Maintaining optimal tire pressure is a critical yet often overlooked aspect of vehicle management, particularly when sourcing equipment and services for tire inflation. For B2B buyers operating in diverse markets like Africa, South America, the Middle East, and Europe—including key regions such as Brazil and Saudi Arabia—understanding how to inflate car tires properly is essential for enhancing vehicle safety, improving fuel efficiency, and extending tire lifespan. This comprehensive guide delves into various types of tire inflation systems, the applications of different inflation methods, and the vital role of supplier vetting in ensuring quality and reliability.

In this resource, we will explore the intricacies of tire pressure management, including best practices for checking and adjusting tire pressure, the importance of using calibrated equipment, and the benefits of nitrogen inflation. Additionally, we will provide insights into cost considerations, helping buyers make informed purchasing decisions that align with their operational needs. By equipping B2B buyers with the knowledge to navigate the global market for tire inflation solutions, this guide aims to empower businesses to enhance their fleet management practices, optimize vehicle performance, and ultimately drive down operational costs. Prepare to gain valuable insights that will transform your approach to tire maintenance and contribute to your business’s success in a competitive landscape.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Manual Air Pump | Operated manually, portable, and often hand-held. | Automotive service shops, roadside assistance | Плюсы: Cost-effective, no power needed. Конс: Labor-intensive, slower inflation. |

| Electric Air Compressor | Plugged into a power source, often portable. | Fleet management, car rental services | Плюсы: Quick inflation, user-friendly. Конс: Requires power source, can be bulkier. |

| Nitrogen Inflation | Uses nitrogen instead of air, often in specialized shops. | High-performance tire services, luxury vehicle maintenance | Плюсы: Maintains pressure longer, reduces wear. Конс: More expensive, limited availability. |

| Gas Station Air Pumps | Located at service stations, often coin-operated. | General consumer use, small businesses | Плюсы: Convenient, widespread access. Конс: Potentially inaccurate gauges, may require payment. |

| Integrated Tire Monitoring | Systems that monitor and inflate tires automatically. | Automotive manufacturers, fleet operators | Плюсы: Real-time monitoring, enhanced safety. Конс: High initial investment, complex installation. |

Manual air pumps are portable devices that require physical effort to inflate tires. They are commonly used in automotive service shops and by roadside assistance providers due to their simplicity and cost-effectiveness. Buyers should consider the labor aspect, as inflation can be slower compared to powered options. While these pumps do not require electricity, their effectiveness diminishes with larger tire sizes or for high-volume applications.

Electric air compressors are powered devices that inflate tires rapidly and with minimal effort. They are particularly suitable for fleet management and car rental services where efficiency is crucial. These compressors can be used in various settings, from workshops to service stations. Buyers should evaluate the power requirements and portability, as some models may be bulkier. However, the time-saving aspect often outweighs these considerations.

Nitrogen inflation involves using nitrogen gas instead of regular air, which minimizes pressure loss and enhances tire longevity. This method is popular among high-performance tire services and luxury vehicle maintenance due to its benefits in maintaining optimal tire pressure. B2B buyers should consider the higher costs and the need for specialized equipment or services. While nitrogen inflation can be advantageous, its availability may be limited in some regions.

Gas station air pumps are ubiquitous and offer a quick solution for tire inflation. They are primarily used by consumers and small businesses needing occasional tire maintenance. Buyers should be cautious of the accuracy of the gauges, as they can sometimes be unreliable. Despite this drawback, their convenience and accessibility make them a popular choice for basic tire inflation needs.

Integrated tire monitoring systems provide real-time data on tire pressure and can automatically inflate tires as needed. These systems are gaining traction among automotive manufacturers and fleet operators due to their ability to enhance safety and reduce maintenance costs. However, buyers should weigh the high initial investment and installation complexity against the long-term benefits of improved tire performance and safety.

| Промышленность/сектор | Specific Application of how to inflate car tires | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Repair Shops | Routine tire maintenance services | Enhances customer safety and satisfaction, reduces liability | Reliable air compressors, calibrated tire gauges, and training for staff on proper inflation techniques |

| Управление автопарком | Tire pressure monitoring and inflation protocols | Increases fuel efficiency, extends tire lifespan, reduces downtime | Need for portable inflation units, bulk purchasing of gauges, and consistent supply of air compressors |

| Transportation & Logistics | Pre-trip inspections for commercial vehicles | Ensures compliance with safety regulations, minimizes breakdowns | Access to high-capacity inflators, training on tire pressure standards, and availability of replacement parts |

| Car Rental Services | Efficient tire maintenance for rental fleets | Reduces operational costs, improves vehicle reliability | Regular access to air filling stations, partnerships with local tire shops, and monitoring systems for tire pressure |

| Agricultural Equipment | Inflation of tires on tractors and heavy machinery | Enhances productivity and safety on farms, reduces equipment wear | Durable inflation tools suitable for rugged environments, local sourcing of parts, and knowledge of agricultural tire specifications |

Automotive repair shops frequently offer tire maintenance services, which include checking and inflating tires to the manufacturer’s recommended pressure. This practice not only ensures customer safety but also enhances overall vehicle performance. For international B2B buyers, it is crucial to source reliable air compressors and calibrated tire gauges to maintain service quality. Additionally, training staff on proper tire inflation techniques is essential to minimize liability and enhance customer trust.

In the fleet management sector, maintaining correct tire pressure is vital for optimizing fuel efficiency and extending the lifespan of tires. By implementing systematic tire pressure monitoring and inflation protocols, businesses can reduce vehicle downtime and enhance operational efficiency. Buyers in this sector should consider portable inflation units for on-site maintenance and establish relationships with suppliers for bulk purchasing of gauges and compressors to streamline operations.

Transportation and logistics companies rely on well-maintained vehicles to comply with safety regulations and avoid costly breakdowns. Regular pre-trip inspections that include tire inflation checks are essential to ensure that vehicles are roadworthy. B2B buyers in this industry should prioritize sourcing high-capacity inflators that can accommodate a variety of vehicles and invest in training for staff to understand tire pressure standards specific to their fleet.

Car rental services must ensure that their vehicles are safe and reliable for customers, which includes regular tire maintenance. Efficient tire inflation practices can significantly reduce operational costs and improve vehicle reliability, ultimately leading to higher customer satisfaction. For international buyers, establishing partnerships with local tire shops for regular maintenance and ensuring access to air filling stations is crucial for maintaining fleet quality.

In the agricultural sector, the correct inflation of tires on tractors and heavy machinery is critical for maximizing productivity and ensuring safety on farms. Properly inflated tires reduce equipment wear and enhance traction on various terrains. Buyers should focus on sourcing durable inflation tools designed for rugged environments and ensure local availability of parts to maintain equipment efficiency. Understanding agricultural tire specifications is also essential for effective tire management.

Проблема: Many B2B buyers, especially those managing fleets or automotive service stations, struggle with ensuring accurate tire pressure readings. Variability in gauges across different service stations can lead to miscalculations, resulting in either underinflated or overinflated tires. This not only affects vehicle performance and fuel efficiency but also poses safety risks. For fleet managers in regions like Africa or South America, where access to high-quality equipment may be limited, this inconsistency can be a significant operational challenge.

Решение: To overcome this issue, B2B buyers should invest in high-quality, calibrated tire pressure gauges. These gauges should be regularly checked against a standard to ensure accuracy. Additionally, implementing a routine maintenance schedule that includes periodic checks of all tire pressure gauges used in the operation can help maintain consistent accuracy. For service stations, offering a calibration service for customers can enhance trust and reliability. Educating staff on the importance of tire pressure accuracy and how to use these tools effectively can further mitigate risks associated with improper tire inflation.

Проблема: B2B buyers, particularly those in automotive retail or service sectors, often encounter clients who lack knowledge about the best practices for tire inflation. Misunderstandings regarding when to check tire pressure, how to adjust it based on temperature changes, and the importance of maintaining the correct PSI can lead to numerous issues, including increased operational costs and safety hazards. This is particularly critical in regions with extreme weather conditions, such as the Middle East, where temperature fluctuations can significantly affect tire pressure.

Решение: To address this knowledge gap, B2B companies can create comprehensive training programs for their staff and customers. These programs should cover essential topics such as understanding tire specifications, the impact of temperature on tire pressure, and the correct use of inflation tools. Additionally, providing easy-to-understand reference materials, such as infographics or instructional videos, can enhance user understanding. Hosting workshops or webinars can also help foster a culture of safety and best practices within the automotive community, ultimately reducing the risks associated with improper tire inflation.

Проблема: In many regions, particularly in developing markets in Africa or South America, B2B buyers face challenges in accessing reliable tire inflation equipment. Many gas stations may have outdated or poorly maintained air compressors, leading to difficulties in obtaining the right tire pressure. This situation can result in increased downtime for vehicles and additional costs associated with frequent tire replacements due to improper inflation.

Решение: B2B buyers should prioritize sourcing high-quality, durable tire inflation equipment from reputable manufacturers. Establishing partnerships with reliable suppliers ensures access to the latest technology in tire inflation, such as portable air compressors with built-in pressure gauges. Additionally, companies can consider investing in mobile tire inflation units that can be deployed to various locations, offering on-site services for clients. Providing training on proper usage and maintenance of this equipment can also enhance service quality. By ensuring that reliable tire inflation solutions are readily available, businesses can improve operational efficiency and enhance customer satisfaction.

Illustrative image related to how to inflate car tires

When selecting materials for tire inflation equipment, it’s essential to consider various factors such as durability, cost, and compatibility with different environments. Here, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Основные свойства: Rubber is highly elastic and can withstand a wide range of temperatures, making it suitable for tire valves and hoses. It typically has a pressure rating that can accommodate standard tire inflation pressures.

Плюсы и минусы: Rubber is durable and resistant to wear, but it can degrade over time due to exposure to UV light and ozone. While it is generally cost-effective, the manufacturing process can be complex, particularly when blending different rubber compounds for specific applications.

Влияние на применение: Rubber’s flexibility allows it to create airtight seals in valves and hoses, essential for maintaining tire pressure. However, its susceptibility to environmental conditions may limit its lifespan in harsh climates.

Illustrative image related to how to inflate car tires

Соображения для международных покупателей: Buyers from regions like Africa and the Middle East should ensure that rubber components comply with local standards, such as ASTM or DIN, particularly regarding UV resistance and durability in high-temperature environments.

Основные свойства: Metals like brass and aluminum are commonly used for tire valve stems and connectors. They boast excellent corrosion resistance and can withstand high pressures.

Плюсы и минусы: Metals are incredibly durable and can handle extreme conditions, but they can be heavier and more expensive than rubber alternatives. The manufacturing process can also be more complex, requiring specialized equipment for shaping and finishing.

Влияние на применение: Metal components provide robust connections that are less likely to fail under pressure, making them ideal for high-performance applications. However, they may not be as flexible as rubber, which could lead to compatibility issues with certain tire designs.

Соображения для международных покупателей: Compliance with international standards is crucial, especially for buyers in Europe where stringent regulations on material safety and performance exist. Additionally, the availability of metal components may vary by region, affecting supply chains.

Основные свойства: Plastics, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), are lightweight and resistant to corrosion. They can also handle moderate pressure levels.

Плюсы и минусы: Plastics are generally lower in cost and easier to manufacture than metals, but they may not withstand high temperatures or pressures as effectively. Their durability can vary significantly based on the specific type of plastic used.

Влияние на применение: Plastic components are often used in tire inflation gauges and hoses, providing a lightweight alternative. However, their lower pressure ratings can limit their use in high-performance applications.

Illustrative image related to how to inflate car tires

Соображения для международных покупателей: Buyers should be aware of the varying quality standards for plastics in different regions. For example, compliance with European Union regulations on materials used in automotive applications is critical for market entry.

Основные свойства: Composite materials combine the strengths of various substances, offering high strength-to-weight ratios and resistance to environmental factors.

Плюсы и минусы: Composites can be tailored to specific applications, providing excellent performance characteristics. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Влияние на применение: Composites are ideal for high-performance tire inflation systems where weight and durability are critical. Their versatility allows for innovative designs but may require specialized knowledge for maintenance and repair.

Illustrative image related to how to inflate car tires

Соображения для международных покупателей: Buyers should assess the availability of composite materials in their regions and ensure compliance with local regulations regarding material safety and performance standards.

| Материал | Typical Use Case for how to inflate car tires | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire valves and hoses | Excellent elasticity and sealing | Degrades under UV and ozone exposure | Низкий |

| Металл | Valve stems and connectors | High durability and pressure rating | Более тяжелые и дорогие | Высокий |

| Пластик | Inflation gauges and hoses | Легкий и экономичный | Lower pressure tolerance | Мед |

| Композит | High-performance tire inflation systems | Tailored performance characteristics | Повышенная сложность производства | Высокий |

This analysis provides a comprehensive overview of the materials used in tire inflation systems, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

The manufacturing process for tire inflation equipment involves several critical stages that ensure the final product meets both performance and safety standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

The initial stage in manufacturing involves sourcing high-quality materials. Common materials include durable plastics for the casing of tire inflators, metal alloys for valves and connectors, and rubber for hose assemblies. Suppliers often source these materials from accredited vendors to ensure compliance with international standards. The selection of materials is crucial because they must withstand high pressure and varied environmental conditions, especially in regions like Africa, South America, and the Middle East, where temperatures can be extreme.

The forming stage involves shaping the materials into components that will later be assembled. Techniques such as injection molding for plastic parts and stamping for metal components are common. Advanced suppliers may also use CNC machining for precision components, ensuring that each part meets tight tolerances. This stage is vital for producing parts that fit together seamlessly, which is essential for the reliability of tire inflation devices.

Once components are formed, they proceed to the assembly stage. This typically involves the following steps:

Finishing processes enhance the durability and aesthetics of the final product. Common techniques include:

Quality assurance (QA) is crucial in ensuring that tire inflation equipment meets safety and performance standards. For international B2B buyers, understanding these protocols can aid in supplier selection.

Manufacturers typically adhere to international standards such as ISO 9001, which outlines criteria for an effective quality management system. This standard ensures that companies consistently provide products that meet customer and regulatory requirements.

Illustrative image related to how to inflate car tires

In addition to ISO 9001, industry-specific standards such as CE marking in Europe or API standards in the oil and gas sector may apply. These certifications indicate that the products have passed rigorous testing and meet specific safety requirements.

Quality control checkpoints are integrated throughout the manufacturing process:

Входящий контроль качества (IQC): This checkpoint involves inspecting raw materials for defects before they enter the production line.

Внутрипроцессный контроль качества (IPQC): During the manufacturing process, ongoing inspections ensure that components are being produced to specification and that any deviations are corrected immediately.

Окончательный контроль качества (ОКК): Before products are packaged and shipped, they undergo a final inspection to verify that they meet all specifications and quality standards.

Manufacturers employ various testing methods to verify the performance and safety of tire inflation equipment, including:

For international buyers, particularly those in Africa, South America, and the Middle East, verifying a supplier’s quality control practices is essential for ensuring reliability and compliance.

Illustrative image related to how to inflate car tires

Аудиты поставщиков: Conducting onsite audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their certifications and compliance with international standards.

Запрос отчетов о качестве: Suppliers should be able to provide documentation of their quality control processes, including test results and certifications.

Проверки третьих сторон: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality control practices and the products they manufacture.

Navigating the complexities of international trade can present unique challenges. Buyers should be aware of:

Regional Regulations: Different regions may have varying regulations that impact quality standards. For example, the CE marking is crucial for products sold in Europe, while other regions may have different requirements.

Культурные различия: Understanding cultural nuances can help in communication and negotiations, particularly when discussing quality expectations and practices.

Currency and Payment Terms: Fluctuating currencies and differing payment practices can affect the overall cost and quality of procurement, making it essential to negotiate clear terms upfront.

By understanding the manufacturing processes and quality assurance protocols associated with tire inflation equipment, B2B buyers can make informed decisions that enhance their supply chain efficiency and ensure product reliability.

This guide serves as a practical checklist for B2B buyers seeking to implement effective tire inflation procedures within their fleet operations or automotive service businesses. Proper tire inflation is crucial for ensuring vehicle safety, enhancing fuel efficiency, and prolonging tire life. By following these steps, buyers can procure the necessary tools and establish effective practices for tire maintenance.

Illustrative image related to how to inflate car tires

Before inflating tires, ensure you have the right tools. Essential items include a tire pressure gauge, an air compressor, and a valve cap remover. These tools facilitate accurate pressure readings and safe inflation, which are vital for maintaining tire integrity and performance.

Understanding the manufacturer’s recommended tire pressure is crucial for effective inflation. This information can typically be found in the vehicle’s user manual or on a sticker located on the driver’s door jamb.

Regular tire pressure checks are essential for optimal vehicle performance and safety. Implement a routine schedule, ideally once a month or before long trips, to ensure all tires, including spares, are adequately inflated.

When sourcing air compressors and inflators, prioritize quality and reliability. Substandard equipment can lead to inaccuracies and potential tire damage.

Invest in training for your team on effective tire inflation practices. This training should cover the correct use of tools, understanding tire pressure specifications, and recognizing signs of tire wear.

Ensure that you have access to high-quality replacement parts, including valve caps and tire pressure monitors. These components play a critical role in maintaining tire pressure and preventing leaks.

Explore the option of nitrogen inflation as an alternative to air. Nitrogen can reduce pressure loss and enhance tire performance, especially in high-usage environments.

By following this checklist, B2B buyers can establish a comprehensive tire inflation strategy that enhances safety, efficiency, and cost-effectiveness in their operations.

Illustrative image related to how to inflate car tires

When sourcing solutions for tire inflation, it’s crucial to understand the various cost components that contribute to the overall pricing structure. The primary costs include:

Материалы: The quality and type of materials used in tire inflation tools, such as hoses, gauges, and compressors, significantly affect pricing. High-quality, durable materials may incur higher upfront costs but lead to lower long-term maintenance expenses.

Труд: Labor costs encompass the wages of workers involved in manufacturing, assembling, and testing tire inflation products. These costs can vary greatly depending on the region, with countries having different labor standards and wage structures.

Производственные накладные расходы: This includes costs associated with utilities, rent, and general factory upkeep. Efficient manufacturing processes can help minimize these overheads, contributing to more competitive pricing.

Инструментальная оснастка: Investment in specialized tools and equipment for producing tire inflation devices can be substantial. This is particularly true for customized or specialized products designed for specific markets or vehicle types.

Контроль качества (QC): Ensuring that tire inflation products meet safety and performance standards requires a dedicated QC process. The costs associated with testing and certification can influence the final price, especially for products sold in regulated markets.

Логистика: Transportation costs for moving products from manufacturers to distributors or end-users can vary based on distance, shipping methods, and regional infrastructure. Buyers should consider these logistics costs when calculating total expenses.

Маржа: Suppliers typically add a profit margin on top of the production costs. This margin can vary widely based on market demand, competition, and brand reputation.

Several factors can influence the pricing of tire inflation solutions:

Объем и минимальное количество заказа (MOQ): Bulk purchases often lead to lower per-unit costs. Establishing a relationship with suppliers for regular orders can yield better pricing structures.

Технические характеристики и персонализация: Customized solutions tailored to specific vehicle types or regional requirements may incur additional costs. Buyers should weigh the benefits of customization against the price increase.

Сертификация материалов и качества: Higher-quality materials that offer enhanced durability or performance will typically raise the price. Certifications (e.g., ISO, CE) also add value but can increase costs due to compliance testing.

Факторы поставщика: The reliability, reputation, and location of suppliers can impact pricing. Established suppliers with a strong track record may charge more, but they often provide greater assurance of product quality and service.

Инкотермс: Understanding the International Commercial Terms (Incoterms) is vital for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, all of which can affect the total cost of procurement.

For B2B buyers, particularly those operating across diverse regions like Africa, South America, the Middle East, and Europe, strategic procurement can enhance cost efficiency:

Переговоры: Engage suppliers in discussions to explore bulk discounts, flexible payment terms, or loyalty rewards. A well-prepared negotiation can lead to significant savings.

Общая стоимость владения (TCO): Consider not only the initial purchase price but also long-term costs associated with maintenance, repairs, and efficiency. A slightly higher upfront investment in quality products can lead to lower overall costs over time.

Нюансы ценообразования для международных покупателей: Be aware of exchange rates, tariffs, and import duties that may affect the total cost. Additionally, consider local supplier options to mitigate shipping costs and reduce lead times.

Prices for tire inflation equipment can fluctuate based on market conditions, supply chain dynamics, and regional economic factors. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing that reflects current market conditions.

Illustrative image related to how to inflate car tires

In the realm of automotive maintenance, tire inflation is a critical task that directly impacts vehicle safety, performance, and fuel efficiency. While traditional methods of inflating car tires using air compressors at service stations are widely known, alternative solutions are emerging that may offer distinct advantages for businesses operating fleets or managing multiple vehicles. This section explores these alternatives, providing a comprehensive comparison to help B2B buyers make informed decisions.

| Сравнительный аспект | How To Inflate Car Tires | Портативный инфлятор шин | Nitrogen Inflation System |

|---|---|---|---|

| Производительность | Effective for most vehicles, pressure can be easily adjusted | Quick inflation; portable and user-friendly | Maintains pressure longer and reduces leaks |

| Стоимость | Low-cost; air is often free at service stations | Moderate initial investment; low ongoing costs | Higher initial cost; potential long-term savings |

| Простота реализации | Requires access to a service station or air compressor | Simple to use; can be done anywhere | Requires specialized service; limited availability |

| Техническое обслуживание | Minimal; occasional checks needed | Low; requires battery or power source | Regular checks needed, but less frequent than air |

| Лучший пример использования | Routine maintenance and long trips | Ideal for emergencies and remote locations | Optimal for high-performance vehicles or fleet management |

A portable tire inflator is a compact device that allows users to inflate tires anywhere, making it especially useful for drivers who may find themselves in remote locations or during emergencies. The ease of use and portability are significant advantages, as they eliminate the need for a nearby service station. However, the initial investment can be moderate, and users must ensure the device is charged or has a power source available. This solution is best suited for individual vehicle owners or small businesses that require flexibility in tire maintenance.

Nitrogen inflation systems provide a method of inflating tires with nitrogen gas rather than regular air. The primary benefit of nitrogen is its larger molecular size, which reduces the rate of pressure loss over time, leading to better tire performance and longevity. This method is particularly advantageous for high-performance vehicles and commercial fleets, where tire pressure stability is crucial. The downside is the higher initial cost and the need for specialized service locations, which may not be available in all regions. For businesses with extensive fleets, the long-term savings in tire wear and fuel efficiency can justify the investment.

Illustrative image related to how to inflate car tires

For B2B buyers evaluating tire inflation solutions, the choice ultimately hinges on specific operational needs and circumstances. Traditional air inflation methods remain effective for general use and routine maintenance. However, for businesses seeking flexibility and convenience, portable tire inflators may offer a compelling solution. On the other hand, companies managing high-performance vehicles or large fleets may find that nitrogen inflation systems provide the best balance of performance and cost savings over time. Assessing the unique requirements of your fleet and the availability of services in your region will guide you in selecting the most appropriate tire inflation method for your operations.

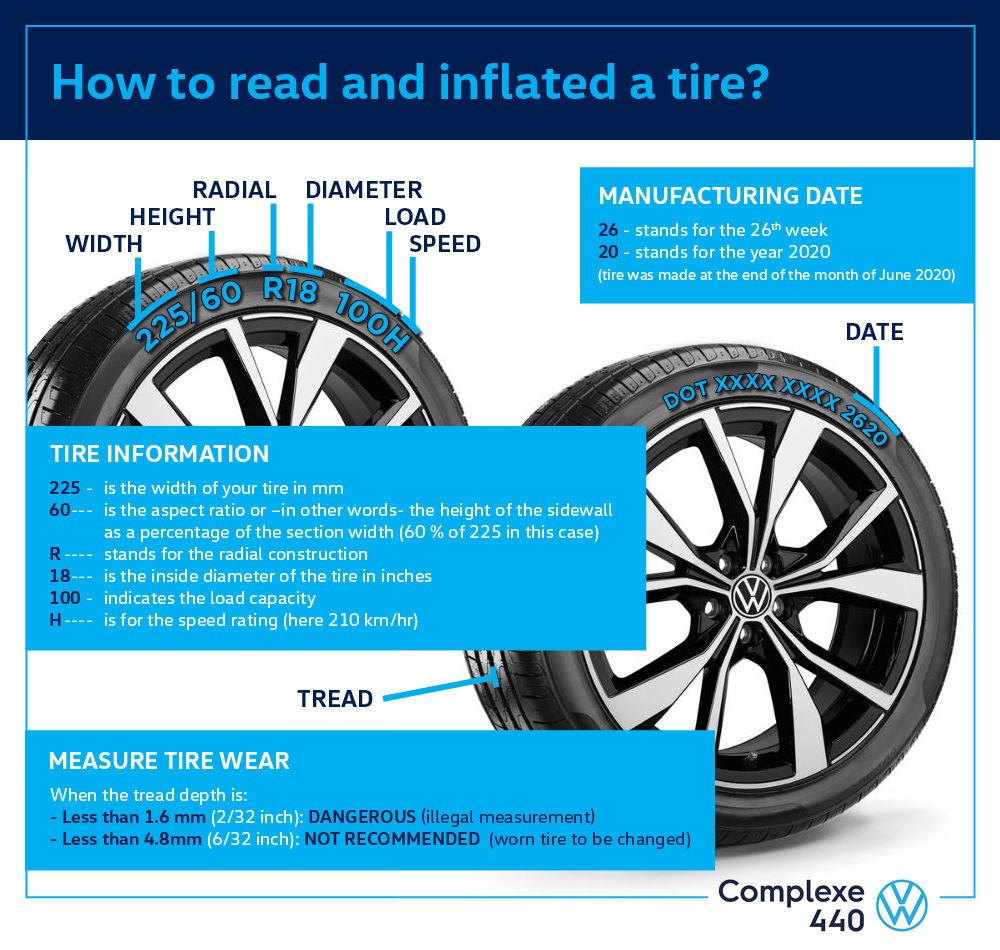

When inflating car tires, understanding the technical specifications is crucial for ensuring safety, performance, and longevity. Here are some essential properties that B2B buyers should consider:

Tire Pressure Specification (PSI/bar)

– Definition: Tire pressure is measured in pounds per square inch (PSI) or bar. Each vehicle has a manufacturer-recommended pressure, which can typically be found on the driver’s door jamb or in the vehicle manual.

– B2B Importance: Maintaining the correct tire pressure is vital for fuel efficiency, tire lifespan, and overall vehicle safety. Under-inflated tires can lead to increased wear and tear, while over-inflated tires can compromise handling and safety.

Tire Composition

– Definition: This refers to the materials used in tire construction, including rubber compounds, fabric, and steel belts.

– B2B Importance: Different compositions affect performance characteristics such as durability, traction, and temperature resistance. Buyers should consider the specific needs of their market, especially in regions with diverse climates.

Tread Depth

– Definition: Tread depth is the measurement of the grooves on the tire’s surface, usually expressed in millimeters.

– B2B Importance: Adequate tread depth is critical for optimal grip and water displacement. In regions with heavy rainfall or off-road conditions, understanding tread depth can help in selecting tires that meet safety regulations and performance expectations.

Temperature Resistance

– Definition: This property indicates a tire’s ability to withstand heat generated during driving.

– B2B Importance: In hotter climates, tires that can handle elevated temperatures without degrading are essential. This can prevent blowouts and extend tire life, making it a key consideration for fleet operators and distributors.

Load Index

– Definition: The load index indicates the maximum load a tire can safely carry, expressed as a numerical code.

– B2B Importance: Choosing tires with the appropriate load index ensures that they can handle the weight of the vehicle and any additional cargo. This is particularly important for businesses involved in logistics or transportation.

Valve Type

– Definition: The tire valve is responsible for maintaining air pressure within the tire and can be either a standard valve or a valve with a pressure monitoring system.

– B2B Importance: Understanding the type of valve is crucial for maintenance and replacement. A defective valve can lead to air loss, making it important for tire retailers and service providers to have the right parts available.

Familiarity with industry terminology can enhance communication and decision-making in B2B transactions. Here are some key terms:

OEM (Original Equipment Manufacturer)

– Definition: Refers to the original manufacturer of the vehicle or its components, including tires.

– Importance: OEM tires are often preferred for their compatibility and reliability. B2B buyers should consider sourcing OEM products to ensure quality and performance standards.

MOQ (минимальное количество заказа)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is essential for inventory management and cost efficiency. Buyers should negotiate MOQs that align with their purchasing capacity and market demand.

RFQ (запрос котировок)

– Definition: A document issued to suppliers requesting pricing and terms for specific goods or services.

– Importance: RFQs are crucial for obtaining competitive pricing and ensuring that buyers are informed about potential suppliers. This can enhance procurement strategies.

Инкотермс (международные коммерческие термины)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international trade.

– Importance: Familiarity with Incoterms helps businesses understand shipping responsibilities, risk management, and cost implications, which is vital for global tire sourcing.

TPMS (Tire Pressure Monitoring System)

– Definition: An electronic system that monitors tire pressure and alerts the driver when levels fall below a certain threshold.

– Importance: Understanding TPMS is important for tire retailers and service providers, as it enhances safety and can impact customer satisfaction.

Calibration

– Definition: The process of adjusting and setting equipment to ensure accurate measurements.

– Importance: Regular calibration of tire inflation gauges and equipment is crucial for maintaining tire pressure accuracy, which directly impacts safety and performance.

By understanding these properties and terminology, B2B buyers can make informed decisions regarding tire inflation, enhancing safety, efficiency, and customer satisfaction.

The global market for car tire inflation is experiencing significant shifts driven by various factors. One of the key trends is the increasing adoption of advanced tire pressure monitoring systems (TPMS) that provide real-time data on tire pressure, enhancing safety and efficiency for users. Additionally, the rise of electric vehicles (EVs) is reshaping tire specifications, necessitating specialized inflation techniques and equipment. B2B buyers in regions like Africa, South America, the Middle East, and Europe should also consider the growing demand for portable tire inflators, which cater to the need for convenience and efficiency in inflation processes.

Emerging technologies such as smart inflators that connect to mobile applications are gaining traction, offering users insights into tire health and maintenance schedules. This trend is particularly relevant for fleet operators who are increasingly focused on optimizing operational costs and ensuring vehicle safety. Furthermore, the emphasis on sustainability is pushing manufacturers to innovate eco-friendly inflation solutions, such as nitrogen inflation systems that reduce tire pressure loss and improve fuel efficiency.

International buyers should be aware of the regional differences in tire inflation practices and regulations, as these can significantly affect sourcing decisions. Factors such as climate, road conditions, and local automotive standards must be taken into account when selecting tire inflation products and suppliers.

Sustainability is becoming a cornerstone of sourcing strategies in the car tire inflation sector. The environmental impact of tire manufacturing and disposal is prompting businesses to seek ethical sourcing practices that minimize carbon footprints. For instance, B2B buyers are increasingly looking for suppliers who utilize sustainable materials in tire production, such as recycled rubber and eco-friendly chemicals.

Illustrative image related to how to inflate car tires

Moreover, the use of nitrogen for tire inflation is gaining popularity due to its potential environmental benefits. Nitrogen-filled tires maintain pressure longer, leading to reduced fuel consumption and lower CO2 emissions. This aligns with the growing global emphasis on reducing greenhouse gas emissions, particularly in regions like Europe and the Middle East, where stringent environmental regulations are in place.

The importance of ethical supply chains cannot be overstated; buyers are increasingly scrutinizing suppliers for their labor practices and sourcing materials responsibly. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers who adhere to these standards, B2B buyers can enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

The practice of tire inflation has evolved significantly from its early days. Initially, tires were inflated with basic air pumps, which required manual effort and offered limited accuracy. With advancements in technology, tire inflation methods have become more sophisticated, integrating tools such as TPMS and automated air compressors.

Historically, tire inflation was often neglected, leading to safety hazards and increased operational costs. However, the modern understanding of the importance of proper tire pressure has led to widespread education on best practices, emphasizing regular maintenance and the use of calibrated inflation tools. This evolution is particularly relevant for B2B buyers today, as they must navigate a landscape where consumer safety, environmental concerns, and technological advancements are intertwined. Adopting best practices in tire inflation not only enhances vehicle performance but also aligns with the broader goals of sustainability and efficiency in the automotive sector.

How do I solve the problem of under-inflated tires affecting vehicle performance?

Under-inflated tires can lead to increased fuel consumption, uneven tire wear, and safety hazards. To address this, regularly check tire pressure using a calibrated gauge and inflate to the manufacturer’s recommended PSI, which can typically be found on a sticker inside the driver’s door or in the vehicle’s manual. Ensuring proper tire pressure not only enhances safety but also extends tire life and improves fuel efficiency, which is crucial for fleet operators aiming to minimize costs.

What is the best equipment for inflating car tires in a commercial setting?

For commercial operations, investing in high-quality air compressors and tire inflation systems is essential. Look for units that offer adjustable pressure settings and built-in pressure gauges for accuracy. Portable tire inflators are also advantageous, especially for mobile services or roadside assistance. Furthermore, consider equipment that allows for nitrogen inflation, as it can help maintain tire pressure longer and improve fuel efficiency, which can be a selling point in your service offerings.

What are the key considerations when sourcing tire inflation equipment internationally?

When sourcing tire inflation equipment internationally, evaluate suppliers based on their reputation, product quality, and compliance with safety standards. It’s important to request certifications and quality assurance documentation. Additionally, consider logistics aspects such as shipping costs, lead times, and any import duties applicable in your region. Establishing clear communication with suppliers regarding specifications and delivery timelines can help mitigate risks associated with international trade.

How can I vet suppliers for tire inflation equipment effectively?

To vet suppliers, start by reviewing their industry experience and client testimonials. Request references from other B2B buyers who have sourced similar equipment. Additionally, assess their production capabilities by asking for samples or visiting their facilities if possible. Ensure they have quality control measures in place, and consider conducting a background check to verify their financial stability and adherence to international trade regulations.

What is the minimum order quantity (MOQ) typically required for tire inflation products?

Minimum order quantities (MOQ) for tire inflation products can vary significantly by supplier and product type. For bulk purchases, MOQs may range from 50 to 500 units. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility for first-time buyers or smaller businesses. Understanding the MOQ can help you plan your budget and inventory levels effectively, especially in regions where demand fluctuates seasonally.

What payment terms should I negotiate with suppliers for tire inflation equipment?

When negotiating payment terms, aim for conditions that align with your cash flow needs. Common terms include a 30% deposit upfront with the balance due upon delivery or after a specified period. Consider using letters of credit for larger orders to ensure security for both parties. Always clarify any additional costs such as shipping or customs duties, and document everything in a formal purchase agreement to avoid disputes later.

How do I ensure quality assurance for tire inflation equipment?

To ensure quality assurance, request detailed product specifications and certifications from suppliers, including compliance with international standards. Conducting factory audits or third-party inspections can further guarantee product quality before shipment. Implementing a quality control process upon receiving the equipment, such as testing functionality and performance, is also crucial. Establishing a long-term relationship with reliable suppliers can lead to better quality assurance practices over time.

What logistics considerations are important when importing tire inflation equipment?

Logistics considerations include shipping methods, customs clearance, and warehousing. Evaluate the cost-effectiveness of different shipping options—air freight is faster but more expensive than sea freight. Understand the customs regulations in your country to avoid delays and additional fees upon arrival. Additionally, plan for warehousing solutions if you need to store equipment before distribution. Collaborating with a logistics provider experienced in international trade can streamline this process.

Домен: michelinman.com

Зарегистрирован: 2001 (24 года)

Введение: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. Their tire families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and Premier. Michelin also provides specialized tires for motorcycles and bicycles, with categories based on usage su…

Домен: acg.aaa.com

Registered: 1990 (35 years)

Введение: AAA Auto Club Group provides services in Colorado, Florida, Georgia, Illinois, Indiana, Iowa, Michigan, Minnesota, Nebraska, North Carolina, North Dakota, Puerto Rico, South Carolina, Tennessee, and Wisconsin. The guide emphasizes the importance of maintaining correct tire pressure for vehicle safety, fuel efficiency, and overall performance. It outlines the necessary tools for inflating tires, in…

As businesses navigate the complexities of automotive maintenance, understanding the critical importance of proper tire inflation emerges as a key factor in enhancing vehicle safety, efficiency, and longevity. By implementing systematic tire pressure checks and utilizing calibrated tools, companies can reduce fuel consumption, extend tire life, and minimize hazardous driving conditions. For international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, strategic sourcing of quality tire maintenance products is essential.

Investing in reliable air compressors, portable inflators, and precision tire gauges not only optimizes operational performance but also fosters a culture of safety and environmental responsibility. Moreover, as global markets increasingly prioritize eco-friendly practices, adopting nitrogen tire inflation can further enhance sustainability efforts.

Looking ahead, businesses should leverage partnerships with reputable suppliers to ensure access to high-quality tire maintenance solutions. By doing so, they position themselves to meet the evolving demands of the automotive industry while driving innovation and efficiency. Now is the time to take action—evaluate your sourcing strategies and invest in the tools that will keep your fleet safe and your operations running smoothly.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.