In today’s fast-paced automotive industry, sourcing high-quality auto tire inflators can be a daunting task for international B2B buyers. With diverse applications ranging from personal vehicles to commercial fleets, the demand for reliable and efficient tire inflation solutions has never been greater. This comprehensive guide aims to navigate the complexities of the global market, providing insights into various types of tire inflators, their specific applications, and the critical factors to consider when evaluating potential suppliers.

As businesses from Africa, South America, the Middle East, and Europe—such as Nigeria and Saudi Arabia—look to enhance their operational efficiency, understanding the nuances of tire inflator technology becomes essential. This guide will delve into the features that distinguish automatic, wall-mounted, and portable inflators, ensuring buyers can make informed decisions based on their unique needs. Additionally, it covers vital aspects such as cost considerations, supplier vetting processes, and market trends, empowering purchasers with the knowledge to negotiate favorable terms and secure the best products.

By leveraging this guide, B2B buyers will be equipped not only to identify the right auto tire inflators for their operations but also to capitalize on market opportunities that drive profitability and enhance customer satisfaction. Whether you are a seasoned procurement professional or exploring new suppliers, this resource is designed to streamline your sourcing journey and foster strategic partnerships in the tire inflation sector.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Automatic Tire Inflators | Wall-mounted, digital gauge, automatic shutoff | Tire service shops, automotive repair centers | Плюсы: Efficient, accurate, saves time. Конс: Higher initial investment. |

| Portable Tire Inflators | Battery-powered, compact, versatile for various tire types | Roadside assistance, small workshops | Плюсы: Easy to transport, versatile. Конс: Limited power for larger tires. |

| Heavy-Duty Tire Inflators | High PSI capacity, robust construction, often battery-operated | Commercial fleets, heavy machinery maintenance | Плюсы: Fast inflation, durable. Конс: Bulky, requires more storage space. |

| Manual Tire Inflators | Hand-operated, simple design, often more affordable | Emergency kits, small-scale operations | Плюсы: Cost-effective, no power source needed. Конс: Labor-intensive, slower inflation. |

| Digital Tire Inflators | Integrated digital pressure gauges, preset inflation settings | Fleet management, automotive diagnostics | Плюсы: Accurate readings, user-friendly. Конс: May rely on batteries, less durable. |

Automatic tire inflators are designed for efficiency and precision, featuring wall-mounted designs that can be connected directly to a compressed air source. These inflators often come equipped with digital gauges and automatic shutoff capabilities, ensuring that tires are inflated to the exact desired pressure without the risk of over-inflation. They are particularly suitable for tire service shops and automotive repair centers where quick turnaround times are essential. When considering a purchase, B2B buyers should evaluate the inflator’s accuracy, ease of installation, and compatibility with nitrogen inflation systems.

Portable tire inflators stand out due to their compact, battery-powered designs, making them ideal for roadside assistance and small workshops. They can easily be stored in a vehicle or carried in a backpack, allowing for quick inflation of various tire types, including those on cars, bicycles, and motorcycles. While these inflators are versatile and convenient, buyers should consider their power limitations, as they may struggle to inflate larger tires effectively. Additionally, the rechargeable battery life is a critical factor for B2B buyers who require consistent performance.

Heavy-duty tire inflators are built to handle the demands of commercial fleets and heavy machinery maintenance. These inflators typically feature high PSI capacities and rugged construction, allowing them to inflate larger tires quickly and efficiently. They are often battery-operated, providing flexibility in various environments. B2B buyers should assess the inflator’s speed, durability, and ease of use, particularly for high-volume operations where downtime can lead to significant losses.

Manual tire inflators, while less sophisticated, serve a critical role in emergency situations and small-scale operations. These hand-operated devices are cost-effective and require no power source, making them an excellent addition to emergency kits. However, they demand more effort and time to inflate tires, which may not be ideal for high-demand environments. B2B buyers should weigh the affordability of manual inflators against the need for speed and efficiency in their operations.

Digital tire inflators enhance the inflation process with integrated digital pressure gauges and preset inflation settings. These features provide accurate readings and user-friendly operation, making them suitable for fleet management and automotive diagnostics. B2B buyers should consider the reliability of the digital components and the potential need for battery replacements. While these inflators offer convenience, their reliance on electronics may be a drawback in rugged environments.

| Промышленность/сектор | Specific Application of auto tire inflators | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Repair Shops | Routine tire maintenance and emergency services | Increases service efficiency, reduces downtime for customers | Durability, ease of use, and compatibility with different tire types |

| Logistics and Transportation | Fleet maintenance for delivery and transportation vehicles | Enhances fleet safety, improves fuel efficiency, prolongs tire lifespan | Speed of inflation, pressure accuracy, and portability |

| Construction and Heavy Equipment | Tire inflation for construction vehicles and machinery | Ensures operational readiness and minimizes equipment failure | Robustness, ability to handle high-pressure tires, and service support |

| Car Rental Services | Quick tire maintenance for rental vehicles | Reduces turnaround time for vehicle servicing, enhances customer satisfaction | Compact design, ease of storage, and fast inflation capabilities |

| Agricultural Sector | Tire inflation for agricultural machinery and vehicles | Improves efficiency in operations and ensures safety during fieldwork | Compatibility with various tire sizes and easy maintenance |

In automotive repair shops, auto tire inflators are essential for routine tire maintenance and emergency services. These inflators allow technicians to quickly check and adjust tire pressures, ensuring optimal vehicle performance and safety. By using automatic tire inflators, shops can enhance service efficiency, ultimately reducing customer wait times and increasing throughput. For international buyers, especially in regions like Africa and South America, sourcing durable inflators that can withstand diverse environmental conditions is crucial.

Illustrative image related to auto tire inflators

In the logistics and transportation industry, maintaining fleet vehicles is critical for operational efficiency. Auto tire inflators are utilized to ensure that delivery trucks and transport vehicles have the correct tire pressure, which directly impacts fuel efficiency and safety. By investing in reliable inflators, companies can minimize the risk of tire blowouts and enhance the overall lifespan of tires. Buyers in the Middle East and Europe should consider inflators that provide accurate pressure readings and fast inflation times to keep their fleets running smoothly.

Construction sites rely heavily on machinery, making tire maintenance vital for preventing downtime. Auto tire inflators are used to ensure that construction vehicles and heavy equipment are always ready for operation. These inflators must handle high-pressure tires and be robust enough for rugged environments. For businesses in Africa and the Middle East, sourcing inflators that can withstand harsh conditions while providing reliable performance is essential to maintaining productivity on-site.

Car rental services use auto tire inflators to perform quick tire maintenance on their fleets, ensuring vehicles are safe and ready for customers. Fast inflation capabilities reduce the turnaround time for servicing, which directly enhances customer satisfaction and operational efficiency. Buyers from regions with diverse climatic conditions, such as Europe and South America, should prioritize compact and portable inflators that can easily be stored in rental vehicles while still delivering reliable performance.

In the agricultural sector, auto tire inflators are crucial for maintaining the tire pressure of various farming machinery and vehicles. Correct tire pressure is vital for ensuring safety and efficiency during fieldwork. Agricultural operations often demand inflators that can accommodate different tire sizes and are easy to maintain. Buyers in regions like Africa, where agricultural machinery operates in challenging terrains, need to focus on sourcing robust and versatile inflators that can handle the demands of their operations.

Illustrative image related to auto tire inflators

Проблема: One common issue faced by B2B buyers, especially those managing fleets or tire shops, is the challenge of accurately inflating tires across various vehicle types. Different vehicles, from compact cars to heavy-duty trucks, require specific tire pressures, and using a single inflator might lead to under-inflation or over-inflation. This not only affects vehicle performance and safety but can also lead to increased tire wear, affecting the bottom line.

Решение: To address this issue, buyers should prioritize tire inflators equipped with digital gauges and preset pressure settings. These features allow users to input the desired tire pressure for specific vehicles, ensuring accurate inflation every time. When sourcing tire inflators, look for models that offer compatibility with a wide range of pressure levels (up to 160 psi for larger vehicles) and have built-in safety mechanisms that prevent over-inflation. Regular training on how to utilize these features effectively will also enhance operational efficiency and safety.

Проблема: For businesses that operate in remote or mobile settings, such as roadside assistance or mobile tire repair services, the bulkiness and weight of traditional tire inflators can be a significant drawback. Heavy and cumbersome inflators can hinder quick response times and limit the ability to serve clients effectively, leading to customer dissatisfaction and lost business opportunities.

Illustrative image related to auto tire inflators

Решение: To overcome this challenge, B2B buyers should invest in compact, portable tire inflators that are lightweight yet powerful. Models like cordless inflators or those that can be easily powered through a vehicle’s 12-volt outlet are ideal. When selecting inflators, consider those with built-in rechargeable batteries that can handle multiple tire fills on a single charge. Additionally, incorporating inflators with multi-functional capabilities—such as built-in lights or USB charging ports—can further enhance convenience for mobile operations. Ensuring that staff are trained to use these portable units efficiently will also maximize productivity on the job.

Проблема: Inconsistent performance, such as slow inflation rates or inaccurate pressure readings, is a frequent pain point for B2B buyers who rely on tire inflators for their operations. These performance issues can cause delays in service delivery, increase operational costs due to tire damage, and ultimately lead to dissatisfaction among customers who expect timely and efficient service.

Решение: To mitigate these frustrations, B2B buyers should conduct thorough evaluations of inflators before purchase, focusing on user reviews and performance metrics. Opting for tire inflators from reputable manufacturers known for quality assurance can significantly reduce the likelihood of performance inconsistencies. Buyers should also consider inflators that undergo rigorous testing for speed and accuracy, as detailed in industry reviews. Regular maintenance and calibration of the inflators, as recommended by the manufacturer, will ensure optimal performance over time. Establishing a protocol for checking equipment before use can also prevent service delays and maintain high customer satisfaction levels.

In the manufacturing of auto tire inflators, the selection of materials plays a critical role in determining the product’s performance, durability, and overall user satisfaction. Below is an analysis of several common materials used in tire inflators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Ключевые свойства: Aluminum is lightweight and has excellent corrosion resistance. It can withstand moderate pressures, making it suitable for inflators that require a balance between weight and strength.

Плюсы и минусы: The primary advantage of aluminum is its durability and resistance to rust, which is crucial for products exposed to various environmental conditions. However, it can be more expensive than other materials like plastic and may require additional manufacturing processes, such as anodizing, to enhance its surface properties.

Illustrative image related to auto tire inflators

Влияние на применение: Aluminum’s compatibility with various gases, including nitrogen, makes it ideal for tire inflators. Its lightweight nature also contributes to the portability of the inflator.

Соображения для международных покупателей: Buyers in regions like Africa and the Middle East should ensure that aluminum components comply with standards such as ASTM B209 for aluminum alloys. Additionally, understanding local corrosion challenges, especially in coastal areas, is essential for product longevity.

Ключевые свойства: Plastic is versatile and can be molded into complex shapes. It is generally resistant to chemicals and can handle moderate temperatures and pressures.

Illustrative image related to auto tire inflators

Плюсы и минусы: The main advantage of plastic is its cost-effectiveness and ease of manufacturing. However, it may not provide the same level of durability or pressure resistance as metals. Over time, exposure to UV light can degrade certain plastics, impacting performance.

Влияние на применение: Plastics are often used for housing components and smaller parts of inflators, which do not require high-pressure resistance. They can also be engineered to be lightweight, enhancing portability.

Соображения для международных покупателей: Buyers should look for plastics that meet international standards such as ISO 9001 for quality management. In regions with extreme temperatures, selecting UV-resistant plastics is crucial to ensure longevity.

Ключевые свойства: Steel is known for its high strength and durability, with excellent pressure ratings. It is often used in components that require robust construction.

Illustrative image related to auto tire inflators

Плюсы и минусы: The primary advantage of steel is its strength, which allows it to withstand high pressures without deforming. However, it is heavier than aluminum and can corrode if not properly coated or treated, increasing maintenance needs.

Влияние на применение: Steel is commonly used in the pressure vessel components of tire inflators, where high-pressure performance is critical. Its robustness makes it suitable for heavy-duty applications.

Соображения для международных покупателей: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers should also consider the local availability of corrosion-resistant coatings to enhance the longevity of steel components in humid or coastal environments.

Ключевые свойства: Rubber is flexible and has excellent sealing properties, making it ideal for components that require airtight seals.

Плюсы и минусы: The flexibility of rubber allows it to absorb vibrations, which can enhance user experience. However, rubber can degrade over time, especially when exposed to ozone or UV light, which may lead to leaks.

Illustrative image related to auto tire inflators

Влияние на применение: Rubber is primarily used in seals and hoses within tire inflators. Its ability to maintain a tight seal under varying pressures is critical for effective operation.

Соображения для международных покупателей: Buyers should ensure that rubber components meet international standards such as ASTM D2000 for rubber materials. Understanding local environmental conditions is also vital, as extreme temperatures can affect rubber longevity.

| Материал | Typical Use Case for auto tire inflators | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Housing and structural components | Легкий и устойчивый к коррозии | Higher cost and requires surface treatment | Средний |

| Пластик | Housing and non-pressurized parts | Cost-effective and easily molded | Less durable under high pressure and UV exposure | Низкий |

| Сталь | Pressure vessels and heavy-duty components | Высокая прочность и долговечность | Heavier and prone to corrosion without treatment | Высокий |

| Резина | Seals and hoses | Excellent sealing and vibration absorption | Can degrade over time due to environmental factors | Средний |

This material selection guide provides B2B buyers with essential insights into the properties and implications of various materials used in auto tire inflators, facilitating informed purchasing decisions tailored to their regional needs and standards.

The manufacturing process for auto tire inflators involves several critical stages that ensure the final product meets the required standards of functionality and durability. The main stages are material preparation, forming, assembly, and finishing.

The manufacturing process begins with sourcing high-quality materials. Common materials include:

Suppliers must ensure that these materials comply with international standards to guarantee safety and performance.

Illustrative image related to auto tire inflators

Forming involves shaping the materials into the necessary components. This can include injection molding for plastic parts and machining for metal components. Key techniques include:

Once the components are formed, they move to the assembly stage. Here, parts are meticulously put together, which may involve:

Quality assurance (QA) is paramount in the manufacturing of auto tire inflators to ensure that each unit performs reliably and safely. Various standards and checkpoints are essential in this process.

B2B buyers should ensure that their suppliers adhere to relevant international standards such as:

Quality control checkpoints are integral to the manufacturing process. They typically include:

To ensure the reliability and safety of tire inflators, several testing methods are commonly employed:

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are effective strategies:

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring product quality. Here are some considerations:

The manufacturing processes and quality assurance practices for auto tire inflators are critical to delivering reliable products to the market. By understanding the stages of manufacturing, the importance of quality control, and the international standards that apply, B2B buyers can make informed decisions when selecting suppliers. Implementing thorough verification methods ensures that the inflators meet the necessary performance and safety standards, ultimately leading to greater customer satisfaction and business success.

Procuring auto tire inflators for your business requires a systematic approach to ensure you select high-quality equipment that meets your operational needs. This step-by-step checklist is designed for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Following these steps will help streamline the sourcing process and mitigate potential risks.

Illustrative image related to auto tire inflators

Understanding the technical requirements of the tire inflators you need is essential. Consider factors such as pressure range (psi), inflation speed, power source (battery, AC, or DC), and size. These specifications will determine the effectiveness and efficiency of the inflators in your operations.

Staying informed about the latest trends in tire inflators can give your business a competitive edge. Innovations in technology, such as digital pressure gauges and automatic shut-off features, can enhance user experience and operational efficiency.

Before committing to a supplier, it is critical to conduct thorough due diligence. Research potential vendors to ensure they have a solid reputation and experience in supplying tire inflators.

Obtaining samples allows you to assess the quality and performance of the inflators firsthand. This step is crucial in ensuring that the products meet your specifications and quality expectations.

Illustrative image related to auto tire inflators

While price is a crucial factor, consider the total cost of ownership, which includes maintenance, warranty, and operational costs. This approach will provide a clearer picture of the financial implications over the lifespan of the equipment.

Once you have identified the preferred supplier and products, enter into negotiations to finalize pricing, delivery timelines, and payment terms. Clear communication at this stage can help avoid misunderstandings and establish a strong working relationship.

Establishing a plan for after-sales support can enhance the longevity of your investment. Ensure that the supplier provides comprehensive support, including technical assistance and access to replacement parts.

When analyzing the cost structure of auto tire inflators, several components play a crucial role. These include:

Материалы: The choice of materials significantly impacts the cost. High-quality plastics, metals, and electronic components contribute to durability and functionality but also increase expenses. For instance, inflators with digital gauges or those compatible with nitrogen inflation typically require higher-grade materials.

Труд: Labor costs can vary based on the manufacturing location. Regions with lower wage standards may offer cost advantages, while skilled labor in developed countries might demand higher wages, impacting overall pricing.

Производственные накладные расходы: This encompasses costs related to factory operations, such as utilities, equipment depreciation, and maintenance. Efficient production processes can help minimize these overheads.

Инструментальная оснастка: Initial setup costs for molds and specialized equipment for production can be substantial. These costs are often amortized over large production runs, making them more manageable for high-volume orders.

Контроль качества (QC): Investing in rigorous quality control processes ensures the reliability of the inflators, which is crucial for maintaining brand reputation. While this adds to the cost, it can reduce returns and enhance customer satisfaction.

Логистика: Transportation and warehousing costs must be factored into the pricing. Depending on the destination and shipping method, these costs can fluctuate significantly, particularly for international buyers.

Маржа: Suppliers typically apply a margin to cover risks and generate profit. This margin can vary based on market competition and the perceived value of the product.

Several factors influence the pricing of auto tire inflators, particularly for B2B buyers:

Объем/МОК: Larger orders often lead to lower per-unit costs due to economies of scale. Minimum order quantities (MOQs) can also dictate pricing, with manufacturers offering discounts for bulk purchases.

Технические характеристики и персонализация: Tailoring inflators to specific needs (e.g., branding, additional features) can increase costs. Customization often requires additional tooling or materials, which impacts the overall pricing structure.

Качество и сертификация: Products that meet international standards or possess specific certifications (e.g., CE, ISO) may command higher prices. Buyers should consider the long-term benefits of investing in certified products that ensure safety and reliability.

Факторы поставщика: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

Инкотермс: The agreed Incoterms affect the final cost by determining who bears the shipping and handling responsibilities. Understanding these terms is crucial for accurate cost estimation and negotiation.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can benefit from strategic approaches:

Illustrative image related to auto tire inflators

Переговоры: Engaging suppliers in negotiations can yield better pricing, especially for larger orders. Discussing long-term partnerships may also open avenues for discounts or favorable terms.

Общая стоимость владения (TCO): When evaluating inflators, consider not only the purchase price but also the TCO, which includes maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality inflators may lead to lower TCO over time.

Нюансы ценообразования: Be aware of regional pricing trends and currency fluctuations that may affect costs. Staying informed about market conditions can provide leverage in negotiations.

Supplier Diversity: Explore multiple suppliers to compare prices and offerings. This approach can help identify the best value for specific needs and ensure competitive pricing.

Long-Term Relationships: Building relationships with reliable suppliers can lead to better service, pricing, and priority during supply chain disruptions.

Prices for auto tire inflators can vary widely based on the factors discussed above. Buyers should conduct thorough market research and consider obtaining quotes from multiple suppliers to ensure they are getting competitive pricing tailored to their specific needs.

In the automotive maintenance sector, the ability to maintain optimal tire pressure is crucial for safety, fuel efficiency, and tire longevity. While auto tire inflators are a popular solution for this need, there are alternative methods and technologies that can also achieve similar results. This analysis will compare auto tire inflators with two viable alternatives: manual tire pumps and nitrogen inflation systems.

| Сравнительный аспект | Auto Tire Inflators | Manual Tire Pumps | Nitrogen Inflation Systems |

|---|---|---|---|

| Производительность | Quick and efficient, often with digital gauges for accuracy. | Slower; requires physical effort; accuracy depends on the user’s skill. | Provides stable pressure over time; minimizes fluctuations. |

| Стоимость | Ranges from $40 to $100+ depending on features. | Generally low-cost, ranging from $10 to $50. | Higher initial investment; typically $100+ for equipment, plus ongoing nitrogen costs. |

| Простота реализации | Simple to use; plug and go, often portable. | Requires manual effort; can be cumbersome. | Requires specialized equipment and training for staff. |

| Техническое обслуживание | Minimal; occasional calibration needed. | Low; primarily cleaning and checking for leaks. | Requires regular checks and refills of nitrogen tanks. |

| Лучший пример использования | Ideal for quick tire repairs on-the-go, suitable for both personal and commercial use. | Best for low-budget consumers or emergency situations. | Optimal for fleets and high-performance vehicles requiring consistent tire pressure. |

Manual tire pumps are a straightforward, low-cost solution for inflating tires. Their primary advantage is affordability, making them accessible for budget-conscious buyers. However, they require significant physical effort and can be time-consuming, especially when inflating larger tires. Additionally, the accuracy of pressure readings relies heavily on the user’s ability to gauge the tire pressure manually, which can lead to potential over-inflation or under-inflation risks. Manual pumps are best suited for occasional use or emergency situations where convenience is not a priority.

Nitrogen inflation systems offer a sophisticated alternative for maintaining tire pressure. The primary benefit of using nitrogen is that it reduces the rate of pressure loss in tires, as nitrogen molecules are larger than those of air, preventing quicker diffusion through the tire walls. This stability in pressure can lead to improved fuel efficiency and longer tire life. However, the initial setup cost is considerably higher, and businesses need to ensure that they have trained personnel to manage the equipment. Nitrogen systems are particularly advantageous for commercial fleets and performance vehicles where consistent tire pressure is critical for safety and performance.

When selecting a tire inflation solution, B2B buyers should carefully consider their specific requirements, including budget, usage frequency, and the level of precision needed. Auto tire inflators are ideal for businesses that require quick and efficient service, while manual pumps may suffice for low-volume operations or emergency preparedness. Conversely, nitrogen inflation systems represent a long-term investment that can yield significant savings in tire maintenance and fuel efficiency for fleets. Ultimately, the choice will hinge on balancing cost against performance needs and operational capabilities.

Understanding the technical specifications of auto tire inflators is crucial for B2B buyers, particularly in industries reliant on fleet management or automotive service. Here are some essential properties:

The maximum pressure, measured in pounds per square inch (PSI), indicates how much air pressure the inflator can deliver. This specification is critical for ensuring that the inflator can handle a variety of tire types, especially in commercial vehicles or heavy-duty applications. Inflators with a higher PSI capability can cater to larger vehicles like trucks and SUVs, which often require pressures exceeding 80 PSI.

Illustrative image related to auto tire inflators

The duty cycle refers to the amount of time an inflator can run continuously before needing a cooldown period. This property is particularly important in commercial settings where multiple tires may need inflation in quick succession. A higher duty cycle means less downtime and improved efficiency, allowing operators to serve more customers or complete more tasks within a limited timeframe.

Inflators can be powered by various sources, including battery packs, 12-volt car outlets, or AC power. Understanding the power source is vital for B2B buyers, as it affects portability and usability in different environments. For example, battery-operated models are ideal for roadside assistance, while AC-powered inflators are better suited for stationary applications in garages.

An accurate pressure gauge ensures that tires are inflated to the correct specifications, which is crucial for vehicle safety and performance. Digital gauges often provide quicker and more precise readings compared to analog ones. For B2B buyers, investing in inflators with reliable gauges can reduce the risk of under or over-inflating tires, leading to better fuel efficiency and tire longevity.

Inflation speed refers to how quickly the inflator can fill a tire from a flat state to the desired pressure. This metric is essential for businesses that need to maximize efficiency and minimize customer wait times. Inflators that can quickly inflate multiple tires can significantly enhance service delivery in high-demand environments.

Illustrative image related to auto tire inflators

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, OEM products are often of higher quality and reliability, making them a preferred choice for businesses focused on long-term performance.

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure they can meet demand without over-committing to excess stock.

An RFQ is a document sent to suppliers requesting a detailed quote for specific products or services. This term is essential for B2B buyers as it helps in comparing prices and terms from different suppliers, ensuring they make informed purchasing decisions.

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and obligations involved in importing tire inflators from different countries.

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is essential for businesses that need to plan inventory and operations efficiently, particularly when dealing with high-demand products like tire inflators.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they choose the right tire inflators that meet their operational needs and contribute to overall efficiency.

The auto tire inflators market is experiencing significant transformation driven by various global factors. Increasing vehicle ownership in emerging markets, particularly in Africa and South America, fuels demand for efficient and portable tire inflation solutions. Additionally, the rising emphasis on vehicle safety and maintenance has heightened awareness about the importance of maintaining optimal tire pressure, which directly impacts fuel efficiency and vehicle performance. This growing consciousness among consumers and businesses alike has made tire inflators a necessary tool in fleet management and personal vehicle upkeep.

Technological advancements are also shaping the market. Innovations such as smart tire inflators that connect to mobile apps for monitoring tire pressure and inflation status are gaining traction. This is particularly relevant for international B2B buyers, who are increasingly seeking reliable and technologically advanced solutions to enhance their operational efficiency. Furthermore, the trend towards automation is evident, with automatic and wall-mounted tire inflators becoming popular in commercial settings, enabling businesses to streamline tire maintenance processes.

Illustrative image related to auto tire inflators

Additionally, the market is influenced by regional dynamics. In the Middle East, for instance, the harsh climate necessitates robust and durable tire inflators that can withstand extreme conditions. In contrast, European buyers may prioritize compact and portable designs due to urban living constraints. Understanding these regional preferences is crucial for international B2B buyers when sourcing tire inflators.

Sustainability and ethical sourcing are becoming increasingly important in the auto tire inflators sector. As businesses globally recognize the environmental impact of their operations, the demand for eco-friendly products is rising. Auto tire inflators made from sustainable materials and featuring energy-efficient designs are gaining favor among B2B buyers. This trend is not just a response to consumer preferences; it’s also driven by regulatory pressures and the need to comply with sustainability certifications.

Furthermore, ethical supply chains are crucial in today’s market. Buyers are more aware of the social implications of their sourcing decisions, seeking suppliers who adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and compliance with the REACH regulation in the European Union are becoming essential criteria for sourcing decisions. B2B buyers must prioritize partnerships with manufacturers that demonstrate a commitment to sustainability, as this can enhance brand reputation and foster customer loyalty.

The use of recyclable materials in product design is another key area for innovation. Manufacturers are increasingly focusing on creating tire inflators that not only perform well but also minimize waste at the end of their lifecycle. For buyers in regions like Africa and South America, where waste management infrastructure may be limited, choosing products with a lower environmental footprint can be a significant factor in procurement decisions.

Illustrative image related to auto tire inflators

The evolution of auto tire inflators can be traced back to the early 20th century when manual pumps were the norm. Initially designed for basic inflation, these tools have undergone substantial advancements, transitioning from manual to electric and battery-operated models. The introduction of portable tire inflators in the late 20th century marked a significant shift, allowing vehicle owners to maintain tire pressure conveniently without relying on service stations.

As vehicle technology advanced, so did the need for more sophisticated tire maintenance solutions. The integration of digital gauges and automatic shut-off features in modern inflators reflects a growing demand for accuracy and ease of use. This historical context is essential for B2B buyers, as it underscores the importance of investing in reliable, high-quality products that reflect the latest technological advancements. Understanding this evolution can help buyers make informed decisions that align with current market trends and future innovations in the auto tire inflator sector.

1. How do I choose the right auto tire inflator for my business needs?

Selecting the right auto tire inflator involves assessing your specific operational requirements. Consider factors such as the volume of tires you handle, the types of vehicles in your portfolio (passenger cars, trucks, etc.), and whether you need portable or stationary units. Look for features like digital gauges for accuracy, speed of inflation, compatibility with nitrogen, and ease of use. Additionally, evaluate the inflator’s power source options, such as battery or direct vehicle connection, especially if you’re working in diverse environments.

2. What are the key features to look for in a commercial tire inflator?

When sourcing a commercial tire inflator, prioritize features that enhance efficiency and usability. Look for automatic shut-off capabilities to prevent over-inflation, built-in pressure gauges for accurate readings, and the ability to inflate to higher pressures for larger tires. Portability can be crucial for mobile service providers, so consider inflators that are lightweight and come with carrying cases. Also, check for additional functionalities like USB ports or LED lights, which can add value in various service scenarios.

3. What is the minimum order quantity (MOQ) for auto tire inflators?

Minimum order quantities (MOQ) for auto tire inflators vary by supplier and product type. Generally, MOQs can range from as few as 10 units for smaller suppliers to 100 or more for larger manufacturers. It’s advisable to discuss your needs directly with potential suppliers to negotiate terms that align with your business goals. If you are testing a new product line, some manufacturers may offer lower MOQs for initial orders, allowing you to gauge market demand before committing to larger quantities.

4. How can I ensure the quality of the tire inflators I purchase?

To ensure quality, conduct thorough supplier vetting by checking certifications, reviews, and previous client testimonials. Request samples to evaluate product performance, durability, and compliance with international safety standards. Additionally, inquire about the supplier’s quality assurance processes, including testing protocols for their inflators. Establishing a clear agreement regarding warranties and after-sales support can also provide peace of mind regarding product reliability.

5. What payment terms should I expect when sourcing tire inflators internationally?

Payment terms in international trade can vary widely. Common options include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer net 30, 60, or even 90-day terms, depending on your relationship with them and the order size. It’s crucial to clarify these terms upfront and consider using secure payment methods such as letters of credit or escrow services to protect your investment.

6. How do I handle logistics and shipping for tire inflators from international suppliers?

When importing tire inflators, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Partner with a reliable freight forwarder who can manage the complexities of international shipping, including documentation and compliance with local regulations. Understand the incoterms (like FOB or CIF) to clarify responsibilities for shipping costs and risks. Finally, plan for potential delays by allowing ample time in your supply chain for customs clearance and transportation.

7. What customization options are available for tire inflators?

Many manufacturers offer customization options for tire inflators, including branding, color, and features tailored to specific market needs. Customization can include adding your company’s logo, adjusting the pressure range, or integrating specialized connectors for different tire types. Discuss your requirements with suppliers to see what options are available and any associated costs. Custom products can enhance brand recognition and provide a competitive edge in your local market.

8. How do I assess the reliability of a tire inflator supplier?

To assess a tire inflator supplier’s reliability, review their history in the industry, including years of operation and customer feedback. Request references from other businesses that have sourced products from them. Analyze their responsiveness to inquiries and their willingness to provide detailed product information and support. Certifications and compliance with international standards also signal a commitment to quality and reliability. Engaging with suppliers through trade shows or industry events can further enhance your understanding of their reputation and product offerings.

Домен: martinsindustries.com

Зарегистрирован: 2005 (20 лет)

Введение: Automatic Tire Inflators, Wall-mounted Tire Inflators, handheld or manual options, certified inflators for accurate inflation/deflation, digital gauge, nitrogen-inflation compatibility, various models including Handheld digital tire inflator (Flate Mate Handheld MH-30), Analog Handheld Tire Inflator (Flate Mate Analog Handheld MH-31-PSI), Automatic Tire Inflator (Flatematic Handheld MHA-100), Auto…

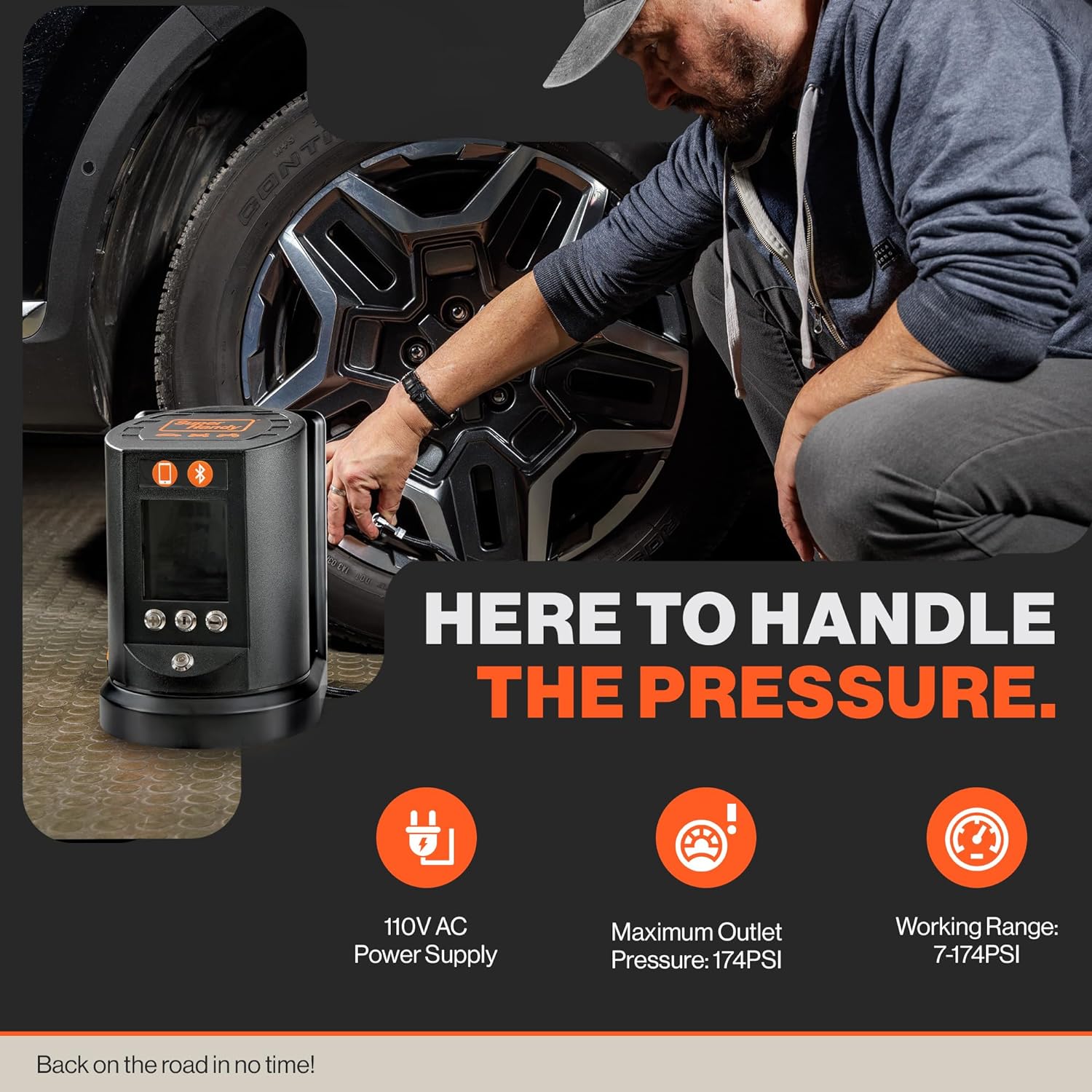

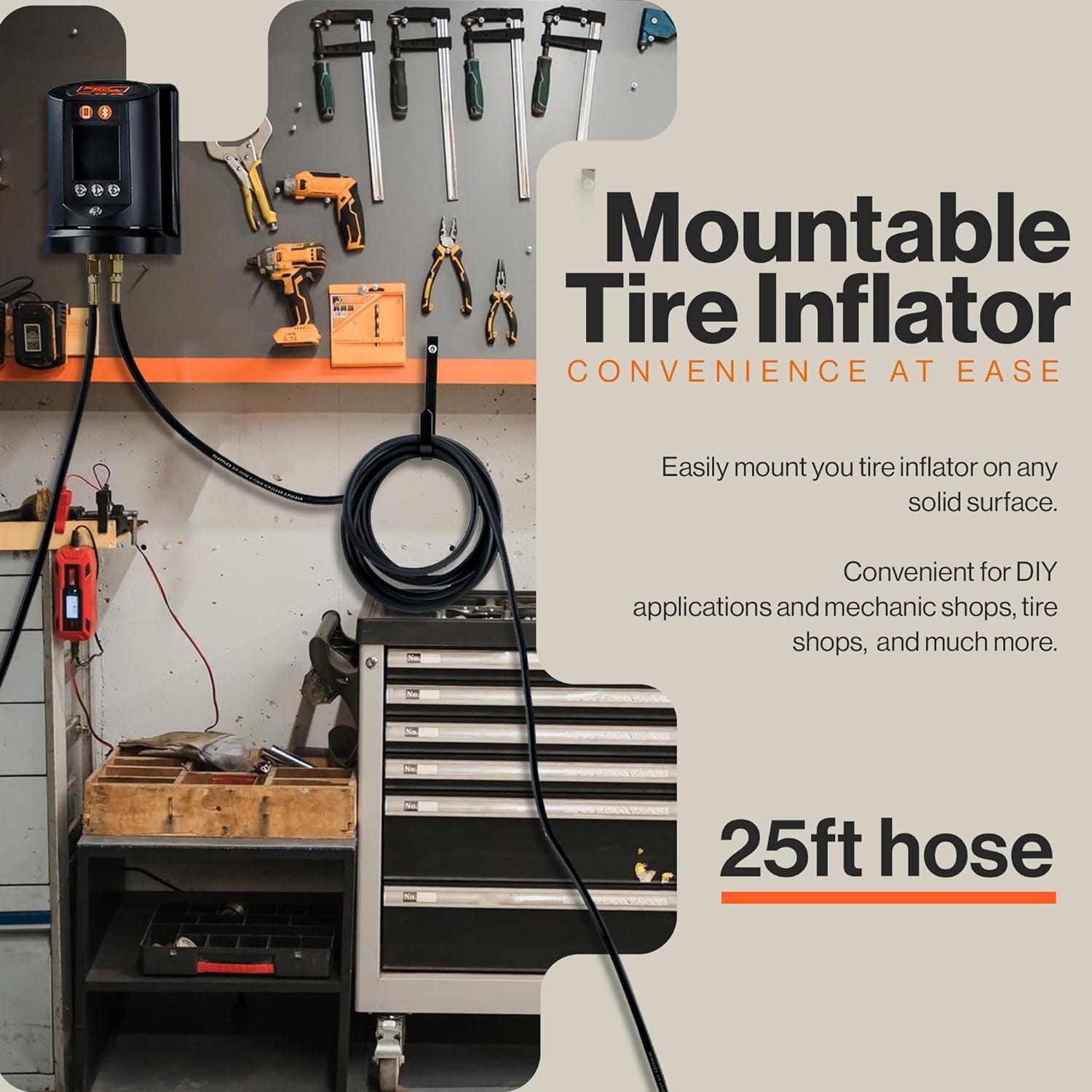

Домен: superhandyus.com

Зарегистрирован: 2022 (3 года)

Введение: {“product_name”: “SuperHandy Automatic Tire Inflator”, “suitable_for”: [“Cars”, “Trucks”, “Motorcycles”, “ATVs”], “max_pressure”: “174 PSI”, “air_hose_length”: “25 feet”, “accuracy”: “1 PSI”, “features”: [“High-accuracy gauge”, “User-friendly operation”, “Bluetooth and APP operation”], “sale_price”: “$193.59”, “regular_price”: “$154.98”, “sku”: “GUT160-FBA”, “availability”: “In stock”}

Домен: lasfit.com

Зарегистрирован: 2016 (9 лет)

Введение: Lasfit Tire Inflator | Portable Tire Pumps for Pickup Trucks & Large SUVs & Off-Road Vehicles. Key features include fast inflation, accurate pressure readings, compact design, multi-purpose use (suitable for car tires, bikes, motorcycles, and more), digital display, and auto shut-off. Designed for 12V DC outlets, built with durable components for long-lasting performance. Available models include …

In the evolving landscape of auto tire inflators, strategic sourcing emerges as a pivotal component for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe continue to prioritize efficiency and cost-effectiveness, understanding the nuances of tire inflator technology is essential. Buyers should focus on the diverse features available—from automatic systems that ensure precise inflation to portable models that cater to various vehicle types.

Choosing the right inflator not only enhances operational efficiency but also minimizes downtime and maintenance costs, ultimately driving profitability. Evaluating suppliers based on product reliability, technological advancements, and after-sales support will further empower buyers to make informed decisions that align with their business goals.

As we look to the future, the demand for innovative tire inflators is expected to rise, driven by increasing vehicle ownership and maintenance awareness. B2B buyers are encouraged to seize opportunities in this growing market, leveraging strategic sourcing to enhance their competitive edge. Engage with suppliers today to explore the best solutions that meet your specific needs, ensuring your operations remain efficient and cost-effective in a dynamic marketplace.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.