In an increasingly interconnected global market, sourcing the best 12V air compressors can be a daunting challenge for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With diverse applications ranging from automotive repairs to off-road adventures, the demand for reliable and efficient air compressors has surged. This comprehensive guide addresses the complexities of selecting the right 12V air compressor by exploring various types, their applications, and critical considerations for supplier vetting.

Buyers will gain insights into performance specifications, duty cycles, and features that enhance usability, ensuring they make informed decisions tailored to their specific needs. Furthermore, we delve into cost considerations, helping businesses understand the balance between quality and budget constraints. This guide empowers B2B buyers to navigate the competitive landscape effectively, equipping them with the knowledge necessary to select high-performance compressors that meet their operational requirements. Whether you are a distributor looking to stock reliable products or an end-user seeking the best equipment for your fleet, this resource provides the essential information to enhance your purchasing strategy.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

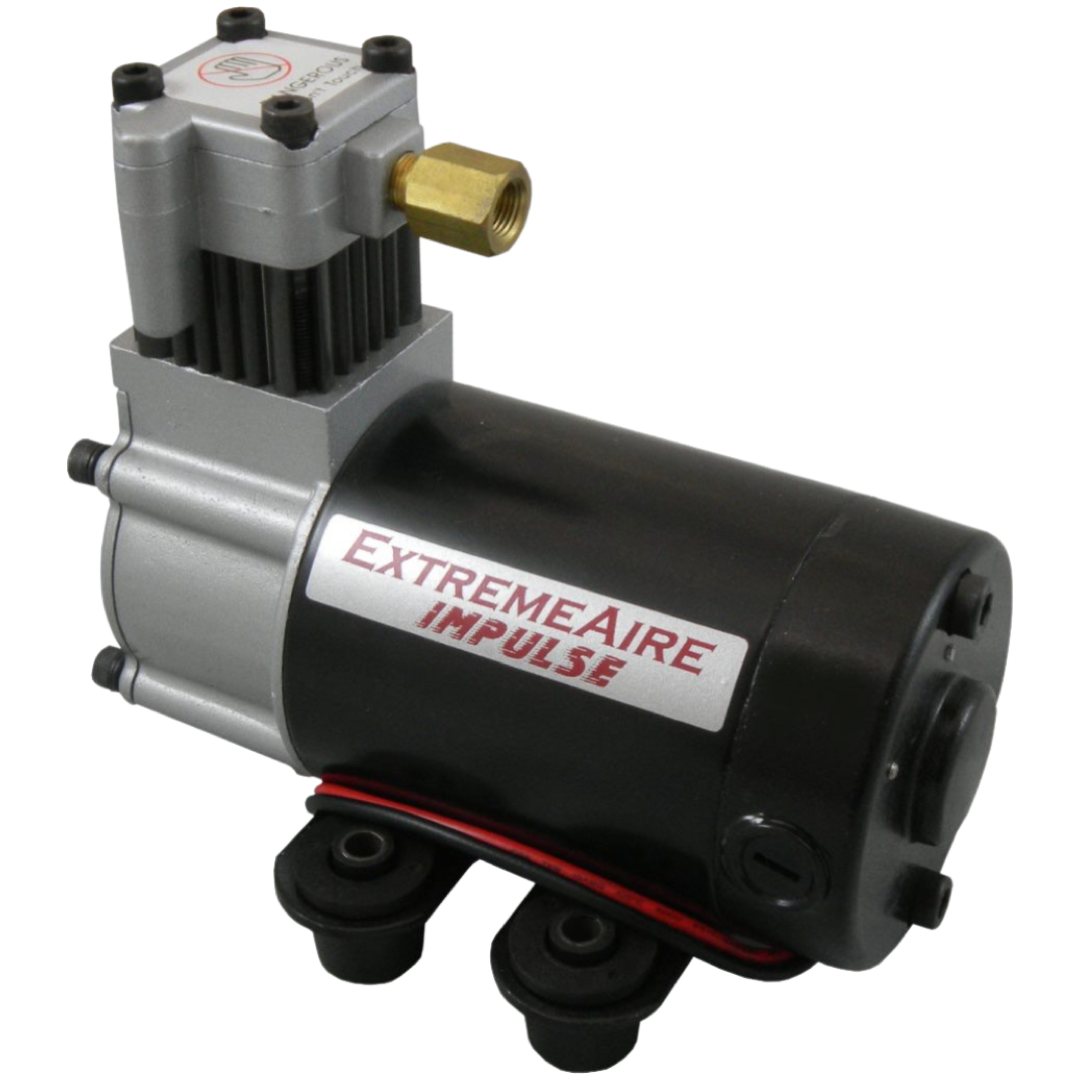

| Portable 12V Air Compressors | Compact, lightweight, and easy to transport; often plug into vehicle’s power outlet. | Automotive service, roadside assistance, camping | Pros: Highly portable; easy to use. Cons: Limited power and capacity compared to mounted options. |

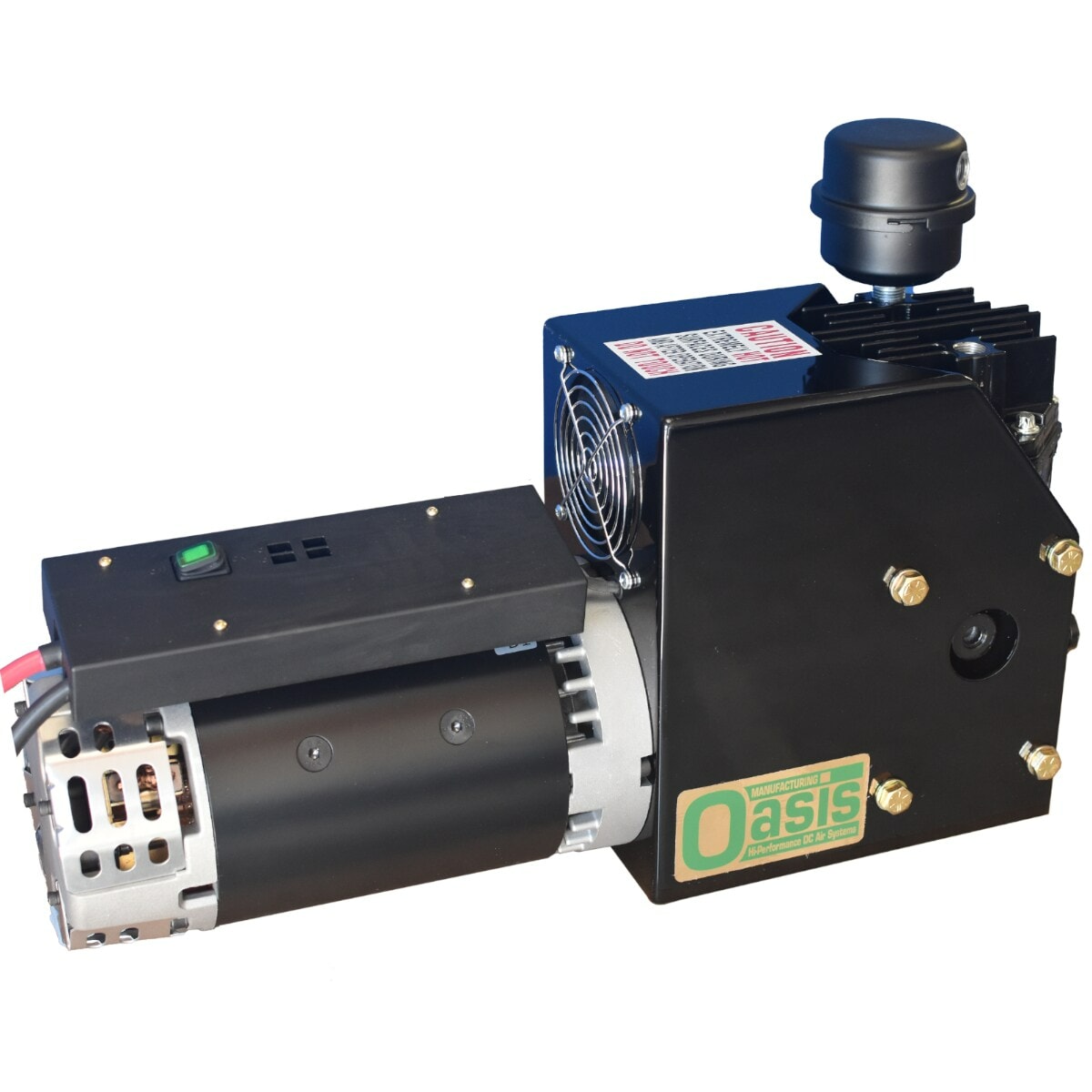

| Onboard 12V Air Compressors | Installed within the vehicle; provides continuous air supply; often used for air suspension systems. | Off-road vehicles, fleet vehicles, emergency services | Pros: Always ready for use; powerful. Cons: Installation complexity; requires vehicle modification. |

| Heavy-Duty 12V Air Compressors | Built for high-pressure applications; designed for continuous duty; often used in demanding environments. | Construction, heavy machinery, industrial applications | Pros: High performance; durable. Cons: Higher cost; larger size may limit portability. |

| Brushless 12V Air Compressors | Feature advanced motor technology for improved efficiency and lower noise levels. | Automotive, HVAC, pneumatic tools | Pros: Quieter operation; longer lifespan. Cons: Typically more expensive; may require specialized parts. |

| Dual Motor 12V Air Compressors | Equipped with two motors for increased airflow and faster inflation times. | Tire inflation for large vehicles, air tools | Pros: Faster inflation; higher output. Cons: Heavier; more complex installation. |

Portable 12V air compressors are designed for convenience and ease of use, making them ideal for automotive services and roadside assistance. Their compact size allows for easy transport, fitting into various vehicles without taking up much space. These compressors typically connect directly to a vehicle’s power outlet, which makes them a practical choice for temporary inflation tasks, such as tires or recreational equipment. However, buyers should consider their limited power and capacity, which may not be sufficient for larger applications.

Onboard 12V air compressors are permanently installed within vehicles, providing a reliable air source for continuous use. They are particularly beneficial in off-road and fleet vehicles, where quick access to air is essential for tire adjustments or powering air tools. These compressors are designed to withstand harsh conditions, making them suitable for emergency services and off-road adventures. However, potential buyers should be prepared for the complexities of installation and the need for vehicle modifications.

Illustrative image related to best 12v air compressors

Heavy-duty 12V air compressors are engineered for high-pressure applications and continuous duty cycles, making them essential in construction and industrial settings. Their robust build ensures reliability under demanding conditions, providing consistent air supply for pneumatic tools and machinery. Buyers should weigh the benefits of high performance and durability against the higher costs and larger size, which may limit portability and ease of use.

Brushless 12V air compressors utilize advanced motor technology, offering improved efficiency and reduced noise levels. They are suitable for a range of applications, including automotive and HVAC systems, where quieter operation is desired. These compressors have a longer lifespan due to fewer moving parts, making them an attractive option for businesses prioritizing durability. However, buyers should consider the higher initial investment and the potential need for specialized components.

Dual motor 12V air compressors feature two motors, resulting in increased airflow and faster inflation times. They are particularly useful for large vehicles and applications requiring rapid air delivery, such as tire inflation for trucks or buses. While they provide significant advantages in terms of performance, buyers should be aware of the increased weight and installation complexity, which may necessitate additional resources for setup.

| Industry/Sector | Specific Application of best 12v air compressors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Enhances service speed and customer satisfaction | Reliability, PSI ratings, duty cycle, and portability |

| Construction & Heavy Equipment | Powering pneumatic tools and equipment on-site | Increases productivity by reducing downtime for tool setup | Airflow capacity, durability, and compatibility with existing systems |

| Off-Road & Adventure Sports | Adjusting tire pressure for off-road vehicles | Improves vehicle performance and safety in challenging terrains | Compact size, ease of use, and ability to handle varying PSI requirements |

| Agriculture | Inflating and maintaining air suspension systems in machinery | Enhances operational efficiency and equipment longevity | Continuous duty capability and resistance to harsh environmental conditions |

| Emergency Services | Providing portable air supply for rescue and medical equipment | Critical for timely response and operational readiness | Compact design, quick deployment features, and robust construction |

In the automotive repair industry, 12V air compressors are essential for tire inflation and routine maintenance. These compressors enable mechanics to quickly inflate tires, ensuring vehicles are road-ready in minimal time, which directly boosts customer satisfaction. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing compressors that offer high PSI ratings and durability is crucial, given the varying climates and road conditions. Additionally, the ability to operate on a vehicle’s battery makes these compressors practical for mobile service applications.

In construction, 12V air compressors are utilized to power pneumatic tools and equipment on job sites. This capability significantly increases productivity by minimizing downtime associated with manual setups. For businesses in South America and Europe, sourcing compressors with high airflow capacity and durability is vital, as these tools often face rigorous use in harsh conditions. Buyers should consider compressors that can withstand the demands of continuous operation, ensuring that their teams can maintain high efficiency on-site.

Off-road and adventure sports enthusiasts rely on 12V air compressors to adjust tire pressure for optimal performance on rugged terrains. By easily inflating or deflating tires, these compressors enhance traction and vehicle safety, making them indispensable for off-road adventures. For B2B buyers in regions like Germany and Nigeria, the compact size and ease of use of these compressors are critical factors. They must also ensure that the compressors can handle varying PSI requirements, especially in unpredictable environments.

In agriculture, 12V air compressors are employed to inflate and maintain air suspension systems in various machinery, such as tractors and harvesters. This application enhances operational efficiency and extends the life of equipment, which is crucial in high-stakes agricultural environments. Buyers from Africa and South America should focus on sourcing compressors designed for continuous duty and that can withstand harsh weather conditions. Durability and reliability are key factors, as agricultural operations often require equipment to perform consistently over extended periods.

Emergency services utilize 12V air compressors to provide a portable air supply for rescue operations and medical equipment. These compressors are vital for ensuring timely responses in critical situations, where every second counts. For international buyers, particularly in the Middle East and Europe, the ability to quickly deploy these compressors and their robust construction are significant considerations. Ensuring that the compressors are compact and easy to transport can enhance operational readiness in emergencies, making them a valuable asset for any emergency response team.

The Problem: One common pain point for B2B buyers in need of 12V air compressors is the inconsistency in performance. Companies that rely on these compressors for tasks like inflating tires or powering pneumatic tools often encounter issues with pressure delivery and airflow. Inconsistent PSI levels can lead to operational delays, impacting project timelines and increasing costs. This inconsistency is particularly problematic in industries such as construction or automotive service, where time is money, and reliability is crucial.

The Solution: To mitigate performance inconsistencies, buyers should prioritize compressors with robust specifications that include maximum PSI and CFM ratings. When sourcing, look for models designed for continuous duty cycles, as they are built to maintain performance over longer periods without overheating. It’s also beneficial to invest in compressors that offer features such as automatic shut-off and thermal protection, which help maintain consistent performance and prevent damage from prolonged use. Conducting thorough market research and reading user reviews can aid in identifying models that have proven reliability in demanding environments.

Illustrative image related to best 12v air compressors

The Problem: Many B2B buyers require 12V air compressors that are portable enough for field operations, particularly in industries like agriculture, emergency services, and off-road vehicle maintenance. However, the weight and size of some compressors can hinder mobility, making it challenging to transport them to job sites. This issue can lead to inefficiencies as teams may struggle with cumbersome equipment, ultimately affecting productivity and service delivery.

The Solution: When selecting a portable 12V air compressor, buyers should assess the compressor’s weight-to-performance ratio. Opt for models that strike a balance between portability and power, such as compact, lightweight designs that do not compromise on airflow and pressure capabilities. Additionally, consider compressors with built-in storage solutions or carry handles to facilitate easier transport. Buyers can also look for compressors that come with vehicle-mount kits, ensuring that the equipment is securely stored and readily accessible during field operations. Investing in a high-quality, portable air compressor can significantly enhance operational efficiency and responsiveness.

The Problem: Another significant pain point for B2B buyers is the maintenance of 12V air compressors and the availability of spare parts. Compressors that are difficult to service can lead to prolonged downtime, which is particularly detrimental in industries that require high equipment availability, such as logistics and transportation. Additionally, if spare parts are not readily available, companies may face increased repair costs and delays in getting equipment back in operation.

The Solution: To address maintenance challenges, buyers should choose brands known for their durability and ease of service. Select compressors that are designed for rebuildability, ensuring that spare parts can be easily sourced when needed. Prior to purchase, inquire about the availability of parts and whether the manufacturer offers comprehensive support and maintenance resources. Establishing a proactive maintenance schedule can also help prolong the lifespan of the compressor. Regularly checking components such as air hoses, pressure gauges, and filters can prevent issues before they escalate, ensuring that the compressor remains in optimal working condition. By focusing on these aspects, buyers can significantly enhance the reliability and longevity of their 12V air compressors, reducing overall operational costs.

When selecting materials for 12V air compressors, various factors such as performance, durability, and cost-effectiveness come into play. Here’s an analysis of four common materials used in the construction of these compressors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties:

Aluminum is known for its excellent strength-to-weight ratio, making it ideal for portable air compressors. It also offers good corrosion resistance, particularly when anodized, and can withstand moderate temperatures and pressures.

Pros & Cons:

The lightweight nature of aluminum enhances portability, which is crucial for mobile applications. However, it can be more expensive than some alternatives and may not handle extreme pressures as effectively as steel. Manufacturing complexity can also be higher due to the need for specialized machining.

Illustrative image related to best 12v air compressors

Impact on Application:

Aluminum is suitable for applications where weight is a concern, such as in off-road vehicles or portable units. Its corrosion resistance makes it a good choice for humid or coastal environments.

Considerations for International Buyers:

Compliance with international standards such as ASTM or DIN is essential. Buyers from regions like Africa and South America may prefer aluminum for its lightweight properties, especially in transportation-heavy applications.

Key Properties:

Steel is renowned for its strength and durability, with high temperature and pressure ratings. It is often treated for corrosion resistance, enhancing its longevity in harsh environments.

Pros & Cons:

The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. However, it is heavier than aluminum, which can be a disadvantage for portable units. Additionally, the cost of high-quality steel can be significant, impacting overall pricing.

Impact on Application:

Steel is ideal for stationary compressors or those used in industrial settings where durability is paramount. Its ability to withstand high pressures makes it suitable for applications requiring consistent air delivery.

Illustrative image related to best 12v air compressors

Considerations for International Buyers:

Steel components must meet specific standards for pressure vessels. Buyers from Europe, particularly Germany, often look for compliance with DIN standards, while buyers in Africa may prioritize cost-effectiveness.

Key Properties:

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are lightweight and resistant to corrosion. They can handle moderate pressures and temperatures, making them suitable for specific applications.

Pros & Cons:

The primary advantage of plastic is its low cost and lightweight nature, which enhances portability. However, its pressure ratings are lower than metals, limiting its use in high-demand applications. Additionally, certain plastics may degrade under UV exposure.

Impact on Application:

Plastic is often used in smaller, portable compressors or components that do not require high-pressure capabilities. It is suitable for inflating recreational items or low-demand applications.

Illustrative image related to best 12v air compressors

Considerations for International Buyers:

Buyers should ensure that the plastics used comply with relevant safety and environmental regulations, especially in regions with strict compliance standards. In South America, where cost sensitivity is high, plastic components may be favored.

Key Properties:

Copper is an excellent conductor of electricity and offers good corrosion resistance. It can handle high temperatures and is often used in electrical windings and connections in compressors.

Pros & Cons:

The main advantage of copper is its superior electrical conductivity, which enhances compressor efficiency. However, it is more expensive than aluminum or plastic and can be prone to corrosion if not properly treated.

Impact on Application:

Copper is essential in components that require efficient electrical connections, such as motors and wiring. Its thermal conductivity also helps in heat dissipation.

Considerations for International Buyers:

B2B buyers should consider the availability of copper and its pricing fluctuations. Compliance with electrical standards is crucial, particularly in regions like Europe where regulations are stringent.

Illustrative image related to best 12v air compressors

| Material | Typical Use Case for best 12v air compressors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable and off-road applications | Lightweight and corrosion-resistant | Higher cost and pressure limitations | Medium |

| Steel | Heavy-duty and industrial applications | High strength and durability | Heavier and more expensive | High |

| Plastic | Small, portable compressors | Low cost and lightweight | Limited pressure ratings | Low |

| Copper | Electrical components in compressors | Excellent conductivity | Higher cost and corrosion potential | High |

This analysis provides valuable insights for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and regional compliance considerations.

The manufacturing process of high-quality 12V air compressors involves several critical stages, each designed to ensure product reliability and performance. The main stages typically include:

The foundation of any robust air compressor begins with the selection of high-grade materials. Manufacturers often use metals such as aluminum and steel for the compressor body due to their strength and lightweight properties. Additionally, components like rubber and plastic are selected for seals and housings. Material preparation also includes rigorous testing to ensure that materials meet specified standards for durability and performance.

Illustrative image related to best 12v air compressors

Once the materials are prepared, they undergo various forming techniques. Common methods include machining, casting, and forging. For instance, precision machining is essential for creating parts like cylinders and pistons to ensure they fit together seamlessly, which is critical for maintaining air pressure. Advanced techniques such as CNC (Computer Numerical Control) machining are frequently employed to enhance accuracy and reduce production time.

The assembly of the compressor involves integrating various components, including the motor, pump, and electronic systems. This stage often utilizes automated assembly lines to improve efficiency and consistency. Skilled technicians perform critical checks during this phase to ensure that each component is correctly fitted and functions as intended. Additionally, assembly often includes the installation of safety features, such as thermal overload protection and automatic shut-off mechanisms.

After assembly, the compressors undergo finishing processes, which may include painting, powder coating, and quality polishing. These not only enhance the aesthetic appeal of the product but also improve resistance to environmental factors, such as corrosion. Quality control checkpoints are established at this stage to ensure that the final product meets both aesthetic and functional standards.

Illustrative image related to best 12v air compressors

Quality assurance (QA) is an integral part of the manufacturing process for 12V air compressors, ensuring that each unit meets international standards and customer expectations. Key elements of QA include:

Manufacturers of 12V air compressors often adhere to several international standards to ensure quality and safety. ISO 9001 is one of the most recognized standards, focusing on quality management systems. Compliance with this standard signifies that the manufacturer has established procedures for consistent quality in its products. Additionally, certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for specific applications are crucial for global acceptance.

Quality control (QC) consists of several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials before they enter the production line. Materials are assessed against predefined specifications to prevent defects in the final product.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC is conducted to monitor production parameters and ensure adherence to quality standards. This includes regular inspections and testing of components as they are manufactured.

Final Quality Control (FQC): After the assembly of the compressors, FQC is performed to evaluate the entire unit’s performance. This may involve pressure testing, airflow measurement, and operational checks to confirm that the compressor meets all functional specifications.

Testing methods are vital for verifying that each compressor functions correctly and safely. Common testing procedures include:

Pressure Testing: Compressors are subjected to high-pressure tests to ensure they can handle specified pressures without leaks or failures.

Flow Rate Testing: This assesses the compressor’s airflow capabilities, ensuring that it meets the required CFM (Cubic Feet per Minute) ratings for various applications.

Durability Testing: Units are often run through extended cycles to simulate real-world usage, checking for wear and tear over time.

Thermal Testing: This evaluates the compressor’s ability to operate under high temperatures, ensuring that thermal protection features function correctly.

B2B buyers looking to source 12V air compressors should conduct due diligence to ensure that their suppliers maintain high-quality standards. Effective methods to verify supplier QC include:

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and compliance with international standards. This firsthand observation can provide insights into the supplier’s operational capabilities.

Quality Assurance Reports: Requesting detailed QC reports from suppliers can help buyers understand the specific measures taken during production. These reports should outline the results of various tests and inspections.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These organizations can perform thorough evaluations and provide certifications that ensure compliance with industry standards.

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Key considerations include:

Illustrative image related to best 12v air compressors

Regional Compliance Standards: Different regions may have specific compliance requirements that suppliers must meet. Understanding these standards can help buyers avoid regulatory issues.

Cultural Differences: Variations in manufacturing practices and quality expectations may exist across different countries. Buyers should be aware of these differences to ensure that their expectations align with local practices.

Communication and Language Barriers: Effective communication is crucial for ensuring that quality standards are met. Buyers should establish clear lines of communication with suppliers and, if necessary, utilize translation services to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices of 12V air compressors, B2B buyers can make informed decisions, ensuring they source reliable and high-performance products that meet their specific needs.

This practical sourcing guide is designed to assist B2B buyers in identifying and procuring the best 12V air compressors suited for their specific needs. Given the diverse applications and environments in which these compressors are used, it is essential to follow a structured approach to ensure that your investment meets performance, reliability, and operational requirements.

Establishing clear technical specifications is the first step in the sourcing process. Consider the maximum pressure (PSI) and airflow (CFM) ratings required for your applications, whether for inflating tires, powering tools, or other uses. This clarity will help narrow down suitable models and ensure that the compressor you select can meet your operational demands effectively.

Ensure that the air compressor is compatible with your vehicle or power system. Most 12V air compressors connect directly to a vehicle’s battery, so it’s crucial to verify that the power supply can handle the compressor’s requirements. Pay attention to the wiring and connector specifications to avoid any electrical issues during operation.

Determine whether you need a portable unit or an onboard compressor. Portability is vital if the compressor will be moved frequently, while onboard systems are ideal for vehicles that require a permanent installation. Assess the size and weight for portable models, and check mounting options for fixed installations to ensure they fit within your operational space.

The duty cycle indicates how long the compressor can operate continuously before needing to cool down. A longer duty cycle is beneficial for extensive or demanding applications. Review performance ratings closely, focusing on both PSI and CFM to ensure the compressor can handle your specific needs efficiently without overheating.

Investigate potential suppliers to understand their market reputation. Look for certifications that demonstrate compliance with international standards, which is particularly important for buyers in regions like Europe and the Middle East. Request references and case studies from similar industries to gauge reliability and performance.

Before making a bulk purchase, request product demonstrations or samples to evaluate performance firsthand. This step is crucial, especially for high-value investments, as it allows you to assess the compressor’s functionality, ease of use, and compatibility with your specific applications.

Evaluate the after-sales support offered by the supplier, including warranty terms and availability of spare parts. A comprehensive warranty and reliable support can significantly enhance the longevity and performance of your compressor, ensuring that any issues can be addressed promptly without incurring additional costs.

By following this structured checklist, B2B buyers can make informed decisions when sourcing the best 12V air compressors, ultimately ensuring a successful procurement process that meets their operational needs.

Illustrative image related to best 12v air compressors

When sourcing 12V air compressors, understanding the cost structure is critical for B2B buyers. The primary cost components include:

Materials: The quality and type of materials used in manufacturing the compressor significantly affect the cost. High-grade metals, durable plastics, and specialized components (like motors and pumps) contribute to the overall expense.

Labor: Labor costs vary by region and manufacturing capability. Skilled labor may be required for assembly, especially in more complex compressor designs.

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

Tooling: Initial tooling costs can be substantial, especially for custom or specialized compressors. This is an upfront investment that affects the unit price, especially for low-volume orders.

Quality Control (QC): Implementing rigorous QC processes ensures reliability and safety, which can increase costs but ultimately protects the buyer from future liabilities.

Logistics: Transportation costs, including shipping and customs duties, can vary widely based on the origin of the product and destination. It’s crucial to factor in these costs, especially for international shipments.

Margin: Suppliers typically add a margin to cover their expenses and profit. This margin can fluctuate based on market competition and demand.

Several factors can influence the pricing of 12V air compressors:

Volume/MOQ: Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials: The choice of materials impacts both performance and price. Premium materials may enhance durability but will also raise costs.

Quality and Certifications: Compressors that meet specific industry standards or certifications (like ISO or CE) may command higher prices but offer assurance of quality.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record.

Incoterms: The chosen Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in shipping. They can significantly affect total landed costs, impacting pricing negotiations.

To enhance cost-efficiency and secure better pricing, international B2B buyers should consider the following strategies:

Negotiate Effectively: Understand the supplier’s cost structure to negotiate from an informed position. Highlight potential for larger future orders to encourage better pricing.

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational costs, and longevity when evaluating compressors. A lower upfront cost may result in higher TCO.

Be Aware of Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to labor costs, tariffs, and shipping expenses. Buyers from Africa, South America, the Middle East, and Europe should research local market conditions.

Request Samples: Before committing to a large order, request samples to evaluate quality and performance. This can prevent costly mistakes.

Stay Informed on Market Trends: Keeping abreast of industry trends and pricing changes can provide leverage in negotiations. Understanding demand cycles can also help in planning purchases.

The prices mentioned in various sources may fluctuate based on market conditions, supplier changes, and shipping costs. Always verify current pricing and terms directly with suppliers before making purchasing decisions.

In the quest for efficient air delivery systems, businesses often consider various alternatives to 12V air compressors. While these compressors are renowned for their portability and versatility, other solutions may better suit specific applications or operational needs. This analysis compares the best 12V air compressors against two viable alternatives: portable gas-powered air compressors and stationary electric air compressors.

Illustrative image related to best 12v air compressors

| Comparison Aspect | Best 12V Air Compressors | Portable Gas-Powered Air Compressors | Stationary Electric Air Compressors |

|---|---|---|---|

| Performance | Moderate PSI (up to 200) with varying CFM ratings suitable for tires and small tools. | High PSI (up to 200+) and CFM ratings, ideal for heavy-duty applications. | High PSI and CFM, designed for continuous duty in industrial settings. |

| Cost | Ranges from $200 to $1,400, depending on features and performance. | Typically between $300 and $1,500, depending on size and output. | Generally $300 to $2,000, depending on specifications and brand. |

| Ease of Implementation | Easily connects to vehicle batteries; portable units can be used anywhere. | Requires fuel (gasoline) and may need more space; less portable. | Fixed installation needed, requiring dedicated space and electrical setup. |

| Maintenance | Low maintenance; regular checks on hoses and seals. | Moderate maintenance; requires oil changes and fuel management. | Low to moderate; periodic servicing needed for electrical components. |

| Best Use Case | Ideal for off-road enthusiasts, emergency situations, and light-duty tasks. | Best for construction sites and heavy-duty tasks requiring high air output. | Suitable for workshops and factories needing continuous air supply. |

Portable gas-powered air compressors offer significant advantages, particularly in terms of performance. They deliver higher PSI and CFM ratings, making them ideal for demanding tasks such as powering pneumatic tools or inflating large tires. However, the need for fuel and potential emissions can be drawbacks in certain environments, particularly in urban settings or enclosed spaces. Additionally, they can be heavier and less portable than their 12V counterparts.

Stationary electric air compressors excel in environments where continuous air supply is needed. They typically provide consistent performance with high PSI and CFM ratings, making them ideal for industrial applications. However, their installation can be cumbersome, requiring a dedicated electrical supply and space, which may not be feasible for all businesses. Furthermore, they lack the portability of 12V compressors, limiting their use in mobile applications.

When evaluating air delivery solutions, B2B buyers should consider their specific operational needs and constraints. Best 12V air compressors are optimal for mobile applications and light-duty tasks, while portable gas-powered compressors are better suited for high-demand environments. Stationary electric compressors, on the other hand, are ideal for businesses requiring a reliable, continuous air supply. By aligning the choice of compressor with specific use cases, businesses can maximize efficiency and ensure they have the right tools for their operations.

When selecting a 12V air compressor for B2B applications, understanding critical specifications is essential. Here are some key technical properties that buyers should consider:

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the compressor’s ability to inflate tires or power pneumatic tools. Higher PSI ratings are crucial for applications requiring robust performance, such as off-road vehicle maintenance or industrial uses. A compressor with a higher PSI can ensure efficient operation, reducing downtime and improving productivity.

Illustrative image related to best 12v air compressors

Airflow rate, expressed in cubic feet per minute (CFM), measures the volume of air delivered by the compressor. This specification is vital for determining how quickly a compressor can inflate tires or power air tools. For businesses that rely on quick turnarounds, a higher CFM can enhance operational efficiency and reduce waiting time during inflation tasks.

The duty cycle defines the amount of time a compressor can operate before needing a cooldown period. Typically expressed as a percentage, a higher duty cycle means the compressor can run longer without overheating. For continuous operations, such as in automotive workshops or construction sites, a compressor with a long duty cycle ensures reliability and minimizes interruptions.

Most 12V air compressors connect directly to a vehicle’s battery, making power source compatibility a critical factor. It is essential to verify that the compressor can be easily integrated into existing power systems without requiring extensive modifications. This consideration is particularly important for B2B buyers operating in regions with varying electrical standards.

The materials used in the compressor’s construction impact its durability and performance. High-quality materials, such as aluminum or reinforced plastics, can enhance resistance to wear and corrosion, extending the lifespan of the compressor. For businesses operating in harsh environments, selecting compressors with robust construction can lead to lower maintenance costs and improved reliability.

Understanding industry-specific jargon can facilitate smoother transactions and negotiations. Here are several essential trade terms relevant to 12V air compressors:

Illustrative image related to best 12v air compressors

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air compressors, OEM components ensure compatibility and reliability, making them a preferred choice for businesses seeking high-quality parts for their systems.

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and cost-effectiveness. Buyers must assess their needs against the supplier’s MOQ to ensure that they are making economically viable purchases.

An RFQ is a formal process in which buyers request pricing and terms from suppliers for specific products. Submitting an RFQ for 12V air compressors allows businesses to compare options and negotiate better pricing, ensuring they receive the best value for their investment.

Illustrative image related to best 12v air compressors

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers engaging in cross-border purchases of air compressors, as they clarify shipping costs and risk responsibilities.

A warranty provides assurances regarding the performance and lifespan of a product, while a service agreement outlines the support and maintenance provided by the supplier. Understanding these terms is vital for B2B buyers to ensure they are protected against defects and can maintain their compressors efficiently.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when selecting the best 12V air compressors for their specific needs, ultimately enhancing their operational efficiency and profitability.

The global market for 12V air compressors is witnessing significant growth driven by several factors. Increasing demand in automotive applications, particularly in off-road and recreational vehicles, has heightened the need for reliable, portable air solutions. Additionally, the rise of e-commerce has facilitated easier access for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Buyers are increasingly looking for high-performance compressors that offer versatility for various applications, including tire inflation, powering tools, and air suspension systems.

Illustrative image related to best 12v air compressors

Emerging technologies are reshaping sourcing trends, with innovations like brushless motors enhancing efficiency and durability. Furthermore, manufacturers are increasingly incorporating smart features such as automatic shut-off and thermal protection, appealing to businesses that prioritize safety and reliability. The demand for compact and lightweight designs is also on the rise, catering to customers who require portability without compromising on performance.

Market dynamics are influenced by the regulatory landscape, with stricter environmental standards pushing manufacturers to develop eco-friendly products. This trend is particularly relevant for international buyers who are keen on aligning their procurement practices with sustainability goals. Ultimately, understanding these dynamics is crucial for B2B buyers to make informed sourcing decisions and remain competitive in the evolving marketplace.

The environmental impact of manufacturing processes and the importance of ethical supply chains are becoming increasingly significant for B2B buyers in the 12V air compressor sector. As global awareness of climate change rises, companies are under pressure to source products that minimize their ecological footprint. This includes selecting manufacturers who adhere to sustainable practices, such as using recycled materials and energy-efficient production methods.

B2B buyers are also looking for products certified by recognized environmental standards, which can include ISO 14001 or Energy Star certifications. These certifications not only assure buyers of a product’s environmental compliance but also enhance their brand image in the eyes of environmentally conscious consumers. Additionally, companies that prioritize sustainability often benefit from reduced operational costs, as energy-efficient compressors lead to lower electricity consumption.

Ethical sourcing practices also extend to labor conditions and fair trade principles. International buyers from regions like Africa and South America are increasingly favoring suppliers who demonstrate a commitment to social responsibility, ensuring fair wages and safe working conditions for workers involved in the manufacturing process. This focus on sustainability and ethics is not just a trend but a strategic imperative for companies looking to thrive in a socially aware marketplace.

Illustrative image related to best 12v air compressors

The evolution of the 12V air compressor market can be traced back to the increasing need for portable air solutions in various industries. Initially, these compressors were primarily utilized in automotive applications for tire inflation. Over time, advancements in technology have led to the development of more robust models capable of handling diverse tasks, from powering pneumatic tools to inflating recreational gear.

As consumer preferences shifted towards more efficient and compact designs, manufacturers began to innovate. The introduction of brushless motors and enhanced duty cycles allowed for longer operational times and reduced maintenance needs, catering to a growing segment of users who demand high performance in rugged conditions.

Today, the market is characterized by a broader range of applications and a keen focus on sustainability. As B2B buyers seek out products that align with their operational needs and environmental values, the 12V air compressor sector continues to adapt, ensuring it remains relevant and competitive in a dynamic global landscape.

Illustrative image related to best 12v air compressors

1. How do I choose the right 12V air compressor for my business needs?

Choosing the right 12V air compressor involves assessing your specific requirements such as pressure (PSI) and airflow (CFM) ratings. Consider the intended applications—whether for tire inflation, air tools, or onboard systems. Evaluate the compressor’s duty cycle to ensure it can handle your workload without overheating. Additionally, factor in portability versus fixed installation, as well as the compatibility with your vehicle’s power supply. Research various brands and models to find one that balances performance, reliability, and cost-effectiveness.

2. What features should I look for in a 12V air compressor?

Key features to consider include maximum pressure output, airflow capacity, and duty cycle, which indicates how long the compressor can run without cooling down. Look for built-in safety features such as automatic shut-off and thermal protection. Additional functionalities like a dial pressure gauge for precise inflation and easy portability can enhance usability. Ensure the compressor is designed for durability, especially if it will be used in harsh conditions typical of off-road or industrial applications.

3. What are the common applications for 12V air compressors in B2B settings?

12V air compressors are versatile and can be utilized in various B2B applications including tire inflation for vehicles, powering pneumatic tools, and providing air supply for air suspension systems. They are particularly beneficial in sectors like automotive, construction, and outdoor recreation. Additionally, businesses in remote areas can use them to operate air tools and equipment where traditional power sources are unavailable, increasing efficiency and productivity.

4. How can I vet suppliers for 12V air compressors?

To effectively vet suppliers, start by assessing their reputation and industry experience. Check reviews and testimonials from other B2B buyers, and inquire about their product certifications and compliance with international standards. Request sample products to evaluate quality firsthand. Additionally, consider their responsiveness to inquiries, ability to customize products, and willingness to provide after-sales support. A reliable supplier should offer transparent communication and a clear understanding of your business needs.

5. What is the typical minimum order quantity (MOQ) for 12V air compressors?

The minimum order quantity for 12V air compressors can vary significantly depending on the supplier and the type of product. Generally, MOQs can range from as low as 10 units to several hundred. It’s essential to discuss your specific requirements with potential suppliers, as many are willing to negotiate MOQs for new customers or bulk orders. Understanding the MOQ is crucial for managing inventory and ensuring you meet your business demand without overcommitting.

6. What payment terms should I expect when sourcing 12V air compressors?

Payment terms can vary by supplier but often include options like upfront deposits (commonly 30-50%) with the balance due upon delivery or before shipment. Some suppliers may offer credit terms for established businesses, allowing for payment after a specified period. It’s important to clarify these terms upfront and ensure they align with your cash flow management. Additionally, consider using secure payment methods that provide buyer protection to mitigate risks.

7. How do I ensure quality assurance for imported 12V air compressors?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Consider arranging for third-party quality inspections before shipment, especially for large orders. Establish clear quality control standards that the products must meet upon arrival. Additionally, inquire about warranties and return policies to safeguard your investment. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations.

8. What logistics considerations should I keep in mind when importing 12V air compressors?

Logistics considerations include understanding shipping methods, costs, and delivery timelines. Assess whether the supplier offers direct shipping or if you need to arrange logistics through a freight forwarder. Be aware of customs regulations and potential duties that may apply to your imports, particularly when sourcing from international suppliers. Ensure proper packaging to prevent damage during transit, and maintain clear communication with your shipping provider for timely updates on your order’s status.

Domain: liveworkdream.com

Registered: 2006 (19 years)

Introduction: Helteko 12v DC Air Compressor:

– Compact size

– Rated to 150 psi

– Auto inflation shut-off limit

– Price: $35±

– Cons: Motor started smoking at 70± psi after minutes of use.

Kobalt 120v AC / 12v DC Portable Air Compressor:

– Sturdy build

– Rated to 120 psi

– Programmable auto inflation shut-off limit

– Easy to read display

– Accurate pressure gauge

– Price: $55±

– Cons: Short AC powe…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Onboard 12v air compressors discussed include: 1. Belt drive compressor with 8 CFM capacity. 2. Electric compressor with 10.6 CFM from MorrFlate. 3. Chinese single cylinder (160LPM) and twin cylinder (300LPM) compressors available under various brands like Iron Man, Smittybilt, Ridge Ryder, etc. 4. Price range typically under $100. 5. Features include pressure control, pressure release valve, and …

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems by ARB 4×4 USA. Key features include: 1. Reliable, high-performance compressors for tires, tools, and Air Lockers. 2. Available types: Onboard and Portable compressors. 3. Promotions: 10% off Air Compressors & Accessories, free ground shipping over $75 (excludes Brushless Compressors). 4. Product range includes: Twin Motor Onboard 12V Air Compresso…

Domain: trailtacoma.com

Registered: 2019 (6 years)

Introduction: 1. MORRFlate Portable Air Systems TenSix PSI Pro: Max Pressure: 150 PSI, Duty Cycle: 50%, Volts and Amps: 12v, 90amp peak, 50amp running, Size: 14″ x 7″ x 9″, Weight: 20 lbs., CFM: 10.6, Warranty: 1-year. 2. ARB Twin High-Performance (CKMTA12): Max Pressure: 150 PSI, Duty Cycle: 100%, Volts and Amps: 12v, 90amp peak, 50amp running, Size: 19.69 X 10.24 x 4.72 (inches), Weight: 21 lbs., CFM: 6.16, W…

Domain: mavericktruckclub.com

Registered: 2020 (5 years)

Introduction: Tozalazz 12V air compressor, 11.65 CFM, capable of inflating two front tires simultaneously or four tires with FlexInflate 4-tire inflation/deflation Hose System.

Domain: mygrandrv.com

Registered: 2019 (6 years)

Introduction: 1. VIAIR 450RV – 150psi unit, standalone, comes with accessories, takes 1-2 minutes to top up tires by 10 pounds. 2. VIAIR 300P Portable Compressor – works well for 110 PSI tires. 3. Black and Decker 12V DC Multipurpose Inflator – can do both tires and low pressure items. 4. Harbor Freight 12V 150 PSI Compact Air Compressor – fills tires quickly. 5. Smittybilt 12V compressor – heavy duty, better s…

Domain: hornblasters.com

Registered: 2003 (22 years)

Introduction: Heavy-Duty 12V Air Compressors – Reliable & Powerful

In summary, selecting the right 12V air compressor involves understanding the specific needs of your business and the operational environments in which these compressors will be deployed. Key factors such as performance specifications, portability, and duty cycle are essential in ensuring that the compressor meets the demands of various applications—from tire inflation to powering air tools. Strategic sourcing plays a crucial role in this process, enabling buyers to evaluate and choose high-quality products that align with their operational goals while optimizing cost-efficiency.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, investing in reliable and durable air compressor solutions can significantly enhance operational efficiency and service delivery. As demand for versatile air compressors continues to rise, it is imperative to stay ahead of market trends and innovations.

We encourage you to leverage this guide to explore your options and make informed purchasing decisions. Connect with trusted suppliers and manufacturers who can provide tailored solutions to meet your unique needs, ensuring you are well-equipped to tackle any challenges your business may face in the future.

Illustrative image related to best 12v air compressors

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.