In the ever-evolving landscape of international trade, sourcing reliable suppliers for air fillers can pose a significant challenge for B2B buyers, especially those looking for “air filler near me.” The need for dependable air inflation solutions is crucial for industries ranging from automotive repair to logistics, where tire maintenance directly impacts operational efficiency. This comprehensive guide aims to equip businesses with the knowledge to navigate the global market for air fillers effectively.

Within these pages, we delve into various types of air fillers, their applications across different sectors, and the critical aspects of supplier vetting processes. Additionally, we discuss cost considerations and best practices for procurement, ensuring that buyers make informed decisions that align with their operational needs. By synthesizing insights tailored for international markets, particularly in Africa, South America, the Middle East, and Europe—including regions like Vietnam and Brazil—this guide empowers B2B buyers to enhance their sourcing strategies.

Whether you are a small business owner seeking localized solutions or a larger corporation requiring bulk air filler supplies, this guide will serve as your roadmap to achieving cost-effective, high-quality sourcing. Let’s embark on this journey to streamline your procurement processes and elevate your business operations.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Gas Station Air Pumps | Typically located at fuel stations; may charge a fee; widely available | Fleet management, automotive services | Плюсы: Convenient, accessible; Конс: Potential fees, variable quality. |

| Tire Shops | Professional-grade compressors; often free for customers; trained staff | Tire maintenance, vehicle repair businesses | Плюсы: High-quality service; Конс: Limited hours, potential wait times. |

| Portable Air Compressors | Compact, user-friendly; powered by electricity or batteries; versatile | Small businesses, personal use | Плюсы: Mobility, cost-effective; Конс: Requires maintenance, limited capacity. |

| Bike Repair Stations | Focus on bicycles; often free; community-oriented locations | Cycling services, community engagement | Плюсы: Accessible, promotes cycling; Конс: Limited to bike tires, less common. |

| Automotive Service Centers | Comprehensive services including air filling; often part of larger chains | Fleet services, automotive repair | Плюсы: Multi-service options; Конс: May require appointments, potential higher costs. |

Gas station air pumps are commonly found at fuel stations and offer a convenient option for inflating vehicle tires. While many stations provide this service for free, some may charge a nominal fee. For B2B buyers, especially those managing fleets, the accessibility of these pumps can be a significant advantage. However, buyers should consider the potential variability in pump quality and reliability, which may impact the efficiency of tire maintenance.

Tire shops typically offer professional-grade air compressors and may provide free air filling services to customers. They are staffed by trained professionals who can ensure tires are inflated to the correct pressure, which is crucial for vehicle safety and performance. For B2B buyers, utilizing tire shops can lead to enhanced vehicle maintenance and reduced downtime. However, it’s essential to be aware of their operational hours and potential wait times during peak periods.

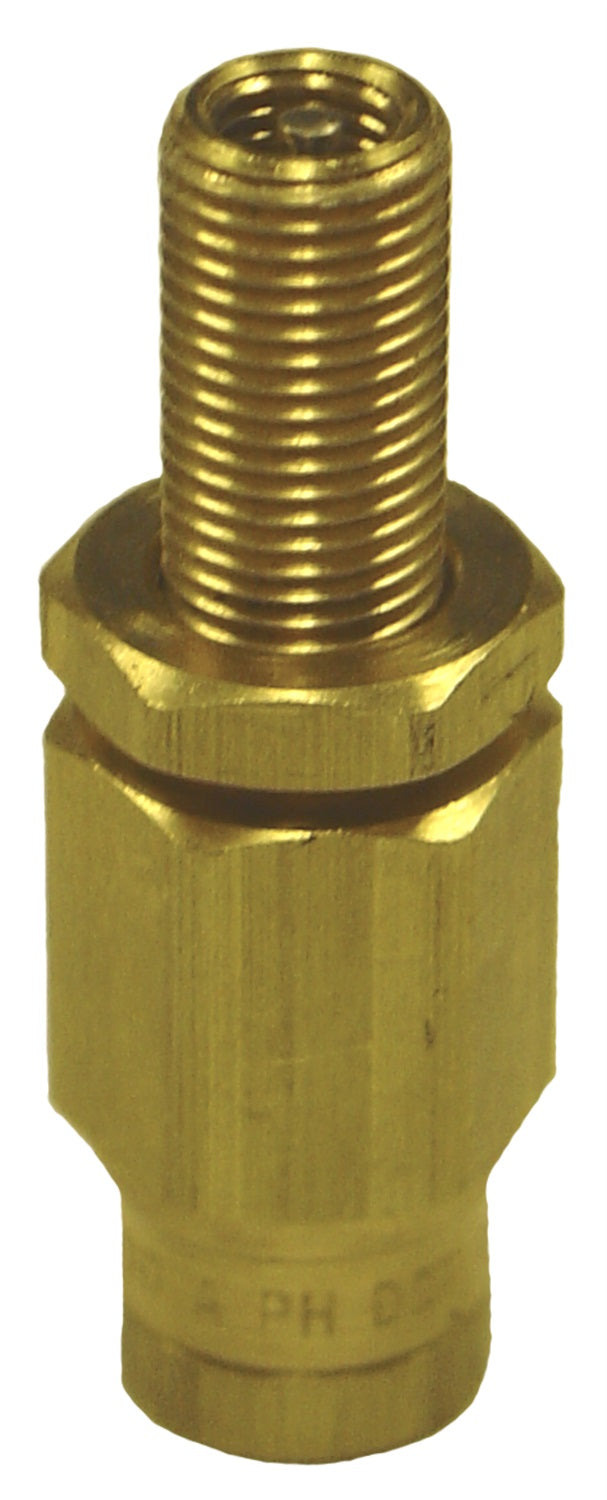

Illustrative image related to air filler near me

Portable air compressors are compact, user-friendly devices that can be powered by electricity or batteries, making them suitable for various applications. These compressors are particularly beneficial for small businesses or individuals who require flexibility in tire maintenance. While they can be a cost-effective solution, B2B buyers must consider the maintenance needs and limitations in capacity compared to larger, stationary compressors.

Bike repair stations focus on servicing bicycles and often provide free air for tires. These stations are typically located in public spaces and promote community engagement and cycling. For businesses involved in cycling services or community initiatives, partnering with or utilizing these stations can enhance visibility and customer satisfaction. However, their primary focus on bicycles means they are not suitable for those needing air for motor vehicles.

Automotive service centers offer a comprehensive range of services, including tire inflation. These centers are often part of larger chains, providing reliability and standardized services. For B2B buyers managing fleets or requiring regular vehicle maintenance, automotive service centers can be a one-stop shop. However, buyers should be prepared for possible appointment requirements and higher costs associated with full-service options.

| Промышленность/сектор | Specific Application of air filler near me | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive | Tire Inflation Stations | Reduces operational costs and enhances customer satisfaction by providing free air services. | Location accessibility, maintenance of air pumps, reliability of air supply. |

| Bicycle Repair Shops | Free Air Stations for Cyclists | Attracts more customers and fosters community goodwill by offering essential services. | Visibility, ease of use for cyclists, maintenance frequency. |

| Логистика и транспорт | Fleet Maintenance Facilities | Ensures vehicle safety and efficiency, reducing downtime and repair costs. | Proximity to major transport routes, equipment compatibility, service reliability. |

| Строительство | Equipment Maintenance | Maintains pneumatic tools and machinery, enhancing operational efficiency and safety on job sites. | Equipment compatibility, air pressure requirements, maintenance services. |

| Recreational Vehicle (RV) | RV Parks and Campgrounds | Provides added convenience for travelers, enhancing customer experience and loyalty. | Accessibility for large vehicles, service hours, pressure specifications. |

In the automotive sector, ‘air filler near me’ services are critical for tire inflation stations located at gas stations and repair shops. These stations reduce operational costs for businesses by eliminating the need for paid air services, thus improving customer satisfaction. B2B buyers in this industry should consider the accessibility and reliability of air supply, as well as the maintenance of air pumps to ensure consistent service delivery.

Bicycle repair shops often provide free air filling stations, attracting cyclists who require quick maintenance. By offering this service, shops can enhance customer loyalty and community engagement. For international buyers, particularly in developing regions, sourcing air pump systems that are easy to maintain and accessible for cyclists is crucial. Visibility and user-friendliness are key considerations to effectively serve the cycling community.

In logistics and transport, fleet maintenance facilities utilize nearby air filling services to ensure the safety and efficiency of their vehicles. Regular tire maintenance can significantly reduce downtime and repair costs, leading to improved operational efficiency. Businesses in this sector should prioritize the proximity of air filling stations to major transport routes and ensure compatibility with various vehicle types for seamless operations.

The construction industry relies heavily on pneumatic tools and machinery, making access to air filling services essential. Regular maintenance of these tools through adequate air supply enhances operational efficiency and safety on job sites. Buyers in this sector should focus on sourcing air filling solutions that meet specific air pressure requirements and ensure reliable service to minimize work disruptions.

RV parks and campgrounds that provide air filling services enhance the travel experience for guests. By offering convenient air inflation for tires, these facilities can attract more visitors and foster loyalty. Key considerations for B2B buyers in this industry include ensuring accessibility for larger vehicles and maintaining service hours that accommodate travelers’ needs.

Проблема: B2B buyers, especially those managing fleets or logistics companies, often face challenges locating reliable air fill stations. Inconsistent availability of air fill services can lead to unplanned downtime, negatively impacting operational efficiency. For instance, a delivery vehicle with low tire pressure may require immediate attention, but if the driver cannot find a nearby station offering free air, this could lead to delays and additional costs. Moreover, the stress of not knowing whether an air fill station is operational can be frustrating and time-consuming.

Решение: To alleviate this issue, businesses should leverage technology by utilizing dedicated apps and websites that provide updated maps of air fill locations. Platforms like FreeAirPump.com offer user-generated databases where businesses can search for air fill stations by entering their location. Additionally, companies can encourage their drivers to carry portable air compressors as a backup option. By investing in high-quality, battery-operated inflators, businesses can ensure that their vehicles can be serviced anywhere, thus reducing reliance on external air fill services and minimizing downtime.

Проблема: Many businesses find themselves frustrated with the rising costs associated with air filling services, especially in areas where gas stations charge for air. B2B buyers managing transportation services are particularly sensitive to these costs, as they can add up quickly over time. For instance, if a fleet of delivery trucks frequently requires air filling, the cumulative expense could significantly impact the overall budget.

Решение: One effective strategy for reducing these costs is to form partnerships with local gas stations and tire repair shops that offer free air filling services. By establishing relationships with these businesses, companies can negotiate bulk service agreements or loyalty programs that may provide discounts or incentives. Furthermore, encouraging employees to utilize portable air compressors can eliminate the need to stop at service stations altogether. Providing training on proper tire maintenance can also empower staff to ensure tires are filled correctly and efficiently, preventing unnecessary expenses.

Проблема: B2B buyers often encounter the problem of inconsistent air fill service quality. Some air fill stations may provide inadequate pressure or contaminated air, leading to potential tire damage. This inconsistency can have serious implications for businesses relying on vehicles for transportation and logistics, as it can compromise vehicle safety and performance. For example, a poorly inflated tire can lead to increased fuel consumption and higher risks of accidents.

Решение: To address this challenge, businesses should implement a vetting process for air fill stations used by their drivers. Creating a checklist of preferred locations based on service quality, maintenance, and customer feedback can help ensure that employees only utilize reliable air fill services. Additionally, companies can invest in training programs for staff on how to evaluate air fill quality. This includes checking tire pressure with reliable gauges and understanding the importance of using clean, uncontaminated air for vehicle maintenance. By fostering a culture of accountability and awareness, businesses can mitigate risks associated with poor air filling practices and enhance overall fleet performance.

In the context of air fillers, particularly for tire inflation, several materials are commonly utilized. Each material possesses unique properties that influence its performance, cost, and suitability for various applications. Below, we explore four prevalent materials: rubber, thermoplastic elastomers (TPE), metal, and composite materials.

Основные свойства: Rubber is known for its excellent elasticity and flexibility, making it ideal for sealing and maintaining air pressure. It can withstand a temperature range of -40°C to 120°C and has good pressure resistance.

Плюсы и минусы: Rubber is durable and cost-effective, often the go-to choice for tire inflation hoses and seals. However, it can degrade over time due to exposure to UV light and ozone, which can lead to cracks and reduced lifespan.

Влияние на применение: Rubber’s compatibility with air and various tire types makes it suitable for automotive applications. However, its degradation can affect performance, particularly in regions with extreme weather conditions.

Соображения для международных покупателей: Buyers from regions like Africa and South America should be aware of local climatic conditions that may accelerate rubber degradation. Compliance with standards such as ASTM D2000 is crucial for ensuring product quality.

Основные свойства: TPE combines the properties of rubber and plastic, offering excellent flexibility and resistance to chemicals and UV light. It typically operates effectively within a temperature range of -30°C to 80°C.

Illustrative image related to air filler near me

Плюсы и минусы: TPE is lightweight and can be produced in various colors, making it aesthetically appealing. However, it may not be as durable as traditional rubber under high-pressure conditions, which could limit its use in heavy-duty applications.

Влияние на применение: TPE’s chemical resistance makes it suitable for applications involving various fluids, including air. Its versatility allows for use in both automotive and non-automotive applications.

Соображения для международных покупателей: Buyers in Europe may prefer TPE due to its recyclability and compliance with environmental regulations. Understanding local regulations regarding materials can help in selecting appropriate TPE formulations.

Основные свойства: Metals like aluminum and stainless steel offer high strength and durability, with excellent pressure ratings. They can withstand extreme temperatures and resist corrosion, making them suitable for various environments.

Плюсы и минусы: Metal air fillers are robust and long-lasting, providing excellent sealing capabilities. However, their higher cost and weight can be a disadvantage in applications where portability is essential.

Влияние на применение: Metal is often used in high-performance applications where reliability is critical, such as in heavy machinery or commercial vehicles. Its compatibility with high-pressure systems makes it a preferred choice for industrial applications.

Соображения для международных покупателей: Buyers from the Middle East, where high temperatures are common, should consider corrosion-resistant metals. Compliance with standards such as DIN EN 10088 for stainless steel is essential for ensuring quality.

Основные свойства: Composite materials combine various substances to enhance strength while reducing weight. They can offer good pressure resistance and are often designed to withstand harsh environmental conditions.

Плюсы и минусы: Composites can be tailored for specific applications, providing flexibility in design. However, they can be more expensive to manufacture and may require specialized processing techniques.

Illustrative image related to air filler near me

Влияние на применение: Composites are suitable for specialized applications where weight savings are critical, such as in aerospace or high-performance vehicles. Their ability to withstand extreme conditions makes them versatile.

Соображения для международных покупателей: Buyers in regions with stringent environmental regulations should consider composites that meet local standards. Understanding the manufacturing processes and certifications is crucial for ensuring compliance.

| Материал | Typical Use Case for air filler near me | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire inflation hoses and seals | Экономичность и долговечность | Degrades under UV and ozone exposure | Низкий |

| Thermoplastic Elastomers | Lightweight tire repair applications | Chemical and UV resistance | Less durable under high pressure | Средний |

| Металл | Heavy-duty air filler applications | High strength and pressure rating | Higher cost and weight | Высокий |

| Композит | Specialized high-performance applications | Tailored strength-to-weight ratio | Более дорогие и сложные в производстве | Высокий |

This analysis provides a comprehensive overview of the materials used in air fillers, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Manufacturing air fillers, particularly those designed for tire inflation, involves several critical stages that ensure the product meets performance and safety standards. The main processes include material preparation, forming, assembly, and finishing. Each stage plays a vital role in the overall quality of the final product.

The manufacturing process begins with material preparation. Common materials for air fillers include durable plastics, metals, and rubber. Suppliers typically source these materials from certified vendors who meet international quality standards.

Once the materials are procured, they undergo inspection for quality assurance. This includes checking for defects, consistency in material composition, and compliance with specifications. Effective material preparation is essential for ensuring that the air fillers can withstand high pressures and rough handling during use.

After material preparation, the forming stage follows. This is where the raw materials are shaped into the desired components of the air filler. Common techniques include injection molding for plastic parts and die-casting for metal components.

Injection molding allows for high precision and the ability to produce complex shapes, which is crucial for ergonomic designs in portable air compressors. Die-casting, on the other hand, is often used for making sturdy metal components that require durability.

The choice of forming technique can significantly affect the performance and lifespan of the air filler, making it essential for manufacturers to select the most suitable methods for their designs.

The assembly process is where all the formed components come together to create the final product. This stage may involve manual labor or automated assembly lines, depending on the scale of production.

During assembly, manufacturers must ensure that all parts fit correctly and function together seamlessly. This often requires the use of specialized tools and fixtures. Quality checks are typically integrated into the assembly line to catch any defects early in the process, ensuring that only high-quality products reach the market.

Finishing processes are crucial for enhancing the aesthetic appeal and functional performance of air fillers. This stage may include surface treatments such as painting, polishing, or coating to improve durability and resistance to environmental factors.

Finishing not only enhances the appearance of the product but also helps in preventing corrosion and wear, which are critical for products exposed to outdoor conditions. Manufacturers must adhere to specific guidelines during this stage to maintain quality standards.

Quality assurance (QA) is a fundamental aspect of manufacturing air fillers. It ensures that products meet international standards and customer expectations. The QA process typically involves several checkpoints throughout the manufacturing cycle.

For air filler manufacturers, adhering to international quality standards is essential. ISO 9001 is one of the most recognized standards, focusing on quality management systems. Compliance with ISO 9001 indicates that the manufacturer has a robust system for ensuring quality throughout the production process.

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with European regulations or API standards for products used in the petroleum industry may be relevant. These certifications provide assurance to B2B buyers that the products meet stringent safety and performance criteria.

Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include:

Входящий контроль качества (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before they are used in production.

Внутрипроцессный контроль качества (IPQC): Throughout the manufacturing process, various tests are conducted to monitor the production line’s efficiency and product quality.

Окончательный контроль качества (ОКК): Once the air fillers are assembled, they undergo final inspections and testing. This may include pressure tests to check for leaks and functional tests to ensure they operate as intended.

These checkpoints help identify defects early, reducing waste and ensuring that only high-quality products reach the market.

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are several effective strategies:

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can schedule on-site visits to evaluate manufacturing practices, equipment, and QC measures.

During these audits, buyers should look for compliance with international standards, the presence of quality control documentation, and the overall organization of the manufacturing facility. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

Requesting quality control reports from suppliers is another method for verifying quality practices. These reports should detail the results of various quality checks and tests conducted during production.

Buyers should also inquire about the methodologies used for testing and any corrective actions taken in response to identified issues. Comprehensive reports can offer reassurance regarding the supplier’s ability to maintain quality standards consistently.

Engaging third-party inspection services can further enhance the verification process. These independent organizations can conduct thorough inspections of the manufacturing facility and product quality, providing an unbiased assessment.

Illustrative image related to air filler near me

Third-party inspectors can also verify compliance with international standards and certifications, adding an extra layer of confidence for B2B buyers.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in verifying quality control. Factors such as differing regulations, quality expectations, and logistical considerations can complicate the purchasing process.

Different regions have varying standards and regulations that can affect the quality assurance process. Buyers should familiarize themselves with local regulations regarding air fillers and ensure that suppliers comply with these standards.

Additionally, understanding the nuances of certification processes in different regions can help buyers make informed decisions. For instance, while CE marking is crucial for European markets, other regions may have their own specific requirements that must be met.

Cross-border transactions can pose challenges in quality verification due to distance and potential language barriers. Buyers should establish clear communication channels with suppliers and consider using local representatives or agents to facilitate the process.

Furthermore, understanding the logistics of transporting goods across borders can help mitigate risks associated with product quality during transit. Ensuring that products are properly packaged and handled can prevent damage that could compromise quality.

By being proactive and informed about manufacturing processes and quality assurance practices, B2B buyers can make confident decisions when sourcing air fillers, ensuring they receive high-quality products that meet their needs.

In the competitive landscape of B2B procurement, finding reliable sources for essential equipment like air fillers can significantly impact operational efficiency and cost management. This guide offers a practical checklist for international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to effectively source air fillers in their vicinity.

Before initiating the sourcing process, clearly define your specific needs regarding air fillers. Consider the type of air filler required—whether for automotive, industrial, or recreational purposes. Understanding your volume requirements, pressure specifications, and any additional features will streamline your search and ensure compatibility with your existing operations.

Conduct thorough research to identify potential suppliers offering air fillers near your location. Utilize online directories, local trade associations, and industry forums to compile a list of businesses. Pay attention to their reputation, customer reviews, and the range of products they offer. Engaging with local suppliers can facilitate quicker delivery and lower shipping costs.

Illustrative image related to air filler near me

It is essential to vet suppliers for credibility and reliability. Request documentation such as business licenses, product certifications, and any relevant industry compliance standards. This step ensures that you are partnering with reputable companies that meet the necessary safety and quality regulations, reducing the risk of procurement issues.

Before finalizing your supplier, request samples or demonstrations of their air fillers. This hands-on approach allows you to assess the quality, functionality, and ease of use of the products. Additionally, observing the equipment in action can provide insights into its performance and suitability for your specific needs.

Once you have identified suitable suppliers, compare their pricing, payment terms, and warranty policies. Look for transparency in pricing structures, including any hidden costs related to shipping or handling. Understanding the total cost of ownership is crucial for effective budgeting and ensuring you receive value for your investment.

Illustrative image related to air filler near me

After evaluating your options, engage in negotiations with your preferred supplier. Clearly outline your expectations regarding delivery timelines, quality standards, and support services. A well-defined contract will protect both parties and provide a framework for addressing potential issues that may arise during the procurement process.

Building a long-term relationship with your supplier can yield benefits beyond your immediate procurement needs. Regular communication fosters trust and opens up opportunities for better pricing, priority service, and access to new products. Consider establishing a preferred vendor status if the supplier meets your expectations consistently.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for air fillers, ensuring they make informed decisions that align with their operational requirements and budget considerations.

Understanding the cost structure of sourcing air fillers involves several critical components. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to air filler near me

Материалы: The choice of materials significantly impacts the overall cost. High-quality materials may increase initial expenses but can lead to better performance and longevity, ultimately affecting the total cost of ownership (TCO).

Труд: Labor costs vary depending on the region and the complexity of production. In regions with higher wage standards, labor costs can contribute significantly to the overall expense.

Производственные накладные расходы: This includes costs related to facilities, equipment, and utilities. Efficient manufacturing processes can help minimize these overheads, but initial investments in technology may be necessary.

Инструментальная оснастка: Custom tooling for specific air fillers can be a substantial upfront cost. However, shared tooling can reduce these costs if multiple buyers are interested in similar specifications.

Контроль качества (QC): Implementing strict QC measures ensures product reliability but can increase costs. Certifications (e.g., ISO) may also add to expenses, depending on the market requirements.

Логистика: Transportation costs must be factored into the pricing analysis. Factors such as distance, mode of transport, and Incoterms can influence logistics costs.

Маржа: Finally, suppliers will build a profit margin into their pricing, which varies based on market conditions, competition, and perceived value.

Several factors influence pricing in the air filler market, particularly for international buyers:

Объем/МОК: Minimum order quantities (MOQs) can impact pricing significantly. Higher volumes typically lead to lower per-unit costs. Negotiating for bulk purchases can yield substantial savings.

Технические характеристики/настройка: Custom specifications often lead to increased costs. Buyers should balance their needs for customization with the potential for higher prices.

Материалы: The quality of materials used in production directly influences price. Buyers should assess whether premium materials are necessary for their application or if more economical options suffice.

Качество/сертификация: Products with recognized certifications may command higher prices. However, they often provide assurance of quality, which can justify the investment.

Факторы поставщика: Supplier reliability, reputation, and service levels can also affect pricing. Established suppliers may charge more but offer better support and quality assurance.

Инкотермс: The chosen Incoterms can drastically change the total cost. Buyers should understand their responsibilities under each term to avoid unexpected charges.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness:

Переговоры: Engage suppliers in discussions about pricing and terms. Leverage your purchasing power, especially if ordering in bulk.

Экономическая эффективность: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like maintenance, durability, and warranty when assessing value.

Нюансы ценообразования: Be aware of currency fluctuations and trade tariffs that may affect pricing when sourcing internationally. Understanding local market conditions can provide leverage in negotiations.

Отношения с поставщиками: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products or services.

Research and Comparison: Always compare multiple suppliers and their offerings. Understanding the market landscape can provide insights into fair pricing and quality benchmarks.

Prices for air fillers can vary widely based on the aforementioned factors. This analysis provides a framework for understanding costs and pricing dynamics but should be supplemented with specific market research and supplier quotes to ensure accurate budgeting and sourcing decisions.

In the quest for efficient tire inflation solutions, B2B buyers often encounter various alternatives to traditional air fillers available at local locations. Understanding these alternatives can aid in making informed decisions that align with operational needs and budget constraints. Below is a comparative analysis of ‘Air Filler Near Me’ against alternative solutions, such as portable air compressors and gas station air pumps.

| Сравнительный аспект | ‘Air Filler Near Me’ | Портативный воздушный компрессор | Gas Station Air Pumps |

|---|---|---|---|

| Производительность | Generally reliable; location-dependent | High pressure and consistent output | Varies; may be limited by equipment quality |

| Стоимость | Как правило, бесплатно или по низкой цене | $30-$200 one-time purchase | $0.75 to $5 per use |

| Простота реализации | Easy to locate via apps/maps | Requires initial purchase; easy to use | Usually straightforward but may involve a wait |

| Техническое обслуживание | Minimal; depends on location | Requires regular maintenance | Little to none, but may vary by station |

| Лучший пример использования | Quick, local, and convenient | Ideal for remote locations and emergencies | Good for occasional users near stations |

Портативный воздушный компрессор

Portable air compressors provide an excellent alternative for businesses that need a reliable inflation method without dependency on external locations. They offer high pressure and can quickly inflate tires, making them suitable for fleet vehicles or emergency situations. The initial investment can be higher, ranging from $30 to $200, but they save money in the long run, especially for companies that frequently require tire inflation. However, maintenance is essential to ensure optimal performance, and users must consider storage space.

Illustrative image related to air filler near me

Gas Station Air Pumps

Gas station air pumps represent a conventional solution, often available at various locations. These machines are easy to use and can accommodate different tire sizes. However, costs can vary widely, typically ranging from $0.75 to $5 per use, which may add up over time for businesses with a large fleet. Additionally, the reliability of these machines can be inconsistent, and users may experience long wait times during peak hours. This solution is best for businesses located near gas stations that do not require frequent tire inflation.

When selecting the appropriate tire inflation solution, B2B buyers should consider several factors, including frequency of use, budget, and operational requirements. For businesses operating in remote areas or with a high volume of vehicles, investing in a portable air compressor may prove advantageous. Conversely, for companies situated in urban environments with easy access to gas stations, relying on ‘Air Filler Near Me’ services might suffice. Ultimately, understanding the unique needs of your business will guide you toward the most effective tire inflation strategy.

Understanding the technical specifications of air fillers is crucial for B2B buyers, as these properties can significantly impact performance and compatibility with various applications. Here are some essential specifications to consider:

Illustrative image related to air filler near me

Состав материала

The construction material of air fillers can vary, typically ranging from high-density plastics to metals like aluminum or stainless steel. The choice of material affects durability, weight, and resistance to environmental factors. For instance, metal air fillers may offer better longevity in harsh climates, making them suitable for outdoor applications.

Номинальное давление

This specification indicates the maximum pressure the air filler can withstand. It is essential for ensuring that the filler can safely operate within the required pressure range without risk of failure or accidents. B2B buyers should consider the operational environment to select air fillers that meet their specific pressure requirements.

Flow Rate

The flow rate, often measured in liters per minute (LPM), determines how quickly air can be delivered. A higher flow rate is beneficial for applications requiring rapid inflation or deflation, such as tire filling. Evaluating flow rates helps buyers match the air filler’s capabilities with their operational needs.

Size and Portability

The dimensions and weight of the air filler are critical, particularly for businesses that require mobility or limited storage space. Compact and lightweight models are preferable for on-the-go applications, whereas larger units may be more suited for stationary use in workshops or repair stations.

Energy Source

Air fillers can be powered by electricity, batteries, or manual pumps. Understanding the energy source is vital for operational planning, especially in areas with limited access to power. Electric models may offer higher efficiency and ease of use, while manual options can be more versatile in remote locations.

Durability and Warranty

Assessing the durability of an air filler involves looking at its resistance to wear, temperature fluctuations, and chemical exposure. A robust warranty can also indicate the manufacturer’s confidence in the product’s longevity, providing peace of mind for B2B buyers.

Familiarity with industry jargon is essential for effective communication and negotiation in the air filler market. Here are some common terms you should know:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that may be marketed by another manufacturer. For air fillers, OEMs typically provide parts that are critical for maintaining equipment used in various industries. Understanding OEM relationships can help buyers ensure compatibility and quality.

MOQ (минимальное количество заказа)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers to understand as it can affect inventory management and overall costs. Negotiating MOQs can lead to better pricing but may require larger upfront purchases.

RFQ (запрос котировок)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. In the air filler market, using RFQs can streamline the procurement process and ensure that buyers receive competitive pricing and terms.

Инкотермс (международные коммерческие термины)

These are standardized trade terms used in international shipping to define the responsibilities of buyers and sellers regarding transportation costs, risk, and insurance. Familiarity with Incoterms helps B2B buyers mitigate risks and clarify obligations in cross-border transactions.

Время выполнения

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for supply chain planning, as longer lead times can affect production schedules and inventory levels.

Certification Standards

Many air fillers must comply with specific industry standards or certifications, such as ISO or CE marks. These certifications ensure that products meet quality and safety requirements, providing assurance to buyers about the reliability of the equipment.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions and enhance their purchasing strategies in the air filler market.

The air filler sector is experiencing significant shifts influenced by various global drivers. One key trend is the increasing demand for convenience among consumers, particularly in emerging markets such as Africa, South America, and parts of Europe. With more urbanization, the need for accessible air filling stations at gas stations and tire shops is on the rise. Additionally, the proliferation of mobile applications that allow users to locate nearby air filling stations is transforming how consumers interact with these services.

Moreover, the rise in e-commerce is driving B2B suppliers to enhance their online presence, offering portable air compressors and inflators directly to businesses and consumers. The trend of “smart” devices is also emerging, with tech-savvy solutions integrating IoT capabilities, enabling users to monitor tire pressure via their smartphones. This innovation is particularly appealing to international B2B buyers looking for cutting-edge solutions in vehicle maintenance.

Furthermore, sustainability is becoming a crucial factor in sourcing decisions. Buyers are increasingly interested in suppliers that prioritize eco-friendly practices, such as using recycled materials in the manufacturing of air fillers. Understanding these dynamics allows B2B buyers to make informed decisions that align with market trends and consumer expectations.

Sustainability is a growing priority in the ‘air filler near me’ sector, driven by environmental concerns and consumer preferences for greener products. The production and disposal of traditional air fillers can have significant environmental impacts, prompting buyers to seek alternatives that minimize their carbon footprint.

Ethical sourcing is crucial, as buyers are now looking for suppliers who adhere to responsible practices throughout their supply chains. This includes sourcing materials from certified sustainable sources and ensuring fair labor practices. Green certifications, such as ISO 14001 for environmental management, are becoming essential for suppliers aiming to attract international buyers who prioritize sustainability.

Additionally, innovative materials, such as biodegradable plastics and recycled rubber, are gaining traction in the market. By investing in these sustainable options, B2B buyers not only meet regulatory requirements but also align with the increasing consumer demand for eco-friendly products. This commitment to sustainability can serve as a competitive advantage in the marketplace.

The air filler market has evolved significantly over the past few decades. Initially, air filling was a manual process dominated by tire shops and gas stations, often involving cumbersome, mechanical devices. As vehicle ownership surged globally, particularly in developing regions, the demand for accessible air filling solutions grew.

The introduction of portable air compressors revolutionized the market, providing convenience for consumers and businesses alike. With technological advancements, these devices have become more compact, efficient, and user-friendly, catering to the needs of modern consumers.

Today, the integration of digital technology into air filling services marks a new era, with mobile apps and smart devices playing a pivotal role in enhancing user experience. This evolution reflects broader trends in consumer behavior, emphasizing convenience, accessibility, and sustainability, which are essential for B2B buyers navigating the current market landscape.

1. How do I find reliable suppliers for air fillers in my region?

To locate trustworthy suppliers of air fillers, begin by leveraging online B2B marketplaces such as Alibaba, TradeIndia, or Global Sources. Utilize search filters to narrow down your results by region, ensuring you focus on suppliers from Africa, South America, the Middle East, or Europe. Additionally, consider attending industry trade shows, which provide opportunities to meet suppliers face-to-face and assess their offerings. Always request references and verify their business credentials to ensure reliability before making any commitments.

2. What factors should I consider when vetting air filler suppliers?

When evaluating potential suppliers, consider their industry experience, product quality, and certifications (like ISO 9001). Review their production capabilities, lead times, and customer service responsiveness. It’s also crucial to check their financial stability and reputation by reading reviews or seeking testimonials from previous clients. Ensure they have a clear understanding of international shipping regulations, especially if you’re importing from different continents, which can impact delivery timelines and costs.

3. What is the typical minimum order quantity (MOQ) for air fillers?

The minimum order quantity (MOQ) for air fillers can vary significantly based on the supplier and the product specifications. Generally, MOQs can range from 100 to 1,000 units. Suppliers may set higher MOQs for customized or specialized products. When negotiating, communicate your needs clearly and explore the possibility of smaller trial orders to establish a working relationship without committing to large quantities upfront.

4. How can I ensure the quality of air fillers from international suppliers?

To ensure quality, request samples before placing a bulk order. Conduct a thorough quality assurance (QA) check, which may include testing for functionality, durability, and compliance with international standards. Additionally, consider third-party inspections during production or prior to shipment to verify that the products meet your specifications. Establishing clear quality standards and expectations in your contract can also help mitigate risks.

5. What payment terms are common in international B2B transactions for air fillers?

Common payment terms in international B2B transactions include letters of credit (LC), advance payments, or payment upon delivery. Some suppliers may accept partial payments upfront, with the balance due upon receipt of goods. It’s essential to clarify payment methods and timelines in your contract, considering factors like currency fluctuations and transaction fees. Building a relationship with your supplier can also facilitate more favorable payment terms over time.

6. How do logistics and shipping impact the procurement of air fillers?

Logistics and shipping play a crucial role in the procurement process, affecting lead times, costs, and product availability. When sourcing air fillers internationally, consider shipping options such as air freight for faster delivery or sea freight for cost-effectiveness. Evaluate potential customs duties and regulations that may affect your shipments, and work with reliable freight forwarders to ensure smooth transportation. Clear communication with your supplier regarding shipping terms (Incoterms) is essential to avoid misunderstandings.

7. What customization options are available for air fillers?

Many suppliers offer customization options for air fillers, including branding, color, size, and functionality tailored to specific market needs. When discussing customization, provide detailed specifications and consider the impact on production time and cost. Some suppliers may have limitations on the extent of customization based on their manufacturing capabilities, so it’s advisable to inquire about these aspects early in the negotiation process.

8. How can I stay informed about market trends in air fillers?

To keep abreast of market trends in air fillers, subscribe to industry publications, attend trade shows, and engage with online forums or professional networks related to your sector. Following key industry players on social media and joining relevant LinkedIn groups can also provide insights into innovations and changing consumer preferences. Additionally, consider utilizing market research reports that analyze trends and forecasts, helping you make informed procurement decisions.

Домен: freeairpump.com

Зарегистрирован: 2012 (13 лет)

Введение: Map of places that provide free air for tires; over 12k locations in the U.S.; user-generated database; ability to submit new locations; search by device location or address; indicates bike repair stations and free air for autos; suggests portable air compressors; mentions common places offering free air: tire shops, car repair stations, bike shops, and specific gas station chains (Co-op, Family E…

Домен: yelp.com

Зарегистрирован: 2003 (22 года)

Введение: This company, Yelp – User Reviews, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Домен: freeairnear.me

Registered: 2023 (2 years)

Введение: There are 282 locations in 106 cities in Texas offering free air pumps for tires. In 64 spots, free air is available for bicycles only, while 218 businesses provide free air for cars and bikes. 171 gas stations offer free air for tires, including QuikTrip (123), Shell (18), Exxon (13), Texaco (5), Chevron (3), RaceTrac (3), 7-Eleven (2), Citgo (1), Conoco (1), Mobil (1), and OnCue (1). Gas station…

Домен: locations.oreillyauto.com

Зарегистрирован: 1996 (29 лет)

Введение: FREE Brake Pads with purchase of 2 Rotors. Discount applied automatically in Cart. Exclusions apply. FREE NEXT DAY DELIVERY & FREE PICKUP IN STORE.

Домен: amerigas.com

Зарегистрирован: 1995 (30 лет)

Введение: AmeriGas offers propane refill and tank exchange locations, allowing customers to swap out empty propane grill tanks for full ones at local gas stations, hardware stores, and convenience stores. They provide easy and convenient propane cylinder refills, where customers can bring their empty cylinders to be topped off safely. Local AmeriGas offices assist with service or account questions, emergenc…

As the global demand for efficient and cost-effective solutions increases, the strategic sourcing of air fillers—both free and paid—presents significant opportunities for international B2B buyers. Understanding local regulations and market dynamics is crucial, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging resources like crowdsourced databases and location maps, businesses can identify optimal suppliers and locations for air fillers, ensuring they meet both customer needs and cost constraints.

Furthermore, the growing trend towards sustainability and cost savings makes it imperative for companies to explore partnerships with local tire shops, gas stations, and auto parts retailers that offer free air services. This not only enhances customer satisfaction but also fosters community engagement.

Looking ahead, international B2B buyers should prioritize strategic sourcing initiatives that encompass a diverse range of suppliers. By doing so, they can capitalize on market opportunities while ensuring they remain competitive in an evolving landscape. Engage with local suppliers today to enhance your supply chain resilience and position your business for future growth in the air filler market.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.