In today’s global marketplace, understanding the intricacies of cold tire inflation pressure is critical for businesses looking to optimize their fleet operations and enhance safety standards. Many B2B buyers face the challenge of sourcing reliable information and products that ensure their vehicles are operating at peak efficiency. This guide offers a comprehensive exploration of cold tire inflation pressure, covering essential topics such as the science behind tire pressure dynamics, the impact of temperature fluctuations, and the implications for vehicle performance.

We delve into various tire types and applications, providing insights into how proper inflation can affect tire longevity and fuel economy. Moreover, the guide offers practical advice on vetting suppliers, understanding pricing structures, and identifying the best solutions tailored to the unique demands of your region.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—this resource is designed to empower you with the knowledge necessary for informed purchasing decisions. By equipping your organization with a deeper understanding of cold tire inflation pressure, you can enhance operational efficiencies, reduce costs, and ensure the safety and reliability of your fleet.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Standard Cold Inflation | Recommended pressure when tires are at ambient temperature | Fleet management, logistics, transportation | Плюсы: Optimizes fuel efficiency and tire longevity. Конс: Requires regular monitoring to maintain accuracy. |

| Seasonal Cold Inflation | Adjusted pressure for seasonal temperature changes | Agriculture, construction vehicles | Плюсы: Enhances performance in varying climates. Конс: May require frequent adjustments based on weather. |

| Load-Specific Cold Inflation | Tailored pressure based on load capacity | Heavy-duty transport, construction | Плюсы: Improves safety and handling under load. Конс: Miscalculations can lead to tire damage or blowouts. |

| High-Performance Cold Inflation | Higher pressure for performance tires | Racing, luxury vehicle markets | Плюсы: Maximizes handling and responsiveness. Конс: Can lead to a harsher ride and increased tire wear. |

| Eco-Friendly Cold Inflation | Optimized for fuel efficiency and reduced emissions | Green logistics, eco-friendly fleets | Плюсы: Reduces overall carbon footprint. Конс: May not suit all vehicle types or driving conditions. |

Standard cold inflation pressure refers to the tire pressure recommended by manufacturers when the tires are at ambient temperature. This pressure is crucial for ensuring optimal performance, fuel efficiency, and tire longevity. In B2B contexts, particularly for fleet management, maintaining this pressure is essential to minimize operational costs and maximize vehicle uptime. Regular monitoring is necessary, as neglecting this can lead to underperformance and increased fuel consumption.

Seasonal cold inflation pressure adjustments are vital for vehicles operating in regions with significant temperature fluctuations. These adjustments enhance vehicle performance and safety, particularly in agriculture and construction sectors where equipment often operates in varying climates. B2B buyers should consider the costs associated with frequent pressure checks and adjustments, as well as the potential benefits of improved handling and reduced wear on tires.

Load-specific cold inflation pressure is tailored to the weight each tire must support. This is especially relevant for heavy-duty transport and construction vehicles. Properly inflated tires under load enhance safety and handling, reducing the risk of blowouts. For B2B buyers, understanding the specifications for load capacity is crucial to avoid costly accidents and ensure compliance with safety regulations.

High-performance cold inflation pressure is designed for vehicles that require enhanced handling and responsiveness, such as racing or luxury vehicles. This pressure setting can significantly improve the driving experience but may lead to a harsher ride and increased tire wear. B2B buyers in the automotive or racing sectors should weigh the benefits of improved performance against the potential for higher maintenance costs.

Eco-friendly cold inflation pressure focuses on optimizing tire pressure to enhance fuel efficiency and reduce emissions. This approach is particularly relevant for businesses aiming to minimize their carbon footprint, such as green logistics companies. While this strategy can lead to long-term savings and an improved public image, B2B buyers must ensure that the selected tires and vehicles are compatible with eco-friendly practices, as not all models may deliver the desired results.

| Промышленность/сектор | Specific Application of what is cold tire inflation pressure | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Transportation & Logistics | Ensuring optimal tire pressure for fleet vehicles | Improved fuel efficiency and reduced operational costs | Reliable tire pressure monitoring systems and maintenance services |

| Сельское хозяйство | Maintaining proper tire inflation in agricultural machinery | Enhanced equipment performance and reduced tire wear | Access to specialized agricultural tires and inflation equipment |

| Строительство | Monitoring tire pressure in heavy construction vehicles | Increased safety and reduced downtime due to tire failures | Durable tires suited for rough terrain and inflation monitoring tools |

| Mining | Using cold tire inflation pressure for mining trucks and equipment | Enhanced load capacity and fuel efficiency | Heavy-duty tires with proper specifications for mining conditions |

| Automotive Manufacturing | Implementing quality control for tire pressure during production | Consistent product quality and safety assurance | Compliance with international tire safety standards and testing equipment |

In the transportation and logistics sector, maintaining cold tire inflation pressure is crucial for fleet management. Fleet operators benefit from improved fuel efficiency and reduced operational costs when tires are properly inflated. Underinflated tires lead to increased rolling resistance, which can significantly raise fuel consumption. International buyers should consider sourcing reliable tire pressure monitoring systems and maintenance services to ensure ongoing compliance with recommended pressure levels, especially in regions with extreme temperature fluctuations.

In agriculture, maintaining the correct cold tire inflation pressure is vital for the performance of tractors and other machinery. Properly inflated tires enhance traction, reduce soil compaction, and extend tire life, ultimately improving operational efficiency. Buyers in this sector should focus on accessing specialized agricultural tires designed for varying field conditions, along with inflation equipment that can withstand harsh environments. This ensures that machinery operates effectively, minimizing downtime during critical planting and harvesting periods.

For the construction industry, monitoring cold tire inflation pressure in heavy vehicles is essential for safety and efficiency. Proper tire inflation reduces the risk of blowouts and enhances vehicle stability, which is critical on uneven terrain. Buyers should prioritize sourcing durable tires that meet the specific requirements of construction applications, along with reliable inflation monitoring tools. This attention to detail can lead to increased safety and reduced downtime, ultimately benefiting project timelines and budgets.

In mining, maintaining correct cold tire inflation pressure in trucks and equipment is crucial for optimizing load capacity and fuel efficiency. Overinflated or underinflated tires can lead to increased wear and tear, affecting overall productivity. Buyers in the mining sector should seek heavy-duty tires with specifications tailored to harsh mining conditions, along with robust inflation monitoring solutions. This ensures that equipment operates at peak performance, reducing the likelihood of costly operational disruptions.

In automotive manufacturing, implementing strict quality control measures for tire pressure during production is essential. Ensuring that tires meet the recommended cold inflation pressure helps maintain consistent product quality and safety standards. International buyers should consider compliance with global tire safety regulations and invest in advanced testing equipment to guarantee that tires are produced to specification. This commitment to quality not only enhances brand reputation but also reduces the risk of recalls and liability issues.

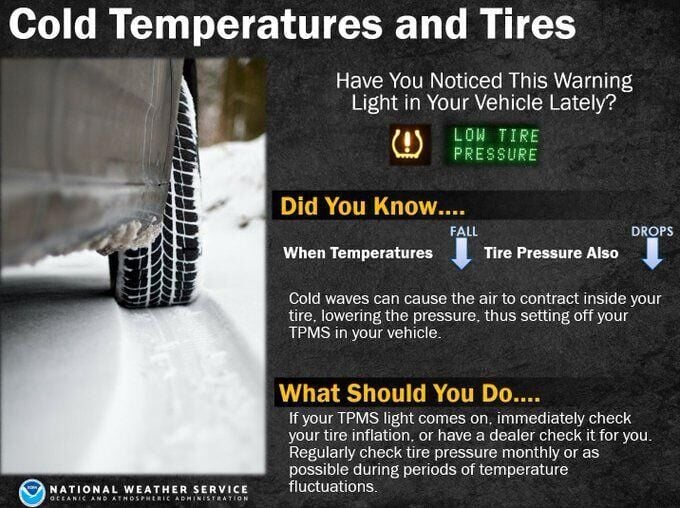

Проблема: Many B2B buyers in the automotive or logistics sectors struggle with fluctuating tire pressures due to temperature changes. For instance, a fleet manager in Brazil might find that tire pressures drop significantly during the cooler months, leading to increased fuel consumption and reduced vehicle handling. This not only affects safety but also results in higher operating costs, as under-inflated tires can lead to premature wear and costly replacements. These challenges are compounded in regions with extreme temperature variations, making it critical for businesses to maintain optimal tire pressure.

Решение: To address this issue, fleet managers should implement a proactive tire pressure monitoring system (TPMS) that alerts them when tire pressure deviates from the recommended cold inflation levels. This technology allows for real-time monitoring and data collection, ensuring that tire pressures are adjusted according to the ambient temperature. Additionally, establishing a routine for checking tire pressures in cooler conditions before dispatching vehicles can significantly mitigate these issues. Fleet managers should educate their drivers on the importance of checking tire pressures regularly and provide them with easy access to inflation tools, ensuring that all vehicles are properly inflated before hitting the road.

Проблема: B2B buyers, especially those managing vehicle fleets or automotive service centers, often face confusion regarding the specifications for cold tire inflation pressure. Misinterpretation of manufacturer recommendations can lead to either over-inflation or under-inflation of tires. For example, a fleet operating in the Middle East may mistakenly inflate tires based on hot conditions, resulting in poor handling and increased risk of blowouts. This can have severe implications for safety and operational efficiency, especially when transporting goods.

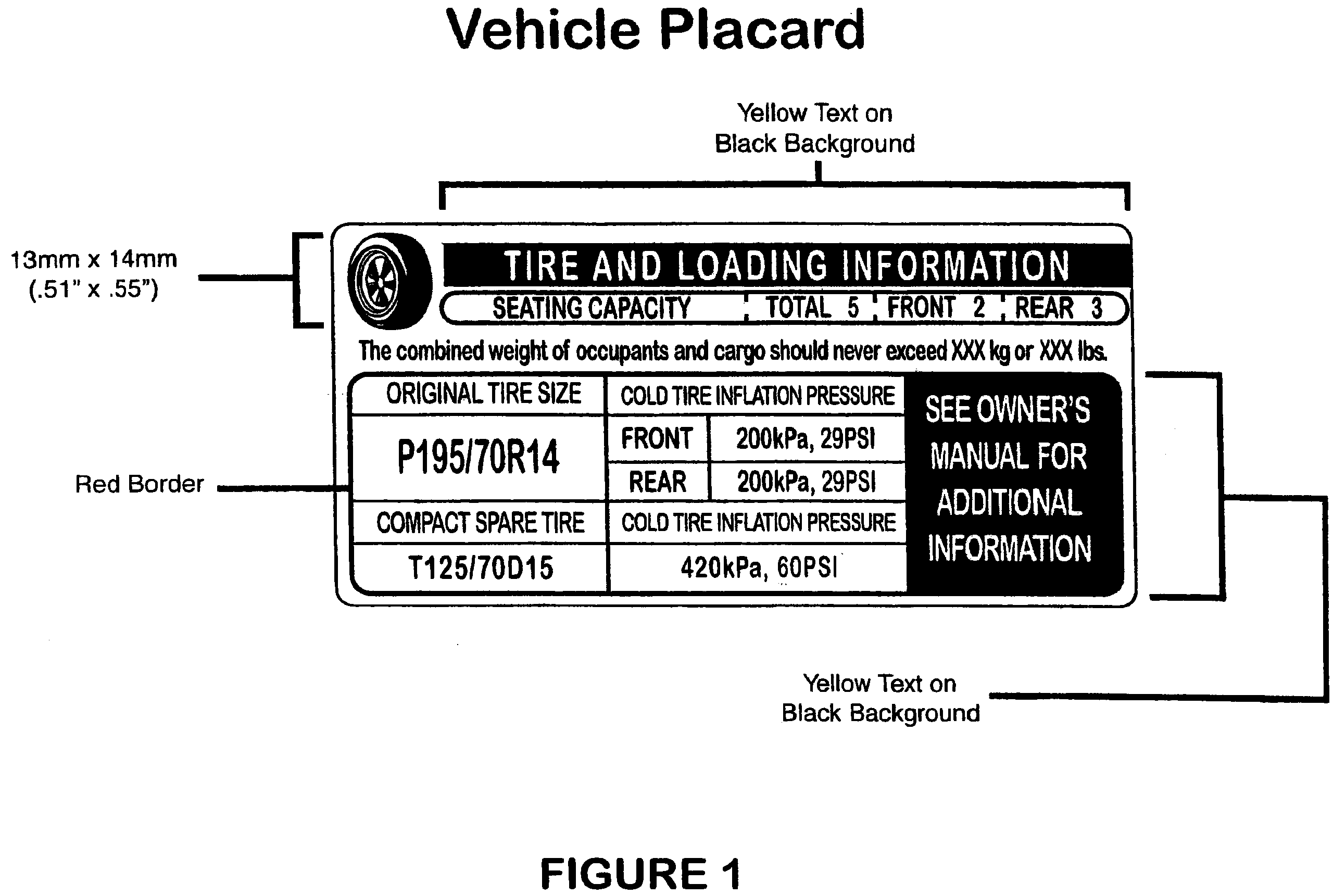

Решение: To alleviate this confusion, businesses should invest in training programs for their staff that cover the nuances of cold tire inflation pressure. This training should include how to locate the manufacturer-recommended tire pressure, typically found on a sticker inside the driver’s door or in the owner’s manual, and the importance of checking these pressures when tires are cold. Additionally, businesses can develop a checklist for drivers to follow, which includes measuring tire pressure in shaded areas and ensuring that vehicles have been stationary for a sufficient period. This structured approach can enhance understanding and compliance, leading to safer and more efficient operations.

Проблема: Many B2B buyers in logistics and transportation experience inefficiencies due to inconsistent tire maintenance practices across their fleets. For instance, a company operating in South America may find that some drivers regularly check tire pressures while others neglect this critical task. This inconsistency can lead to variations in fuel efficiency and vehicle performance, ultimately affecting the bottom line. Furthermore, without a standardized approach, tire-related issues can escalate, resulting in unexpected downtime and costly repairs.

Illustrative image related to what is cold tire inflation pressure

Решение: To standardize tire maintenance practices, businesses should implement a comprehensive tire management program that includes regular training and accountability measures. This program can feature scheduled tire pressure checks, documented maintenance logs, and performance reviews tied to tire upkeep. Businesses can also leverage technology by utilizing mobile apps that remind drivers to check tire pressures and report their findings. By fostering a culture of accountability and awareness around tire maintenance, companies can ensure that all vehicles in their fleet operate at optimal efficiency, reducing costs and enhancing overall performance.

When considering the materials used in systems designed to manage cold tire inflation pressure, it’s essential to evaluate their properties, advantages, disadvantages, and suitability for various applications. Here, we analyze four common materials: rubber, steel, aluminum, and composite materials.

Rubber is the traditional material used for tire construction and inflation systems. Its key properties include excellent flexibility, good temperature resistance, and the ability to maintain a seal under varying pressure conditions. Rubber can typically withstand temperatures ranging from -40°C to 100°C, making it suitable for diverse climates.

Плюсы: Rubber is durable and provides a reliable seal, which is crucial for maintaining the correct tire pressure. It is also relatively low-cost and easy to manufacture.

Конс: However, rubber can degrade over time due to exposure to UV light and ozone, which can lead to leaks. Additionally, it may not perform well in extremely high temperatures.

Влияние на применение: Rubber is compatible with air and nitrogen, the two most common gases used for tire inflation.

Соображения для международных покупателей: Buyers from regions like Africa and the Middle East should ensure that the rubber used complies with local standards, such as ASTM or DIN, especially for high-temperature applications.

Steel is often used in tire rims and valves due to its strength and durability. It has a high-temperature rating, typically exceeding 200°C, and offers excellent corrosion resistance when properly treated.

Плюсы: Steel provides structural integrity and is less prone to deformation under load, making it ideal for heavy-duty applications.

Illustrative image related to what is cold tire inflation pressure

Конс: The primary disadvantage of steel is its weight, which can affect vehicle performance and fuel efficiency. Additionally, it can be more expensive than other materials.

Влияние на применение: Steel is compatible with various gases and is suitable for high-pressure applications.

Соображения для международных покупателей: Buyers should look for steel components that meet international corrosion resistance standards, especially in humid or coastal environments.

Illustrative image related to what is cold tire inflation pressure

Aluminum is increasingly popular for tire rims and valves due to its lightweight nature and good corrosion resistance. It generally has a temperature rating similar to steel but is lighter, which can improve vehicle performance.

Плюсы: The lightweight nature of aluminum contributes to better fuel efficiency and handling. It also has a modern aesthetic appeal, which can be a selling point in consumer markets.

Конс: Aluminum can be more expensive than steel and may require special coatings to enhance its durability against corrosion.

Влияние на применение: Aluminum is compatible with air and nitrogen and is suitable for both standard and high-pressure applications.

Illustrative image related to what is cold tire inflation pressure

Соображения для международных покупателей: Buyers from Europe and South America should ensure that aluminum components meet relevant standards for safety and performance, such as JIS or ISO specifications.

Composite materials, including reinforced plastics and carbon fiber, are becoming more common in tire inflation systems due to their lightweight and high strength-to-weight ratio. They can withstand temperatures up to 150°C, depending on the specific type of composite.

Плюсы: Composites offer excellent resistance to corrosion and can be engineered to meet specific performance requirements.

Конс: The manufacturing process can be complex and costly, making composites a more expensive option compared to traditional materials.

Влияние на применение: Composites can be tailored for specific applications, making them suitable for high-performance vehicles.

Illustrative image related to what is cold tire inflation pressure

Соображения для международных покупателей: Buyers should verify that composite materials comply with international standards, particularly in performance and safety, to ensure reliability in various climates.

| Материал | Typical Use Case for what is cold tire inflation pressure | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire construction and inflation systems | Excellent flexibility and sealing capability | Degrades over time due to UV exposure | Низкий |

| Сталь | Tire rims and valves | Высокая прочность и долговечность | Heavier, affecting vehicle performance | Мед |

| Алюминий | Lightweight rims and valves | Improved fuel efficiency and aesthetic appeal | More expensive and may require coatings | Высокий |

| Композит | High-performance tire applications | Customizable and excellent corrosion resistance | Complex manufacturing process | Высокий |

This analysis provides a comprehensive overview of the materials commonly used in cold tire inflation pressure systems, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

The manufacturing of tires is a complex process that involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the tires meet the necessary performance and safety standards, particularly regarding cold tire inflation pressure.

Material preparation is the initial phase where raw materials are sourced and processed. This includes rubber compounds, fabric, and steel cords. Manufacturers typically use a blend of natural and synthetic rubber to achieve the desired elasticity and durability. The rubber is mixed with additives such as carbon black, silica, and curing agents to enhance its properties.

In this stage, suppliers must ensure that all materials meet international quality standards, such as ISO 9001, which focuses on quality management systems. B2B buyers should verify that their suppliers have robust sourcing practices and conduct material testing to ensure consistency and performance.

The forming stage involves shaping the tire components. Key techniques include:

Extrusion: This process shapes rubber into specific forms, such as treads and sidewalls. The rubber is forced through a die to create long strips, which are then cut to size.

Calendering: This technique is used to create fabric-reinforced rubber sheets. Layers of rubber are passed through rollers, combining them with fabric to enhance strength and flexibility.

Molding: The final tire shape is achieved through molding. Tire components are placed in a mold, and heat and pressure are applied to cure the rubber, solidifying the structure.

Each technique is carefully monitored to ensure that the dimensions and material properties align with the specifications required for optimal cold tire inflation pressure.

The assembly stage integrates the various components into a complete tire. This process includes:

The finishing stage includes quality checks to ensure that each tire meets the required specifications. This involves visual inspections, dimensional checks, and performance testing to confirm that the tire can maintain proper cold inflation pressure under various conditions.

Quality control (QC) is paramount in tire manufacturing to ensure that tires maintain their integrity and performance standards, especially regarding cold tire inflation pressure. Several international and industry-specific standards guide this process.

ISO 9001 is a widely recognized standard that focuses on quality management systems. Manufacturers adhering to this standard demonstrate their commitment to continuous improvement and customer satisfaction. Additionally, specific certifications such as the European CE mark and the American API standards may apply, depending on the market region.

Quality control checkpoints are integrated throughout the manufacturing process. These include:

Входящий контроль качества (IQC): This initial checkpoint verifies the quality of incoming raw materials. It ensures that materials meet the required specifications before they enter production.

Внутрипроцессный контроль качества (IPQC): During production, ongoing checks are performed to monitor key parameters, such as dimensions and material properties, to ensure compliance with specifications.

Окончательный контроль качества (ОКК): Once the tires are completed, they undergo rigorous testing, including pressure tests, visual inspections, and performance assessments. This step confirms that the tires can withstand the pressures associated with cold tire inflation.

Several testing methods are employed to ensure that tires perform optimally at the specified cold tire inflation pressure. Common methods include:

Illustrative image related to what is cold tire inflation pressure

Pressure Testing: This assesses the tire’s ability to maintain the recommended inflation levels under various conditions, simulating real-world scenarios.

Испытания на долговечность: Tires are subjected to stress tests to evaluate their performance over extended periods. This includes testing under different load conditions and temperature variations.

Tread Wear Testing: This assesses how the tire tread performs over time, ensuring that it can handle the rigors of driving without compromising safety or performance.

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. This can be achieved through:

Audits: Conducting regular audits of suppliers allows buyers to assess compliance with quality standards and identify areas for improvement.

Reports: Requesting detailed QC reports can provide insights into the manufacturing processes and testing outcomes, helping buyers make informed decisions.

Third-party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality assurance processes.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial.

Regional Standards: Buyers must be aware of the specific standards and regulations applicable in their regions, as these can vary significantly. For instance, CE certification is crucial for European markets, while other certifications may be more relevant in South America or the Middle East.

Cultural Considerations: Different regions may have varying expectations regarding quality and compliance. B2B buyers should engage in clear communication with suppliers to ensure mutual understanding and adherence to standards.

Logistical Challenges: The international movement of goods can introduce complexities in quality assurance. Buyers should consider the implications of transportation on tire integrity and ensure that suppliers have measures in place to mitigate risks.

In conclusion, a thorough understanding of manufacturing processes and quality assurance in tire production is essential for B2B buyers. By focusing on these elements, buyers can ensure they procure tires that meet the necessary standards for cold tire inflation pressure, thus enhancing safety and performance.

This guide is designed to help B2B buyers understand the critical aspects of cold tire inflation pressure, ensuring safety, efficiency, and optimal performance in tire management. Proper tire inflation is vital not only for vehicle performance but also for fuel efficiency and longevity of the tires. Following this checklist will enable you to make informed purchasing decisions regarding tire maintenance and supplier selection.

Recognizing the definition of cold tire inflation pressure is essential. This pressure refers to the optimal inflation level when tires are at ambient temperature, typically measured after the vehicle has been stationary for several hours. Understanding these standards helps in maintaining tire safety and performance, as operating under incorrect pressures can lead to increased wear and potential safety hazards.

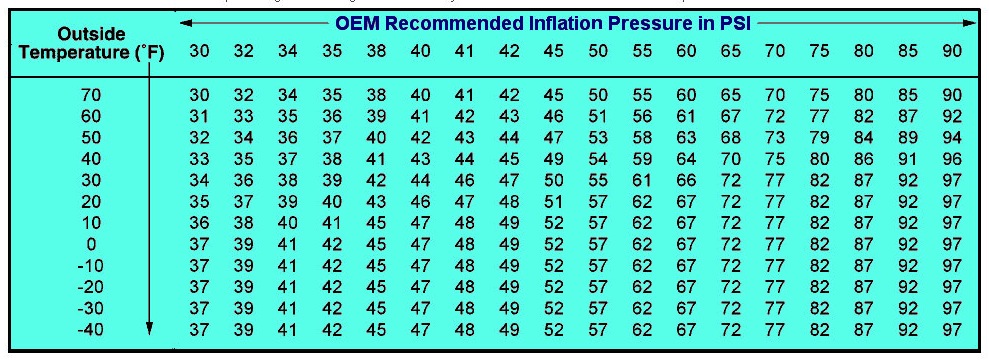

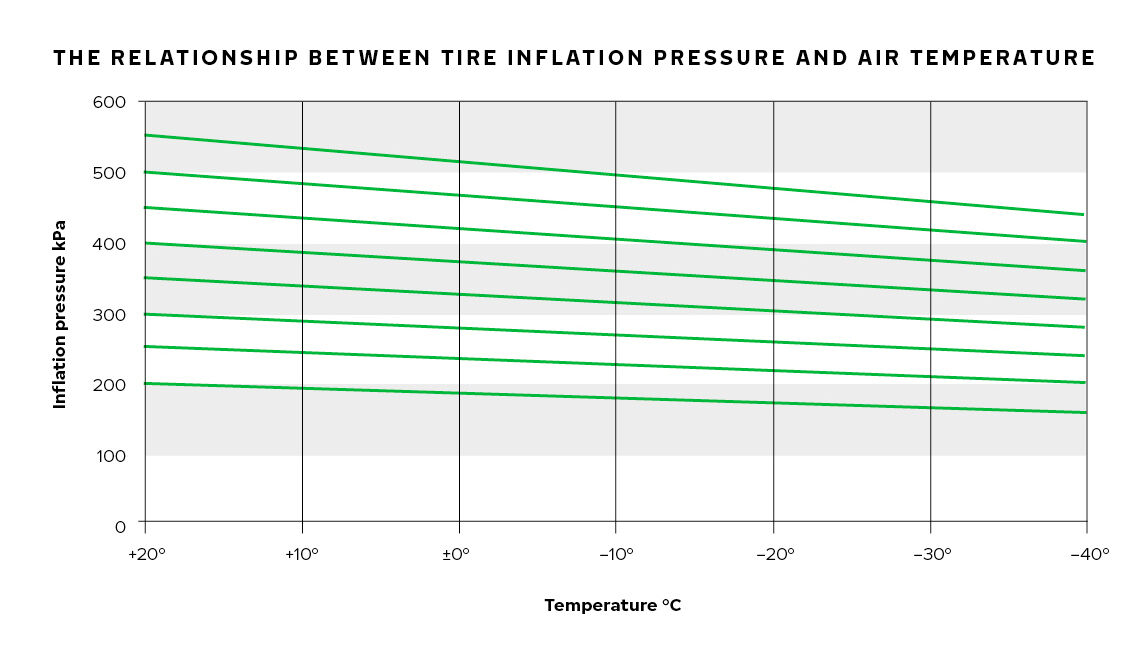

Temperature fluctuations can significantly affect tire pressure. It is generally accepted that for every 10°F change in temperature, tire pressure can vary by approximately 1 psi. This is particularly relevant in regions with extreme climates, such as parts of Africa and the Middle East, where temperature variations are pronounced.

Investing in reliable tire pressure gauges and inflation equipment is crucial for maintaining accurate tire pressure. High-quality gauges ensure precise readings, which are essential for safety and efficiency.

When sourcing tires or tire maintenance equipment, ensure that suppliers possess relevant certifications and industry experience. This guarantees that products meet safety standards and performance requirements.

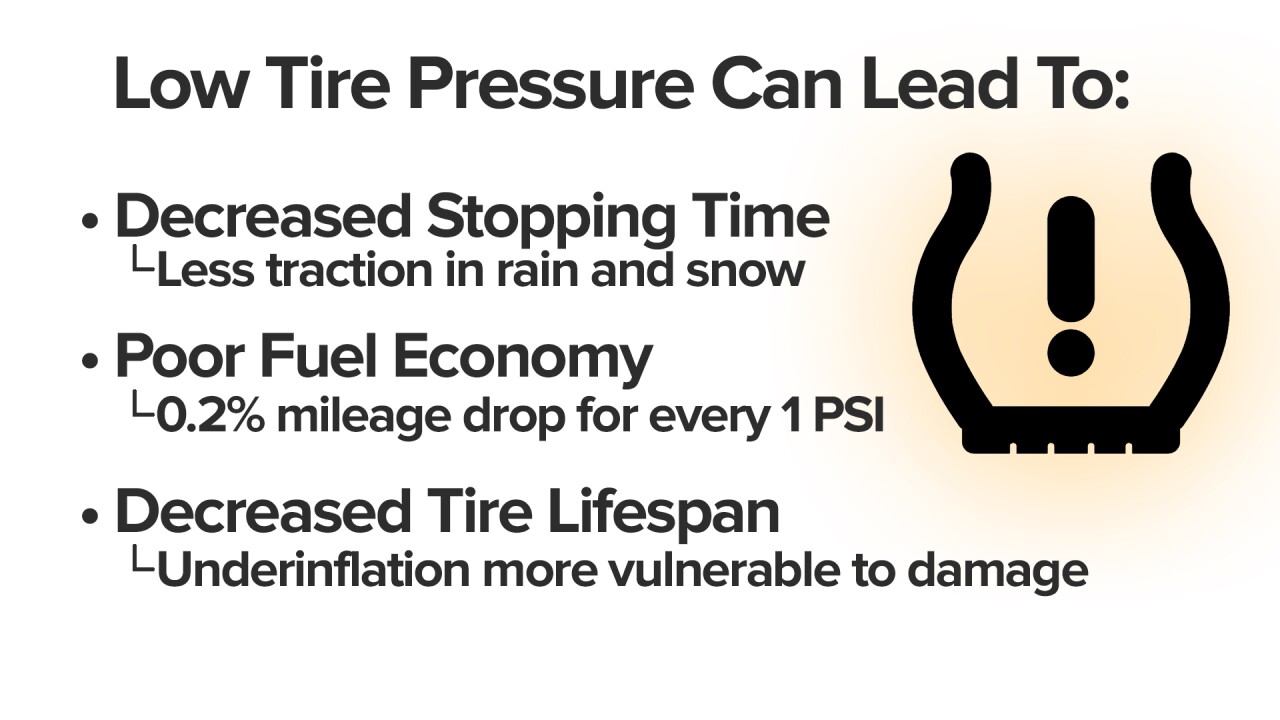

Establishing a routine for regular tire pressure checks is essential for optimal tire performance. Frequent monitoring helps identify underinflation or overinflation issues, which can lead to tire wear and decreased fuel efficiency.

Keeping up-to-date with the latest advancements in tire technology and inflation systems can enhance your procurement strategy. Innovations may include automatic inflation systems or advanced monitoring technologies that provide real-time pressure updates.

By following this comprehensive checklist, B2B buyers can ensure that they are well-equipped to manage cold tire inflation pressure effectively, ultimately leading to improved vehicle safety and performance.

When sourcing solutions related to cold tire inflation pressure, various cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Материалы: The primary materials involved are the tires themselves and the inflation equipment, which may include compressors and gauges. The quality of rubber compounds, synthetic materials, and the technology used in manufacturing can significantly influence costs.

Труд: Labor costs encompass the workforce involved in production, assembly, and maintenance of the equipment. Skilled labor may be required for quality assurance, which can increase overall costs.

Производственные накладные расходы: This includes costs related to facilities, utilities, and machinery maintenance. Efficient production processes can help reduce overhead costs, thus lowering the overall pricing.

Инструментальная оснастка: Investment in specialized tooling for tire production and inflation equipment can be substantial. This is particularly relevant for custom tire specifications, where tooling costs must be factored into pricing.

Контроль качества: Ensuring that tires meet safety and performance standards requires robust QC processes. Investments in testing equipment and personnel to uphold these standards can add to the overall cost structure.

Логистика: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping methods, and customs duties can impact pricing significantly.

Маржа: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on market demand, competition, and the perceived value of the product.

Several key factors influence the pricing of cold tire inflation pressure solutions:

Объем/МОК: Bulk purchasing often leads to lower prices per unit due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to maximize cost efficiency.

Технические характеристики и персонализация: Custom specifications can increase costs due to additional tooling and materials required. Buyers should clearly outline their requirements to avoid unexpected price hikes.

Materials Quality and Certifications: Higher-quality materials and certifications (like ISO or safety standards) usually come at a premium. Buyers should assess whether the added cost aligns with their operational needs and standards.

Факторы поставщика: The reputation, reliability, and production capabilities of suppliers can affect pricing. Established suppliers may charge more due to their experience and trustworthiness, while new entrants might offer lower prices to gain market share.

Инкотермс: The choice of Incoterms influences logistics costs and responsibilities between buyers and sellers. Understanding these terms can help buyers negotiate better shipping arrangements and manage total costs effectively.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing efficiency:

Переговоры: Effective negotiation can lead to better terms and pricing. Buyers should come prepared with market data and comparable pricing to strengthen their position.

Экономическая эффективность: Evaluate the total cost of ownership (TCO), including maintenance and operational costs, rather than just the initial purchase price. This holistic view can lead to more informed purchasing decisions.

Нюансы ценообразования для международных покупателей: Currency fluctuations, import tariffs, and local taxes can significantly affect pricing. Buyers should factor these elements into their budget and financial planning.

Отношения с поставщиками: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive deals. Regular communication and feedback can foster trust and collaboration.

It is essential to note that pricing for cold tire inflation pressure sourcing can vary widely based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

In the context of tire maintenance, understanding cold tire inflation pressure is essential for optimal vehicle performance and safety. However, several alternative methods and technologies can also achieve effective tire pressure management. This section provides a comparative analysis of cold tire inflation pressure against other viable solutions, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, and maintenance requirements.

| Сравнительный аспект | What Is Cold Tire Inflation Pressure | Tire Pressure Monitoring Systems (TPMS) | Nitrogen Tire Inflation |

|---|---|---|---|

| Производительность | Maintains optimal tire pressure based on temperature | Continuously monitors and alerts for low pressure | Maintains stable pressure and reduces fluctuations |

| Стоимость | Minimal cost (manual checking) | Moderate cost (installation and maintenance) | Higher initial cost (nitrogen filling) but long-term savings |

| Простота реализации | Requires manual checking and adjustment | Automated system, easy to use once installed | Requires specialized equipment for filling |

| Техническое обслуживание | Regular checks needed (monthly recommended) | Low maintenance after installation | Requires periodic refilling, but less frequent than air |

| Лучший пример использования | Ideal for routine vehicle maintenance | Best for fleets and high-use vehicles needing constant monitoring | Suitable for performance vehicles and long-distance travel |

TPMS is an advanced technology that provides real-time monitoring of tire pressure. It alerts drivers when pressure falls below a certain threshold, reducing the risk of tire-related incidents. The primary advantage of TPMS is its automation, which eliminates the need for manual checks. However, the initial installation cost can be moderate, and ongoing maintenance is essential to ensure sensor functionality. Additionally, some systems may require calibration after tire changes, adding to the overall complexity.

Nitrogen tire inflation involves filling tires with nitrogen gas instead of regular air. This method offers several benefits, such as reduced pressure fluctuations due to temperature changes and slower deflation rates. As a result, tires maintain optimal pressure longer, enhancing fuel efficiency and tire lifespan. While the initial cost of nitrogen filling is higher, many users find that the long-term savings in tire wear and fuel economy justify the expense. However, it requires specialized equipment for filling and may not be as readily available as traditional air inflation.

For B2B buyers, selecting the right tire inflation solution depends on specific operational needs and budget considerations. Cold tire inflation pressure remains a fundamental practice for routine maintenance, especially for businesses with limited resources. However, investing in TPMS can significantly enhance safety and efficiency for fleets or high-usage vehicles. Meanwhile, nitrogen tire inflation may be ideal for businesses focused on performance and long-term cost savings. By evaluating these options, buyers can align their tire maintenance strategies with their operational goals, ensuring optimal vehicle performance and safety across their fleets.

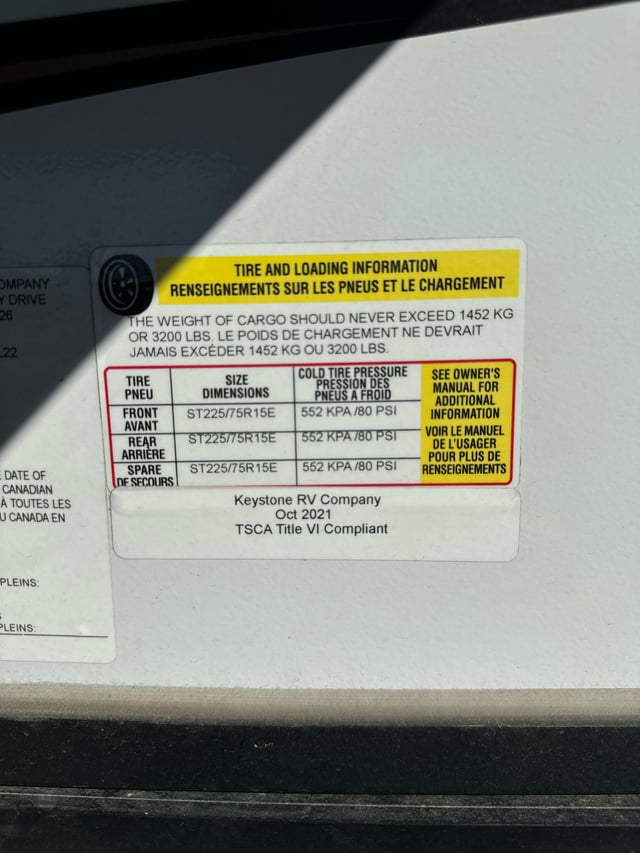

Understanding cold tire inflation pressure is essential for ensuring optimal tire performance and safety. Here are some critical specifications that B2B buyers should consider:

Pressure Measurement Units (PSI, Bar, kPa)

The most common unit for measuring tire pressure is pounds per square inch (PSI), while other regions may use bar or kilopascals (kPa). For instance, 1 bar is approximately equal to 14.5 PSI. Understanding these units is crucial for international trade, as it ensures compliance with regional standards and prevents miscommunication during procurement.

Temperature Sensitivity

Tire pressure can fluctuate significantly with temperature changes, typically decreasing by 1 to 2 PSI for every 10°F drop in temperature. This property is particularly important for markets with extreme temperature variations, as maintaining optimal tire pressure can enhance fuel efficiency and tire longevity, ultimately reducing operational costs.

Recommended Cold Inflation Pressure

Each vehicle has a manufacturer-recommended cold tire inflation pressure, usually found on a sticker inside the driver’s door or in the owner’s manual. Adhering to these specifications is vital for vehicle safety, optimal handling, and maximizing tire lifespan. B2B buyers should ensure that their fleet vehicles are consistently checked and maintained according to these recommendations.

Tire Pressure Monitoring Systems (TPMS)

Many modern vehicles come equipped with TPMS, which alerts drivers when tire pressure falls below a certain threshold. Understanding the function and calibration of these systems is essential for fleet management, as they can prevent tire blowouts and improve safety on the road.

Air Volume and Tire Composition

The composition of the tire and the volume of air it holds can affect how pressure is maintained. Tires made with advanced materials may have better air retention properties. This is an important consideration for B2B buyers focusing on durability and performance in varied environments.

Familiarity with industry terminology is crucial for effective communication and negotiations in the tire market. Here are some common terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle or tire. When purchasing tires, knowing whether they are OEM or aftermarket can affect warranty, performance, and compatibility. Buyers should ensure that the tires meet the specifications set by the vehicle’s OEM for optimal safety and performance.

MOQ (минимальное количество заказа)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers, as it can impact inventory management and cash flow. Understanding MOQ helps in planning purchases and negotiating better terms with suppliers.

RFQ (запрос котировок)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the context of tire procurement, an RFQ can help buyers gather competitive quotes from multiple suppliers, aiding in decision-making.

Инкотермс (международные коммерческие термины)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Knowledge of Incoterms is essential for B2B buyers engaged in cross-border tire procurement to avoid misunderstandings and ensure smooth transactions.

Tread Depth

Tread depth is a crucial specification that affects tire performance, especially in wet conditions. It’s essential for buyers to understand how tread depth impacts safety and compliance with regional regulations, as this can affect tire procurement decisions.

Load Index

The load index indicates the maximum load a tire can support at a specified pressure. This specification is critical for fleet operators, as it ensures that the tires are suitable for the vehicles they are fitted on, particularly when carrying heavy loads.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance safety, performance, and cost-efficiency in their tire management strategies.

The global market for cold tire inflation pressure is shaped by several key drivers, significantly impacting international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. One of the most notable trends is the increasing emphasis on fuel efficiency and safety. As fuel prices fluctuate, businesses are motivated to optimize their vehicle maintenance practices, including regular tire pressure checks, to enhance fuel economy and extend tire lifespan. This trend is particularly pronounced in emerging markets where transportation costs are a critical factor for operational efficiency.

Illustrative image related to what is cold tire inflation pressure

Technology is also playing a pivotal role in shaping sourcing trends. The adoption of advanced tire pressure monitoring systems (TPMS) is becoming more prevalent, offering real-time data on tire conditions. Such systems are valuable for fleet management, allowing companies to mitigate risks associated with under-inflated tires, such as blowouts and reduced handling capabilities. Moreover, the integration of IoT solutions for predictive maintenance is on the rise, enabling businesses to make data-driven decisions regarding tire health and performance.

International buyers must also navigate regional differences in regulatory standards and consumer preferences, which can affect sourcing strategies. For instance, in Europe, there are stringent regulations regarding tire safety and environmental impact, prompting suppliers to offer products that comply with these standards. Understanding these dynamics can help B2B buyers in various regions make informed decisions about sourcing and maintenance practices.

Sustainability has become a paramount concern in the tire industry, influencing sourcing decisions for B2B buyers. The environmental impact of tire production and disposal is substantial, leading to a growing demand for ethically sourced materials and sustainable manufacturing practices. Buyers are increasingly looking for suppliers that prioritize eco-friendly materials, such as recycled rubber and sustainable sourcing methods, to reduce their carbon footprint.

Furthermore, certification programs like ISO 14001 and the Global Recycled Standard are gaining traction, enabling businesses to verify the sustainability credentials of their suppliers. This is particularly important for companies looking to enhance their corporate social responsibility (CSR) initiatives and appeal to environmentally conscious consumers.

In addition, the promotion of cold tire inflation pressure as a sustainability measure is noteworthy. Properly inflated tires can significantly improve fuel efficiency, reducing greenhouse gas emissions associated with transportation. By emphasizing the importance of maintaining cold tire inflation pressure, businesses can contribute to sustainability efforts while simultaneously lowering operational costs. This dual focus on environmental responsibility and cost-effectiveness positions B2B buyers favorably in a competitive marketplace.

Illustrative image related to what is cold tire inflation pressure

The concept of cold tire inflation pressure dates back to the early days of automotive engineering when tire maintenance was primarily based on visual inspections. Over the decades, advancements in tire technology and a better understanding of tire performance dynamics have led to standardized practices for maintaining tire pressure. Initially, tire pressure recommendations were rudimentary, often varying widely among manufacturers.

As vehicle safety became a more significant concern in the latter half of the 20th century, the industry began to recognize the critical role that proper tire inflation plays in vehicle performance. The introduction of tire pressure monitoring systems in the late 1990s marked a significant evolution, providing drivers with real-time insights into tire conditions. Today, the emphasis on cold tire inflation pressure is not just about safety; it is also intertwined with environmental sustainability and economic efficiency, making it a vital consideration for modern B2B buyers.

By understanding the historical context and current trends surrounding cold tire inflation pressure, international buyers can better navigate the complexities of sourcing and maintenance in a rapidly evolving marketplace.

How do I ensure accurate cold tire inflation pressure measurements?

To achieve accurate cold tire inflation pressure measurements, first check the recommended psi for your vehicle, typically found on a sticker inside the driver’s door or in the owner’s manual. Ensure the vehicle has been stationary for at least three hours before measuring, as driving can heat the tires and artificially inflate the readings. Use a reliable tire pressure gauge, and measure when the tires are cool, ideally in a shaded area to avoid temperature fluctuations caused by direct sunlight.

What are the consequences of incorrect cold tire inflation pressure?

Incorrect cold tire inflation pressure can lead to a range of issues, including reduced fuel efficiency, compromised handling, and accelerated tire wear. Under-inflated tires increase rolling resistance, which can decrease fuel economy and increase the risk of blowouts, especially under heavy loads or at high speeds. Conversely, over-inflated tires can lead to a harsher ride and decreased traction, particularly in wet conditions. Regular checks and maintenance can mitigate these risks.

How can I find reliable suppliers for tire pressure monitoring systems (TPMS)?

To find reliable suppliers for TPMS, consider using trade directories and B2B marketplaces like Alibaba or Global Sources, which feature verified suppliers and customer reviews. It’s advisable to assess their certifications, such as ISO standards, and request samples to evaluate product quality. Additionally, attending industry trade shows can provide networking opportunities with reputable manufacturers and distributors, allowing for direct engagement and negotiation on terms.

What factors should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider factors like order size, supplier reliability, and your cash flow needs. Common terms include net 30 or 60 days, but for larger orders, you might negotiate partial upfront payments or escrow arrangements to mitigate risk. It’s also beneficial to discuss potential discounts for early payments or bulk purchases. Ensure all terms are clearly documented to avoid misunderstandings and protect your interests.

How do temperature fluctuations affect tire pressure in different regions?

Temperature fluctuations can significantly impact tire pressure, particularly in regions with extreme climates. For every 10°F change in temperature, tire pressure can change by approximately 1 psi. In hotter climates, tires may over-inflate, leading to safety concerns, while in colder areas, under-inflation is common. B2B buyers in varying climates should educate their clients about regular pressure checks and consider offering products that are better suited for local conditions.

What is the minimum order quantity (MOQ) for tire pressure monitoring products?

The minimum order quantity (MOQ) for tire pressure monitoring products varies by supplier and product type. Typically, it can range from 100 to 1,000 units. When sourcing, inquire about MOQs to ensure they align with your inventory needs and budget. Some suppliers may offer flexibility on MOQs for initial orders or if you commit to future purchases, making it essential to establish a good relationship with your supplier.

How can I ensure quality assurance for tire inflation products?

To ensure quality assurance for tire inflation products, request detailed product specifications and certifications from suppliers. It’s also advisable to conduct third-party inspections during production or before shipment to verify compliance with industry standards. Establishing a clear quality control process, including regular audits and feedback loops with suppliers, can help maintain high-quality standards throughout the supply chain.

What logistics considerations should I keep in mind for importing tire pressure products?

When importing tire pressure products, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on urgency and budget. Ensure you understand the import duties and taxes applicable in your region, and work with a reliable logistics partner who can navigate customs procedures efficiently to prevent delays.

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: 2014 Dodge Dart SXT 2.4L multiair; recommended tire pressure: 38 psi; current tire pressure filled to: 35 psi.

Домен: cars.com

Зарегистрирован: 1998 (27 лет)

Введение: Recommended tire pressures are commonly found on a sticker inside the driver’s door, in the glove box, or on the inside of the fuel-filler door. The recommended pressure is a cold inflation pressure, meaning it should be checked when the vehicle has been sitting in the shade. Some vehicles may have different recommended pressures for front and rear tires, and a higher pressure may be listed for he…

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: This company, Facebook – Tire Pressure Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Домен: pirelli.com

Зарегистрирован: 1995 (30 лет)

Введение: Recommended tire pressure is established by the vehicle manufacturer and typically falls between 28 and 36 PSI. The correct pressure can be found in the car’s operator manual or on a sticker inside the driver’s door. It is important to check tire pressure when the tires are cold. Maximum tire pressure is indicated on the tire’s sidewall and should not be used for everyday driving, as it can impair…

In summary, maintaining the correct cold tire inflation pressure is crucial for optimizing vehicle performance, enhancing fuel efficiency, and prolonging tire life. For B2B buyers across Africa, South America, the Middle East, and Europe, strategic sourcing of tire maintenance products and services can significantly impact operational costs and safety standards. Ensuring that your fleet operates with properly inflated tires not only reduces the risk of accidents but also contributes to a lower total cost of ownership.

Investing in quality tire pressure monitoring systems and establishing regular tire maintenance protocols will empower your organization to respond proactively to inflation changes caused by temperature fluctuations. This strategic foresight can lead to improved vehicle handling, reduced downtime, and an overall boost in productivity.

As you navigate the complexities of tire management in diverse climates, consider collaborating with reputable suppliers who understand the regional challenges and can provide tailored solutions. By prioritizing effective tire inflation practices, you position your business for greater efficiency and resilience in an ever-evolving marketplace. Take the initiative today—review your tire sourcing strategies and make informed decisions that drive your operational success forward.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.