In today’s rapidly evolving global market, sourcing reliable and efficient Slime 12V air compressors presents a significant challenge for B2B buyers. With the growing demand for compact, versatile tire inflators that cater to various applications—from automotive to recreational uses—businesses must navigate a landscape filled with numerous product options and supplier variations. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Vietnam.

Throughout this guide, we will explore the diverse types of Slime 12V air compressors available, their applications across different industries, and the critical factors to consider when vetting suppliers. We will delve into essential aspects such as pricing structures, product specifications, and quality assurance measures that can significantly impact purchasing decisions. By offering actionable insights and expert recommendations, this guide empowers B2B buyers to make informed choices that align with their operational needs and market demands.

As you navigate the complexities of sourcing Slime 12V air compressors, this resource will provide the knowledge necessary to optimize your procurement strategies, ensuring that your business remains competitive and well-equipped to meet customer expectations.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 12V Tire Inflator | Compact design, inflates a tire in 8 minutes, built-in gauge | Automotive repair shops, roadside assistance | Pros: Lightweight, easy to use. Cons: Limited to tire inflation only. |

| Cordless Tire Inflator | Rechargeable battery, portable, no power outlet needed | Mobile tire services, emergency kits | Pros: High portability, versatile. Cons: Battery life may limit usage. |

| Digital Tire Inflator | Digital display, automatic shut-off, precise inflation | Fleet maintenance, automotive workshops | Pros: Accurate, user-friendly. Cons: Slightly bulkier than manual models. |

| Multi-Purpose Inflator | Adapters for various inflatables, versatile functionality | Sports equipment retailers, event organizers | Pros: Multi-functional, ideal for various applications. Cons: May lack high pressure output. |

| Dual Power Tire Inflator | Operates on both 12V and 120V, robust design | Heavy-duty vehicle maintenance, workshops | Pros: Flexible power options, durable. Cons: Heavier, higher cost. |

Standard 12V tire inflators are designed for straightforward tire inflation, typically featuring a compact and lightweight design. They can inflate a standard mid-sized car tire from flat to full in approximately eight minutes, making them efficient for quick roadside assistance. B2B buyers in automotive repair shops or roadside assistance services will find these inflators essential due to their simplicity and reliability. However, their functionality is limited to tire inflation, which may not meet all operational needs.

Cordless tire inflators are powered by rechargeable batteries, providing unmatched portability. This feature is particularly beneficial for mobile tire services and emergency roadside kits, allowing for tire inflation without needing a power outlet. While their versatility is a significant advantage, buyers should consider potential limitations in battery life, which may restrict prolonged use during high-demand situations.

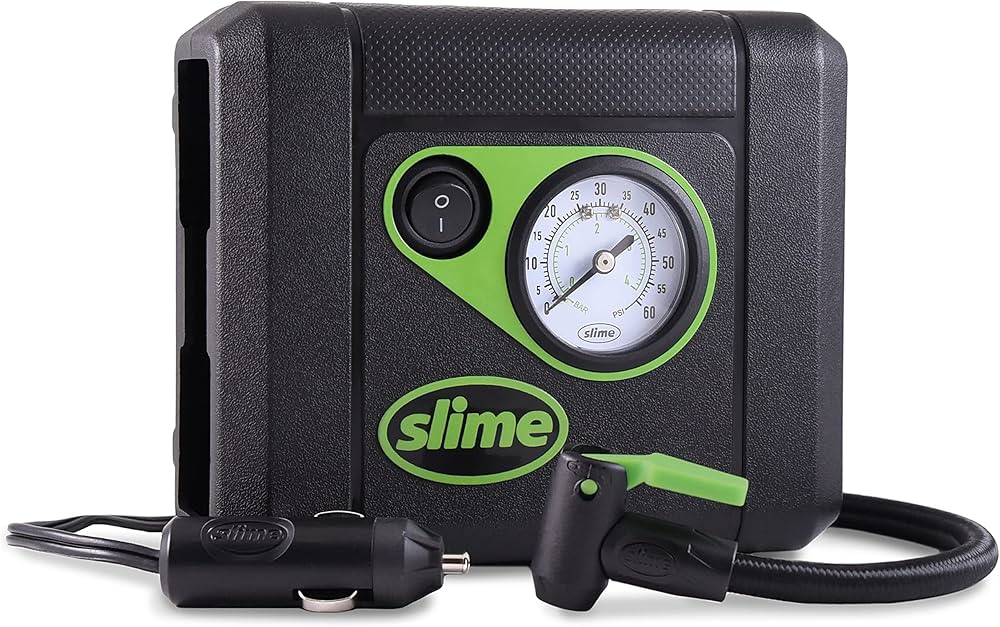

Illustrative image related to slime 12v air compressor

Digital tire inflators come equipped with a digital display and automatic shut-off features, allowing for precise inflation and ease of use. These characteristics make them particularly suitable for fleet maintenance and automotive workshops where accuracy is crucial. The user-friendly interface reduces the risk of over-inflation, ensuring tire longevity. However, these models can be bulkier, which might be a consideration for businesses with limited storage space.

Multi-purpose inflators are designed with adapters for various inflatables, making them suitable for a range of applications beyond just tires, such as sports equipment and recreational items. This versatility is advantageous for businesses like sports equipment retailers or event organizers who require flexibility in their inflating solutions. However, potential buyers should note that these inflators may not deliver the high pressure needed for heavy-duty applications.

Dual power tire inflators can operate on both 12V and 120V power sources, making them particularly robust for heavy-duty vehicle maintenance and workshops. This flexibility allows businesses to use them in various environments, whether in a garage or out in the field. While their durability is a significant advantage, buyers should consider the increased weight and higher cost associated with these models compared to simpler inflators.

| Industry/Sector | Specific Application of slime 12v air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Roadside assistance for flat tire repairs | Reduces downtime and increases customer satisfaction | Ensure compatibility with various tire types and sizes |

| Transportation & Logistics | Fleet maintenance and emergency tire inflation | Enhances operational efficiency and safety | Evaluate power source options and portability |

| Sports & Recreation | Inflating sports equipment and recreational inflatables | Facilitates quick and easy setup for events | Assess multi-purpose capabilities and adapter types |

| Agriculture | Tire inflation for farm machinery and vehicles | Minimizes delays in agricultural operations | Consider ruggedness and resistance to environmental factors |

| Construction | On-site tire inflation for construction vehicles | Improves productivity and reduces project delays | Look for durability and ease of use under harsh conditions |

In the automotive sector, the Slime 12V air compressor is essential for roadside assistance, allowing quick inflation of flat tires. This capability not only reduces vehicle downtime but also enhances customer satisfaction by providing immediate solutions. For international buyers, especially in regions with vast rural areas, sourcing a reliable compressor that can handle varying tire sizes and types is crucial. The compact design of the compressor also makes it easy to store in vehicles, making it an ideal choice for service providers.

Within transportation and logistics, the Slime 12V air compressor is vital for fleet maintenance. It ensures that vehicle tires are consistently inflated to optimal levels, which enhances fuel efficiency and safety. Businesses in this sector must consider the compressor’s portability and power source options, as these factors impact the ability to perform tire maintenance in remote locations. A compressor that is easy to operate and store can significantly improve the efficiency of fleet operations.

In the sports and recreation industry, the Slime 12V air compressor is used to inflate various sports equipment, including balls and recreational inflatables. This application is particularly beneficial for event organizers who require quick setups. For B2B buyers in this sector, assessing the compressor’s multi-purpose capabilities and the availability of different adapters is essential to ensure versatility for various equipment types. A reliable compressor can enhance event experiences and operational efficiency.

The agricultural sector utilizes the Slime 12V air compressor to maintain tire pressure in farm machinery and vehicles. Proper tire inflation is crucial for minimizing delays during planting and harvesting seasons, which directly impacts productivity. Buyers in this industry should prioritize sourcing compressors that are rugged and can withstand harsh environmental conditions. Additionally, ease of use and quick inflation times are essential features that can significantly benefit agricultural operations.

In construction, the Slime 12V air compressor is used for on-site tire inflation of construction vehicles, ensuring that machinery remains operational without delays. This efficiency is critical for meeting project deadlines and maintaining productivity levels. When sourcing compressors for this application, durability and ease of use under demanding conditions should be key considerations. A robust air compressor can greatly enhance the overall effectiveness of construction operations, leading to better project outcomes.

Illustrative image related to slime 12v air compressor

The Problem: B2B buyers, especially those managing fleets or in industries reliant on transportation, often face the challenge of flat tires in remote areas where access to repair services is limited. This can lead to significant downtime, increased costs, and logistical nightmares. For companies operating in regions like Africa or South America, where road conditions may be poor, the inability to quickly inflate a tire can halt operations and compromise safety.

The Solution: To mitigate this issue, businesses should consider equipping their vehicles with the Slime 12V Air Compressor. This compressor is compact and designed for emergency use, making it ideal for remote operations. Buyers should ensure that they source units with robust features, such as a built-in LED light for nighttime visibility and an integrated dial gauge for precise inflation. Regular training for drivers on how to effectively use the compressor can also enhance operational readiness. By maintaining these units and ensuring they are always charged, businesses can minimize downtime and maintain fleet efficiency.

The Problem: Many B2B buyers, particularly in emerging markets, may lack comprehensive knowledge about tire maintenance and the importance of maintaining proper tire pressure. This can lead to frequent flats and premature tire wear, which ultimately affects operational costs and safety. The lack of understanding can be exacerbated by cultural differences in maintenance practices and available resources.

The Solution: To address this knowledge gap, companies should invest in educational programs that highlight the importance of tire maintenance and proper inflation. Providing employees with Slime 12V Air Compressors as part of a tire maintenance kit can facilitate a proactive approach. The compressor’s user-friendly design allows even those with limited experience to effectively inflate tires. Additionally, creating simple instructional materials or videos in local languages can empower staff and encourage regular tire checks, ultimately leading to longer tire life and reduced costs.

The Problem: B2B buyers often face concerns regarding the quality and reliability of tire inflators, especially when sourcing from different suppliers. This inconsistency can result in purchasing air compressors that do not meet performance expectations, leading to frustration and wasted resources. In regions where product availability varies, it becomes crucial to ensure that the chosen equipment performs reliably under various conditions.

The Solution: To ensure the procurement of high-quality Slime 12V Air Compressors, buyers should focus on sourcing from reputable suppliers with proven track records. Conducting thorough market research and reading customer reviews can provide insights into the reliability of specific models. Additionally, establishing relationships with manufacturers or authorized distributors can ensure access to authentic products with warranties and support. Implementing a testing phase where a small batch of compressors is evaluated in real-world conditions can also help identify potential issues before committing to larger orders. By prioritizing quality over cost, businesses can enhance their operational efficiency and reduce the risk of equipment failure.

Illustrative image related to slime 12v air compressor

When selecting materials for the Slime 12V air compressor, it is essential to consider factors such as performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the construction of air compressors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Plastic is commonly used in the housing and components of air compressors due to its lightweight nature and resistance to corrosion. Key properties include:

Pros & Cons: Plastics are cost-effective and easy to mold into complex shapes, reducing manufacturing complexity. However, they may not offer the same durability as metals, particularly under high-stress conditions.

Impact on Application: While plastics are suitable for non-pressurized components, they may not be ideal for parts exposed to high temperatures or pressures.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile strength and ISO 527 for plastic properties is crucial. Buyers in regions like Africa and the Middle East should ensure that the selected plastics are suitable for local climatic conditions.

Aluminum is often used for structural components due to its strength-to-weight ratio.

Pros & Cons: Aluminum is lightweight and durable, which enhances the overall performance of the compressor. However, it is more expensive than plastic and can require more complex manufacturing processes.

Impact on Application: Its strength allows for the design of compact, robust components that can withstand rigorous use.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is essential. Buyers from Europe and South America should also consider the recyclability of aluminum, which may align with sustainability goals.

Steel is often used for internal components such as pistons and crankshafts due to its high strength.

Pros & Cons: Steel provides exceptional durability and strength, but it is heavier and can increase manufacturing costs.

Impact on Application: Steel components are ideal for high-stress applications, ensuring reliability and longevity.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is important. Buyers in regions with high humidity, like parts of Africa, should prioritize stainless steel to mitigate corrosion risks.

Rubber is primarily used for seals and hoses within the compressor.

Pros & Cons: Rubber is flexible and provides excellent sealing capabilities, but it may wear out faster than other materials, especially in extreme conditions.

Impact on Application: Rubber seals ensure air-tightness, which is crucial for compressor efficiency.

Considerations for International Buyers: Compliance with standards like ASTM D2000 for rubber materials is vital. Buyers in regions with extreme temperatures should consider the specific rubber grades that can withstand local conditions.

| Material | Typical Use Case for slime 12v air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-pressurized components | Lightweight and corrosion-resistant | Less durable under high stress | Low |

| Aluminum | Structural components | High strength-to-weight ratio | More expensive and complex to manufacture | Medium |

| Steel | Internal components (pistons, crankshafts) | Exceptional durability and strength | Heavier and can rust without treatment | High |

| Rubber | Seals and hoses | Excellent sealing capabilities | Can degrade under extreme conditions | Low |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize the performance and durability of the Slime 12V air compressor while ensuring compliance with regional standards.

The manufacturing process of the Slime 12V air compressor involves several critical stages that ensure the product meets the required performance standards and quality expectations. Understanding these stages is crucial for B2B buyers who prioritize reliability and efficiency in their sourcing decisions.

The first stage of manufacturing involves the selection and preparation of materials. For the Slime 12V air compressor, high-quality plastics, metal components, and electrical parts are sourced from reputable suppliers. The materials undergo rigorous testing to ensure they meet industry standards.

Before production, materials are cleaned and, if necessary, pre-treated to enhance adhesion and durability. This preparation is essential for ensuring that the components can withstand the operational demands of the air compressor, especially in varied environmental conditions across different markets.

Once materials are prepared, the forming stage begins. This typically involves techniques such as injection molding for plastic components and stamping or machining for metal parts.

Injection molding allows for precision in creating intricate designs for parts like the housing and connectors, while machining ensures that metal components fit together seamlessly. Advanced forming techniques may also include die casting for more complex shapes, ensuring that every component is robust and functional.

The assembly stage is where the individual components come together to form the complete air compressor. This process often employs automated assembly lines, which enhance efficiency and reduce human error.

Key steps in assembly include attaching the motor to the compressor housing, integrating the pressure gauge, and installing the LED lights. Each assembly line is designed to ensure that components are fitted accurately and securely. Quality assurance checkpoints are embedded throughout this process to catch any defects early.

In the finishing stage, the assembled compressors undergo surface treatments such as painting or coating to enhance durability and aesthetics. This stage may also include the installation of labels and packaging for branding and compliance with international standards.

A thorough inspection is conducted at this stage to ensure that the finished product meets all specifications before moving to the quality control (QC) phase.

Quality assurance is a critical aspect of manufacturing, especially for products like the Slime 12V air compressor that must perform reliably under various conditions. Here’s an overview of how QC is managed throughout the manufacturing process.

Manufacturers of the Slime 12V air compressor typically adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that the manufacturing process is consistent and meets customer and regulatory requirements.

Illustrative image related to slime 12v air compressor

Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, particularly for markets in Europe and the Middle East. These certifications indicate that the products have been tested for safety and performance, providing assurance to buyers.

Quality control is strategically integrated into the manufacturing process at various checkpoints:

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line. Inspectors check for compliance with specifications, ensuring that only quality materials are used.

In-Process Quality Control (IPQC): During assembly, inspectors monitor the process to identify defects in real-time. This proactive approach helps minimize waste and ensures that issues are addressed promptly.

Final Quality Control (FQC): Once the compressors are fully assembled, they undergo comprehensive testing. This includes functional tests, pressure tests, and safety checks to ensure that each unit meets the performance benchmarks.

Common testing methods for the Slime 12V air compressor may include:

Functional Testing: Ensures that the compressor operates as intended, inflating a standard mid-sized car tire within the specified time.

Pressure Testing: Confirms that the compressor can withstand operational pressures without failure.

Durability Testing: Simulates real-world conditions to assess how the compressor performs over time.

These testing methods provide critical data that can be documented in quality assurance reports.

B2B buyers looking to source the Slime 12V air compressor should prioritize suppliers who demonstrate robust quality control practices. Here are several ways to verify supplier QC:

Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and QC measures. Buyers can request access to audit reports to gain insights into the supplier’s compliance with international standards.

Review Quality Reports: Suppliers should provide detailed quality reports that outline testing methodologies, results, and any corrective actions taken. This transparency is crucial for establishing trust.

Engage Third-Party Inspection Services: Utilizing independent inspection services can provide unbiased evaluations of the manufacturing process and product quality. These services can verify compliance with international standards and offer additional peace of mind.

When sourcing from manufacturers in regions like Africa, South America, the Middle East, and Europe, international buyers should be aware of specific nuances in quality control and certification:

Illustrative image related to slime 12v air compressor

Regional Compliance: Different regions may have varying regulatory requirements. For instance, CE certification is crucial for products sold in Europe, while other regions may have different standards.

Cultural Considerations: Understanding local manufacturing practices and quality expectations can help buyers make informed decisions. Engaging with local experts or consultants can provide valuable insights.

Supply Chain Transparency: Given the complexities of international supply chains, buyers should seek suppliers who provide clear visibility into their manufacturing processes and quality assurance practices.

By understanding the manufacturing processes and quality assurance measures for the Slime 12V air compressor, B2B buyers can make informed sourcing decisions that align with their business needs and compliance requirements.

In the competitive landscape of B2B procurement, sourcing a reliable and efficient product like the Slime 12V air compressor requires a strategic approach. This guide serves as a step-by-step checklist to assist international buyers in making informed decisions, ensuring the chosen compressor meets their operational needs and standards.

Establishing clear technical specifications is crucial for ensuring that the Slime 12V air compressor meets your operational requirements. Consider the required inflation speed, portability, and power source. Look for features such as built-in gauges and LED lights that enhance usability in various environments.

Illustrative image related to slime 12v air compressor

Understanding market trends can provide insights into the demand for the Slime 12V air compressor in your region. Analyze regional needs, such as the prevalence of flat tires or the popularity of outdoor activities that require inflatables. This knowledge can help you gauge potential sales volumes and optimize your inventory.

Before finalizing a supplier, conduct thorough evaluations to ensure reliability and quality. Request detailed company profiles, including years in business, client testimonials, and case studies. Focus on suppliers with a proven track record in your target market, as this will reduce risk and enhance your supply chain stability.

Before committing to a bulk order, request samples of the Slime 12V air compressor. Testing the product will allow you to evaluate its performance, durability, and ease of use firsthand. Pay attention to how well the compressor meets the specified technical requirements and assess its overall quality.

Once you have identified a suitable supplier, negotiate pricing and terms that align with your budget and business goals. Be transparent about your purchasing volume to secure better rates. Discuss payment terms, delivery timelines, and any additional costs related to shipping or customs, particularly for international transactions.

Evaluate the logistics involved in importing the Slime 12V air compressor to your region. Understand the shipping options, customs requirements, and potential tariffs that may apply. Establishing efficient distribution channels will ensure timely delivery to your customers and maintain your competitive edge.

After procurement, continuously monitor the performance of the Slime 12V air compressors in your inventory. Gather feedback from users to assess satisfaction and identify any issues early. This proactive approach will help you make informed decisions for future purchases and enhance your overall product offering.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for the Slime 12V air compressor, ensuring that they secure a product that meets their needs while optimizing operational efficiency.

When analyzing the cost structure of sourcing Slime 12V air compressors, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margin.

Materials: The cost of raw materials is a significant factor. For air compressors, this includes metal components, plastic housing, electrical components, and rubber parts. Prices can fluctuate based on global supply and demand, impacting overall costs.

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with lower labor costs can offer more competitive pricing but may also raise concerns about quality and consistency.

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, facility maintenance, and salaries of non-production staff. Efficient manufacturing processes can help minimize these costs.

Tooling: Tooling costs involve the creation and maintenance of molds and machinery needed for production. Custom designs or modifications can increase these costs significantly.

Quality Control (QC): Ensuring product quality is essential, particularly for B2B buyers. QC processes add to the overall cost but are vital for maintaining standards and reducing returns.

Logistics: Transportation costs from the manufacturing facility to the buyer’s location can vary greatly based on distance, shipping method, and Incoterms. Efficient logistics management can help mitigate these costs.

Margin: Suppliers will add a profit margin to cover their risks and ensure sustainability. Understanding industry standards for margins can aid buyers in negotiating better deals.

Several factors can influence the pricing of Slime 12V air compressors, impacting the final cost to buyers.

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities can significantly reduce the per-unit cost. Suppliers often offer discounts for bulk orders, making it essential for buyers to assess their needs accurately.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (like ISO) can affect pricing. Higher-quality materials typically incur higher costs but may offer better durability and performance.

Supplier Factors: The supplier’s reputation, reliability, and geographic location can impact pricing. Established suppliers may command higher prices due to their proven track record and quality assurance.

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk during transportation. Different terms can lead to varying total costs, making it essential to negotiate favorable terms.

To maximize cost-efficiency when sourcing Slime 12V air compressors, buyers should consider the following negotiation strategies:

Research Market Prices: Knowledge of current market prices can provide leverage in negotiations. Buyers should gather data on competitor pricing and industry standards.

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better terms and pricing over time. Loyalty can often yield discounts or priority during supply shortages.

Evaluate Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential downtime. A slightly higher upfront cost may lead to lower TCO.

Be Flexible with Specifications: If buyers can compromise on certain specifications or features, they may be able to secure better pricing.

Consider Alternative Suppliers: Exploring multiple suppliers can help identify the best price and terms. A competitive bidding process can drive down costs.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of several pricing nuances:

Currency Fluctuations: Exchange rates can impact costs significantly. Buyers should consider hedging strategies or fixed contracts to mitigate risks.

Import Duties and Taxes: Understanding the local regulations regarding import duties and taxes is essential. These additional costs can affect the total price and should be factored into budgeting.

Cultural Negotiation Practices: Different regions have varying negotiation styles. Familiarity with local customs can enhance communication and lead to better deals.

Shipping and Handling Costs: International shipping can be unpredictable. Buyers should clarify shipping terms and be aware of potential delays or additional fees.

Regulatory Compliance: Compliance with local regulations and certifications can influence costs. Buyers should ensure that products meet local safety and quality standards to avoid additional expenses.

The prices and cost structures outlined in this analysis are indicative and may vary based on numerous factors including market conditions, supplier negotiations, and geographic considerations. Buyers are encouraged to conduct thorough due diligence and engage in comprehensive discussions with suppliers to obtain accurate pricing tailored to their specific needs.

Illustrative image related to slime 12v air compressor

In the automotive and industrial sectors, having efficient and reliable air inflation solutions is crucial for maintaining operational efficiency. The Slime 12V Air Compressor is a popular choice for tire inflation, but several alternatives exist that may better meet specific business needs. This analysis will compare the Slime 12V Air Compressor with two viable alternatives: a portable battery-operated air compressor and a traditional AC-powered air compressor.

| Comparison Aspect | Slime 12V Air Compressor | Portable Battery-Operated Air Compressor | Traditional AC-Powered Air Compressor |

|---|---|---|---|

| Performance | Inflates a standard tire in 8 minutes, 0-60 psi | Varies by model, typically slower than 12V | Generally faster, high PSI capability |

| Cost | Moderate, typically around $30-$50 | Varies widely, usually $50-$150 | Typically $100-$300, depending on power |

| Ease of Implementation | Simple plug-and-play with car battery | Requires charging or battery replacement | Needs a power outlet and often more setup |

| Maintenance | Minimal, occasional checks on hoses | Moderate, battery checks and replacements | Higher, requires regular maintenance checks |

| Best Use Case | Ideal for emergency roadside assistance | Suitable for remote locations without power | Best for garage or workshop settings |

Portable Battery-Operated Air Compressor

Portable battery-operated air compressors are designed for convenience and flexibility. They can be used in remote locations without access to a vehicle’s power source, making them ideal for outdoor activities or emergencies away from the road. However, their performance may vary significantly depending on the battery’s charge, and they often take longer to inflate tires compared to the Slime compressor. Additionally, these units typically require regular battery maintenance and eventual replacement, which can add to long-term costs.

Traditional AC-Powered Air Compressor

Traditional AC-powered air compressors are commonly used in workshops and garages. They are capable of delivering higher pressures and faster inflation times, making them suitable for heavier-duty applications such as commercial vehicle maintenance. However, their reliance on a constant power source limits their portability. Moreover, they tend to be more expensive and require ongoing maintenance, such as oil changes and filter replacements, which can be a downside for businesses looking to minimize overhead costs.

When selecting an air inflation solution, B2B buyers should consider the specific operational requirements of their business. The Slime 12V Air Compressor is an excellent choice for those needing a compact, efficient, and easy-to-use solution for emergency situations or light-duty applications. Conversely, if your operations frequently occur in remote locations or require higher performance, a portable battery-operated compressor may be more suitable. For businesses with a dedicated workspace and higher inflation demands, investing in a traditional AC-powered compressor could yield better long-term efficiency. Ultimately, the right choice will depend on balancing performance needs, budget constraints, and maintenance capabilities.

When evaluating the Slime 12V air compressor, several technical specifications are vital for B2B buyers. These specifications not only reflect the product’s performance but also indicate its suitability for various applications, particularly in international markets.

Inflation Rate: The Slime 12V air compressor can inflate a standard mid-sized car tire from flat to full in approximately 8 minutes. This rapid inflation capability is crucial for businesses that require efficiency in roadside assistance or emergency tire repairs, ensuring minimal downtime for vehicles.

Maximum Pressure: With a built-in dial gauge that measures up to 60 psi, this air compressor allows users to monitor tire pressure accurately. Understanding maximum pressure is essential for compliance with vehicle safety standards and ensuring optimal tire performance, reducing the risk of blowouts or accidents.

Power Source: Operating on a 12-volt accessory power, this compressor is designed for use in vehicles, making it particularly useful for automotive repair businesses and roadside assistance services. Its compatibility with standard vehicle power systems enhances its versatility in different markets, from Africa to Europe.

Portability: The compact and lightweight design of the Slime 12V air compressor makes it easy to store and transport. For B2B buyers, this is an important factor, especially for companies that need to carry multiple units for mobile service applications or emergency kits.

Durability and Build Quality: Constructed with robust materials, this air compressor is designed to withstand regular use in various conditions. Buyers should consider the durability as it affects the long-term investment and reliability of the product in demanding environments.

Included Accessories: The compressor comes with inflation adapters for sports balls and rafts, enhancing its utility beyond just tires. This adaptability can be a selling point for retailers looking to provide versatile products to consumers.

Understanding industry jargon is critical for B2B buyers to navigate procurement processes effectively. Here are several key trade terms related to the Slime 12V air compressor.

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help assess product quality and compatibility with existing equipment.

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to determine if a supplier meets their purchasing needs without overcommitting financially.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, submitting an RFQ for the Slime 12V air compressor can lead to better pricing negotiations and terms tailored to their purchasing volume.

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with the importation of the compressor.

Lead Time: This term refers to the time it takes from placing an order until the product is delivered. Buyers should consider lead times in their supply chain planning to ensure they have the necessary inventory to meet demand.

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition and performance of the product. Understanding warranty terms can give buyers confidence in their investment, as well as the potential for support in case of defects or failures.

By familiarizing themselves with these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing the Slime 12V air compressor, ensuring they meet their operational needs effectively.

The global market for 12V air compressors, particularly in the context of Slime products, is witnessing significant growth driven by several factors. Increased vehicle ownership in emerging markets, particularly in Africa, South America, and the Middle East, has led to a higher demand for portable tire inflators. The convenience of 12V air compressors, which can be powered by a car battery, appeals to consumers and businesses alike, making them essential tools for roadside emergencies and regular vehicle maintenance.

Illustrative image related to slime 12v air compressor

Emerging technologies are also reshaping the market landscape. The integration of digital pressure gauges and LED lighting in products enhances usability, while features like quick-connect hoses streamline the inflation process. In addition, the rise of e-commerce platforms has expanded access for international B2B buyers, allowing them to source products more efficiently and at competitive prices. Countries like Saudi Arabia and Vietnam are particularly poised for growth, with increasing investments in infrastructure and automotive sectors.

Furthermore, the trend toward multi-purpose devices is on the rise. Many buyers are looking for air compressors that can also inflate sports equipment and recreational items, increasing the appeal of products that offer versatility. This demand for multifunctional devices is an important consideration for B2B buyers when selecting suppliers and products.

Sustainability is becoming a cornerstone of purchasing decisions in the B2B landscape, and the slime 12V air compressor sector is no exception. Companies are increasingly aware of their environmental impact, pushing for products that incorporate sustainable materials and manufacturing processes. Buyers are particularly interested in suppliers that can demonstrate compliance with environmental standards and certifications, which can enhance brand reputation and consumer trust.

Ethical sourcing is also gaining traction. Businesses are looking for suppliers who prioritize fair labor practices and transparency in their supply chains. This trend is critical in regions like Africa and South America, where ethical concerns can significantly influence purchasing decisions. Certifications such as ISO 14001 for environmental management and fair trade standards can serve as indicators of a supplier’s commitment to sustainability.

For the Slime 12V air compressor, using recycled materials in product packaging and ensuring that the manufacturing process minimizes waste can be appealing to buyers focused on corporate social responsibility. As B2B buyers increasingly prioritize sustainability, aligning product offerings with these values can provide a competitive edge in the marketplace.

Illustrative image related to slime 12v air compressor

The Slime 12V air compressor has evolved significantly since its introduction, reflecting advancements in technology and changing consumer needs. Originally designed as a basic tire inflator, it has incorporated features such as built-in pressure gauges, LED lights, and multi-purpose functionality to meet the demands of modern consumers.

This evolution has been particularly relevant in the context of increasing urbanization and vehicle ownership in developing regions. As consumers seek reliable and versatile tools for vehicle maintenance, the Slime 12V air compressor stands out as a practical solution. Its adaptability for various inflation needs—from tires to sports equipment—makes it an attractive option for international B2B buyers.

The growth of online marketplaces has also facilitated access to Slime products, allowing buyers from diverse regions to source these innovative tools easily. As the market continues to develop, the Slime 12V air compressor remains a key player, combining reliability with advanced features that cater to the evolving needs of consumers and businesses alike.

1. How do I choose the right 12V air compressor for my business needs?

Selecting the appropriate 12V air compressor requires understanding your specific application. Consider the types of vehicles or equipment you will be servicing and the frequency of use. For example, if you are inflating tires for commercial vehicles or heavy machinery, opt for models with higher PSI and faster inflation times. Additionally, evaluate portability and power source compatibility to ensure the compressor meets your operational requirements.

2. What are the key features to look for in a 12V air compressor?

When sourcing a 12V air compressor, prioritize features such as inflation speed, built-in gauges, and LED lights for night use. Look for models with multiple inflation adapters to accommodate different items, such as sports balls and inflatable rafts. Durability is also crucial; select compressors designed for heavy-duty use to ensure longevity and reliability in various environments, particularly in regions with harsh conditions.

3. What is the minimum order quantity (MOQ) for Slime 12V air compressors?

The MOQ for Slime 12V air compressors can vary based on the supplier and your location. Typically, suppliers offer competitive pricing on bulk orders, which can range from 50 to 500 units. It’s advisable to communicate directly with suppliers to negotiate favorable terms based on your purchasing capacity and market demands.

4. How can I verify the credibility of a supplier for Slime 12V air compressors?

To vet suppliers, conduct thorough research by checking their business credentials, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with the products. Additionally, consider visiting trade shows or industry expos to meet suppliers in person and assess their product quality directly.

5. What payment terms are commonly accepted for international purchases?

Payment terms can vary by supplier, but common options include letters of credit, advance payments, and net payment terms (e.g., net 30 or net 60). It’s crucial to discuss and agree on payment methods that provide security for both parties. Using escrow services can also be beneficial for high-value transactions, ensuring that funds are only released upon satisfactory delivery.

6. How do I handle logistics and shipping for importing 12V air compressors?

When importing, collaborate with a reliable freight forwarder familiar with international shipping regulations. Consider factors such as shipping costs, transit times, and customs duties. Ensure that your supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate a smooth customs clearance process.

7. Can I customize the Slime 12V air compressor for my brand?

Yes, many suppliers offer customization options for branding purposes, including private labeling and custom packaging. Discuss your requirements with the supplier to understand the possibilities and any associated costs. Customization can enhance your brand visibility and create a distinct market presence, particularly in competitive regions.

8. What quality assurance measures should I expect from suppliers of 12V air compressors?

Reputable suppliers typically adhere to strict quality control standards, including testing products for functionality and safety before shipment. Inquire about their quality assurance processes, certifications, and warranty offerings. Consider requesting samples to evaluate product quality firsthand, ensuring that the compressors meet your expectations and industry standards.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Slime Pro COMP06 air compressor, 12v, priced around $60 on Amazon but found for $35, user reliability and quality concerns noted, comparison to Viair air pumps which are preferred in the off-road community for quality and performance.

In conclusion, the Slime 12V air compressor presents a strategic opportunity for B2B buyers focused on enhancing their product offerings in the automotive and outdoor markets. Its compact design, rapid inflation capabilities, and versatile application—ranging from vehicle tires to sports equipment—position it as a valuable addition to any inventory.

The value of strategic sourcing cannot be overstated; it not only ensures the procurement of high-quality products but also fosters strong supplier relationships that can lead to competitive pricing and better service. For international buyers in regions such as Africa, South America, the Middle East, and Europe, aligning with reputable suppliers of the Slime 12V air compressor can significantly enhance market competitiveness.

As demand for portable and efficient tire inflators continues to rise, now is the time to act. By integrating this innovative product into your offerings, you can meet evolving customer needs while positioning your business for future growth. Explore partnerships with Slime and elevate your product portfolio to seize emerging opportunities in the global marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to slime 12v air compressor