In an increasingly competitive global market, sourcing reliable tire inflation sensors—critical components of tire pressure monitoring systems (TPMS)—presents a significant challenge for international B2B buyers. As automotive safety regulations tighten and consumer expectations rise, understanding the nuances of different TPMS technologies is essential. This guide delves into the various types of tire inflation sensors, exploring their applications across diverse vehicle types and regions, while also addressing the complexities of supplier vetting, pricing structures, and regulatory compliance.

International buyers from Africa, South America, the Middle East, and Europe, including countries like Germany and Saudi Arabia, will find actionable insights that empower them to make informed purchasing decisions. With the growing emphasis on vehicle safety and efficiency, selecting the right tire inflation sensors not only enhances operational performance but also minimizes risks associated with under-inflated tires.

By navigating the intricate landscape of tire inflation sensor procurement, this comprehensive guide equips B2B buyers with the necessary knowledge to evaluate suppliers effectively, compare product offerings, and assess total cost of ownership. With a focus on sustainability and innovation, we aim to facilitate strategic partnerships that foster growth and safety in the automotive sector. Let’s embark on this journey to optimize your sourcing strategy and elevate your business in the global market for tire inflation sensors.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Direct TPMS | Utilizes internal sensors for real-time pressure and temperature monitoring. | Automotive manufacturing, fleet management | Плюсы: Accurate readings, low maintenance. Конс: Higher cost, complex installation. |

| Indirect TPMS | Relies on wheel speed sensors; does not measure actual tire pressure. | Cost-sensitive vehicle models, retrofitting | Плюсы: Lower cost, easier installation. Конс: Less accurate, requires resets. |

| Smart TPMS | Connects via Bluetooth to mobile devices for monitoring and alerts. | Fleet operators, logistics companies | Плюсы: Remote monitoring, user-friendly. Конс: Battery-dependent, potential connectivity issues. |

| Universal TPMS | Compatible with various vehicle makes and models; often aftermarket. | Independent repair shops, aftermarket sales | Плюсы: Versatile, easy to install. Конс: May lack advanced features, variable quality. |

| Integrated TPMS | Embedded within the vehicle’s existing systems, offering seamless monitoring. | High-end vehicle manufacturers | Плюсы: Streamlined design, minimal maintenance. Конс: Limited customization, higher initial cost. |

Direct Tire Pressure Monitoring Systems (TPMS) are equipped with sensors inside each tire that provide real-time data on tire pressure and temperature. This technology allows for precise monitoring, which is crucial for enhancing vehicle safety and performance. B2B buyers in automotive manufacturing and fleet management often prefer direct TPMS due to its accuracy and reliability. However, the higher cost and complexity of installation may necessitate specialized training for technicians, making it essential for companies to consider their technical capabilities when purchasing.

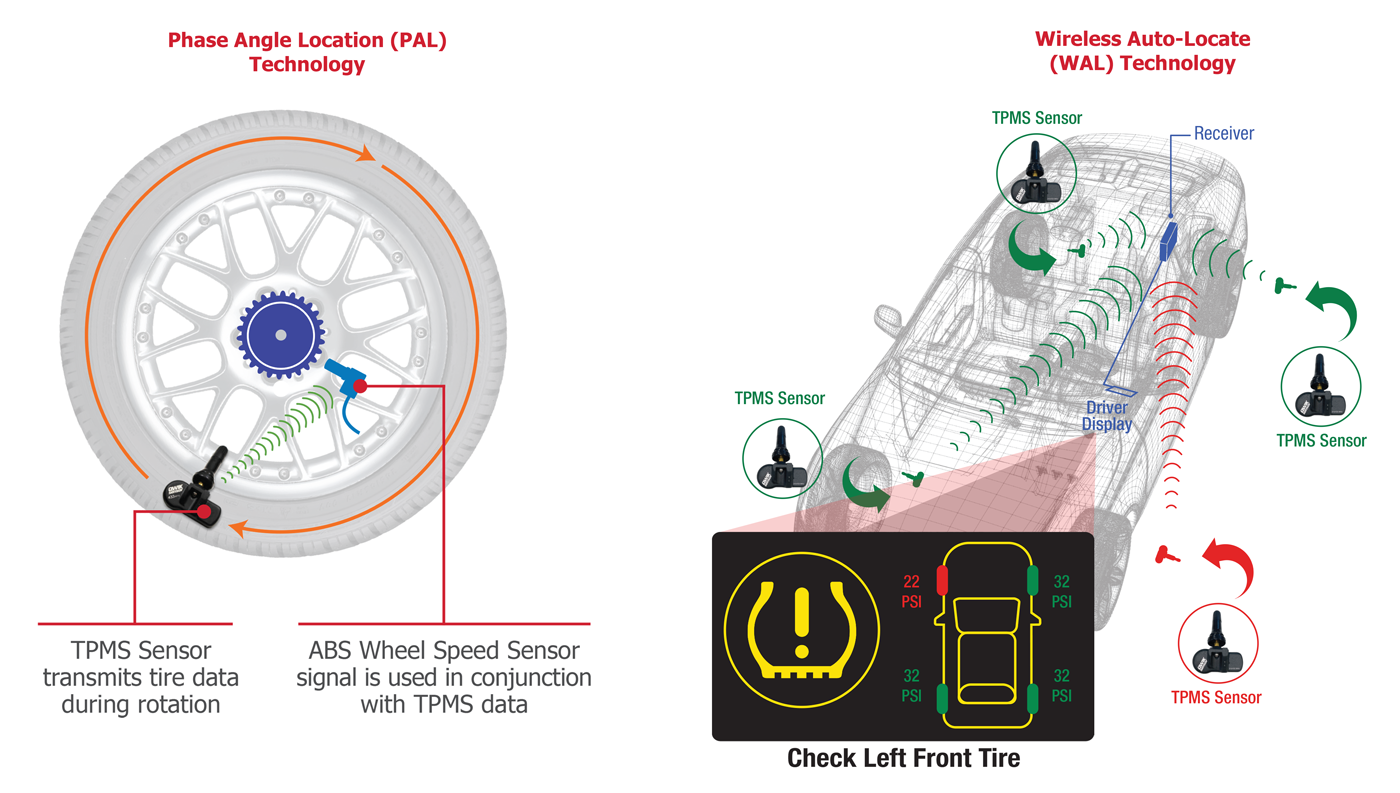

Indirect TPMS uses wheel speed sensors to infer tire pressure by monitoring the rotational speed of each wheel. While this system is more cost-effective, it does not measure actual tire pressure, which can lead to inaccuracies, especially if tire sizes are changed. This makes indirect TPMS suitable for cost-sensitive vehicle models and retrofitting existing vehicles. Buyers should weigh the lower upfront costs against the potential for less reliable performance, especially in critical applications like fleet operations.

Smart TPMS integrates with mobile devices via Bluetooth, allowing for remote monitoring and alerts. This system is particularly beneficial for fleet operators and logistics companies, as it enables real-time data access and can significantly enhance operational efficiency. While the convenience of smart TPMS is appealing, buyers must consider the dependency on battery life and potential connectivity issues, which can affect performance in remote areas.

Universal TPMS sensors are designed to be compatible with a wide range of vehicle makes and models, making them a popular choice for independent repair shops and aftermarket sales. Their versatility and ease of installation appeal to businesses looking to provide cost-effective solutions. However, buyers should be cautious of variable quality and the absence of advanced features that may be present in more specialized systems.

Integrated TPMS is built into the vehicle’s existing systems, providing seamless monitoring without the need for additional components. This integration is often found in high-end vehicles, where manufacturers prioritize advanced safety features. While the streamlined design and minimal maintenance requirements are attractive, B2B buyers should be aware of the limitations in customization options and the higher initial investment associated with these systems.

| Промышленность/сектор | Specific Application of tire inflation sensor | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Manufacturing | Integration in new vehicle models for enhanced safety features | Increases vehicle safety and compliance with regulations | Compatibility with various vehicle models and standards |

| Logistics and Transportation | Fleet management systems for monitoring tire health | Reduces operational costs by preventing tire-related breakdowns | Robustness and accuracy in diverse environmental conditions |

| Сельское хозяйство | Equipment monitoring for tractors and agricultural vehicles | Improves efficiency and reduces fuel consumption | Durability in harsh agricultural environments |

| Mining and Construction | Heavy machinery tire pressure monitoring | Enhances safety and extends tire life, reducing downtime | Ability to withstand extreme conditions and heavy loads |

| Public Transportation | Implementation in buses and taxis for passenger safety | Ensures passenger safety and reduces maintenance costs | Compliance with local regulations and ease of integration |

In the automotive manufacturing sector, tire inflation sensors are integrated into new vehicle models to enhance safety features. These sensors provide real-time monitoring of tire pressure, alerting drivers to any potential issues before they become serious. This application not only improves vehicle safety but also ensures compliance with international regulations, particularly in regions like Europe where stringent safety standards are in place. Buyers in this sector should consider compatibility with various vehicle models and the need for advanced technology that can adapt to future automotive innovations.

In logistics and transportation, tire inflation sensors are crucial for fleet management systems that monitor tire health across a range of vehicles. By ensuring optimal tire pressure, businesses can significantly reduce operational costs associated with fuel consumption and tire wear, ultimately preventing costly breakdowns. The sensors must be robust and accurate, capable of functioning effectively in diverse environmental conditions, especially in regions with extreme temperatures or rough terrains, such as parts of Africa and South America.

In the agricultural sector, tire inflation sensors are essential for monitoring the tire pressure of tractors and other farming equipment. Maintaining optimal tire pressure leads to improved efficiency, reduced fuel consumption, and enhanced operational safety. For international buyers, particularly in regions with challenging terrains, the durability of these sensors in harsh environments is a key consideration. Ensuring that sensors can withstand the rigors of agricultural use while providing accurate data is vital for maximizing productivity.

In mining and construction, tire inflation sensors are implemented to monitor the tire pressure of heavy machinery. These sensors play a critical role in enhancing safety by preventing tire blowouts and extending tire life, which in turn reduces downtime for repairs. Buyers in these industries should prioritize sensors that can withstand extreme conditions and heavy loads, ensuring reliability in the toughest working environments. This is particularly relevant for operations in remote areas of the Middle East and Africa, where equipment failure can lead to significant operational delays.

For public transportation systems, tire inflation sensors are vital for ensuring passenger safety in buses and taxis. By monitoring tire pressure continuously, these sensors help prevent accidents related to tire failure, contributing to overall fleet reliability. Additionally, they can reduce maintenance costs by alerting operators to issues before they escalate. Buyers in this sector need to ensure that the sensors comply with local regulations and can be easily integrated into existing fleet management systems, especially in urban areas in Europe and the Middle East where regulatory compliance is critical.

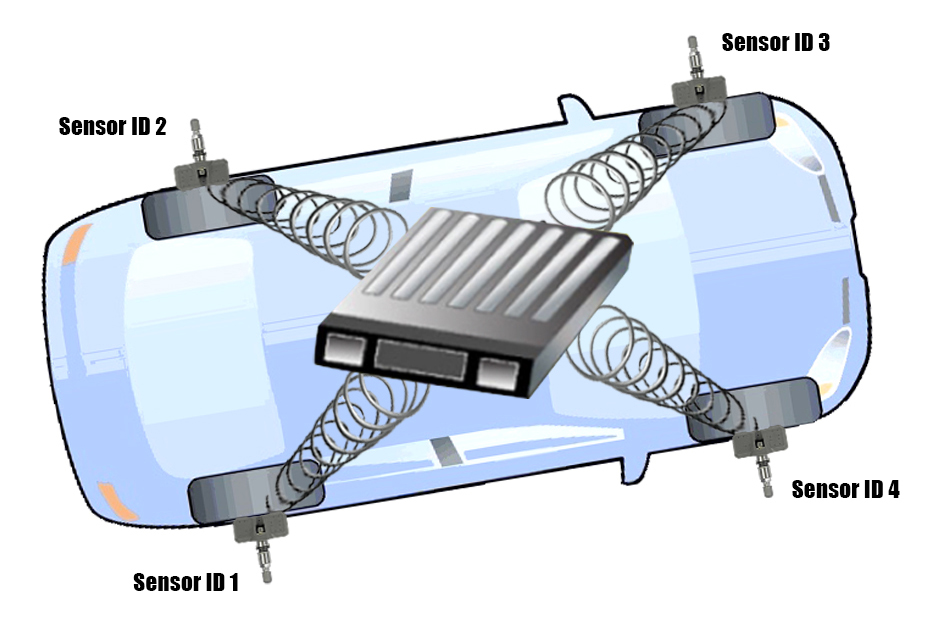

Illustrative image related to tire inflation sensor

Проблема: B2B buyers often face significant challenges when trying to source tire inflation sensors that are compatible with a wide variety of vehicle makes and models. This issue can arise from the proprietary nature of many TPMS technologies, where different manufacturers utilize unique sensor designs and communication protocols. As a result, buyers may inadvertently purchase sensors that do not integrate seamlessly with their fleet’s existing systems, leading to costly installation delays and operational inefficiencies.

Решение: To mitigate compatibility issues, it is crucial for B2B buyers to conduct thorough research before procurement. Start by maintaining a detailed inventory of the vehicles in your fleet, including make, model, and year. Leverage this data to consult with reputable suppliers who can provide guidance on compatible tire inflation sensors. Additionally, consider investing in multi-vehicle TPMS solutions that offer flexible compatibility with various brands. When negotiating with suppliers, request samples or trial units to validate compatibility before making bulk purchases. This proactive approach ensures that your investment in tire inflation sensors supports your fleet’s operational efficiency without the risk of costly mismatches.

Проблема: One of the recurring pain points for B2B buyers is the maintenance and longevity of tire inflation sensors. Direct TPMS, while more accurate, can be more susceptible to damage during tire changes or replacements, leading to unexpected costs and downtime. Furthermore, the batteries in these sensors typically have a finite lifespan, adding another layer of complexity to maintenance schedules and replacement planning.

Решение: To enhance the longevity of tire inflation sensors, establish a comprehensive maintenance program that includes regular checks and battery assessments. Work closely with your tire service providers to ensure that proper installation techniques are followed during tire mounting and demounting, reducing the risk of sensor damage. Additionally, consider investing in sensors with replaceable batteries or those designed for extended life. This can help minimize replacement frequency and associated costs. Implementing a tracking system for sensor battery life and performance will enable timely replacements and reduce the risk of sensor failure, ultimately promoting safety and efficiency within your operations.

Проблема: B2B buyers, particularly those operating in diverse international markets, often struggle with varying regulatory compliance standards for tire inflation sensors. Different regions may have specific requirements for TPMS functionality, accuracy, and reporting, which can complicate sourcing decisions. Failure to comply with local regulations can lead to legal repercussions, fines, and damage to brand reputation.

Illustrative image related to tire inflation sensor

Решение: To navigate the complexities of regulatory compliance, B2B buyers should prioritize partnerships with suppliers who have a deep understanding of local and international TPMS regulations. Engage in discussions to clarify any regional compliance requirements that affect your purchasing decisions. It is also beneficial to stay informed about the latest regulations by subscribing to industry publications or joining relevant associations. Implement a compliance checklist that includes certification requirements, testing standards, and installation guidelines for each market you operate in. This proactive approach will not only ensure adherence to legal standards but also enhance your credibility and reliability in the marketplace.

When selecting materials for tire inflation sensors, it is crucial to consider their properties, advantages, and disadvantages. This analysis focuses on four common materials: Aluminum, Stainless Steel, Polycarbonate, and Rubber. Each material has unique characteristics that influence the performance and suitability of tire inflation sensors in various environments.

Aluminum is a lightweight and corrosion-resistant metal frequently used in tire inflation sensors. It typically has a temperature rating of up to 150°C and can withstand pressures of 3-5 bar, making it suitable for standard automotive applications.

Плюсы:

– Долговечность: Aluminum is resistant to corrosion, which is essential for sensors exposed to various environmental conditions.

– Cost-Effectiveness: Generally, aluminum is less expensive than other metals like stainless steel.

– Manufacturing Simplicity: It can be easily machined and shaped, allowing for efficient production.

Illustrative image related to tire inflation sensor

Конс:

– Thermal Conductivity: Aluminum can conduct heat, potentially affecting sensor readings in extreme temperature conditions.

– Mechanical Strength: While adequate for many applications, it may not be as robust as other materials in high-stress environments.

Влияние на применение: Aluminum’s compatibility with various media makes it suitable for automotive applications, but its thermal properties may necessitate additional design considerations in hotter climates.

Соображения для международных покупателей: In regions like Europe and the Middle East, compliance with standards such as DIN and ASTM is vital. Buyers should ensure that aluminum components meet these specifications.

Stainless steel is another popular choice for tire inflation sensors, valued for its strength and resistance to corrosion. It typically performs well under high-pressure conditions and can withstand temperatures up to 200°C.

Плюсы:

– High Durability: Stainless steel offers exceptional mechanical strength, making it ideal for rugged applications.

– Corrosion Resistance: It maintains integrity in harsh environments, including those with high humidity or saline conditions.

Конс:

– Cost: Stainless steel is generally more expensive than aluminum.

– Manufacturing Complexity: It requires specialized machining processes, which can increase production time and costs.

Влияние на применение: The robust nature of stainless steel makes it suitable for heavy-duty vehicles and applications in regions with extreme weather conditions.

Соображения для международных покупателей: Buyers in Africa and South America should consider the availability of stainless steel and its associated costs, as well as compliance with international standards.

Illustrative image related to tire inflation sensor

Polycarbonate is a thermoplastic material often used in the housing of tire inflation sensors. It is known for its impact resistance and can operate effectively at temperatures ranging from -40°C to 120°C.

Плюсы:

– Lightweight: Polycarbonate is significantly lighter than metals, which can benefit overall vehicle weight reduction.

– Impact Resistance: Its toughness makes it suitable for applications where sensors may experience physical shocks.

Конс:

– Chemical Sensitivity: Polycarbonate can be susceptible to certain chemicals, which may limit its use in specific environments.

– Lower Temperature Resistance: It may not perform well in extremely high-temperature conditions compared to metals.

Влияние на применение: Polycarbonate is ideal for sensors that require lightweight and durable housing but may not be suitable for high-temperature applications.

Соображения для международных покупателей: Compliance with safety standards is crucial, especially in regions like Europe, where regulations are stringent.

Rubber is often used for sealing components in tire inflation sensors. It is flexible and can operate effectively in a temperature range of -30°C to 100°C.

Плюсы:

– Flexibility: Rubber provides excellent sealing capabilities, which is essential for maintaining pressure.

– Cost-Effective: It is generally less expensive than metals and can be easily molded.

Конс:

– Долговечность: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures.

– Limited Pressure Resistance: It may not withstand high-pressure environments as effectively as metals.

Влияние на применение: Rubber is crucial for ensuring airtight seals in tire inflation sensors, but its longevity may be a concern in harsh environments.

Illustrative image related to tire inflation sensor

Соображения для международных покупателей: Buyers should ensure that rubber components meet relevant standards for temperature and chemical resistance, particularly in regions with extreme climates.

| Материал | Typical Use Case for tire inflation sensor | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Standard automotive applications | Легкий и экономичный | Lower mechanical strength | Низкий |

| Нержавеющая сталь | Heavy-duty vehicles | Высокая прочность и коррозионная стойкость | Higher cost and complexity | Высокий |

| Polycarbonate | Sensor housing | Impact-resistant and lightweight | Chemical sensitivity | Средний |

| Резина | Sealing components | Excellent flexibility and cost-effective | Limited durability | Низкий |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and regional compliance.

The manufacturing process of tire inflation sensors, also known as Tire Pressure Monitoring Systems (TPMS), is a complex sequence that ensures the delivery of high-quality, reliable products. The main stages of this process include material preparation, forming, assembly, and finishing.

Material preparation is critical for ensuring the quality and durability of tire inflation sensors. The primary materials used include high-grade plastics, metals for sensor components, and electronic circuits. Manufacturers typically source these materials from certified suppliers who meet international standards. Rigorous inspections are conducted upon receipt to ensure that all materials conform to specified requirements.

Illustrative image related to tire inflation sensor

Forming is the next stage, where materials are shaped into functional components. Techniques such as injection molding are commonly employed to create the plastic housings, while metal stamping may be used for the sensor’s internal components. Precision is vital in this phase, as any discrepancies can lead to malfunctioning sensors. Advanced technologies like CNC machining may also be utilized for high-precision components, ensuring uniformity and reducing waste.

The assembly stage involves the integration of various components into a complete tire inflation sensor. This process is often automated to enhance efficiency and consistency. Workers or machines assemble electronic circuits, sensors, and housings, ensuring that each component fits seamlessly. During assembly, it is crucial to maintain cleanroom conditions to prevent contamination, which could affect sensor performance.

Finishing techniques are essential for enhancing the functionality and aesthetics of tire inflation sensors. This stage may involve applying protective coatings to prevent corrosion or wear. Additionally, quality checks are performed to ensure that all sensors meet the design specifications and are free from defects. Some manufacturers may also conduct environmental testing to ensure that the sensors can withstand extreme conditions such as temperature fluctuations and humidity.

Quality assurance is a critical aspect of the manufacturing process for tire inflation sensors. International standards such as ISO 9001 provide frameworks for ensuring consistent quality management systems. For B2B buyers, understanding these standards is crucial when evaluating potential suppliers. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, particularly for sensors used in commercial and industrial applications.

Quality control (QC) checkpoints are integral to maintaining the integrity of tire inflation sensors throughout the manufacturing process. The typical QC checkpoints include:

Входящий контроль качества (IQC): This initial stage involves inspecting raw materials and components for conformity to specifications before they enter the production line.

Внутрипроцессный контроль качества (IPQC): Continuous monitoring during the manufacturing process ensures that each stage adheres to quality standards. This might include regular inspections at various assembly points to identify any deviations early.

Окончательный контроль качества (ОКК): Once the sensors are fully assembled, FQC involves rigorous testing to ensure functionality. This can include pressure tests, temperature tolerance assessments, and performance evaluations.

Various testing methods are employed to validate the performance and reliability of tire inflation sensors. Common tests include:

Функциональное тестирование: Verifies that the sensor operates correctly under normal conditions, including accurate pressure readings.

Испытание на долговечность: Assesses how well the sensors withstand environmental factors such as temperature extremes, moisture, and vibration.

Calibration Testing: Ensures that the sensor provides accurate readings by comparing its output against a known standard.

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Buyers can undertake several actions:

Illustrative image related to tire inflation sensor

Аудиты поставщиков: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand.

Запрос отчетов о качестве: Buyers should ask suppliers for detailed quality assurance documentation, including test results and compliance certificates.

Проверки третьих сторон: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes.

Navigating the landscape of quality control and certification can be challenging for international B2B buyers. Different regions may have varying standards and regulatory requirements. For example, European buyers may prioritize CE certification, while those in the Middle East might focus on local compliance standards. Understanding these nuances is crucial for successful procurement. Additionally, buyers should consider language barriers and cultural differences when communicating quality expectations with suppliers.

The manufacturing processes and quality assurance practices for tire inflation sensors are vital for ensuring product reliability and safety. By understanding the stages of manufacturing, the importance of quality control, and the relevant standards, B2B buyers can make informed decisions when sourcing tire inflation sensors. Prioritizing suppliers who adhere to stringent quality practices will ultimately lead to better performance and safety in their automotive applications.

This sourcing guide aims to assist B2B buyers in procuring tire inflation sensors, specifically Tire Pressure Monitoring Systems (TPMS). Proper selection of these components can enhance vehicle safety, improve fuel efficiency, and ensure compliance with international standards. This checklist will provide actionable steps to streamline your procurement process.

Establishing clear technical specifications is crucial before initiating the sourcing process. Identify whether you require direct or indirect TPMS based on your vehicle fleet’s needs. Consider specifications such as sensor type, operating temperature range, and compatibility with different tire sizes.

Understanding and adhering to regional regulations regarding TPMS is essential. Each country may have different standards that affect the design and functionality of tire inflation sensors.

Before making a purchase, it’s vital to conduct a thorough evaluation of potential suppliers. Request detailed company profiles, case studies, and references from other businesses within your industry.

Obtaining samples of the tire inflation sensors is a key step in your sourcing process. Testing these samples will help assess their compatibility and performance in real-world conditions.

Once you have identified suitable suppliers and tested their products, the next step is negotiating pricing and contract terms. This is an essential phase to ensure you receive the best value for your investment.

Finally, develop a logistics plan for the timely delivery of the tire inflation sensors. Effective supply chain management will ensure that you maintain stock levels and minimize downtime.

Illustrative image related to tire inflation sensor

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing tire inflation sensors. Thorough preparation and careful evaluation will lead to better procurement decisions, ultimately enhancing vehicle safety and efficiency in your operations.

Understanding the cost structure of tire inflation sensors is crucial for B2B buyers. The primary components include:

Материалы: The core materials for tire inflation sensors generally consist of high-quality plastics, metals for the sensor housing, and electronic components. The choice of materials directly influences durability and performance, which can affect the overall cost.

Труд: Labor costs vary significantly based on geographic location. Skilled technicians are essential for assembly, calibration, and testing, particularly for direct TPMS systems which require precise installation.

Производственные накладные расходы: This includes costs associated with utilities, rent, equipment maintenance, and administrative expenses. Overhead can fluctuate based on the scale of production and the manufacturing environment.

Инструментальная оснастка: Initial tooling costs can be substantial, especially for custom sensors. These costs include the design and creation of molds and other machinery necessary for production.

Контроль качества (QC): Ensuring the reliability and accuracy of tire inflation sensors is paramount. QC processes involve rigorous testing and certification, which can add to the overall cost but is essential for safety and compliance.

Логистика: Shipping and handling costs are significant, especially for international buyers. Factors such as distance, mode of transport, and packaging requirements can affect logistics expenses.

Маржа: Suppliers typically mark up their prices to cover all costs and ensure profitability. Understanding the margin can provide insight into the pricing strategy of different suppliers.

Several factors can impact the pricing of tire inflation sensors, including:

Объем/MOQ (минимальное количество заказа): Ordering in bulk can lead to significant discounts. Suppliers are often willing to negotiate prices based on larger orders, which can provide cost savings for buyers.

Технические характеристики и персонализация: Custom specifications, such as unique sensor designs or additional features, can lead to higher costs. Standardized products typically have more competitive pricing.

Сертификация материалов и качества: Sensors made from premium materials or those that meet stringent quality certifications (e.g., ISO standards) will command higher prices. Buyers should weigh the benefits of these certifications against their needs.

Факторы поставщика: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers may offer competitive rates to gain market share.

Инкотермс: Understanding the Incoterms agreed upon for shipping is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall landed cost of the sensors.

To ensure cost-effective sourcing of tire inflation sensors, buyers should consider the following tips:

Проведите тщательное исследование рынка: Understand the average market prices and the factors that influence them. This knowledge will empower you during negotiations.

Leverage Volume Discounts: If your business has the capacity to order in larger quantities, negotiate for bulk pricing. Suppliers often offer better rates for larger orders.

Оцените общую стоимость владения (TCO): Look beyond the initial purchase price. Consider long-term factors such as maintenance costs, warranty offerings, and the expected lifespan of the sensors.

Be Open to Multiple Suppliers: Engaging with multiple suppliers can create competition, leading to better pricing and terms. This approach can also help mitigate risks associated with relying on a single source.

Understand International Pricing Nuances: For buyers in Africa, South America, the Middle East, and Europe, consider currency fluctuations, tariffs, and local regulations that can affect overall pricing.

While prices for tire inflation sensors can vary widely, understanding the cost components and pricing influencers is essential for effective sourcing. Buyers should approach negotiations with a clear understanding of their needs and the market landscape. Always request detailed quotes and be aware of any additional costs associated with international shipping and compliance. As prices can fluctuate, it is advisable to check with suppliers regularly for the most accurate and indicative pricing.

In the realm of tire management and safety, various solutions exist to monitor and maintain proper tire inflation. The tire inflation sensor, particularly the Tire Pressure Monitoring System (TPMS), is widely adopted for its ability to provide real-time data on tire pressure. However, it is essential for B2B buyers to evaluate alternative solutions that may offer distinct advantages depending on specific operational needs and constraints.

| Сравнительный аспект | Tire Inflation Sensor | Manual Tire Pressure Gauge | Indirect TPMS |

|---|---|---|---|

| Производительность | Real-time pressure monitoring | Periodic checks only | Alerts based on wheel speed |

| Стоимость | Moderate initial investment | Low cost | Generally lower than direct TPMS |

| Простота реализации | Requires professional installation | Simple, user-operated | Less complex than direct TPMS |

| Техническое обслуживание | Regular battery replacements | Не требуется | Requires recalibration after tire changes |

| Лучший пример использования | Fleet management, safety compliance | Small businesses, DIY users | Budget-conscious operations |

The manual tire pressure gauge is a traditional method that allows users to check tire pressure directly. It involves physically removing the valve stem cap and inserting the gauge to obtain a reading.

Illustrative image related to tire inflation sensor

Плюсы:

– Cost-Effective: These gauges are relatively inexpensive and require no installation or technical knowledge.

– Simplicity: Easy to use, making it accessible for anyone to perform checks on their own.

Конс:

– Labor-Intensive: Requires manual checks, which can be overlooked, leading to potential safety issues.

– Inconsistent Results: User error can lead to inaccurate readings if not used correctly.

Indirect TPMS uses wheel speed sensors to monitor tire pressure indirectly by measuring the rotation of each tire. This system is less intrusive as it leverages existing vehicle sensors.

Плюсы:

– Cost-Effective Alternative: Generally cheaper than direct TPMS and requires less complex maintenance.

– Ease of Integration: Can be integrated into vehicles without extensive modifications.

Конс:

– Less Accurate: Relies on the assumption that tire pressure correlates with wheel speed, which can lead to false alerts.

– Requires Calibration: Needs to be recalibrated after tire changes or rotations, adding to potential downtime.

Illustrative image related to tire inflation sensor

When selecting the appropriate tire monitoring solution, B2B buyers should consider their specific operational context and needs. For organizations prioritizing safety and real-time monitoring, tire inflation sensors or direct TPMS offer the most reliable data. However, for smaller operations or those with budget constraints, manual gauges or indirect TPMS can provide sufficient oversight with lower costs and maintenance requirements. Ultimately, the choice will depend on balancing the initial investment, ease of use, and the level of monitoring required to ensure optimal tire performance and safety.

When considering the procurement of tire inflation sensors, understanding their technical properties is crucial. These specifications not only influence the performance and reliability of the sensors but also affect the overall safety of vehicles. Here are some essential properties to be aware of:

Sensor Type

Tire inflation sensors can be classified into direct and indirect systems. Direct sensors measure actual tire pressure and temperature, providing real-time data. Indirect sensors estimate tire pressure based on wheel speed. For B2B buyers, knowing the type helps in selecting the right sensor based on application needs and budget constraints.

Класс материала

The materials used in manufacturing tire inflation sensors significantly impact durability and performance. Common materials include high-grade plastics and metals that resist corrosion and wear. For buyers, understanding material grade is important to ensure the sensors can withstand environmental conditions prevalent in regions like Africa and the Middle East.

Operating Temperature Range

Tire inflation sensors must function effectively across a wide temperature range. Typical operating temperatures can span from -40°C to +125°C. For international buyers, this specification is vital to ensure that the sensors perform reliably in diverse climates, especially in extreme weather conditions.

Срок службы батареи

The battery life of a tire inflation sensor is a critical factor, often ranging from 5 to 10 years. A longer battery life reduces maintenance costs and enhances operational efficiency. For B2B purchasers, evaluating battery longevity can inform purchasing decisions regarding total cost of ownership.

Communication Protocol

Tire inflation sensors communicate with the vehicle’s onboard systems via various protocols, such as Bluetooth or CAN bus. The choice of communication method can affect compatibility with existing vehicle systems. Understanding these protocols is essential for buyers to ensure seamless integration into vehicle platforms.

Pressure Range and Accuracy

Most tire inflation sensors are designed to monitor a specific pressure range, typically between 0 to 4 bar, with an accuracy of ±0.1 bar. This precision is crucial for safety and performance. For B2B buyers, assessing the pressure range and accuracy helps in selecting sensors that meet regulatory standards and customer expectations.

Navigating the procurement landscape involves familiarizing oneself with industry terminology. Here are some key trade terms relevant to tire inflation sensors:

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to source compatible sensors for vehicle models, ensuring quality and reliability.

MOQ (минимальное количество заказа)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers to understand, as it impacts inventory management and cost planning.

RFQ (запрос котировок)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, crafting a clear RFQ helps in obtaining accurate quotes and facilitates competitive bidding from various suppliers.

Инкотермс (международные коммерческие термины)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding Incoterms is vital for buyers to clarify shipping responsibilities, risk, and costs.

Aftermarket

This term refers to parts and accessories that are not sourced from the OEM but are instead produced by other manufacturers. Buyers should be aware of the aftermarket options for tire inflation sensors, as they can provide cost-effective alternatives without compromising quality.

Гарантийный срок

The warranty period refers to the time frame during which the manufacturer guarantees the performance of the tire inflation sensor. Knowing the warranty terms is crucial for B2B buyers to assess the risk and value of their investment.

Familiarity with these technical properties and trade terms enables B2B buyers to make informed decisions, ensuring they choose the right tire inflation sensors for their needs while navigating the complexities of international procurement.

The tire inflation sensor market is currently experiencing robust growth, driven by increasing safety regulations, rising consumer awareness of vehicle maintenance, and the growing adoption of advanced driver-assistance systems (ADAS). As automotive manufacturers prioritize safety features, the integration of Tire Pressure Monitoring Systems (TPMS) has become standard in many regions, particularly in Europe and North America. This trend is gradually making its way to emerging markets in Africa and South America, where vehicle safety standards are evolving.

Illustrative image related to tire inflation sensor

In addition, advancements in technology are reshaping sourcing trends. The rise of smart sensors that offer real-time data on tire pressure and temperature is becoming increasingly prevalent. These sensors are often integrated with telematics systems, allowing fleet operators to monitor their vehicles remotely. For B2B buyers in sectors such as logistics and transportation, investing in these advanced sensors can lead to reduced operational costs and improved safety records.

Furthermore, the ongoing push for electric vehicles (EVs) is influencing market dynamics. As EV adoption rises, manufacturers are developing TPMS that cater specifically to the unique requirements of electric vehicles, such as weight distribution and tire pressure variations. This shift presents opportunities for international buyers to source specialized products that meet the demands of modern automotive technology.

Sustainability is becoming a focal point in the tire inflation sensor sector, particularly as global regulations on environmental impact tighten. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes sourcing materials that are eco-friendly and ensuring that production processes minimize waste and energy consumption.

Ethical sourcing is equally important, as companies face pressure to ensure that their supply chains are transparent and socially responsible. Buyers are encouraged to partner with manufacturers who have obtained ‘green’ certifications, such as ISO 14001 for environmental management systems or similar standards that reflect their commitment to sustainable practices. These certifications not only enhance brand reputation but also appeal to environmentally conscious consumers.

Illustrative image related to tire inflation sensor

Moreover, the use of recycled materials in the production of tire inflation sensors is gaining traction. This approach not only reduces the environmental footprint but also resonates with buyers looking to improve their sustainability credentials. By investing in suppliers that prioritize ethical sourcing, B2B buyers can contribute to a more sustainable future while also meeting the expectations of stakeholders.

The tire inflation sensor technology has evolved significantly since its inception in the late 20th century. Initially introduced as a response to rising accident rates caused by under-inflated tires, the first TPMS was mandated in the United States following the TREAD Act of 2000. This legislation aimed to enhance vehicle safety by ensuring that drivers are alerted to low tire pressures.

Over the years, the technology has advanced from basic warning systems to sophisticated direct TPMS that provide real-time data on tire pressure and temperature. These innovations have improved the accuracy and reliability of tire monitoring, making it an indispensable feature in modern vehicles.

As the market continues to evolve, B2B buyers should stay informed about historical trends that shape current technologies and consumer expectations. Understanding the trajectory of tire inflation sensors can help businesses make informed decisions about sourcing and integrating these technologies into their operations.

Illustrative image related to tire inflation sensor

How do I choose the right tire inflation sensor for my fleet?

When selecting tire inflation sensors, consider the type of system you need: direct or indirect. Direct TPMS provides precise tire pressure readings and temperature data, while indirect systems use wheel speed sensors and are generally more cost-effective. Assess your fleet’s specific requirements, including vehicle types and operating conditions. Compatibility with existing systems is crucial, so verify that the sensors can be integrated seamlessly. Additionally, consider factors such as durability, battery life, and ease of installation to ensure long-term reliability.

What is the best tire inflation sensor for commercial vehicles?

The best tire inflation sensor for commercial vehicles typically depends on the specific needs of your operation. Direct TPMS sensors are often recommended due to their accuracy in providing real-time tire pressure and temperature data, which is critical for safety and efficiency in commercial fleets. Look for sensors with robust construction to withstand harsh environments and those that offer easy integration with fleet management systems. Brands with proven reliability and good customer support should also be prioritized to ensure ongoing assistance.

What are the typical payment terms for purchasing tire inflation sensors in bulk?

Payment terms for bulk purchases of tire inflation sensors can vary widely among suppliers. Common terms include a net 30 or net 60 days payment period, which allows buyers to pay after receiving the products. Some suppliers may offer discounts for early payments or larger orders. It’s essential to negotiate terms that align with your cash flow and procurement cycles. Always clarify any potential additional costs, such as shipping fees or tariffs, particularly when dealing with international suppliers.

How can I vet suppliers of tire inflation sensors?

To vet suppliers effectively, start by researching their industry reputation through reviews and testimonials. Request references from existing clients and evaluate their experience in the tire sensor market. Check for certifications and compliance with international standards, such as ISO or CE markings, which indicate quality assurance. It’s also beneficial to assess their customer service responsiveness and after-sales support, as this can significantly impact your purchasing experience and ongoing relationship.

What is the minimum order quantity (MOQ) for tire inflation sensors?

Minimum order quantities for tire inflation sensors can vary significantly based on the supplier and the type of sensors being purchased. Some manufacturers may have a MOQ of 100 units, while others might require larger orders to justify production costs. When negotiating, consider the implications of MOQ on your inventory management and cash flow. If you’re unsure about committing to a large order, discuss potential options for smaller test orders or pilot programs to evaluate product performance before scaling up.

What logistics considerations should I be aware of when importing tire inflation sensors?

When importing tire inflation sensors, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your target markets, especially for regions like Africa and South America, where logistical challenges may arise. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared for smooth customs clearance. Additionally, factor in potential tariffs or taxes that could affect the overall cost of your order.

How do I ensure quality assurance for tire inflation sensors?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Look for manufacturers that implement rigorous testing protocols, including pressure and durability tests, to validate their products. Consider asking for samples before placing a bulk order to assess the sensors’ performance firsthand. Establish a clear return policy for defective products and maintain open lines of communication with your supplier to address any quality concerns promptly.

Can tire inflation sensors be customized for specific applications?

Yes, many manufacturers offer customization options for tire inflation sensors to meet specific application needs. Customizations may include modifications in sensor size, pressure ranges, or wireless communication protocols to ensure compatibility with existing systems. When discussing customization, provide detailed specifications and requirements to your supplier. Be mindful of potential impacts on pricing and lead times, as customized products may require additional development and testing before delivery.

Домен: tires.bridgestone.com

Зарегистрирован: 1996 (29 лет)

Введение: The Tire Pressure Monitoring System (TPMS) warns drivers of significantly under-inflated tires, indicated by a yellow symbol resembling a tire cross-section with an exclamation point on the dashboard. TPMS is mandated for most vehicles sold in the U.S. since 2007 due to safety concerns. There are two types of TPMS: Indirect TPMS, which uses wheel speed sensors to detect under-inflation based on ti…

Домен: ford.com

Registered: 1988 (37 years)

Введение: This company, Ford – Tire Pressure Monitoring System Sensor Kit, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

As the demand for tire inflation sensors continues to grow globally, strategic sourcing emerges as a critical component for B2B buyers looking to optimize procurement. The insights from varying technologies—direct and indirect tire pressure monitoring systems (TPMS)—highlight the importance of understanding the unique benefits and limitations of each. Buyers must prioritize quality, compatibility, and the total cost of ownership when selecting sensors, ensuring that they align with their specific operational needs.

Investing in high-quality tire inflation sensors not only enhances vehicle safety but also contributes to reduced operational costs through improved fuel efficiency and prolonged tire life. Furthermore, the increasing regulatory emphasis on vehicle safety, particularly in markets like Germany and Saudi Arabia, underscores the necessity of reliable TPMS solutions.

Looking ahead, international B2B buyers in Africa, South America, the Middle East, and Europe are encouraged to leverage strategic partnerships with reputable suppliers to stay ahead of industry trends. By focusing on innovative technologies and sustainable sourcing practices, businesses can position themselves for future growth. Embrace this opportunity to enhance your fleet’s safety and efficiency—consider upgrading your tire inflation sensor solutions today.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.