efficiency and effectiveness in delivering air. However, various alternatives exist that can cater to different needs and contexts. This analysis compares the air compressor nozzle for tires with other viable solutions, helping B2B buyers make informed decisions based on performance, cost, and usability.

| Сравнительный аспект | Air Compressor Nozzle for Tires | Portable Electric Tire Inflator | Hand Pump Tire Inflator |

|---|---|---|---|

| Производительность | High PSI output; quick inflation | Moderate PSI; quick inflation | Lower PSI; manual effort |

| Стоимость | Moderate ($20 – $40) | Higher ($30 – $100) | Low ($10 – $30) |

| Простота реализации | Requires compressor setup | Plug-and-play; easy to use | Simple mechanics; very portable |

| Техническое обслуживание | Minimal; check hoses regularly | Moderate; battery care needed | Low; minimal parts to wear |

| Лучший пример использования | Commercial vehicles; heavy-duty | Personal vehicles; light use | Bicycles; occasional use |

Portable electric tire inflators are a strong alternative to air compressor nozzles, particularly for personal use. They are generally easy to operate, requiring only a power source, which makes them suitable for quick tire inflation on the go. Their moderate pressure output is often sufficient for passenger vehicles and small SUVs. However, they can be more expensive than traditional nozzles and may require periodic battery maintenance, which could pose a challenge in remote areas where charging is limited.

Hand pump tire inflators are the most economical option for tire inflation. They are lightweight and easy to transport, making them ideal for cyclists and those who require an occasional boost for smaller tires. The downside is that they require physical effort to operate and typically deliver lower PSI, making them unsuitable for larger vehicles or frequent use. Additionally, their manual nature means that inflation can be time-consuming compared to powered options.

When selecting the appropriate tire inflation solution, B2B buyers should consider their specific use cases and operational contexts. For heavy-duty applications, the air compressor nozzle for tires is ideal due to its high PSI output and efficiency. In contrast, if the need is for convenience and portability, a portable electric tire inflator may be the better choice. Hand pumps are best reserved for low-frequency users or those who prioritize cost-effectiveness over speed.

Ultimately, the decision should be guided by the balance between performance needs, budget constraints, and the intended frequency of use. Understanding these factors will enable B2B buyers to make informed purchases that align with their operational requirements and enhance overall efficiency in tire maintenance.

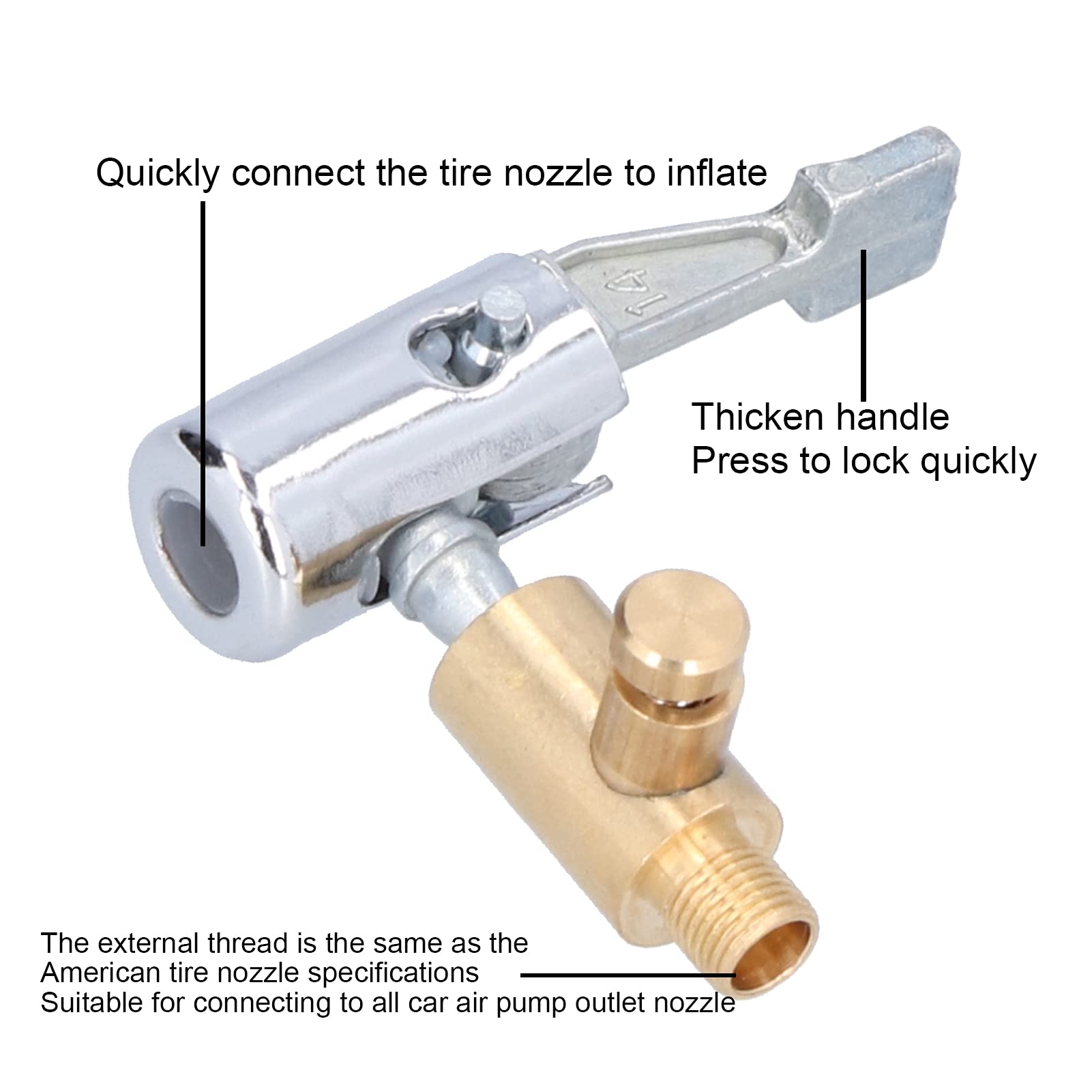

When selecting air compressor nozzles for tires, understanding their technical specifications is essential for ensuring efficiency and compatibility with various tire inflation applications. Here are some critical properties to consider:

Класс материала

The material used for the nozzle significantly impacts its durability and performance. Common materials include brass, aluminum, and high-grade plastic. Brass is often favored for its resistance to corrosion and wear, making it suitable for long-term use in diverse environments. Understanding the material grade helps buyers ensure that the nozzle can withstand the conditions it will face, particularly in regions with extreme temperatures or humidity.

Номинальное давление (PSI)

The pressure rating indicates the maximum pressure the nozzle can handle, typically measured in pounds per square inch (PSI). Most tire inflators operate between 30 to 150 PSI, depending on the type of vehicle. A nozzle with an appropriate pressure rating ensures safety and efficiency during operation. Buyers must match the nozzle’s PSI rating with their air compressor’s output to avoid equipment failure.

Connector Type

The type of connector (e.g., screw-on, clip-on, or push-on) determines how the nozzle attaches to the tire valve. Different vehicles and applications may require different connector types. Selecting the right connector type is crucial for ensuring a secure fit and preventing air leaks, which can lead to inefficient inflation and wasted time.

Flow Rate (CFM)

Flow rate, measured in cubic feet per minute (CFM), indicates how much air the nozzle can deliver in a given time. A higher CFM rating means faster inflation, which is particularly important for commercial applications where time efficiency is critical. Buyers should consider their operational needs—larger vehicles may require nozzles with higher flow rates for quicker tire servicing.

Tolerance

Tolerance refers to the allowable deviation from specified dimensions in manufacturing. A tighter tolerance ensures better fit and performance, which is vital in preventing air leaks and ensuring consistent inflation. For B2B buyers, understanding tolerance levels can help in selecting nozzles that meet their specific operational requirements, ensuring reliability and reducing maintenance costs.

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are some key terms to know:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing air compressor nozzles, buyers may seek OEM parts to ensure compatibility and quality equivalent to the original products used in their machinery.

MOQ (минимальное количество заказа)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers negotiate better deals and manage inventory effectively, particularly when sourcing nozzles for large-scale operations.

RFQ (запрос котировок)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. For B2B buyers, issuing an RFQ for air compressor nozzles allows for comparison of prices, terms, and delivery options from multiple suppliers, aiding in informed decision-making.

Инкотермс (международные коммерческие термины)

Incoterms are a set of rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers clarify shipping terms when procuring air compressor nozzles, ensuring that both parties understand their obligations and costs.

Время выполнения

Lead time refers to the time taken from placing an order to the delivery of the goods. Knowing the lead time for air compressor nozzles is crucial for planning inventory and ensuring timely availability, especially in industries where equipment downtime can lead to significant losses.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding air compressor nozzles for tires, ultimately enhancing their operational efficiency and product reliability.

Illustrative image related to air compressor nozzle for tires

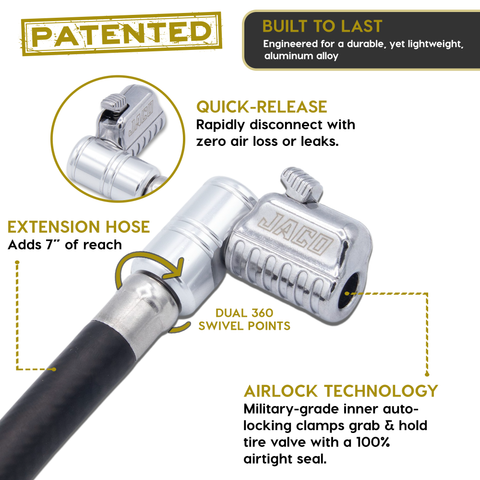

The global air compressor nozzle market for tires is experiencing significant growth driven by several factors. The increasing number of vehicles, particularly in emerging markets like Nigeria and Saudi Arabia, has heightened the demand for effective tire maintenance solutions. Additionally, the rise of e-commerce has simplified sourcing, allowing international B2B buyers to access a wider range of products and suppliers. Key trends include the introduction of advanced nozzles with self-locking mechanisms and quick-release features, which enhance usability and efficiency, catering to the growing consumer preference for convenience.

Moreover, technological advancements are influencing sourcing trends. Innovations such as smart tire inflators, which integrate with mobile apps for real-time monitoring, are gaining traction. Buyers are also seeking nozzles that are compatible with various tire inflators, reflecting a trend towards universal compatibility to maximize utility across different applications. For international buyers, especially from regions like South America and the Middle East, understanding these dynamics is crucial for making informed purchasing decisions.

Sustainability is becoming an essential consideration in the sourcing of air compressor nozzles for tires. As global awareness of environmental issues rises, buyers are increasingly prioritizing products that minimize ecological impact. This includes sourcing from manufacturers that implement ethical supply chain practices, ensuring that raw materials are responsibly sourced and production processes are environmentally friendly.

The demand for ‘green’ certifications is also on the rise. Buyers are looking for products made from recyclable materials or those that have a reduced carbon footprint. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainable practices. For B2B buyers, particularly those in Europe, aligning with suppliers that prioritize sustainability not only enhances brand reputation but also meets regulatory requirements that are becoming stricter in many regions.

Illustrative image related to air compressor nozzle for tires

The evolution of air compressor nozzles for tires can be traced back to the early 20th century, when basic manual pumps and nozzles dominated the market. As vehicles became more widespread, the need for efficient tire inflation solutions led to the development of powered inflators and specialized nozzles designed for ease of use.

In the late 20th century, advancements in materials and technology, such as the introduction of durable plastics and the shift towards more ergonomic designs, marked a significant turning point. The rise of the internet in the 2000s further transformed the market, enabling manufacturers to reach global audiences and facilitating the emergence of e-commerce platforms. Today, the market is characterized by a blend of traditional and innovative solutions, with an increasing focus on technology integration, sustainability, and user-centric designs. Understanding this historical context helps B2B buyers appreciate the current landscape and anticipate future developments in the air compressor nozzle sector.

How do I select the right air compressor nozzle for tire inflation?

Choosing the right air compressor nozzle involves considering the specific application and tire types you’ll be servicing. Look for nozzles that feature compatibility with various valve types, such as Schrader or Presta. Additionally, consider the nozzle’s design, like self-locking or quick-release features, which can enhance efficiency during inflation. Ensure the nozzle can handle the required PSI for your tires and check for durability materials that can withstand frequent use, especially in commercial applications.

What types of air compressor nozzles are available for tire inflation?

Air compressor nozzles for tire inflation come in various types, including screw-on, clip-on, and thumb-lock designs. Each type offers unique advantages; for instance, screw-on nozzles provide a secure fit, while clip-on nozzles allow for quick attachment and detachment. Additionally, some nozzles feature patented designs for enhanced airflow, which can speed up the inflation process. It’s essential to assess the specific needs of your operations to select the most suitable type.

What are the minimum order quantities (MOQs) for air compressor nozzles?

Minimum order quantities for air compressor nozzles can vary significantly between suppliers. Typically, MOQs range from 100 to 1,000 units, depending on the manufacturer and the specific product line. For bulk purchases, it is advisable to negotiate MOQs with suppliers, as many are open to adjusting quantities for larger orders or long-term contracts. Always inquire about potential discounts for bulk purchases, as this can significantly impact your overall costs.

How can I vet suppliers for air compressor nozzles?

Vetting suppliers is crucial for ensuring product quality and reliability. Start by researching their reputation within the industry through reviews and testimonials. Request samples to assess the quality of their nozzles firsthand. Verify their certifications and compliance with international standards, which can be particularly important for trade in regions like Africa and the Middle East. Additionally, consider their production capacity, lead times, and customer service responsiveness to gauge their overall reliability.

What payment terms should I expect when sourcing nozzles internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common terms include payment in advance, letters of credit, or net 30/60 days after delivery. It’s essential to negotiate terms that protect your interests while ensuring the supplier feels secure. Consider using escrow services for larger transactions to minimize risk. Additionally, ensure you are aware of any currency exchange considerations that may affect the final costs.

How do I ensure quality assurance for air compressor nozzles?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request third-party inspection services to evaluate the products prior to shipment, which can help identify defects or non-compliance with your requirements. Additionally, maintain open communication with your supplier regarding quality control processes. Implementing a return policy for defective items can also protect your investment and ensure that you receive the quality necessary for your operations.

What logistics considerations should I keep in mind when importing nozzles?

Logistics play a significant role in the timely delivery of your air compressor nozzles. Consider shipping options, such as air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure you are familiar with customs regulations in your country to avoid unexpected delays or additional fees. Partnering with a reliable freight forwarder can simplify this process and provide insights into the best shipping practices for your specific needs.

Can I customize air compressor nozzles for my specific applications?

Yes, many manufacturers offer customization options for air compressor nozzles, allowing you to tailor features such as size, material, and design to meet your specific applications. Custom nozzles can enhance compatibility with your equipment and improve efficiency. When discussing customization, provide detailed specifications and requirements to the supplier. Keep in mind that custom orders may have longer lead times and potentially higher costs, so plan accordingly to align with your operational needs.

Домен: jacosuperiorproducts.com

Зарегистрирован: 2014 (11 лет)

Введение: Product Name: Lightning S2X Tire Inflator Hose Extension Self-Locking Nozzle

Price: $27.99 (Original Price: $39.99)

Description: Patented air hose adapter for tire pumps (open flow) designed to replace standard connectors for enhanced utility and efficiency in tire inflation.

Product Name: Lightning L2X Tire Inflator Hose Extension Self-Locking Nozzle

Price: $29.99 (Original Price: $39.99)

Descri…

As the demand for reliable tire inflators continues to rise globally, strategic sourcing of air compressor nozzles has become increasingly vital for businesses looking to enhance their product offerings. By focusing on high-quality, innovative designs like self-locking and quick-release nozzles, companies can significantly improve the user experience and operational efficiency. Understanding regional preferences and market trends is essential for international buyers from Africa, South America, the Middle East, and Europe, as these markets exhibit unique demands that can influence sourcing decisions.

Engaging with trusted suppliers and investing in quality products not only ensures customer satisfaction but also fosters long-term partnerships that can drive growth. By leveraging data-driven insights and understanding the competitive landscape, businesses can make informed sourcing choices that align with their strategic objectives.

Looking ahead, businesses should prioritize flexibility and adaptability in their sourcing strategies to navigate the evolving marketplace effectively. Embracing innovation and sustainability will be key in meeting the future demands of tire maintenance solutions. International buyers are encouraged to explore diverse sourcing options and stay ahead of the curve by investing in cutting-edge air compressor nozzles that promise durability and enhanced performance.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Illustrative image related to air compressor nozzle for tires

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.