In today’s competitive landscape, sourcing reliable air tire machines can be a daunting task for international B2B buyers. With diverse market offerings and varying supplier capabilities, companies must navigate a complex web of options to find machines that meet their operational needs while ensuring cost-effectiveness. This guide delves into the multifaceted world of air tire machines, providing insights into different types, their applications across various industries, and essential criteria for vetting suppliers.

By exploring the latest innovations in air tire technology, such as electric and portable inflators, as well as commercial-grade air machines suitable for gas stations and car washes, buyers can better understand the landscape of available solutions. Furthermore, we will address critical factors such as pricing structures, warranty considerations, and maintenance requirements, empowering buyers to make informed purchasing decisions.

This comprehensive resource is specifically designed for international B2B buyers from regions like Africa, South America, the Middle East, and Europe—countries such as Nigeria and Brazil—where the demand for efficient and durable air tire machines is on the rise. By equipping you with actionable insights and expert recommendations, this guide aims to simplify your procurement process, ensuring that you select the right air tire machine for your business needs while enhancing customer satisfaction and operational efficiency.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Commercial Air Machines | Built for high usage; often includes payment systems | Gas stations, car washes, convenience stores | Плюсы: Durable, revenue-generating, attracts customers. Конс: Higher upfront costs, maintenance required. |

| Portable Tire Inflators | Battery-operated or plug-in; lightweight and easy to transport | Automotive repair shops, roadside assistance | Плюсы: Versatile, easy to use in various locations. Конс: Limited power for heavy-duty tasks. |

| Electric Tire Pumps | Plug into wall or vehicle outlet; high PSI ratings | Automotive workshops, tire retail shops | Плюсы: Быстрое накачивание, подходит для больших шин. Конс: Requires power source, less portable. |

| Hand and Foot Pumps | Manual operation; compact and economical | Bicycle shops, sports retailers | Плюсы: Affordable, no power needed, portable. Конс: Labor-intensive, slower inflation rates. |

| Vac & Air Combo Machines | Combines vacuum and air inflation features | Car washes, service stations | Плюсы: Multifunctional, enhances customer experience. Конс: More complex, higher maintenance. |

Commercial air machines are designed for high-frequency use, typically found in gas stations and car washes. These machines often come equipped with payment systems, allowing businesses to monetize the service. Buyers should consider the durability and reliability of the machine, as these factors contribute to customer satisfaction and retention. While the initial investment may be higher, the potential for revenue generation and customer attraction can justify the cost.

Portable tire inflators are ideal for businesses requiring flexibility and mobility, such as automotive repair shops and roadside assistance services. These devices are lightweight and can be powered by batteries or vehicle outlets, making them suitable for various scenarios. When purchasing, consider the inflator’s power and PSI rating to ensure it meets the demands of your applications. Their ease of use and versatility are significant advantages, although they may lack the power for heavy-duty tasks.

Illustrative image related to air tire machine

Electric tire pumps provide a quick and efficient solution for inflating tires, making them a popular choice in automotive workshops and tire retail shops. These pumps can achieve high PSI ratings, suitable for a range of tire sizes. When selecting an electric tire pump, buyers should evaluate the power source requirements and ensure they have adequate electrical infrastructure. Their speed and efficiency can significantly enhance service times, making them a valuable investment for businesses focused on productivity.

Hand and foot pumps are manual inflation devices that are compact and cost-effective, making them suitable for smaller operations like bicycle shops or sports retailers. These pumps do not require power and are easy to transport, allowing for quick inflation of smaller items. However, buyers should be aware that these pumps can be labor-intensive and may not be suitable for larger tires. Their affordability and simplicity make them an attractive option for businesses with lower inflation needs.

Vac & air combo machines combine vacuum and air inflation features, providing a multifunctional service that enhances customer satisfaction. Commonly found in car washes and service stations, these machines can attract customers looking for convenience. When considering a purchase, businesses should assess the machine’s complexity and maintenance needs, as these factors can impact operational efficiency. The added value of offering multiple services in one machine can lead to increased customer loyalty and higher sales.

| Промышленность/сектор | Specific Application of air tire machine | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Repair Shops | Tire inflation services for vehicles | Enhances customer satisfaction through quick service | Durability, ease of use, and compatibility with various tire types |

| Gas Stations | Providing air for tire inflation | Attracts customers and encourages additional purchases | Payment system options, reliability, and maintenance support |

| Логистика и транспорт | Maintaining fleet tire pressure | Reduces downtime and enhances safety on the road | Capacity for high volume use, portability, and power source |

| Car Wash Facilities | Air machines for customer convenience | Increases service offerings and customer retention | Space requirements, machine reliability, and service options |

| Construction and Heavy Equipment | Tire inflation for construction vehicles | Ensures operational efficiency and reduces tire wear | Heavy-duty specifications, mobility, and serviceability |

In automotive repair shops, air tire machines are essential for providing tire inflation services. They allow mechanics to quickly and accurately inflate tires, ensuring optimal pressure for vehicle safety and performance. This not only enhances customer satisfaction by reducing wait times but also helps in maintaining a high turnover of service. Buyers in this sector should consider machines that are durable and easy to use, as well as those that can accommodate various tire sizes and types, which is particularly important for international buyers in diverse markets such as Nigeria and Brazil.

Illustrative image related to air tire machine

Gas stations utilize air tire machines to provide tire inflation services, which can significantly attract customers. Offering free air can enhance the customer experience and encourage them to purchase fuel or other services. For businesses looking to source these machines, key considerations include the payment systems available (coin, bill, or credit card acceptance) and the reliability of the machine, as consistent performance is critical to maintaining customer trust. In regions like the Middle East and Africa, where vehicle maintenance may be less frequent, having a dependable air machine can set a gas station apart from competitors.

Logistics and transport companies rely heavily on maintaining proper tire pressure across their fleets to ensure safety and reduce the risk of breakdowns. Air tire machines enable quick inflation and pressure checks, which can minimize downtime and enhance road safety. For international buyers in South America or Europe, sourcing machines that can handle high-volume use and offer portability is essential, as these companies often operate across vast distances and varied terrains.

In car wash facilities, air tire machines serve as a convenient service for customers who may need to inflate their tires after a wash. This added value can increase customer retention and satisfaction, as it provides a one-stop solution for vehicle maintenance. When sourcing these machines, businesses should consider the available space, machine reliability, and whether they can offer additional services, such as tire pressure monitoring. This is particularly relevant in European markets where customer experience is a significant driver of business.

Construction and heavy equipment often require proper tire inflation to ensure operational efficiency and reduce wear on tires. Air tire machines facilitate quick inflation, which is crucial on job sites where time is money. Buyers in this sector should look for machines with heavy-duty specifications and those that are easily transportable to various job sites. Additionally, having a reliable service and maintenance plan is crucial, especially in regions where equipment downtime can lead to significant project delays.

Illustrative image related to air tire machine

Проблема: Many businesses operating in remote areas, such as mining sites or rural automotive service stations, face significant challenges when it comes to maintaining a reliable air supply for tire inflation. These locations often lack consistent electricity, making it difficult to operate standard air tire machines. As a result, workers may spend valuable time and resources trying to inflate tires manually or using low-capacity inflators, leading to decreased productivity and operational inefficiencies.

Решение: To address this issue, B2B buyers should consider investing in portable, battery-operated air tire machines that can operate independently of a power source. Look for models with high PSI ratings that are specifically designed for heavy-duty use, as these can handle larger tires common in off-road vehicles and machinery. Additionally, integrating solar-powered air compressors can provide a sustainable solution in areas with unreliable electricity. When sourcing these machines, prioritize suppliers that offer robust customer support and warranties to ensure long-term reliability and assistance in case of issues.

Проблема: Frequent breakdowns of air tire machines can lead to high maintenance costs and significant downtime, which is particularly detrimental for businesses that rely on quick tire service. This issue is often exacerbated by the use of low-quality machines that cannot withstand the rigors of daily use, resulting in frustrated customers and lost revenue opportunities.

Illustrative image related to air tire machine

Решение: To minimize maintenance costs, businesses should invest in commercial-grade air tire machines that are specifically designed for heavy-duty applications. Look for features such as stainless steel construction and corrosion-resistant components to ensure durability. Additionally, establishing a regular maintenance schedule with a trusted technician can help identify potential issues before they lead to breakdowns. When purchasing, consider machines that come with comprehensive service packages or warranties that cover parts and labor, thus reducing long-term operational costs.

Проблема: Automotive service providers often face challenges when catering to a wide range of vehicles, from passenger cars to trucks and agricultural equipment. Standard air tire machines may not have the versatility to accommodate varying tire sizes and pressure requirements, leading to customer dissatisfaction and loss of business to competitors with more adaptable solutions.

Решение: B2B buyers should opt for multi-functional air tire machines that come equipped with adjustable pressure settings and a variety of nozzle attachments. This flexibility allows service providers to efficiently inflate different tire types without needing multiple machines. Additionally, consider machines with digital pressure gauges for precise inflation, which can enhance service quality. When selecting these machines, check for customer reviews and case studies that demonstrate their effectiveness across various applications, ensuring you choose a solution that meets the diverse needs of your clientele.

Illustrative image related to air tire machine

When selecting materials for air tire machines, several options stand out due to their unique properties and suitability for various applications. Understanding these materials helps B2B buyers make informed decisions that align with their operational needs and market demands.

Steel is a primary choice for the structural components of air tire machines due to its excellent strength and durability. It typically has a high tensile strength, allowing it to withstand the pressures generated during tire inflation. Additionally, steel can be treated for corrosion resistance, enhancing its lifespan in various environments.

Плюсы: Steel is highly durable and can handle high-pressure applications, making it suitable for commercial use. It is also relatively cost-effective compared to other metals, which is beneficial for manufacturers looking to minimize production costs.

Illustrative image related to air tire machine

Конс: The main drawback of steel is its susceptibility to corrosion if not properly treated, especially in humid or saline environments. This can lead to increased maintenance costs over time.

Влияние на применение: Steel’s compatibility with high-pressure air systems makes it ideal for heavy-duty tire inflation tasks. However, buyers in regions with high humidity or corrosive conditions, such as coastal areas in Brazil or Nigeria, should consider additional protective coatings.

Aluminum is increasingly popular for air tire machines due to its lightweight nature and inherent corrosion resistance. It is often used in components such as housing and brackets, where weight savings can improve the machine’s portability.

Плюсы: The lightweight characteristic of aluminum allows for easier transport and installation. Its resistance to corrosion makes it suitable for outdoor applications, reducing maintenance needs.

Конс: Aluminum is generally less durable than steel and may not withstand the same high-pressure conditions. This can limit its use in heavy-duty applications.

Illustrative image related to air tire machine

Влияние на применение: Aluminum’s properties make it suitable for portable air tire machines, particularly in regions where mobility is essential, such as remote areas in South America. However, buyers should assess whether the lower pressure rating meets their specific operational requirements.

Plastic is often utilized for non-structural components, such as control panels and hoses, in air tire machines. Its versatility and ease of molding allow for intricate designs that can enhance user experience.

Плюсы: Plastic is lightweight and resistant to corrosion, making it an excellent choice for components exposed to the elements. It can also be produced at a lower cost compared to metals.

Конс: The primary limitation of plastic is its lower strength and pressure tolerance, which may not be suitable for high-demand applications.

Влияние на применение: Plastic components can improve the user interface of air tire machines, particularly in consumer-facing environments. However, buyers should ensure that the plastic used meets relevant safety and performance standards.

Stainless steel is favored for its combination of strength, durability, and corrosion resistance. It is often used in high-wear areas of air tire machines, such as hoses and fittings.

Плюсы: The corrosion resistance of stainless steel makes it ideal for long-term use in various environments. Its strength allows it to withstand high pressures, making it suitable for commercial applications.

Конс: Stainless steel is typically more expensive than other materials, which can increase the overall cost of the machine. Additionally, it can be more challenging to manufacture due to its hardness.

Illustrative image related to air tire machine

Влияние на применение: Stainless steel is particularly beneficial for air tire machines used in harsh environments, such as those found in the Middle East, where sand and dust can accelerate wear. Buyers should consider the long-term cost-benefit of investing in stainless steel components.

| Материал | Typical Use Case for air tire machine | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Structural components | Высокая прочность и долговечность | Susceptible to corrosion | Средний |

| Алюминий | Housing and brackets | Легкий и устойчивый к коррозии | Lower pressure tolerance | Средний |

| Пластик | Control panels and hoses | Low cost and easy to mold | Lower strength and pressure tolerance | Низкий |

| Нержавеющая сталь | High-wear areas like hoses and fittings | Excellent corrosion resistance and strength | Более высокая стоимость и сложность производства | Высокий |

Understanding these materials and their properties allows B2B buyers to choose the right air tire machine that meets their operational needs while considering local environmental factors and compliance standards.

The manufacturing process for air tire machines is a multi-stage operation that emphasizes precision and efficiency. Understanding this process is crucial for B2B buyers who aim to procure high-quality products that meet international standards.

The first step in the manufacturing process involves the careful selection and preparation of materials. Common materials used include steel for the frame, rubber for hoses, and various electronic components for the digital displays and controls. Materials must be sourced from reputable suppliers to ensure durability and performance. Before moving to the next stage, materials undergo quality checks to confirm they meet the required specifications.

Once materials are prepared, they undergo forming and fabrication. This stage often employs techniques such as:

The use of CNC (Computer Numerical Control) machinery during this stage enhances precision, allowing for intricate designs that can improve functionality.

After fabrication, the assembly process begins. This stage involves the integration of various components, including:

Quality control checkpoints are established throughout the assembly process to ensure that each component is correctly installed and functions as intended.

The final stage of manufacturing includes finishing processes such as painting, coating, and testing. A durable powder coating is often applied to protect against corrosion and wear, especially for machines intended for outdoor use. Finally, the machines are subjected to rigorous testing to verify that they meet performance standards before packaging and shipping.

Illustrative image related to air tire machine

Quality assurance (QA) is a critical aspect of the manufacturing process for air tire machines. B2B buyers must be familiar with international standards and industry-specific regulations to ensure they are sourcing reliable products.

ISO 9001: This widely recognized quality management standard focuses on meeting customer expectations and delivering satisfaction. Manufacturers adhering to ISO 9001 demonstrate a commitment to continuous improvement and operational excellence.

CE Marking: For companies targeting the European market, CE marking is essential. It signifies that the product meets EU safety, health, and environmental protection standards.

API Standards: The American Petroleum Institute (API) sets standards for equipment used in the oil and gas industry. If air tire machines are used in such sectors, compliance with API standards is crucial.

UL Certification: Underwriters Laboratories (UL) certification ensures that electrical components meet safety standards. This is particularly important for machines with electric compressors and control systems.

Quality control is integral to ensuring that air tire machines perform reliably and safely. The following checkpoints are commonly implemented:

At this initial stage, incoming materials are inspected for quality and compliance with specifications. This includes checking the physical and chemical properties of metals, the reliability of electronic components, and the integrity of rubber hoses.

During the manufacturing and assembly stages, IPQC ensures that processes are followed correctly. This may involve:

Before packaging, a comprehensive final inspection is conducted. This includes performance testing under simulated conditions to ensure that the air tire machines meet operational standards. Any machines that do not pass this final check are either repaired or discarded.

Illustrative image related to air tire machine

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are actionable strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include on-site visits to observe operations, review documentation, and interview staff.

Requesting detailed quality reports can help buyers understand the frequency and types of quality checks performed. This documentation should include information about defect rates, corrective actions taken, and compliance with international standards.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be scheduled at various stages of production to ensure adherence to quality standards.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of unique quality control nuances:

Illustrative image related to air tire machine

Соответствие нормативным требованиям: Different regions may have varying regulations regarding product safety and performance. Buyers should ensure that their suppliers are familiar with and compliant with local laws and standards.

Cultural Differences in Quality Expectations: Quality perceptions can vary across cultures. It’s essential for buyers to communicate their expectations clearly and establish quality benchmarks that align with both parties.

Logistical Challenges: Ensuring quality during transportation and handling can pose challenges, particularly for international shipments. Buyers should work with suppliers who understand and mitigate these risks.

Understanding the manufacturing processes and quality assurance protocols for air tire machines is vital for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they procure reliable and high-quality products tailored to their specific market needs. Engaging with suppliers who adhere to international standards and implementing rigorous quality verification processes will ultimately lead to better business outcomes and customer satisfaction.

In the competitive landscape of tire service and maintenance, sourcing the right air tire machine is crucial for enhancing customer satisfaction and operational efficiency. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the type of air tire machine (e.g., portable vs. stationary), pressure range (typically between 30 to 150 PSI), and power source (electric or gas-powered). This clarity helps you identify machines that best fit your operational needs and customer expectations.

Illustrative image related to air tire machine

Conduct thorough research to identify potential suppliers who specialize in air tire machines. Utilize online marketplaces, industry directories, and trade shows to compile a list of reputable manufacturers and distributors. Understanding the market landscape helps you narrow down your choices effectively.

Before making a commitment, it is essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Don’t rely solely on their marketing materials; seek insights into their customer service and product reliability.

Ensure that the air tire machines comply with local regulations and industry standards. This step is vital to avoid legal issues and guarantee safety for both employees and customers.

Obtain detailed quotations from shortlisted suppliers and compare not only the prices but also the payment terms. Understanding the total cost of ownership, including shipping, installation, and maintenance, is essential for budgeting.

Once you have gathered all necessary information and evaluated your options, it’s time to make an informed purchase decision. Ensure that all aspects, including price, quality, and supplier reliability, align with your initial requirements.

By following these steps, you can streamline your procurement process for air tire machines, ensuring that you make a well-informed decision that enhances your business operations and customer satisfaction.

When sourcing air tire machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Материалы: The quality and type of materials used in manufacturing air tire machines significantly influence costs. Higher-grade materials, such as stainless steel for durability, may incur higher initial costs but can lead to lower maintenance expenses over time.

Труд: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but buyers should also consider the skill level and experience of the workforce, which can affect product quality.

Производственные накладные расходы: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep overhead costs low.

Инструментальная оснастка: Initial setup costs for specialized tools and molds can be substantial, especially for customized machines. Buyers should assess whether they require bespoke designs that necessitate higher tooling investments.

Контроль качества (QC): Implementing rigorous QC processes ensures product reliability and safety. While this can add to costs, it can prevent costly recalls or failures that could affect business reputation.

Логистика: Transportation costs can significantly impact the total price, especially for international shipping. Factors such as distance, shipping method, and local tariffs must be carefully considered.

Маржа: Suppliers typically add a margin to cover their costs and profit. Understanding the market pricing can help buyers negotiate effectively.

Several factors influence the pricing of air tire machines, and understanding these can provide a competitive edge:

Объем и минимальное количество заказа (MOQ): Purchasing in bulk often leads to significant discounts. Suppliers may offer tiered pricing structures based on order volume, so negotiating for larger quantities can lower the per-unit cost.

Технические характеристики и персонализация: Custom features or specifications can increase costs. Buyers should evaluate whether these enhancements are necessary or if standard models would suffice.

Сертификация материалов и качества: Machines with certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and compliance with international standards. Buyers should weigh the benefits of these certifications against their budget.

Факторы поставщика: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their brand value, while emerging manufacturers may offer lower prices to gain market share.

Инкотермс: The terms of shipping (such as FOB, CIF) can influence the total cost. Buyers should clarify who is responsible for shipping costs, insurance, and tariffs, as these can significantly impact the final price.

Effective negotiation can lead to better pricing and terms. Here are some tips:

Research Market Prices: Before negotiations, research current market prices for similar machines. This knowledge can empower buyers to negotiate from a position of strength.

Ориентируйтесь на общую стоимость владения (TCO): Consider not just the upfront price but also the long-term costs associated with maintenance, efficiency, and potential downtime. A higher-quality machine may offer savings in TCO.

Be Transparent About Your Needs: Clearly communicate your requirements and budget constraints to suppliers. This openness can foster goodwill and lead to better offers.

Изучите нескольких поставщиков: Obtaining quotes from various suppliers can provide leverage in negotiations. It also allows buyers to compare different offerings and select the best fit.

Understand Pricing Nuances in Different Regions: For buyers in Africa, South America, the Middle East, and Europe, local economic conditions, currency fluctuations, and trade tariffs can impact pricing. Being aware of these factors can enhance negotiation effectiveness.

The sourcing of air tire machines involves a complex interplay of costs and pricing factors. By understanding the components that influence pricing and employing strategic negotiation techniques, international B2B buyers can secure favorable deals that align with their operational needs and budget constraints. Always remember that prices can vary widely based on market conditions, and it is essential to stay informed and adaptable in this dynamic landscape.

Illustrative image related to air tire machine

When evaluating tire inflation solutions, businesses must consider various alternatives to the traditional air tire machine. Each option offers unique benefits and drawbacks, influencing the decision-making process for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will compare the air tire machine against two viable alternatives: portable electric inflators and hand-operated pumps.

| Сравнительный аспект | Air Tire Machine | Portable Electric Inflator | Hand-Operated Pump |

|---|---|---|---|

| Производительность | High efficiency; suitable for heavy use. | Moderate efficiency; ideal for occasional use. | Low efficiency; suitable for light tasks. |

| Стоимость | Higher initial investment; ongoing maintenance costs. | Moderate cost; low maintenance. | Low initial cost; minimal maintenance. |

| Простота реализации | Requires installation; can be complex. | Easy to use; plug-and-play functionality. | Simple to operate; no installation needed. |

| Техническое обслуживание | Regular maintenance required; durable. | Low maintenance; replaceable parts. | Minimal maintenance; long lifespan. |

| Лучший пример использования | Commercial settings (gas stations, car washes). | Personal use, roadside assistance, light commercial. | Recreational use, emergencies, or low-volume tasks. |

Portable electric inflators are a popular alternative to air tire machines, particularly for individual consumers and small businesses. These devices are typically compact, easy to transport, and powered by a vehicle’s 12V outlet or a wall socket. The main advantage is their accessibility and convenience, making them ideal for on-the-go situations, such as roadside emergencies or personal vehicle maintenance. However, their performance may be less robust compared to air tire machines, making them unsuitable for high-frequency commercial applications where rapid inflation is necessary. Furthermore, while they are generally lower in cost, they may not withstand heavy usage over time.

Hand-operated pumps are the most basic inflation solution and are often favored for their simplicity and low cost. These pumps are lightweight and portable, making them an excellent choice for recreational activities like biking or camping. They require no power source, which adds to their versatility. However, their performance is limited, as they typically require more physical effort and time to inflate tires, making them impractical for commercial use. They also lack the efficiency and convenience of both air tire machines and electric inflators, which could lead to frustration during urgent situations.

When selecting the appropriate tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the frequency of use. For businesses with high-volume tire inflation needs, such as gas stations or automotive service centers, an air tire machine represents a worthwhile investment despite its higher upfront costs. Conversely, small businesses or individual buyers might find portable electric inflators to be a more suitable and cost-effective solution for occasional use. Hand-operated pumps can serve as a backup or secondary option for low-volume tasks, particularly in recreational settings. Ultimately, the best choice will align with the operational demands and financial considerations of the buyer.

Illustrative image related to air tire machine

When evaluating air tire machines, understanding their technical specifications is crucial for B2B buyers seeking to make informed purchasing decisions. Here are some essential properties that should be considered:

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum air pressure the machine can deliver. Common ratings for commercial air tire machines range from 100 to 250 PSI. For businesses, selecting a machine with an appropriate pressure rating ensures that it meets the inflation requirements of various tire types, from standard passenger vehicles to heavy-duty trucks. Higher PSI ratings can also facilitate faster inflation times, enhancing customer satisfaction.

Air tire machines typically utilize either reciprocating or rotary screw compressors. Reciprocating compressors are often more cost-effective and suitable for lighter duties, while rotary screw compressors are preferred for continuous, heavy-duty operations. Understanding the compressor type helps businesses gauge the reliability and maintenance needs of the machine, influencing long-term operational costs.

Illustrative image related to air tire machine

The construction material of an air tire machine significantly affects its durability and longevity. Stainless steel is commonly used for housing due to its corrosion resistance and strength, making it ideal for outdoor environments. Choosing machines built from high-grade materials can reduce replacement costs and enhance the machine’s lifespan, providing better value for businesses in the long run.

Air tire machines come equipped with either digital or analog pressure gauges. Digital gauges provide more precise readings and are easier to read, which can help reduce user errors during inflation. For businesses, investing in machines with digital gauges can enhance user experience and operational efficiency, particularly in high-traffic locations like gas stations or car washes.

Most air tire machines operate on electric power, either from a standard outlet or a vehicle’s 12V system. Understanding the power supply requirements is essential for installation planning and operational efficiency. Machines that can operate on dual power sources provide flexibility for various settings, whether in a fixed location or for mobile applications.

Inflation speed, often measured in liters per minute (LPM), indicates how quickly the machine can inflate a tire. Faster inflation speeds can improve service efficiency, especially in busy commercial environments. Choosing a machine with a suitable inflation speed helps businesses serve more customers in less time, ultimately driving profitability.

Familiarizing yourself with industry-specific terminology can streamline communication and negotiations in the B2B marketplace. Here are some common terms you may encounter:

An OEM is a company that manufactures products or components that are marketed by another company. In the context of air tire machines, knowing whether a product is OEM can assure buyers of its quality and compatibility with existing equipment, which is particularly important for businesses looking to maintain uniformity in their operations.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for businesses to effectively manage inventory and cash flow. For air tire machines, suppliers may set MOQs based on production costs, making it important for buyers to negotiate terms that align with their operational needs.

An RFQ is a document that businesses send to suppliers to request pricing and terms for specific products or services. When purchasing air tire machines, submitting an RFQ can help businesses compare offers from multiple suppliers, ensuring they secure the best deal while meeting their technical requirements.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for businesses engaged in cross-border purchases of air tire machines, as they clarify shipping responsibilities, risk management, and cost allocation.

Lead time refers to the time taken from placing an order until it is delivered. Understanding lead times for air tire machines is vital for businesses planning their inventory and ensuring they have the necessary equipment available when needed. Longer lead times can impact operational efficiency, making it essential to account for this in procurement planning.

By grasping these key technical properties and trade terms, B2B buyers can make well-informed decisions, ensuring they select the right air tire machines for their specific operational needs.

The global air tire machine market is witnessing substantial growth, driven by increasing vehicle ownership and a rising emphasis on vehicle maintenance. Key trends include the rise of advanced tire inflators equipped with smart technology, enabling features like automatic pressure monitoring and inflation. This technological advancement not only enhances user convenience but also appeals to a tech-savvy consumer base, particularly in emerging markets such as Africa and South America, where mobile connectivity is rapidly expanding.

Illustrative image related to air tire machine

International B2B buyers are increasingly looking for suppliers that can offer integrated solutions, combining air tire machines with complementary services such as tire repair kits and pressure gauges. The demand for portable and cordless inflators is also on the rise, reflecting a shift towards more flexible and user-friendly options for both personal and commercial use. Additionally, the market is seeing a growing interest in commercial-grade machines, especially in gas stations and car washes, where the provision of air services can enhance customer satisfaction and drive additional revenue streams.

Moreover, regional dynamics play a crucial role. For instance, in Africa and the Middle East, the focus on reliable and durable machines is paramount due to varying infrastructure conditions. Conversely, European buyers may prioritize energy efficiency and compliance with stringent environmental regulations. Understanding these regional preferences can help international buyers make informed sourcing decisions.

The environmental impact of manufacturing and operating air tire machines is becoming a focal point for B2B buyers. Companies are increasingly prioritizing sustainability in their sourcing strategies, seeking suppliers who adhere to eco-friendly practices. This includes the use of recyclable materials in machine construction and energy-efficient technologies that reduce carbon footprints during operation.

Illustrative image related to air tire machine

Ethical supply chains are gaining traction, with buyers demanding transparency in sourcing practices. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential criteria for supplier selection. Buyers are also interested in machines that utilize sustainable materials, such as recycled plastics and metals, which can significantly minimize environmental impact.

In addition, the industry is seeing innovations in energy-efficient technologies, such as solar-powered inflators, which are particularly appealing in regions with abundant sunlight. This aligns with the global shift towards renewable energy sources and can enhance the appeal of air tire machines in markets like Africa and South America, where energy access may be inconsistent.

The evolution of the air tire machine market can be traced back to the early 20th century when manual pumps dominated the landscape. As vehicle ownership surged post-World War II, the demand for efficient tire inflation solutions grew, leading to the introduction of electric inflators and air machines in commercial settings like gas stations and car washes.

Over the decades, advancements in technology have transformed air tire machines from simple, mechanical devices into sophisticated, user-friendly machines equipped with digital displays and automated functions. This evolution reflects broader trends in consumer behavior and technological innovation, making air tire machines not just tools for inflation, but essential components of vehicle maintenance and customer service strategies in the automotive sector.

As the market continues to evolve, international B2B buyers must remain aware of these historical shifts to better understand current dynamics and anticipate future trends in the air tire machine sector.

How do I solve issues with tire inflation equipment?

To address problems with tire inflation equipment, start by identifying the specific issue, such as insufficient pressure or mechanical failure. Regular maintenance is crucial; ensure that all components, including hoses and gauges, are functioning properly. Check for blockages or leaks in the system. If the problem persists, consult the manufacturer’s troubleshooting guide or reach out to a qualified technician. Keeping an inventory of spare parts can also minimize downtime and ensure your operations continue smoothly.

What is the best air tire machine for commercial use?

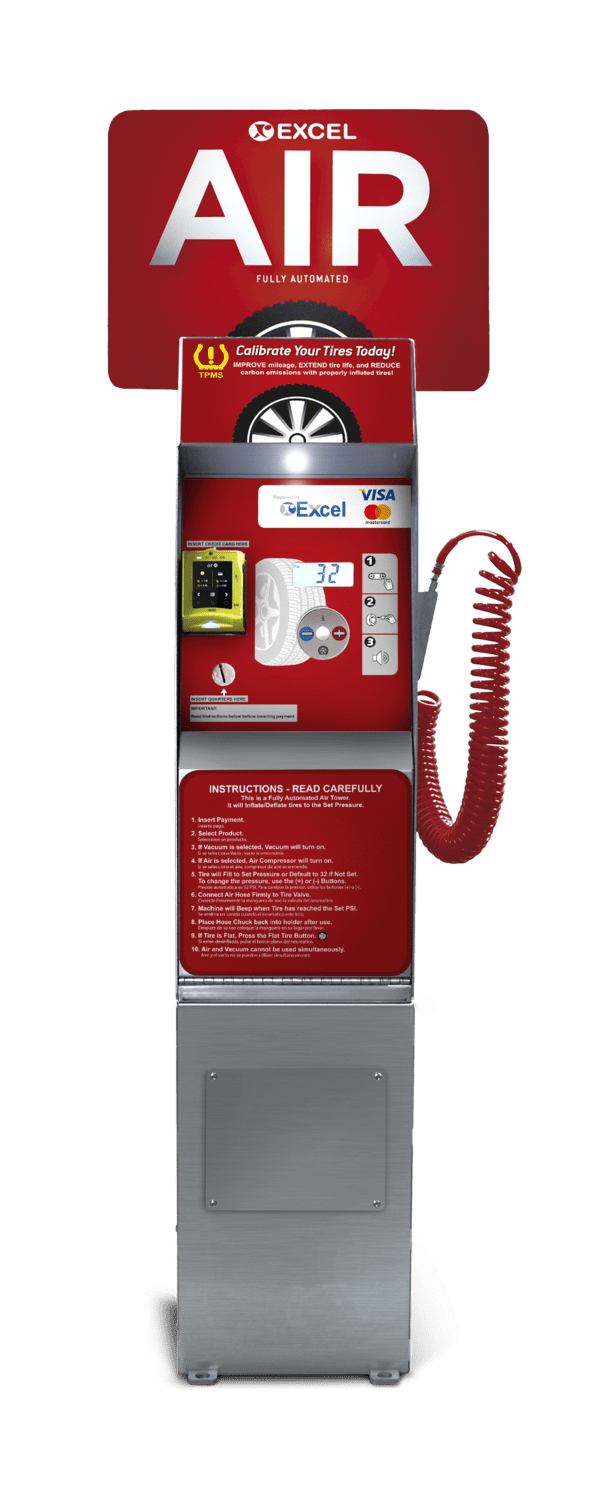

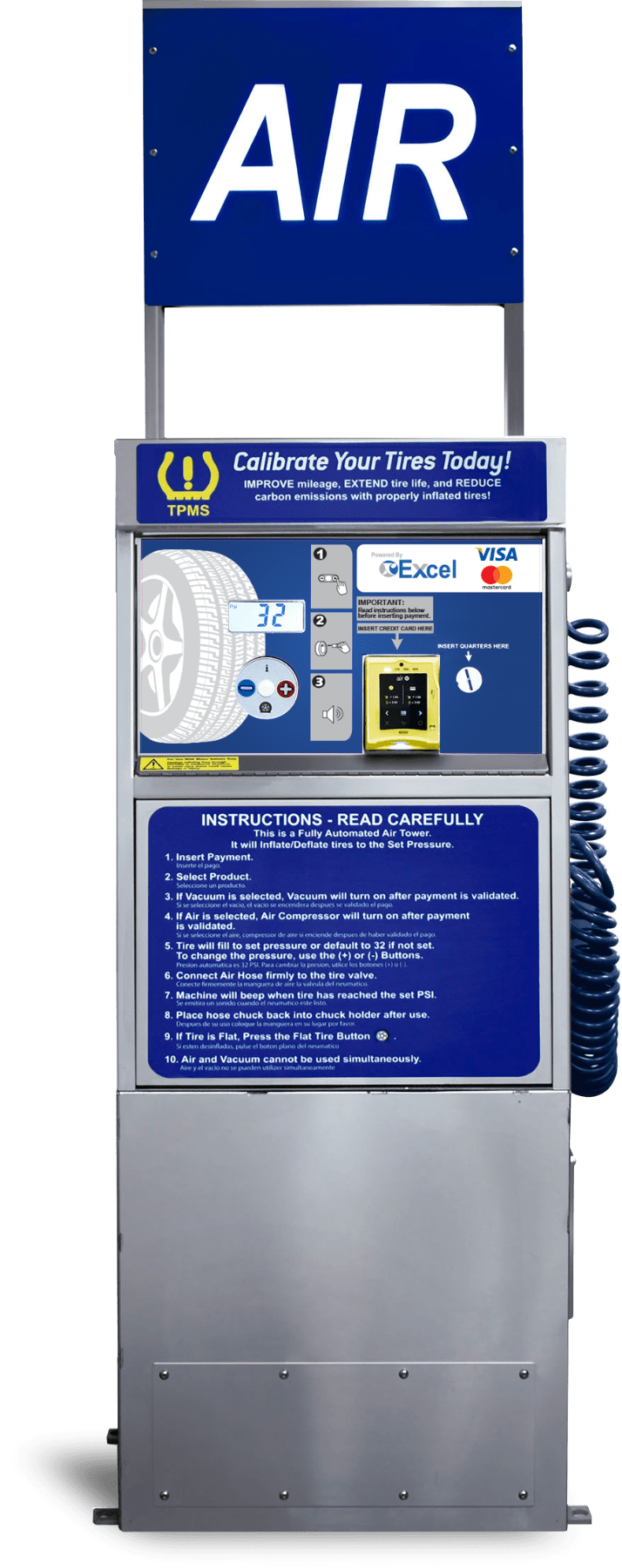

For commercial applications, look for air tire machines that offer durability, high PSI ratings, and a user-friendly interface. Brands like J.E. Adams and Excel are known for their reliability in high-demand environments. Opt for machines with digital pressure gauges for accuracy and ease of use. Consider whether you want a pay-per-use model or a free-service machine, as this can impact customer satisfaction and business revenue. Assess your specific needs, such as volume and types of vehicles serviced, to choose the best model.

What customization options are available for air tire machines?

Many manufacturers offer customization options for air tire machines to meet specific business needs. This can include branding with your logo, color schemes that match your business aesthetics, and tailored features such as payment systems or integrated vacuum functions. Discuss your requirements with potential suppliers to explore available options. Customization can enhance customer experience and promote brand visibility, making it a worthwhile investment for your business.

What are the minimum order quantities (MOQ) when sourcing air tire machines?

Minimum order quantities (MOQ) can vary significantly by supplier and the type of air tire machine. Some manufacturers may require a MOQ of 5-10 units, while others might offer flexibility with lower quantities for new customers. It’s essential to discuss MOQs upfront during negotiations to ensure they align with your purchasing capabilities. If you’re a smaller business, look for suppliers willing to accommodate smaller orders or those that offer bulk purchasing options to reduce costs.

How can I vet suppliers for air tire machines?

When vetting suppliers for air tire machines, consider their industry reputation, experience, and customer reviews. Request references from previous clients and inquire about their after-sales support and warranty policies. It’s also beneficial to check if they comply with international quality standards and certifications. Engage in direct communication to assess their responsiveness and willingness to provide information. Establishing a reliable relationship with suppliers can significantly enhance your procurement process.

What payment terms are typical for purchasing air tire machines?

Payment terms for air tire machines can vary based on the supplier’s policies and your negotiation power. Common terms include a deposit upon order placement (often 30-50%), with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for established businesses. It’s crucial to clarify these terms in the contract to avoid misunderstandings. Additionally, consider using secure payment methods that protect both parties during the transaction.

What quality assurance measures should I expect from suppliers?

Reputable suppliers of air tire machines should implement stringent quality assurance (QA) processes. Look for suppliers that conduct thorough inspections of their products before shipment, including testing for performance and durability. Request documentation of quality standards and certifications that comply with international regulations. A solid QA process not only ensures the reliability of the machines but also minimizes the risk of defects and enhances your operational efficiency.

How do logistics and shipping impact the procurement of air tire machines?

Logistics and shipping are critical factors when procuring air tire machines, especially for international buyers. Consider the shipping methods available (air, sea, or land) based on your urgency and budget. Discuss with suppliers their shipping options, lead times, and whether they handle customs clearance. Understanding import regulations in your country is also vital to avoid delays or additional costs. Collaborate with logistics partners who have experience in international shipping to ensure a smooth delivery process.

Домен: shop.exceltiregauge.com

Зарегистрирован: 2004 (21 год)

Введение: Product Name: Air & Vacuum Machine

Brand: Excel Tire Gauge

Contact Number: (401) 732-8420

Categories: Air Machines & Tire Inflators, Gas Stations & C-stores, Tire Shops, Auto Repairs & Quick Lubes, Car Washes, Fleets, Car Dealerships & Auto Rentals, Workplaces & Residentials

Available Models: SC09-SS, SC05-SS, SCWM-23, PNT PRO, PNT 4

Price: $725.00 (for PNT 4 and PNT PRO)

Features: Automatic Tire …

As the global demand for reliable air tire machines continues to rise, strategic sourcing emerges as a crucial component for B2B buyers looking to optimize their operations. By carefully evaluating suppliers, exploring diverse product offerings, and understanding the unique needs of different markets—particularly in regions like Africa, South America, the Middle East, and Europe—businesses can enhance customer satisfaction and operational efficiency.

Investing in high-quality air tire machines not only provides a valuable service but also serves as a competitive advantage. The ability to offer accessible tire inflation solutions can drive foot traffic to gas stations, car washes, and retail locations, creating additional revenue streams. Moreover, sourcing durable machines from reputable brands ensures longevity and reliability, reducing maintenance costs and downtime.

Illustrative image related to air tire machine

Looking ahead, international B2B buyers should prioritize partnerships with suppliers who demonstrate innovation and responsiveness to market trends. By leveraging strategic sourcing practices, businesses can position themselves to meet the evolving demands of their customers while fostering sustainable growth. Embrace the opportunity to enhance your service offerings and drive profitability—start your sourcing journey today.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.