In today’s global market, the challenge of sourcing proper tire inflation solutions can significantly impact operational efficiency and safety for businesses. Tire inflation is not merely a maintenance task; it is a critical factor that influences vehicle performance, fuel efficiency, and overall safety. This comprehensive guide aims to equip international B2B buyers—especially those from regions such as Africa, South America, the Middle East, and Europe—with the knowledge needed to make informed purchasing decisions.

From understanding the nuances of tire pressure specifications to exploring various applications across different vehicle types, this guide covers all essential aspects of proper tire inflation. We delve into the importance of supplier vetting, highlighting key criteria to assess quality and reliability. Additionally, we provide insights into cost considerations, ensuring that businesses can balance quality with budget constraints.

By the end of this guide, B2B buyers will be empowered to navigate the complexities of tire inflation, making choices that enhance safety and performance while reducing operational costs. Whether you are in Nigeria, Vietnam, or elsewhere, the information provided here will serve as a valuable resource to optimize your fleet management and improve your bottom line.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Recommended Pressure | Optimal PSI as per vehicle manufacturer; typically 28-36 PSI | Fleet management, transportation services | Плюсы: Enhances safety, fuel efficiency; Конс: Requires regular monitoring. |

| Maximum Pressure | Highest PSI tire can safely withstand; indicated on tire sidewall | Heavy-duty transport, specialized vehicles | Плюсы: Useful for heavy loads; Конс: Can impair handling if used regularly. |

| Minimum Pressure | Pressure below which tires operate unsafely; no official value | Safety assessments, compliance checks | Плюсы: Prevents blowouts; Конс: No defined threshold can lead to confusion. |

| Cold Pressure | Measurement taken when tires are cold; essential for accuracy | Maintenance protocols, tire service centers | Плюсы: Ensures accurate readings; Конс: Weather-dependent, may be overlooked. |

| Tire Pressure Monitoring System (TPMS) | Electronic system alerting low tire pressure | Fleet operations, logistics companies | Плюсы: Real-time monitoring; Конс: Initial installation costs can be high. |

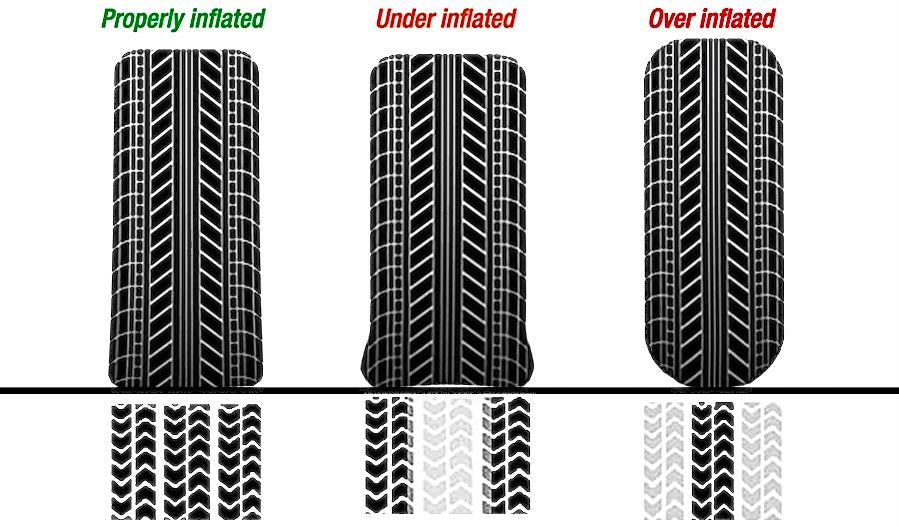

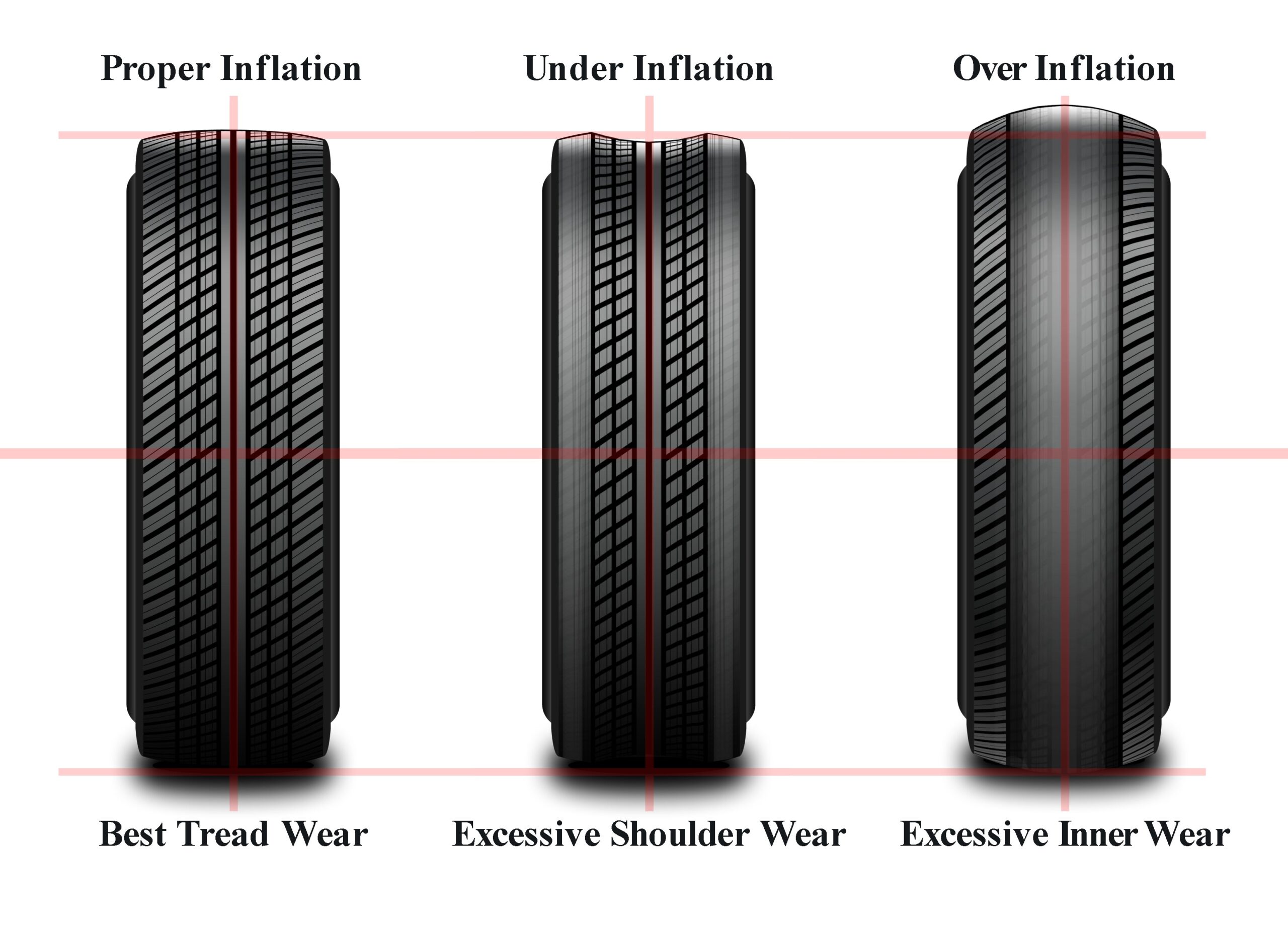

Recommended tire pressure is the optimal air pressure specified by the vehicle manufacturer, typically ranging between 28 and 36 PSI. It is crucial for fleet management and transportation services as it enhances vehicle safety and fuel efficiency. Regular monitoring of tire pressure ensures that vehicles operate within safe limits, reducing the risk of accidents. However, it requires ongoing diligence, as neglecting to check can lead to under-inflation, which negatively impacts tire lifespan and vehicle handling.

Maximum pressure refers to the highest PSI a tire can handle, usually marked on the tire’s sidewall. This type of inflation is particularly relevant for heavy-duty transport and specialized vehicles that carry substantial loads. While it can provide temporary benefits during heavy hauling, using maximum pressure for regular driving can impair vehicle handling and increase the risk of blowouts. Buyers must weigh the need for heavy load capacity against the potential for decreased safety and increased wear on the tires.

Minimum pressure is a less formal term, as most manufacturers do not specify a minimum PSI. However, operating below the recommended pressure can lead to unsafe driving conditions. This concept is crucial for safety assessments and compliance checks, as under-inflation can cause excessive heat buildup, leading to blowouts. The lack of a defined minimum pressure can create confusion, making it vital for B2B buyers to understand the significance of maintaining recommended levels for optimal safety.

Cold pressure is the tire pressure reading taken when the tire is cold, meaning the vehicle has not been driven for several hours. This measurement is essential for ensuring accuracy, especially in maintenance protocols and tire service centers. Cold pressure readings provide a baseline for proper inflation, helping to prevent issues related to heat expansion that can occur after driving. Buyers should incorporate cold pressure checks into their maintenance routines to enhance tire longevity and safety.

Illustrative image related to proper tire inflation

Tire Pressure Monitoring Systems (TPMS) provide real-time alerts about tire pressure levels, making them invaluable for fleet operations and logistics companies. These systems can significantly enhance safety and fuel efficiency by ensuring tires are consistently inflated to recommended levels. While the initial installation costs can be high, the long-term benefits of reduced tire wear and improved safety often justify the investment. Companies should consider TPMS as a proactive measure to maintain tire health across their fleet.

| Промышленность/сектор | Specific Application of proper tire inflation | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Transportation & Logistics | Fleet vehicle maintenance | Improved fuel efficiency and reduced tire wear | Reliable tire pressure monitoring systems and gauges |

| Сельское хозяйство | Agricultural machinery operations | Enhanced safety and operational efficiency | Durable tires designed for agricultural conditions |

| Строительство | Heavy equipment performance | Minimization of downtime and maintenance costs | Access to high-quality, rugged tires suitable for terrain |

| Mining | Mining vehicle and equipment safety | Prevention of accidents and operational disruptions | Specialized tires designed for extreme conditions |

| Retail Automotive | Tire service and maintenance shops | Increased customer satisfaction and repeat business | Comprehensive tire pressure management solutions |

In the transportation and logistics sector, proper tire inflation is critical for fleet vehicle maintenance. Companies often face rising fuel costs due to under-inflated tires, which increase rolling resistance. By ensuring optimal tire pressure, businesses can improve fuel efficiency by up to 3% and extend tire lifespan, leading to significant cost savings. For international buyers, sourcing reliable tire pressure monitoring systems (TPMS) that meet local regulations is essential to maintain safety and compliance.

In agriculture, proper tire inflation is vital for the efficient operation of machinery such as tractors and harvesters. Well-inflated tires provide better traction and stability, which is crucial when working on uneven terrain. Under-inflated tires can lead to soil compaction and increased fuel consumption. Buyers in this sector should consider sourcing durable tires that can withstand agricultural conditions, along with inflation monitoring tools to ensure optimal performance throughout the farming season.

For the construction industry, maintaining proper tire inflation on heavy equipment is essential for safety and efficiency. Under-inflated tires can lead to increased wear and potential blowouts, causing costly downtime. Proper inflation enhances load distribution, reducing the risk of accidents and extending tire life. B2B buyers should focus on sourcing rugged tires specifically designed for construction applications, as well as reliable inflation monitoring equipment to manage tire health effectively.

In the mining sector, proper tire inflation is crucial for the safety and performance of vehicles and equipment operating in harsh environments. Correctly inflated tires can prevent accidents caused by blowouts and improve traction on uneven surfaces. Furthermore, proper inflation reduces the risk of tire damage, which can lead to costly operational disruptions. Buyers should consider specialized tires designed for extreme conditions, along with comprehensive tire pressure management solutions to ensure safety and operational continuity.

Retail automotive businesses, particularly tire service and maintenance shops, can significantly benefit from promoting proper tire inflation practices. Educating customers about the importance of maintaining optimal tire pressure not only enhances customer satisfaction but also encourages repeat business. Shops should consider sourcing comprehensive tire pressure management solutions, including TPMS and inflation gauges, to provide added value to their clientele and ensure safety on the roads.

Проблема: Many B2B buyers operating fleets or managing commercial vehicles often struggle with under-inflation issues. In regions where tire maintenance resources are scarce or inconsistent, such as parts of Africa and South America, tires can frequently be found operating below the recommended pressure. This not only leads to increased fuel consumption due to higher rolling resistance but also accelerates tire wear, resulting in frequent replacements. The financial burden from these expenses can significantly impact operational budgets, making it essential for businesses to address this challenge effectively.

Решение: To combat the issues of under-inflation, businesses should implement a rigorous tire maintenance schedule that includes regular pressure checks. Investing in a reliable tire pressure monitoring system (TPMS) can provide real-time data on tire pressure, allowing for immediate adjustments when necessary. Additionally, training staff on the importance of maintaining proper tire pressure and how to check it correctly can empower them to take proactive measures. By establishing partnerships with local tire suppliers who can offer maintenance services and bulk purchasing options, businesses can ensure their fleets are consistently operating at optimal tire pressure, ultimately reducing costs and enhancing safety.

Illustrative image related to proper tire inflation

Проблема: Over-inflation of tires is a common issue that many fleet managers face, particularly when drivers are unaware of the proper tire pressure specifications. This can lead to compromised vehicle handling and increased risk of blowouts, especially on the diverse terrains found in regions such as the Middle East and parts of Europe. Over-inflated tires wear unevenly and can significantly decrease traction, which poses safety risks and liability concerns for businesses managing transportation services.

Решение: To address over-inflation, companies should ensure that all drivers are well-informed about the recommended tire pressure for their specific vehicle models. Creating a standard operating procedure that includes checking tire pressures before every trip can greatly reduce the likelihood of over-inflation. Additionally, providing accessible resources, such as tire pressure charts or mobile apps that calculate optimal pressure based on load and driving conditions, can help drivers make informed decisions. Regular training sessions that emphasize the differences between recommended and maximum tire pressures will further instill safe practices among staff.

Проблема: In regions with varying climates, such as Europe and South America, tire pressure can fluctuate significantly with temperature changes. Businesses may find that tire performance deteriorates as the seasons change, leading to safety concerns and increased costs due to improper inflation. For instance, colder temperatures can cause tire pressure to drop, while warmer temperatures can lead to over-inflation. Fleet managers often struggle to adapt to these changes, which can affect vehicle safety and operational efficiency.

Illustrative image related to proper tire inflation

Решение: To tackle the challenges posed by seasonal changes, businesses should adopt a proactive tire management strategy that includes adjusting tire pressure with the changing seasons. Implementing a seasonal tire pressure checklist can help ensure that all vehicles are regularly inspected and adjusted according to the climate. Using tire pressure gauges that are calibrated for both cold and warm conditions can assist in making accurate adjustments. Furthermore, investing in high-quality tires designed to perform well in extreme weather conditions can mitigate the effects of temperature fluctuations, enhancing both safety and tire longevity. Regular communication with tire suppliers about seasonal trends and recommended practices can also provide valuable insights for maintaining optimal tire performance throughout the year.

When considering the materials involved in tire inflation systems, several options are commonly utilized. Each material has unique properties that can significantly influence performance, durability, and overall application suitability. Below are analyses of four prevalent materials used in tire inflation systems.

Основные свойства: Rubber is the primary material used in tire manufacturing due to its excellent elasticity and ability to withstand varying temperature and pressure conditions. It typically has a temperature rating of -40°C to 100°C and can handle pressures exceeding 50 PSI.

Плюсы и минусы: Rubber is durable and provides a good seal, which is crucial for maintaining tire pressure. However, it can degrade over time due to UV exposure and ozone, leading to cracks and leaks. The manufacturing process can be complex and costly, especially when incorporating advanced compounds for enhanced performance.

Влияние на применение: Rubber is compatible with air and nitrogen, making it suitable for various inflation methods. However, its performance can be affected by extreme environmental conditions, which are common in regions like Africa and the Middle East.

Illustrative image related to proper tire inflation

Соображения для международных покупателей: Buyers should consider compliance with local standards such as ASTM and ISO. In regions with high UV exposure, selecting UV-resistant rubber compounds can enhance longevity.

Основные свойства: Steel is often used in the construction of tire valves and rims due to its high tensile strength and resistance to deformation. It can withstand high pressures, typically rated up to 100 PSI, and is resistant to corrosion when properly treated.

Плюсы и минусы: Steel is highly durable and provides structural integrity, ensuring that the tire maintains its shape under load. However, it is heavier than alternative materials like aluminum, which can affect vehicle performance. Additionally, the manufacturing process can be energy-intensive, raising costs.

Влияние на применение: Steel components are essential for maintaining the integrity of the tire under high pressure, especially in heavy-duty applications. Corrosion resistance is crucial in humid or saline environments, which are prevalent in coastal regions of South America and Africa.

Соображения для международных покупателей: Buyers should ensure that steel components meet local corrosion resistance standards, particularly in regions with high humidity or saline exposure. Compliance with standards like DIN can also be beneficial.

Основные свойства: Various plastics, including nylon and polycarbonate, are used in tire pressure monitoring systems (TPMS) and valve stems. These materials offer good chemical resistance and can operate effectively in a temperature range of -20°C to 80°C.

Плюсы и минусы: Plastics are lightweight and can be molded into complex shapes, making them suitable for intricate designs in TPMS. However, they may not withstand high temperatures as effectively as metals, and their durability can be compromised under extreme conditions.

Влияние на применение: Plastics are compatible with air and nitrogen, but their performance may degrade in high-temperature environments. This is particularly relevant in regions like the Middle East, where extreme heat can affect material integrity.

Соображения для международных покупателей: Buyers should be aware of local regulations regarding plastic materials, particularly concerning environmental impact and recyclability. Compliance with standards like JIS can also enhance product acceptance in various markets.

Основные свойства: Composite materials, which combine fibers (like carbon or glass) with resin, offer high strength-to-weight ratios and excellent pressure resistance. They can typically handle pressures up to 70 PSI and operate effectively in a wide temperature range.

Плюсы и минусы: Composites are lightweight and resistant to corrosion, making them ideal for high-performance applications. However, they can be more expensive to manufacture and may require specialized processing techniques.

Illustrative image related to proper tire inflation

Влияние на применение: Composites are particularly beneficial in high-performance tires where weight reduction is crucial. Their resistance to environmental degradation makes them suitable for diverse climates, including humid regions in Africa and South America.

Соображения для международных покупателей: Buyers should consider the cost-benefit ratio of composites versus traditional materials. Compliance with international standards such as ASTM for composites is also essential for market acceptance.

| Материал | Typical Use Case for proper tire inflation | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire manufacturing | Excellent elasticity and seal | Degrades under UV exposure | Средний |

| Сталь | Valve and rim construction | High durability and structural integrity | Heavier than alternatives | Средний |

| Пластмассы | TPMS and valve stems | Lightweight and moldable | Limited high-temperature performance | Низкий |

| Композиты | High-performance tires | Высокое соотношение прочности и веса | Более высокие производственные затраты | Высокий |

This analysis provides a comprehensive overview of the materials involved in tire inflation systems, offering actionable insights for international B2B buyers looking to optimize their product offerings.

Proper tire inflation is critical for the safety and efficiency of vehicles, making it essential for manufacturers and suppliers to adhere to rigorous manufacturing processes and quality assurance standards. This section delves into the typical manufacturing processes involved in tire production and the quality control measures that ensure proper tire inflation, particularly for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe.

The manufacturing of tires involves several key stages that ensure the final product meets the required safety and performance standards.

Illustrative image related to proper tire inflation

The tire manufacturing process begins with the selection and preparation of raw materials. This typically includes natural and synthetic rubber, fabric, steel, and various chemical compounds.

Rubber Compounding: The rubber is mixed with additives such as carbon black, silica, and chemical accelerators to enhance durability and performance. This process requires precise measurements and thorough mixing to ensure uniformity.

Fabric and Steel Preparation: The materials used for reinforcement, such as nylon or polyester fabric and steel belts, are cut and prepared according to specifications. This involves quality checks to ensure the integrity of the materials being used.

The next stage involves forming the tire components into their final shapes.

Extrusion: Rubber compounds are extruded into various shapes, including tread and sidewall components. This process must be carefully controlled to maintain the correct dimensions and properties.

Calendering: This technique is used to produce fabric-reinforced rubber sheets. The rubber is passed through rollers to achieve the desired thickness and consistency.

Molding: Once the components are prepared, they are assembled into a “green tire” (unvulcanized) in a mold. This step involves precise placement of the tread, sidewalls, and reinforcement materials.

After forming, the next step is assembling the green tire.

Layering: Different layers of materials are assembled carefully to ensure structural integrity. The order and alignment of the materials are crucial for performance.

Curing (Vulcanization): The green tire is then placed in a curing mold and subjected to heat and pressure. This process hardens the rubber and bonds all components together, giving the tire its final shape and characteristics.

Quality assurance is vital to ensure that tires perform safely and effectively. Several international and industry-specific standards guide manufacturers.

ISO 9001 is a globally recognized standard for quality management systems. It provides a framework for manufacturers to ensure consistent quality and continuous improvement. Compliance with ISO 9001 indicates that the manufacturer has established processes for quality assurance, including:

Documented Procedures: Manufacturers must document their processes for material selection, production, and quality checks.

Regular Audits: Internal audits are conducted to ensure adherence to quality standards and identify areas for improvement.

In addition to ISO standards, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for tire manufacturers, particularly for those exporting to regions with stringent regulatory requirements.

CE Marking: Indicates that the product meets EU safety, health, and environmental protection standards. For tires, this means they have been tested for performance and safety.

API Standards: While primarily for oil and gas, certain API standards may apply to tires used in heavy machinery, ensuring they can withstand specific operational conditions.

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with standards.

IQC involves evaluating raw materials upon arrival at the manufacturing facility. This includes testing for:

Material Integrity: Ensuring that rubber compounds and reinforcements meet specified standards.

Supplier Compliance: Verifying that suppliers adhere to required quality standards and certifications.

IPQC focuses on monitoring the manufacturing process to catch defects as they occur. Key practices include:

Dimensional Checks: Regular measurement of tire dimensions during forming to ensure accuracy.

Visual Inspections: Inspecting components for defects such as bubbles or inconsistencies before assembly.

FQC is the last line of defense before tires are shipped to customers. This involves:

Тестирование производительности: Tires undergo rigorous testing to assess performance under various conditions, including temperature, load, and pressure.

Visual and Functional Inspections: Final inspections to check for surface defects, proper labeling, and overall quality.

For international B2B buyers, verifying the quality control practices of tire manufacturers is essential to ensure reliability and safety.

Conducting audits is one effective way to assess a supplier’s quality control measures. Buyers should:

Request Audit Reports: Review past audit reports to understand the supplier’s compliance with quality standards.

Conduct On-Site Audits: If feasible, perform on-site audits to observe the manufacturing processes and quality control measures firsthand.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can:

Conduct Random Sampling: Test a representative sample of finished products for quality assurance.

Verify Compliance with Standards: Ensure that the manufacturer adheres to both international and industry-specific standards.

B2B buyers from diverse regions should be aware of specific nuances in quality control that may affect their purchasing decisions.

Different regions may have unique regulatory requirements. For instance:

African Markets: Buyers may need to consider local standards for vehicle safety and performance, which can differ significantly from Western standards.

European Regulations: The EU has stringent regulations regarding tire performance and environmental impact, necessitating compliance for imported products.

Cultural attitudes toward quality and operational practices can vary by region. Buyers should:

Engage in Local Partnerships: Collaborate with local experts or consultants to navigate regional standards and practices.

Understand Supply Chain Dynamics: Different regions may experience varying supply chain challenges, which can impact the availability and quality of materials.

By understanding the manufacturing processes and quality assurance measures that underpin proper tire inflation, B2B buyers can make informed decisions that enhance safety and performance in their operations.

To ensure optimal performance and safety in tire management, this step-by-step checklist provides B2B buyers with actionable insights for procuring proper tire inflation solutions. Following these steps will help organizations enhance safety, reduce costs, and extend the lifespan of their tire assets.

Understanding your vehicle’s tire specifications is critical. This includes knowing the recommended tire pressure, which varies by vehicle and tire type. Refer to the vehicle’s operator manual or the sticker on the driver’s door for accurate pressure readings, typically ranging from 28 to 36 PSI.

Implementing a Tire Pressure Monitoring System (TPMS) can significantly enhance safety and efficiency. TPMS alerts drivers when tire pressure falls below a critical threshold, preventing potential blowouts and improving fuel efficiency.

Before committing to a supplier, thorough vetting is essential. Look for suppliers with proven track records in tire management solutions, particularly those familiar with your industry and regional conditions.

Illustrative image related to proper tire inflation

Ensure that the suppliers you are considering comply with local and international safety standards. Certifications from recognized bodies indicate that the products meet quality and safety benchmarks.

Before finalizing any procurement, request product demonstrations or samples. This allows you to assess the effectiveness of the tire inflation solutions firsthand.

Select suppliers who offer robust after-sales support and training for your team. Proper training ensures that staff can effectively use the tire inflation systems, contributing to safety and efficiency.

Finally, conduct a cost-benefit analysis to understand the long-term savings associated with proper tire inflation. Well-maintained tires reduce fuel consumption and increase safety, leading to fewer accidents and lower replacement costs.

By following this checklist, B2B buyers can make informed decisions regarding tire inflation solutions that enhance safety, reduce costs, and improve vehicle performance.

Illustrative image related to proper tire inflation

When sourcing solutions for proper tire inflation, understanding the cost structure is essential for effective budgeting and financial planning. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Материалы: The primary materials involved include high-quality rubber compounds, inflation valves, and tire pressure monitoring systems (TPMS). These materials must comply with international safety standards, which can influence pricing.

Труд: Skilled labor is necessary for the manufacturing and assembly of tire inflation systems. Labor costs may vary significantly based on geographical location, with labor-intensive operations in regions like Africa and South America potentially incurring lower costs compared to Europe.

Производственные накладные расходы: This encompasses costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs, allowing suppliers to offer competitive pricing.

Инструментальная оснастка: Initial tooling costs can be substantial, particularly for custom or specialized tire inflation systems. Buyers should consider the implications of these costs when negotiating terms, especially if large orders are involved.

Контроль качества (QC): Implementing robust QC processes is crucial to ensure product reliability and safety. While this may add to the initial cost, it ultimately reduces the risk of product failure and liability claims.

Логистика: Freight costs can vary widely based on distance and mode of transportation. International buyers should factor in customs duties and taxes, which can add complexity to the logistics cost structure.

Маржа: Suppliers typically include a profit margin in their pricing structure, which can fluctuate based on market demand and competition. Understanding the competitive landscape can help buyers negotiate better terms.

Numerous factors influence pricing for tire inflation solutions, making it vital for buyers to be aware of these variables.

Объем/МОК: Minimum order quantities (MOQs) often dictate pricing. Higher volumes typically yield lower per-unit costs, incentivizing bulk purchases. International buyers should assess their demand to optimize ordering strategies.

Технические характеристики и персонализация: Custom solutions can incur additional costs due to specialized materials or design requirements. Buyers should weigh the benefits of customization against potential price increases.

Материалы: The quality and type of materials used in tire inflation systems significantly impact pricing. Premium materials may come at a higher cost but offer better durability and performance.

Качество и сертификация: Products that meet international quality standards or certifications (like ISO) can demand higher prices. Buyers should consider the long-term value of investing in certified products.

Факторы поставщика: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality and service may charge more, but they often provide greater assurance of product performance.

Инкотермс: The choice of Incoterms (International Commercial Terms) can influence overall costs, including freight, insurance, and customs duties. Buyers should select terms that align with their logistical capabilities and cost expectations.

For international B2B buyers, particularly from diverse markets like Africa, South America, the Middle East, and Europe, employing strategic purchasing tactics can lead to significant cost savings.

Обсудите условия: Leverage volume purchases and long-term partnerships to negotiate better pricing and payment terms. Building relationships with suppliers can lead to discounts and favorable conditions.

Ориентируйтесь на общую стоимость владения (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, durability, and fuel savings from proper tire inflation. A slightly higher upfront cost may translate into lower operational costs over time.

Understand Pricing Nuances: Be aware of regional pricing variations and the impact of currency fluctuations. This knowledge can provide leverage in negotiations and help in budgeting.

Research Suppliers: Conduct thorough research on potential suppliers, including their production capabilities, lead times, and customer reviews. This ensures that you select a partner who aligns with your quality and pricing expectations.

Stay Updated on Market Trends: Keeping abreast of market trends and technological advancements can help buyers anticipate changes in pricing and product offerings, allowing for timely sourcing decisions.

Prices for tire inflation solutions can vary widely based on the above factors and market conditions. Buyers are encouraged to obtain multiple quotes and conduct thorough due diligence to ensure they are making informed purchasing decisions.

In the realm of tire management, proper inflation is critical for vehicle safety, performance, and fuel efficiency. However, several alternative solutions exist that can also enhance tire performance or address the risks associated with improper inflation. This section explores these alternatives, enabling B2B buyers to make informed decisions tailored to their operational needs.

| Сравнительный аспект | Proper Tire Inflation | Tire Pressure Monitoring System (TPMS) | Run-Flat Tires |

|---|---|---|---|

| Производительность | Optimal handling and safety with correct PSI | Alerts for under-inflation, enhancing safety | Allows driving on flat tires for a limited distance |

| Стоимость | Minimal ongoing costs | Initial investment; potential maintenance costs | Higher initial purchase price |

| Простота реализации | Simple checks with gauges; requires training | Installation by professionals; requires periodic checks | Installation requires specific vehicle compatibility |

| Техническое обслуживание | Monthly checks recommended | Regular battery checks and potential replacements | Minimal; tires need replacement after use |

| Лучший пример использования | Standard vehicles; fleet management | Fleet vehicles needing constant monitoring | Emergency scenarios; high-performance vehicles |

Tire Pressure Monitoring Systems (TPMS) provide an automated approach to tire management by using sensors to alert drivers when tire pressure drops below a safe threshold. The primary advantage of TPMS is its ability to enhance safety through real-time monitoring, helping prevent blowouts and accidents caused by under-inflation. However, the initial cost of installation can be high, and ongoing maintenance may be necessary to ensure the system’s reliability. Additionally, while TPMS alerts users to pressure issues, it does not replace the need for regular manual checks and maintenance.

Run-flat tires offer a unique solution to tire management by allowing vehicles to continue driving even after a puncture. The major benefit of run-flat tires is that they provide peace of mind, especially in remote areas where tire failure can be particularly problematic. They eliminate the immediate need for roadside assistance in the event of a flat tire. However, these tires typically come at a higher cost than standard tires and may require specific vehicle compatibility, limiting their use in certain fleets. Additionally, once the tire has been punctured, it will need to be replaced, as driving on a flat can lead to significant wear.

For B2B buyers, the decision between maintaining proper tire inflation and exploring alternative technologies hinges on specific operational needs. If fleet safety and performance are paramount, investing in a TPMS may provide the necessary oversight for tire conditions, especially for companies operating in regions with varying road conditions. Conversely, for businesses that prioritize emergency preparedness or operate in remote locations, run-flat tires can be invaluable. Ultimately, understanding the trade-offs of each option will empower buyers to select the most effective tire management strategy tailored to their unique operational challenges.

Illustrative image related to proper tire inflation

In the realm of tire management, understanding essential technical specifications is vital for ensuring safety, performance, and longevity of tires. Here are several key specifications that B2B buyers should be aware of:

Recommended Tire Pressure (RTP)

This is the optimal air pressure specified by the vehicle manufacturer, typically measured in pounds per square inch (PSI). Maintaining RTP is crucial for vehicle safety, fuel efficiency, and tire durability. Under-inflated tires lead to increased rolling resistance, while over-inflation can result in uneven tire wear and reduced grip.

Maximum Pressure

Indicated on the tire’s sidewall, the maximum pressure denotes the highest air pressure a tire can safely handle. This specification is crucial for preventing blowouts during heavy loads or high-speed driving. B2B buyers must ensure that their operations do not exceed this limit, especially in commercial applications where loads are variable.

Cold Inflation Pressure

This refers to the tire pressure measured when the tire is cold, meaning the vehicle has not been driven for several hours. Checking cold inflation pressure is essential for accuracy, as tire pressure can increase with heat generated during driving. Understanding this specification helps in making informed decisions regarding tire maintenance.

Tire Load Index

This numerical code on the tire indicates the maximum load each tire can support at the recommended pressure. Knowing the load index is essential for B2B buyers, especially those managing fleets or heavy-duty vehicles. It ensures that the tires can safely handle the weight they will be subjected to during operation.

Tread Depth

While not a pressure specification, tread depth is critical for tire performance and safety. A minimum tread depth ensures adequate grip and water displacement, reducing the risk of hydroplaning. Regularly monitoring tread depth can prevent accidents and extend tire life, which is particularly important for businesses that rely on transportation.

Navigating the tire industry requires familiarity with specific jargon. Here are some common terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the assembly of vehicles. For tire buyers, understanding OEM specifications ensures that they are sourcing tires that meet the original standards for performance and safety.

MOQ (минимальное количество заказа)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ is essential for budgeting and inventory planning, especially when sourcing tires in bulk.

RFQ (запрос котировок)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This is a common practice in B2B transactions and is crucial for comparing costs and negotiating favorable terms when purchasing tires.

Инкотермс (международные коммерческие термины)

These are internationally recognized rules that define the responsibilities of buyers and sellers in the delivery of goods. Familiarity with Incoterms helps businesses understand shipping responsibilities, costs, and risk management when importing tires from international suppliers.

TPMS (Tire Pressure Monitoring System)

This system provides real-time data on tire pressure, alerting drivers when pressure deviates from the recommended levels. Understanding TPMS is vital for fleet management, as it enhances safety and can prevent costly tire-related incidents.

Under-inflation and Over-inflation

These terms describe the conditions where tire pressure is below or above the recommended levels, respectively. Both conditions can lead to significant safety risks and increased operational costs, making it essential for B2B buyers to monitor and maintain proper tire inflation consistently.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions regarding tire inflation, leading to enhanced safety, performance, and cost efficiency in their operations.

The proper tire inflation sector is increasingly influenced by global trends such as rising fuel prices, enhanced safety standards, and a growing awareness of vehicle maintenance. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are noticing the importance of adhering to recommended tire pressures, which not only improve vehicle efficiency but also enhance safety. Current trends indicate a shift towards technology integration, with the adoption of tire pressure monitoring systems (TPMS) becoming standard in many vehicles. This technology not only alerts drivers about low tire pressure but also provides data analytics for fleet management, enabling businesses to optimize operational costs.

Emerging technologies such as smart tire systems, which utilize IoT (Internet of Things) capabilities to monitor tire conditions in real-time, are gaining traction. Such innovations allow for proactive maintenance, reducing downtime and improving overall fleet efficiency. Furthermore, as the automotive industry evolves, there is a noticeable demand for training and resources around proper tire inflation practices, particularly in developing markets. This indicates a growing market for B2B suppliers who can provide educational materials and tools that help companies ensure their fleets are operating at optimal performance.

Sustainability is becoming a paramount consideration for B2B buyers, particularly in the tire inflation sector. The environmental impact of improperly inflated tires is significant, as they contribute to increased fuel consumption and higher greenhouse gas emissions. As a result, businesses are prioritizing suppliers who adhere to sustainable practices in their manufacturing processes. This includes utilizing eco-friendly materials, such as recycled rubber and sustainable sourcing of raw materials, which not only reduce environmental harm but also align with corporate social responsibility goals.

Illustrative image related to proper tire inflation

Ethical sourcing is also crucial; buyers are increasingly interested in supply chains that ensure fair labor practices and minimize environmental degradation. Certifications like the Global Recycled Standard (GRS) or the Sustainable Rubber Initiative can enhance a supplier’s credibility and appeal to conscientious buyers. By incorporating sustainable practices, businesses can not only reduce their carbon footprint but also enhance their brand image in a market that increasingly values ethical considerations.

Historically, tire inflation practices have evolved significantly, primarily driven by advancements in automotive technology and increasing safety regulations. In the early days of motoring, tire pressure was often checked manually, with limited understanding of its impact on vehicle performance. As vehicles became more sophisticated, manufacturers began providing specific tire pressure recommendations, leading to the development of standardized practices.

The introduction of tire pressure monitoring systems in the late 20th century marked a turning point, allowing for real-time monitoring and alerting drivers to potential issues. Today, with the integration of smart technologies, the focus has shifted to not only maintaining proper tire pressure but also leveraging data analytics for improved vehicle performance and safety. This evolution reflects a broader trend within the automotive industry toward enhanced efficiency and sustainability, making it crucial for B2B buyers to stay informed about the latest developments in tire inflation practices.

How do I solve tire pressure issues in my fleet vehicles?

To address tire pressure issues in fleet vehicles, implement a routine maintenance schedule that includes monthly tire pressure checks. Utilize tire pressure monitoring systems (TPMS) for real-time updates on tire conditions. Train drivers to conduct pre-trip inspections, focusing on tire pressure and tread depth. Additionally, establish relationships with local tire suppliers to ensure quick access to professional services and tire replacements as needed.

What is the best tire pressure monitoring system (TPMS) for commercial fleets?

The best TPMS for commercial fleets balances cost, ease of use, and reliability. Look for systems that offer real-time monitoring, alerts for low or high pressure, and compatibility with various vehicle types. Systems like the TireMinder or PressurePro provide comprehensive solutions tailored for fleet management, enhancing safety and reducing maintenance costs. Always consult with suppliers to ensure the chosen TPMS meets your operational needs and regulatory requirements.

What should I consider when sourcing tires for international shipping?

When sourcing tires for international shipping, consider factors such as compliance with local regulations, shipping costs, and potential tariffs. Evaluate the reputation and reliability of your suppliers, ensuring they can provide quality products that meet your specifications. Additionally, consider the logistics of transport and delivery timelines, as well as the availability of after-sales support and warranty services in your target market.

How can I vet suppliers for tire products effectively?

To vet suppliers for tire products, conduct thorough research on their industry reputation, customer reviews, and certifications. Request samples or product specifications to assess quality and compliance with international standards. Additionally, verify their production capabilities, lead times, and financial stability through third-party audits or financial reports. Engaging in direct communication can also help gauge their responsiveness and customer service commitment.

What are the minimum order quantities (MOQs) for tire purchases?

Minimum order quantities (MOQs) for tire purchases can vary significantly based on the supplier and type of tire. Typically, MOQs range from a few dozen to several hundred units, depending on the manufacturer’s production scale and inventory policies. When negotiating with suppliers, inquire about flexibility in MOQs, especially for new customers or trial orders, to better manage your initial investment and risk.

What payment terms should I negotiate when sourcing tires?

When sourcing tires, negotiate payment terms that align with your cash flow and financial strategy. Common terms include net 30, net 60, or even advance payments for large orders. Consider discussing options for bulk discounts or payment plans if you’re committing to a significant order. Additionally, ensure that payment methods are secure and efficient, potentially utilizing letters of credit for international transactions to mitigate risk.

How do I ensure quality assurance (QA) in tire purchases?

To ensure quality assurance in tire purchases, establish clear specifications and standards with your suppliers. Request detailed documentation, including test reports and certifications, to verify compliance with safety and performance standards. Conduct periodic audits of your suppliers’ production processes and facilities to ensure adherence to quality protocols. Additionally, consider implementing a return policy for defective products to protect your investment and maintain operational safety.

What logistics considerations should I keep in mind for tire distribution?

Logistics considerations for tire distribution include selecting reliable shipping partners, understanding customs regulations, and planning for warehousing needs. Ensure that your logistics provider has experience with tire shipments to avoid delays or damages. Evaluate the costs associated with different shipping methods, considering both speed and reliability. Additionally, maintain clear communication with suppliers and distributors to optimize inventory levels and streamline the supply chain process.

Домен: pirelli.com

Зарегистрирован: 1995 (30 лет)

Введение: Recommended tire pressure is established by the vehicle manufacturer and typically falls between 28 and 36 PSI. The correct pressure can be found in the car’s operator manual or on a sticker inside the driver’s door. Tire pressure should be checked when the tire is cold for accuracy. Maximum tire pressure is indicated on the tire sidewall and should not be used for regular driving as it can impair…

Домен: cars.com

Зарегистрирован: 1998 (27 лет)

Введение: Recommended tire pressures are commonly listed on a sticker inside the driver’s door, in the glove box, or on the inside of the fuel-filler door. The recommended tire pressure is a cold inflation pressure, meaning it should be checked after the vehicle has been sitting in the shade. Some vehicles may have different recommended pressures for front and rear tires, and higher pressures may be listed …

Домен: bridgestoneamericas.com

Зарегистрирован: 2002 (23 года)

Введение: Proper tire inflation is crucial for maximizing tire performance and mileage. Tires should be checked at least once a month, as they lose approximately 1 PSI of pressure monthly. Tire pressure can change with temperature; for every 10 degrees F change, tire pressure changes by about 1 PSI. The correct inflation pressure is not on the tire’s sidewall but is determined by the vehicle manufacturer ba…

Домен: toyotires.com

Зарегистрирован: 1997 (28 лет)

Введение: Load and Inflation Tables provide assistance for replacing tires with optional sizes, including plus sizes not listed on the vehicle’s tire information placard (T.I.P) or in the owner’s manual. For original equipment (OE) size inflation pressure recommendations, refer to the T.I.P. found on the vehicle door jam, glove compartment, or near the gas cap. Important to consult the vehicle’s owner’s man…

Домен: kaltire.com

Зарегистрирован: 1995 (30 лет)

Введение: Kal Tire offers a range of tire services and products, including passenger car tires, truck and SUV tires, EV and hybrid tires, ATV tires, and tire accessories. They provide a price match guarantee for eligible passenger or light truck tires and offer a free wheel warranty. Tire services include winter tire changes, flat tire repairs, tire rotations, and mechanical services such as wheel alignment…

In conclusion, maintaining proper tire inflation is crucial for ensuring safety, enhancing fuel efficiency, and prolonging tire life. International B2B buyers should prioritize sourcing quality tires that meet recommended pressure standards to minimize operational costs and maximize performance. By understanding the importance of correct tire pressure, businesses can significantly reduce the risk of tire-related incidents, which can lead to costly downtimes and potential liabilities.

Strategic sourcing also plays a vital role in this process. Engaging with reliable suppliers who provide accurate tire specifications and maintenance solutions can empower companies to implement effective tire management practices. This proactive approach not only enhances fleet efficiency but also aligns with sustainability goals by reducing waste and resource consumption.

Illustrative image related to proper tire inflation

As we look forward, it is essential for organizations, particularly in emerging markets across Africa, South America, the Middle East, and Europe, to adopt best practices in tire maintenance and inflation. By investing in proper tire management strategies and building strong supplier relationships, companies can ensure safer, more efficient operations that contribute to overall business growth. Take the next step—evaluate your tire sourcing strategies today to drive future success.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.