In the competitive landscape of global industrial equipment, sourcing a reliable hand air compressor can pose significant challenges for B2B buyers. With a myriad of options available, businesses often struggle to find compressors that not only meet their operational needs but also align with budgetary constraints and quality standards. This guide aims to demystify the intricacies of the hand air compressor market by providing a comprehensive overview of various types, applications, and critical factors for supplier vetting.

Our in-depth exploration covers essential aspects such as the differences between oil-free and oil-lubricated compressors, the importance of tank size, and the implications of portability. Additionally, we delve into the applications of hand air compressors across diverse industries—from automotive repair to construction—ensuring that you understand which type best suits your specific requirements. Furthermore, the guide offers insights into cost considerations, helping you navigate pricing structures and negotiate effectively with suppliers.

Designed specifically for international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Vietnam and established ones like Germany—this guide empowers you to make informed purchasing decisions. By leveraging the knowledge contained within, you can confidently select a hand air compressor that enhances operational efficiency and contributes to your business’s success in a global marketplace.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Oil-Free Compressors | Lightweight, low maintenance, quieter operation | Automotive repair, DIY projects | Плюсы: Less maintenance, no oil changes required. Конс: Typically lower power output compared to oil-lubricated models. |

| Oil-Lubricated Compressors | Higher durability, greater power output, and longer lifespan | Industrial applications, heavy-duty tasks | Плюсы: Better suited for continuous use, more powerful. Конс: Requires regular maintenance and oil changes. |

| Portable Compressors | Compact design, easy transport, battery or AC-powered | Construction sites, remote locations | Плюсы: Versatile, can be used in various locations. Конс: Limited tank size may restrict prolonged use. |

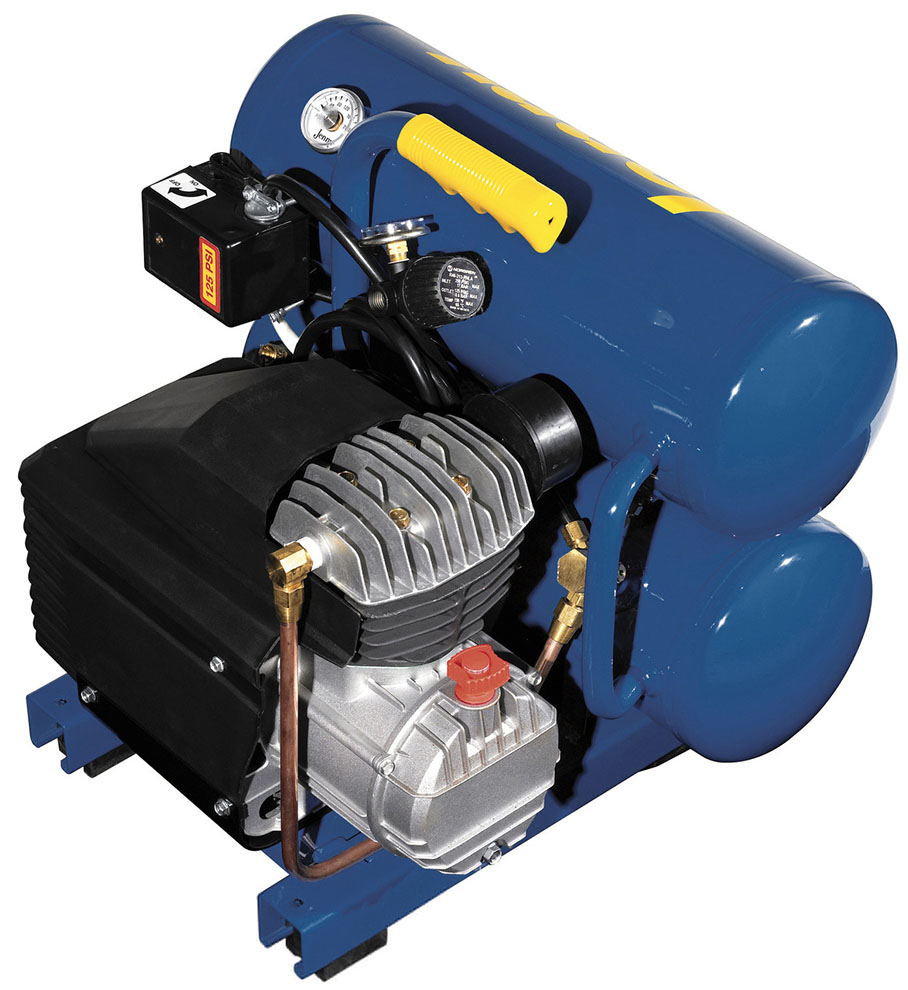

| Twin-Tank Compressors | Dual tank design for increased air storage and pressure | Manufacturing, pneumatic tools operation | Плюсы: Maintains consistent pressure, suitable for heavy-duty applications. Конс: Heavier and less portable than single-tank models. |

| Direct Drive Compressors | Simplified design with fewer moving parts, quieter operation | Workshops, light industrial use | Плюсы: More energy-efficient, lower initial cost. Конс: May have a shorter lifespan compared to belt-driven models. |

Oil-free compressors are designed for applications requiring clean air, making them ideal for automotive repair and DIY projects. These compressors are lightweight and require minimal maintenance, as they do not need regular oil changes. Buyers should consider their lower power output, which may not be suitable for high-demand applications but is perfect for intermittent use.

Oil-lubricated compressors are known for their durability and ability to handle heavy-duty tasks. They provide greater power output and longer lifespans, making them suitable for industrial applications. However, they require regular maintenance, including oil changes, which can be a consideration for B2B buyers looking for long-term reliability versus operational costs.

Portable compressors are compact and easy to transport, making them ideal for construction sites and remote locations. They can be powered by batteries or AC power, offering versatility. However, their limited tank size may restrict prolonged use, which is an important consideration for businesses that require continuous air supply.

Illustrative image related to hand air compressor

Twin-tank compressors feature a dual tank design that allows for increased air storage and pressure consistency. This makes them particularly useful in manufacturing and pneumatic tool operations where a steady air supply is critical. While they offer superior performance, their weight and reduced portability might be a drawback for some buyers.

Direct drive compressors utilize a simplified design with fewer moving parts, resulting in quieter operation and energy efficiency. They are often more affordable upfront, making them attractive for workshops and light industrial use. However, buyers should be aware that they may have a shorter lifespan compared to more robust belt-driven models, which could impact long-term investment considerations.

| Промышленность/сектор | Specific Application of hand air compressor | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

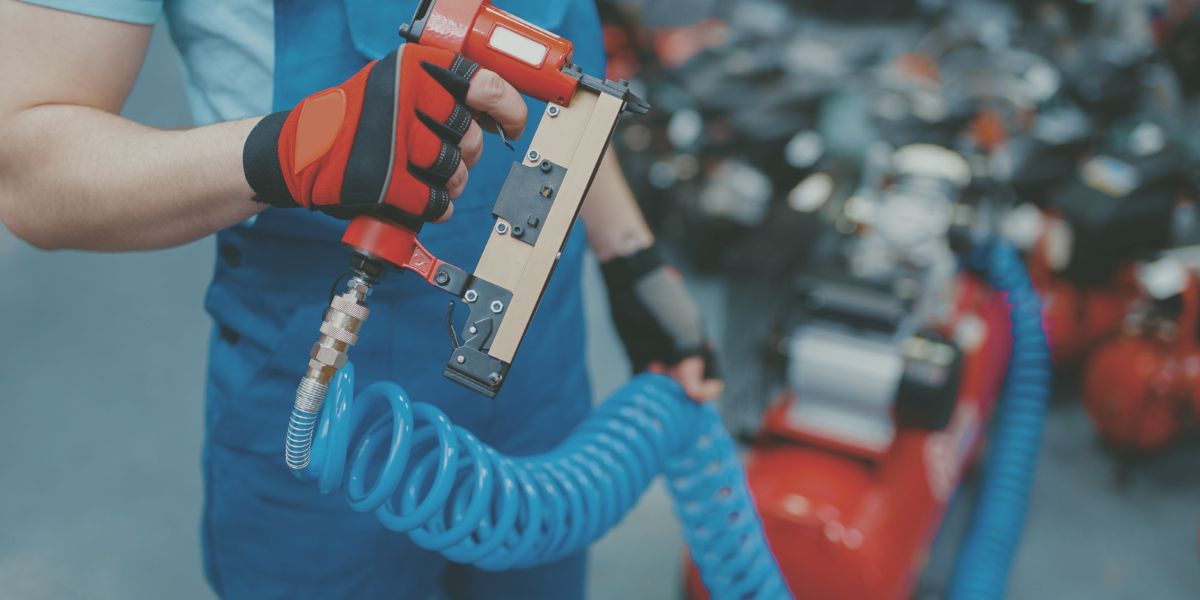

| Строительство | Pneumatic tool operation for nail guns and drills | Enhanced efficiency and productivity on job sites | Durability, portability, and power output needed |

| Ремонт автомобилей | Tire inflation and air tool operation | Quick turnaround on vehicle servicing | Compatibility with various tools and ease of use |

| Производство | Cleaning and maintenance of machinery | Improved operational efficiency and reduced downtime | Noise levels, energy consumption, and maintenance needs |

| Сельское хозяйство | Crop spraying and irrigation systems | Increased yield and efficient resource management | Versatility in pressure settings and portability |

| Painting and Finishing | Spray painting and surface preparation | High-quality finishes and reduced labor costs | Consistency in air pressure and ease of transport |

In the construction industry, hand air compressors are essential for powering pneumatic tools such as nail guns and impact wrenches. These tools significantly increase productivity, allowing workers to complete tasks quickly and efficiently. For international buyers, especially in regions like Africa and South America, sourcing compressors that are durable and portable is crucial, as job sites can often be remote. Additionally, the ability to operate in varying temperatures and humidity levels is a key consideration for these buyers.

Automotive repair shops utilize hand air compressors for tire inflation and operating air tools like impact wrenches and ratchets. This application allows for faster servicing and enhances the overall efficiency of workshops. B2B buyers in the Middle East and Europe should look for compressors that offer compatibility with a range of tools and have a compact design for easy storage. Reliability and ease of maintenance are also important factors to consider to minimize downtime.

Illustrative image related to hand air compressor

In manufacturing, hand air compressors are used for cleaning machinery and powering air-operated tools, which helps maintain operational efficiency. They can also be employed in assembly lines to streamline processes. International buyers should prioritize compressors with low noise levels and energy-efficient models to comply with environmental regulations prevalent in Europe and other regions. Understanding the maintenance requirements and sourcing spare parts is also essential to ensure continuous operation.

Agricultural operations often employ hand air compressors for crop spraying and irrigation systems. These compressors facilitate efficient pesticide application and irrigation, leading to improved crop yields. For buyers in regions like Africa, where agriculture is a primary industry, sourcing compressors that can handle varying pressure settings and are portable is critical. Furthermore, understanding the local climate conditions and ensuring the compressor is adaptable to those conditions can enhance performance.

In the painting and finishing sector, hand air compressors are vital for spray painting and surface preparation, providing a fine finish with less labor involved. This application leads to higher-quality results and reduced costs. For B2B buyers in South America and Europe, it is essential to choose compressors that maintain consistent air pressure and are easy to transport to various job sites. Additionally, considering the size and weight of the compressor can affect mobility and efficiency in multi-location projects.

Проблема: Many B2B buyers encounter challenges when using hand air compressors that lack sufficient air pressure for their specific applications, such as inflating large tires or powering pneumatic tools. This limitation can lead to delays in operations, increased labor costs, and potential safety risks when using underpowered equipment. Buyers often feel frustrated when their equipment fails to meet the demands of their projects, particularly in industries like construction, automotive, or manufacturing where efficiency is critical.

Решение: To address this pain point, buyers should carefully evaluate their air pressure requirements before selecting a hand air compressor. Understanding the needs of specific tasks, such as the PSI (pounds per square inch) required for certain pneumatic tools or equipment, is essential. When sourcing, opt for compressors that offer adjustable pressure settings and sufficient CFM (cubic feet per minute) ratings to ensure compatibility with a range of tools. Additionally, investing in a dual-stage compressor can provide the necessary pressure for demanding applications. Regular maintenance, including checking for air leaks and ensuring proper lubrication, will also help maintain optimal performance and prolong the lifespan of the compressor.

Проблема: B2B buyers operating in various environments often struggle with the portability of hand air compressors. For instance, those in the construction industry may need to transport equipment across job sites, while maintenance teams may require compressors that can be easily moved between different locations. The bulkiness and weight of some models can hinder productivity and complicate workflows, resulting in inefficiencies and frustration.

Решение: To overcome portability issues, buyers should prioritize lightweight and compact hand air compressors designed for easy transport. Look for models that feature built-in wheels and ergonomic handles for enhanced mobility. Additionally, consider battery-operated or rechargeable air compressors that eliminate the need for power outlets, allowing for use in remote locations. When specifying equipment, also evaluate the dimensions and weight to ensure it can be transported without excessive effort. Finally, educating teams on best practices for handling and transporting compressors can further enhance operational efficiency.

Проблема: Noise pollution from hand air compressors can be a significant concern for businesses operating in residential areas or enclosed spaces. Excessive noise levels can disrupt workflows, lead to complaints from nearby residents, and even affect employee productivity and morale. Buyers often find themselves in a dilemma where they need a powerful compressor but are also mindful of the noise it generates.

Illustrative image related to hand air compressor

Решение: Buyers should consider investing in quiet or ultra-quiet hand air compressors that are specifically designed to minimize noise output. These models often feature sound-dampening technology and are ideal for applications in urban settings or noise-sensitive environments. When sourcing, look for specifications indicating decibel levels (dB) to ensure compliance with local regulations or company standards. Additionally, implementing sound-absorbing materials in the workspace can help further reduce noise impact. Training staff on optimal usage practices, such as scheduling compressor use during off-peak hours, can also mitigate disturbances while ensuring that productivity remains high.

When selecting a hand air compressor, the choice of materials significantly impacts the performance, durability, and overall cost-effectiveness of the product. Here, we analyze four common materials used in hand air compressors: aluminum, steel, plastic, and cast iron. Each material has unique properties, advantages, and disadvantages that can influence purchasing decisions for international B2B buyers.

Ключевые свойства: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for portable applications. It can withstand moderate temperature and pressure ratings, typically up to 150 psi.

Плюсы и минусы: The primary advantage of aluminum is its lightweight nature, which enhances portability. It is also resistant to rust, reducing maintenance costs. However, aluminum can be more expensive than other materials and may not offer the same level of durability under extreme conditions.

Влияние на применение: Aluminum is compatible with various media, including air and non-corrosive gases. However, it may not be suitable for high-temperature applications due to its lower melting point compared to metals like steel.

Соображения для международных покупателей: Buyers from regions such as Europe and the Middle East should ensure compliance with European Union regulations regarding material safety and environmental impact. Standards like DIN can guide the selection of aluminum grades.

Ключевые свойства: Steel is known for its high strength and durability, withstanding higher temperatures and pressures (up to 200 psi or more) than aluminum.

Плюсы и минусы: Steel’s strength makes it ideal for heavy-duty applications and environments where impact resistance is crucial. However, it is heavier than aluminum, which can affect portability. Additionally, steel is prone to rust if not properly coated or maintained, leading to increased long-term costs.

Illustrative image related to hand air compressor

Влияние на применение: Steel is suitable for high-pressure applications and can handle a wide range of media, including air and some corrosive gases, when appropriately treated.

Соображения для международных покупателей: Buyers should consider the availability of corrosion-resistant coatings and compliance with ASTM standards. In regions like Africa and South America, where humidity may be higher, selecting the right coating is essential for longevity.

Ключевые свойства: Plastic is lightweight and offers excellent resistance to corrosion and chemicals, making it suitable for various environments.

Illustrative image related to hand air compressor

Плюсы и минусы: The primary advantage of plastic is its cost-effectiveness and lightweight nature, which enhances portability. However, plastics generally have lower pressure ratings (typically under 100 psi) and may not withstand high temperatures, limiting their application scope.

Влияние на применение: Plastic is ideal for low-pressure applications and is often used in consumer-grade compressors. It is compatible with air and non-corrosive gases but may not be suitable for industrial-grade applications.

Соображения для международных покупателей: Buyers should look for compliance with international standards for plastics, such as JIS in Japan or DIN in Germany, to ensure quality and safety.

Ключевые свойства: Cast iron is known for its exceptional durability and ability to withstand high pressures and temperatures, often exceeding 200 psi.

Illustrative image related to hand air compressor

Плюсы и минусы: Cast iron compressors are robust and suitable for heavy-duty applications, making them ideal for industrial use. However, they are significantly heavier and more expensive than aluminum or plastic options, which can limit portability.

Влияние на применение: Cast iron is well-suited for high-pressure air applications and can handle various media, including air and some corrosive gases, depending on the treatment.

Соображения для международных покупателей: Buyers should ensure compliance with relevant standards such as ASTM for quality assurance. In regions with high transportation costs, the weight of cast iron may also impact logistics.

| Материал | Typical Use Case for hand air compressor | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Portable air compressors | Легкий и устойчивый к коррозии | Higher cost, limited durability | Средний |

| Сталь | Heavy-duty industrial compressors | Высокая прочность и долговечность | Heavier, prone to rust | Средний |

| Пластик | Consumer-grade compressors | Экономичный и легкий | Low pressure rating, limited use | Низкий |

| Cast Iron | Industrial-grade compressors | Исключительная долговечность | Heavy and expensive | Высокий |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in hand air compressors, helping them make informed decisions that align with their operational needs and regional standards.

The manufacturing of hand air compressors involves several critical stages, each designed to ensure the product meets high standards of quality and performance. Understanding these processes can help B2B buyers make informed decisions when sourcing compressors for their operations.

Illustrative image related to hand air compressor

The first stage in the manufacturing process is material preparation. This involves selecting high-quality raw materials, typically aluminum or steel, which are essential for the durability and performance of the compressor. Suppliers often conduct metallurgical tests to ensure that materials possess the necessary properties, such as tensile strength and corrosion resistance.

Once the materials are sourced, they undergo cutting and shaping processes. Techniques like laser cutting and CNC machining are commonly employed to create precise components. This precision is crucial, as any defects in the parts can lead to inefficiencies or failures in the compressor’s operation.

After material preparation, the forming stage begins. This stage includes processes such as stamping, bending, and welding. For example, the tank of a hand air compressor is usually formed through a combination of stamping for the sheet metal and welding to join parts.

Advanced technologies such as robotic welding are increasingly used to enhance the quality and consistency of the welds. This automation not only improves efficiency but also reduces human error, leading to a more reliable final product.

The assembly process involves bringing together all the components manufactured in previous stages. This includes the compressor motor, tank, pressure switch, and other critical parts. Skilled technicians typically oversee this process to ensure that each component is installed correctly.

During assembly, it’s essential to follow specific torque specifications and installation guidelines to ensure proper functioning and safety. Manufacturers may also implement modular assembly techniques, which allow for easier repairs and replacements of parts in the future.

Finishing processes enhance the aesthetic and functional qualities of hand air compressors. Common techniques include powder coating and anodizing, which provide a protective layer against corrosion and wear. These finishes also contribute to the overall appearance of the compressor, which can be an important factor for B2B buyers concerned with branding.

Additionally, manufacturers often conduct a final inspection to ensure that all aesthetic and functional aspects meet the required standards before the product is packaged and shipped.

Quality assurance is a critical component of the manufacturing process for hand air compressors. International standards such as ISO 9001 outline the requirements for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with EU safety standards) and API (American Petroleum Institute) certifications may also be relevant, depending on the intended application of the compressor. These certifications help ensure that the compressors are safe and reliable for use in various industrial environments.

Quality control (QC) is implemented at multiple checkpoints throughout the manufacturing process to ensure product integrity. These checkpoints typically include:

Входящий контроль качества (IQC): This initial stage inspects raw materials upon arrival to verify their quality and compliance with specifications.

Внутрипроцессный контроль качества (IPQC): Continuous monitoring occurs during manufacturing to identify any deviations from the established processes. This may involve regular checks on dimensions, performance characteristics, and other critical parameters.

Окончательный контроль качества (ОКК): After assembly, the finished products undergo rigorous testing, including performance tests, pressure tests, and safety checks. This stage ensures that every compressor meets the required operational standards before being dispatched.

Various testing methods are employed to assess the performance and reliability of hand air compressors. These may include:

Функциональное тестирование: Verifying that all components operate as intended under normal operating conditions.

Pressure Testing: Ensuring that the compressor can withstand its specified pressure levels without leaks.

Испытания на долговечность: Subjecting the compressor to extended usage conditions to assess its longevity and reliability.

B2B buyers should implement strategies to verify the quality control processes of potential suppliers. Here are some actionable steps:

Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. Buyers should inquire about the frequency and scope of these audits.

Запросите отчеты о качестве: Suppliers should provide documentation detailing their quality control measures, including results from IQC, IPQC, and FQC stages. This transparency can build trust and confidence in the supplier’s capabilities.

Проверки третьих лиц: Engaging independent third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly important for international buyers who may not have direct oversight.

For international B2B buyers, understanding the nuances of quality control is essential. Different regions may have varying regulations and standards, which can impact the compliance of hand air compressors.

Regional Standards: Buyers should familiarize themselves with specific standards applicable in their region, such as ASME (American Society of Mechanical Engineers) for North America or EN (European Norm) standards for Europe.

Культурные различия: Variations in business practices and quality expectations across cultures can affect supplier relationships. Buyers should communicate their quality expectations clearly and ensure that suppliers understand these requirements.

Documentation and Certification: It’s crucial for international buyers to verify that all necessary documentation, including compliance certificates and test reports, are in order before proceeding with orders. This ensures that products meet both local and international standards.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and establish successful partnerships with suppliers of hand air compressors.

This guide serves as a comprehensive checklist for B2B buyers looking to source hand air compressors effectively. With a variety of models and suppliers available globally, it’s essential to approach the procurement process methodically to ensure that you select the right equipment for your operational needs.

Before beginning your search, clarify the specific applications for which you need the hand air compressor. Understanding the pressure requirements, tank size, and portability needs will help narrow down your options. Consider factors such as the types of tools you will be powering and the environments in which the compressor will operate.

Explore the different types of hand air compressors on the market, including oil-free and oil-lubed models. Each type has distinct advantages, such as maintenance needs and noise levels. Pay attention to features such as noise reduction, weight, and power source, which can significantly impact usability in various settings.

Conduct thorough research on potential suppliers to ensure they are reputable and reliable. Request company profiles, case studies, and references from other buyers in similar industries or regions. It’s crucial to assess their capacity to meet your demands, including lead times and after-sales support.

Ensure that your chosen suppliers hold relevant certifications and comply with international standards. Certifications such as ISO or CE can indicate a supplier’s commitment to quality and safety. This step is particularly important in regions where regulatory compliance may vary, ensuring that the equipment meets local market standards.

Reach out to multiple suppliers to obtain quotes for the hand air compressors you’re considering. Analyze the quotes not only for price but also for the terms of service, warranty options, and shipping costs. Comparing these factors will help you make an informed decision based on total cost of ownership.

Once you have selected a preferred supplier, initiate negotiations on price, payment terms, and delivery schedules. A well-negotiated contract can lead to cost savings and better service levels. Be clear about your expectations and discuss any potential for bulk purchase discounts or long-term agreements.

Illustrative image related to hand air compressor

Finally, consider the logistics of installation and ongoing maintenance for your hand air compressors. Determine if the supplier offers installation services or if you will need to arrange this independently. Additionally, inquire about maintenance plans or training to ensure that your team can operate the equipment efficiently and safely.

By following this structured approach, B2B buyers can streamline the procurement process for hand air compressors, ensuring they select equipment that meets their operational needs while fostering strong supplier relationships.

When sourcing hand air compressors, understanding the cost structure is crucial. The primary cost components include:

Материалы: The quality of materials significantly impacts the cost. Compressors made from high-grade aluminum or steel may have higher upfront costs but provide longer durability and better performance.

Труд: Labor costs vary by region. For instance, manufacturers in regions with lower labor costs can offer competitive pricing, but it’s essential to consider the potential trade-offs in quality and reliability.

Производственные накладные расходы: This includes costs associated with facilities, utilities, and equipment. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

Инструментальная оснастка: Custom tooling for specific designs can add to the initial costs. If you require specialized features, factor in these costs during negotiations.

Контроль качества (QC): Implementing stringent QC measures ensures product reliability, but it can increase costs. Suppliers who prioritize QC may charge more, reflecting the value of reducing defects and returns.

Логистика: Shipping costs can vary widely based on distance, shipping method, and volume. International buyers should also consider import duties and taxes, which can significantly impact the total cost.

Маржа: Supplier margins can vary based on market competition and demand. Understanding the typical margins within the industry can help in evaluating pricing.

Several factors influence the pricing of hand air compressors, particularly in international markets:

Объем/MOQ (минимальное количество заказа): Larger orders often attract discounts. Buyers should assess their needs to determine the optimal order size for cost efficiency.

Технические характеристики и персонализация: Custom features or specifications can lead to higher costs. Clearly defining requirements upfront can minimize unexpected expenses.

Качество материалов и сертификаты: Products with certifications (e.g., ISO, CE) may come at a premium but often provide assurance of quality and compliance with international standards.

Факторы поставщика: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more, but they often offer better customer service and support.

Инкотермс: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final price and responsibility for shipping costs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

Illustrative image related to hand air compressor

Переговоры: Engage suppliers in negotiations. Highlight potential long-term partnerships or repeat orders to leverage better pricing.

Общая стоимость владения (TCO): Beyond initial purchase prices, consider TCO, which includes maintenance, energy consumption, and potential downtime costs. Selecting higher-quality compressors may yield long-term savings despite higher upfront costs.

Нюансы ценообразования: Be aware of currency fluctuations and economic conditions in the supplier’s region, as these can affect pricing. Additionally, factor in payment terms that could influence cash flow.

Исследование рынка: Conduct thorough market research to understand prevailing prices. This knowledge will empower you during negotiations and help identify fair pricing.

Supplier Diversity: Explore multiple suppliers to compare offers. A diverse supplier base can lead to competitive pricing and reduce risks associated with dependency on a single source.

While sourcing hand air compressors, a comprehensive understanding of the cost components and pricing influencers is essential for making informed purchasing decisions. By applying the tips provided, buyers can enhance their procurement strategies and achieve cost-effective solutions tailored to their specific needs. Always remember that prices can vary widely based on numerous factors, and it’s prudent to gather multiple quotes before making a final decision.

In the realm of pneumatic tools, hand air compressors are a popular choice for various applications, particularly in industries requiring portable and efficient air supply. However, several alternative solutions exist that can meet similar needs, each with its unique strengths and weaknesses. This analysis will compare hand air compressors with two viable alternatives: electric air compressors and gas-powered air compressors, helping B2B buyers make informed decisions based on their specific requirements.

| Сравнительный аспект | Hand Air Compressor | Electric Air Compressor | Gas-Powered Air Compressor |

|---|---|---|---|

| Производительность | Moderate; suitable for light tasks | High; consistent power for various applications | Very high; ideal for heavy-duty tasks |

| Стоимость | Low initial investment; affordable | Moderate; varies by capacity and features | High initial cost; fuel costs included |

| Простота реализации | Simple; requires no setup | Easy; plug-and-play design | Moderate; requires fuel and maintenance |

| Техническое обслуживание | Low; minimal upkeep needed | Moderate; occasional servicing required | High; regular maintenance for engine and fuel system |

| Лучший пример использования | Small jobs, DIY projects | Workshops, automotive repairs | Construction sites, industrial applications |

Electric air compressors are widely used in both commercial and industrial settings due to their powerful performance and reliability. They excel in environments where electrical outlets are readily available, making them suitable for workshops and garages. The advantages include a quieter operation and lower emissions compared to gas-powered models. However, they can be limited by the need for electrical access and may not be as portable as hand air compressors, particularly in remote locations without power supply.

Gas-powered air compressors are designed for heavy-duty applications, making them ideal for construction sites and outdoor jobs where electricity may not be available. They offer superior performance and can handle demanding tasks efficiently. The major advantages include their portability and high power output, allowing for extended use without the need for electrical connections. On the downside, they come with higher operational costs due to fuel consumption and require regular maintenance to ensure optimal performance.

When selecting the right air compressor solution, B2B buyers should carefully assess their specific needs, including the scale of operations, available power sources, and budget constraints. For light, occasional tasks, a hand air compressor may suffice. Conversely, for more demanding applications that require consistent performance and power, electric or gas-powered compressors may be more appropriate. Additionally, considering maintenance requirements and long-term operational costs can help buyers make a well-informed decision that aligns with their operational goals.

In conclusion, understanding the strengths and limitations of hand air compressors in comparison to electric and gas-powered alternatives allows B2B buyers to choose the most suitable solution for their applications. By evaluating performance, cost, ease of implementation, and maintenance needs, buyers can ensure that they invest in equipment that enhances productivity and meets their specific operational demands.

When sourcing hand air compressors for industrial or commercial applications, understanding their technical specifications is vital. Here are some essential properties that B2B buyers should consider:

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. A higher PSI is crucial for applications requiring intense air pressure, such as powering pneumatic tools or inflating large tires. Selecting a compressor with the appropriate PSI ensures efficiency and effectiveness in operations.

CFM measures the volume of air the compressor can deliver per minute. This specification is significant for determining whether the compressor can meet the air demand of specific tools or machinery. A compressor with a higher CFM rating is essential for running multiple tools simultaneously or for tools that require a steady air supply.

The tank capacity indicates how much air the compressor can store. A larger tank allows for longer usage times without needing to restart the compressor, making it suitable for heavy-duty tasks. For B2B buyers, understanding the tank capacity helps in selecting a model that aligns with their operational demands and minimizes downtime.

Illustrative image related to hand air compressor

The power source of the compressor, typically indicated in horsepower (HP) and voltage, affects its performance and suitability for various applications. Hand air compressors can be powered by electricity or gasoline, each serving different operational environments. Electric models are generally quieter and more efficient for indoor use, while gasoline-powered compressors are preferable for outdoor jobs where electricity is not accessible.

Weight is a critical consideration for hand air compressors, especially for mobile applications. Lighter models are easier to transport and maneuver, which is advantageous in construction sites or service jobs where equipment needs to be moved frequently. Buyers should assess their specific transport needs when selecting a compressor.

The materials used in the construction of the compressor, including the tank and components, determine its longevity and reliability. Steel tanks are more durable and less prone to rust compared to aluminum. Understanding material quality is essential for B2B buyers to ensure they invest in a compressor that will withstand rigorous use.

Navigating the B2B landscape involves understanding industry-specific terminology. Here are several key terms relevant to hand air compressors:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the air compressor industry, an OEM provides compressors or components used in the assembly of other branded products. Buyers often prefer OEM parts for their quality and compatibility.

MOQ is the minimum number of units a supplier requires buyers to purchase. Understanding MOQ is crucial for B2B buyers to manage inventory levels and ensure they are not overcommitting resources. It can also impact pricing strategies, as larger orders often qualify for discounts.

An RFQ is a formal document soliciting price quotes from suppliers. This process is essential for B2B buyers to compare costs, terms, and specifications of different suppliers before making purchasing decisions. Clear RFQs can help ensure that all necessary details are covered.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and responsibilities associated with the delivery of hand air compressors.

The warranty period refers to the time frame during which the manufacturer guarantees the performance of the compressor. Understanding warranty terms is essential for buyers to assess the risk associated with their purchase and to ensure they receive support in case of defects.

Lead time is the time taken from placing an order to receiving the goods. For B2B buyers, knowing the lead time is critical for planning and inventory management, particularly in industries where equipment is needed urgently.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing hand air compressors, ultimately enhancing their operational efficiency and effectiveness.

The global hand air compressor market is witnessing significant growth, driven by several key factors. The rise of the construction and automotive sectors, particularly in emerging economies across Africa, South America, and the Middle East, has led to increased demand for portable and versatile air compressors. Technological advancements are reshaping the landscape, with innovations such as oil-free compressors and lightweight models enhancing efficiency and user convenience. Moreover, the trend towards automation and IoT integration is gaining momentum, allowing users to monitor performance and optimize usage remotely.

International B2B buyers are increasingly focused on sourcing products that combine quality with cost-effectiveness. This trend is particularly evident in regions like Germany and Vietnam, where the emphasis is on high-performance equipment that meets stringent safety and environmental standards. Additionally, the supply chain dynamics are evolving, with a shift towards localized sourcing to reduce lead times and improve service levels. Buyers are also keen to establish long-term partnerships with manufacturers who can provide comprehensive support, including maintenance and after-sales services.

Illustrative image related to hand air compressor

Sustainability is becoming a crucial consideration for B2B buyers in the hand air compressor sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting companies to adopt greener practices. This includes the use of eco-friendly materials and technologies that reduce energy consumption and emissions during operation.

Buyers are increasingly seeking suppliers who can demonstrate commitment to ethical sourcing and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and ENERGY STAR can serve as indicators of a manufacturer’s dedication to sustainability. Additionally, utilizing recyclable components and ensuring that products have a lower carbon footprint are becoming important selling points.

In regions like Europe, where regulatory frameworks are stringent, sourcing partners who prioritize sustainability can offer a competitive advantage. The emphasis on ethical supply chains not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products.

The hand air compressor market has evolved significantly over the past few decades. Initially dominated by large, stationary models, the sector has shifted towards more portable and user-friendly designs. This evolution has been driven by the increasing need for flexibility in various industries, including construction, automotive, and DIY applications.

As technology advanced, manufacturers began to focus on creating compressors that are not only efficient but also quieter and more environmentally friendly. The introduction of oil-free models has catered to consumers seeking maintenance-free options, while advancements in materials have allowed for lighter designs without compromising durability.

Today, the hand air compressor market reflects a blend of innovation, sustainability, and user-centric design, making it a vital component for businesses looking to enhance operational efficiency while meeting modern environmental standards. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and sustainability commitments.

How do I choose the right hand air compressor for my business needs?

Selecting the right hand air compressor involves evaluating your specific requirements, such as the types of tools you’ll be using, the frequency of use, and the pressure and volume needed. Consider whether you need an oil-free model for lower maintenance or an oil-lubricated one for durability. Additionally, assess the portability if you plan to use it in multiple locations. Consulting with suppliers about the specifications of various models can help in making an informed decision.

What is the best hand air compressor for small-scale operations?

For small-scale operations, a compact and portable hand air compressor with a lower horsepower rating (1-2 HP) is typically sufficient. Models with an oil-free design are often preferred for their low maintenance and quieter operation. Look for compressors with a tank capacity of 1-6 gallons, which can provide adequate pressure for tasks like inflating tires, powering small pneumatic tools, or running airbrushes. Brands with a solid reputation for reliability and customer support should also be prioritized.

What are the key factors to consider when sourcing hand air compressors internationally?

When sourcing hand air compressors internationally, consider factors such as compliance with local regulations, product certifications, and warranties. It’s crucial to evaluate the reputation of suppliers, checking for reviews and testimonials from previous customers. Additionally, understand the logistics of shipping, including customs duties and tariffs, to avoid unexpected costs. Establishing clear communication regarding specifications and delivery timelines is vital for a smooth transaction.

What is the typical minimum order quantity (MOQ) for hand air compressors?

Minimum order quantities (MOQs) for hand air compressors can vary significantly depending on the manufacturer and the region. Typically, MOQs may range from 10 to 50 units for bulk orders, while some manufacturers may allow smaller orders for specific models. It’s advisable to negotiate MOQs with suppliers based on your initial needs and potential for future orders. Establishing a good relationship with the supplier can often lead to more flexible terms.

What payment terms should I expect when purchasing hand air compressors?

Payment terms for purchasing hand air compressors can vary widely among suppliers. Common practices include upfront payment, partial payment before shipment, or payment upon delivery. Some suppliers may offer financing options, especially for larger orders. Always clarify the payment terms during negotiations to ensure transparency. It’s also wise to use secure payment methods that provide buyer protection to mitigate risks associated with international transactions.

How can I ensure the quality of hand air compressors before making a bulk purchase?

To ensure quality, request product samples before committing to a bulk purchase. Ask for certifications that demonstrate compliance with international quality standards, such as ISO or CE marks. Additionally, consider conducting factory visits or audits, if feasible, to assess manufacturing processes. Engaging third-party inspection services can also provide an objective evaluation of the products before they are shipped.

What logistics considerations should I keep in mind when importing hand air compressors?

When importing hand air compressors, consider the logistics of shipping, including freight costs, lead times, and the best shipping method (air vs. sea). It’s essential to understand customs procedures in your country, including documentation requirements and potential tariffs. Collaborating with a reliable freight forwarder can streamline the process and help navigate any challenges that arise during shipping. Always factor in delivery times to meet your operational needs.

How can I customize a hand air compressor to meet my specific business requirements?

Customization options for hand air compressors can include modifications in tank size, pressure settings, and additional features like noise reduction or portability enhancements. Discuss your specific needs with the supplier, as many manufacturers offer tailored solutions for bulk orders. Be clear about your requirements, including design specifications and any additional accessories needed. Remember to evaluate the implications of customization on pricing and lead times.

Could not verify enough suppliers for hand air compressor to create a list at this time.

In the evolving landscape of portable air compressor sourcing, international B2B buyers must prioritize strategic sourcing to maximize value and efficiency. Key insights highlight the importance of understanding product specifications, such as oil-free versus oil-lubricated options, and the varying capacities suited for different applications. By analyzing supplier reliability and regional availability, businesses can ensure timely access to quality products while reducing costs.

Moreover, establishing strong relationships with manufacturers can lead to better pricing, customized solutions, and improved after-sales support. This is particularly vital for buyers from Africa, South America, the Middle East, and Europe, where market dynamics may differ significantly.

Illustrative image related to hand air compressor

As we look ahead, the demand for innovative and efficient air compressors will continue to rise. Buyers should be proactive in exploring new technologies and sustainable practices that can enhance operational efficiency. Engaging with suppliers who prioritize eco-friendly solutions can not only reduce environmental impact but also align with global sustainability goals.

In conclusion, we encourage international buyers to leverage strategic sourcing practices, stay informed about market trends, and foster partnerships that will position their businesses for success in the competitive air compressor market.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.