Navigating the complexities of sourcing the best air compressor for bicycle tires can be a daunting challenge for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. With an array of options available, from electric tire inflators to traditional compressors, understanding which products will meet your specific needs is crucial for optimizing operational efficiency and customer satisfaction. This comprehensive guide will delve into the various types of air compressors suitable for bicycle tires, highlighting their applications, performance metrics, and the latest technological advancements.

Additionally, we will provide actionable insights on supplier vetting processes, enabling you to identify reputable manufacturers and distributors that align with your business goals. Cost considerations will also be examined, ensuring you are equipped to make informed purchasing decisions that balance quality and budgetary constraints.

By leveraging this guide, international B2B buyers will gain a nuanced understanding of the global market landscape, empowering them to select the best air compressor solutions tailored to their unique requirements. Whether you are in Vietnam, Brazil, or beyond, this resource is designed to enhance your procurement strategy and ultimately drive your business success in the cycling industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Bike Pumps | Compact, battery-powered, digital gauges, lightweight | Retail bicycle shops, bike rental services | Pros: Quick inflation, portable, accurate. Cons: Limited battery life, may require recharging. |

| CO2 Inflators | Uses CO2 cartridges, lightweight, portable | Emergency repair kits, cycling events | Pros: Fast inflation, easy to carry. Cons: Disposable cartridges, less sustainable. |

| Floor Pumps | Manual operation, larger size, often features analog/digital gauges | Workshops, bike repair shops | Pros: Durable, cost-effective for high-volume use. Cons: Bulky, requires physical effort. |

| Mini Hand Pumps | Manual, compact, suitable for emergency use | Personal use, bike tours | Pros: Lightweight, portable. Cons: Labor-intensive, lower inflation efficiency. |

| Portable Compressors | Electric, higher capacity, can inflate multiple tire types | Commercial bike shops, fleet maintenance | Pros: Versatile, high performance. Cons: Heavier, requires power source. |

Electric bike pumps are designed for efficiency and ease of use, making them ideal for various B2B applications such as retail bicycle shops and bike rental services. They are compact and lightweight, often featuring digital gauges for precise inflation. This type of air compressor allows businesses to provide quick service, enhancing customer satisfaction. However, buyers should consider the battery life and the need for periodic recharging, which can affect operational efficiency during peak times.

CO2 inflators are popular among cyclists for their fast inflation capabilities, making them perfect for emergency repair kits and cycling events. Their lightweight and portable design allows for easy transport, appealing to businesses that cater to mobile cyclists. However, the reliance on disposable cartridges raises sustainability concerns and can lead to recurring costs for businesses. B2B buyers must weigh the benefits of speed against the environmental impact and ongoing expenses associated with CO2 cartridges.

Illustrative image related to best air compressor for bicycle tires

Floor pumps are a staple in bike workshops and repair shops due to their durability and cost-effectiveness. They can handle high volumes of tire inflation, making them suitable for businesses that service multiple bicycles daily. While they provide accurate pressure readings and are generally robust, their larger size and manual operation can be a drawback for businesses with limited space or those requiring quick service. Buyers should consider the trade-offs between performance and physical effort when selecting this type.

Mini hand pumps are compact and designed for personal use, making them suitable for bike tours and emergency situations. Their lightweight nature allows cyclists to carry them easily without adding significant weight to their gear. However, these pumps typically require more effort to achieve desired tire pressure, which can be less efficient for B2B applications. Businesses targeting individual cyclists may find these pumps appealing, but they should be aware of their limitations in terms of inflation speed and ease of use.

Portable compressors offer a higher capacity for inflation and can be used across various tire types, making them versatile tools for commercial bike shops and fleet maintenance. They provide efficient service and can quickly inflate multiple tires, which is crucial for businesses that require rapid turnaround. However, their heavier weight and dependency on a power source may limit mobility. B2B buyers should evaluate the balance between performance and practicality when considering portable compressors for their operations.

Illustrative image related to best air compressor for bicycle tires

| Industry/Sector | Specific Application of best air compressor for bicycle tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Quality control in tire inflation during production | Ensures consistent product quality and performance | Reliability of compressor, capacity, and precision |

| Sports Retail | Customer service and maintenance in retail environments | Enhances customer satisfaction and promotes repeat business | Portability, ease of use, and serviceability |

| Logistics and Transportation | Tire maintenance for delivery vehicles and bicycles | Reduces downtime and improves operational efficiency | Durability, power source options, and inflation speed |

| Outdoor Sports and Recreation | Inflation of bicycle tires for rental services | Increases rental fleet availability and customer convenience | Compact size, battery life, and compatibility with various tire types |

| Event Management | Tire inflation at cycling events and competitions | Streamlines event operations and enhances participant experience | Speed of inflation, ease of transport, and reliability |

In the bicycle manufacturing sector, the best air compressors are essential for quality control during the tire production process. Ensuring that tires are inflated to the correct pressure directly impacts their performance and safety. Manufacturers require compressors that deliver precise inflation levels consistently, thus minimizing defects and enhancing product reliability. For international buyers, sourcing equipment that meets local standards and can handle varying power supply conditions is crucial.

In sports retail environments, air compressors are vital for customer service and maintenance. Retailers can quickly inflate tires for customers who purchase bicycles or require adjustments. This service not only improves customer satisfaction but also encourages repeat business. Retailers should consider compressors that are portable and easy to operate, ensuring they can efficiently serve customers without delays, especially in regions with high foot traffic.

Logistics and transportation companies rely on the best air compressors for maintaining the tire pressure of delivery bicycles and vehicles. Proper tire inflation is critical for optimizing fuel efficiency and ensuring safety during operations. By reducing downtime for tire maintenance, businesses can enhance their overall operational efficiency. When sourcing compressors, companies should prioritize durability and the ability to inflate tires quickly to keep operations running smoothly.

Illustrative image related to best air compressor for bicycle tires

In the outdoor sports and recreation industry, air compressors are indispensable for inflating bicycle tires in rental services. Quick and efficient tire inflation ensures that rental fleets are ready for use, enhancing customer convenience. Sourcing compact and lightweight compressors is essential for these businesses, as they often operate in diverse outdoor environments. Additionally, compatibility with various tire types is a key consideration to meet diverse customer needs.

Event management companies utilize air compressors to facilitate tire inflation at cycling events and competitions. Having reliable compressors on-site streamlines operations, ensuring that participants can quickly inflate tires before races, thus improving their overall experience. Speed and reliability are critical factors when sourcing compressors for these events, as they must withstand high usage in a short time frame. Event organizers should also consider the transportability of the equipment to handle logistics effectively.

The Problem: B2B buyers often encounter challenges in achieving and maintaining the correct tire pressure for bicycles. This is particularly true for businesses that handle a fleet of bicycles, such as rental companies or delivery services. An inaccurate tire pressure can lead to suboptimal performance, increased wear and tear on tires, and even potential safety hazards. Many traditional air compressors lack precision, relying on analog gauges that can be easily misread, leading to inconsistent inflation.

The Solution: To address this pain point, businesses should prioritize sourcing air compressors equipped with digital gauges that provide precise tire pressure readings. When selecting an air compressor, look for models that offer programmable pressure settings, allowing users to set their desired pressure and avoid over-inflation. Additionally, investing in models with automatic shut-off features can prevent common human errors associated with manual inflation. Implementing regular training sessions for staff on how to effectively use these advanced compressors will ensure consistent and safe operations, ultimately enhancing customer satisfaction and reducing maintenance costs.

The Problem: In regions where bicycle use is prevalent, such as urban environments in Africa or South America, the need for portable solutions is critical. B2B buyers, especially those in the bicycle repair and maintenance sector, often find traditional air compressors to be bulky and impractical for on-the-go repairs. This limitation can lead to downtime, which is costly for businesses that rely on quick turnaround times for their services.

Illustrative image related to best air compressor for bicycle tires

The Solution: To overcome this challenge, B2B buyers should focus on acquiring compact, battery-operated air compressors designed for portability. These models should be lightweight and easy to carry, fitting conveniently into service vehicles or even bicycle panniers. When sourcing these compressors, consider those that offer multiple charging options, such as USB charging capabilities, which can enhance their usability in remote areas. Additionally, businesses should evaluate the compressor’s inflation speed and capacity to ensure it can handle various tire sizes and types efficiently. By equipping technicians with portable solutions, businesses can provide immediate service to customers, improving satisfaction and loyalty.

The Problem: High operating costs are a significant concern for B2B buyers managing bicycle fleets or repair services. Traditional air compressors, while initially cheaper, often consume more energy and require frequent maintenance, leading to escalating operational expenses. Moreover, inefficient inflation processes can result in longer service times, further increasing costs and reducing profitability.

The Solution: To mitigate these costs, businesses should invest in energy-efficient air compressors designed specifically for bicycle tires. When selecting a compressor, prioritize models that offer low power consumption without compromising performance. Look for features such as high-efficiency motors and quick inflation technology, which can significantly reduce the time spent inflating tires. Furthermore, conducting a cost-benefit analysis can help businesses understand the long-term savings associated with purchasing higher-quality, more efficient equipment. Regular maintenance schedules should also be implemented to ensure that compressors operate optimally, preventing unexpected breakdowns and costly repairs. By taking these steps, businesses can enhance their operational efficiency, leading to reduced costs and improved profit margins.

When selecting an air compressor for bicycle tires, the choice of materials is crucial for performance, durability, and overall product life. Below, we analyze four common materials used in the construction of air compressors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for portable air compressors. It has a good temperature rating and is resistant to corrosion, which is particularly beneficial in humid or wet environments.

Pros & Cons: The lightweight nature of aluminum enhances portability, making it suitable for bicycle tire inflation. However, it can be more expensive than other materials like steel. Additionally, while aluminum is durable, it may not withstand extreme impacts as well as heavier metals.

Impact on Application: Aluminum’s corrosion resistance ensures compatibility with various media, including air and moisture, without degrading performance. This is particularly important for outdoor applications where exposure to elements is common.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions with high humidity levels should prioritize aluminum models to ensure longevity and reliability.

Key Properties: Steel is robust and offers high pressure ratings, making it suitable for heavy-duty applications. It has excellent tensile strength and can withstand significant wear and tear.

Illustrative image related to best air compressor for bicycle tires

Pros & Cons: The primary advantage of steel is its durability and resistance to deformation under high pressure. However, it is heavier than aluminum, which can affect portability. Additionally, steel is prone to rust if not properly coated or maintained, especially in humid environments.

Impact on Application: Steel compressors are well-suited for high-pressure applications but may require additional coatings or treatments to ensure compatibility with moisture-laden air.

Considerations for International Buyers: Buyers should look for steel compressors that comply with local corrosion resistance standards, especially in tropical climates. Regular maintenance may be necessary to prevent rust, impacting long-term costs.

Key Properties: Plastic materials are lightweight and can be molded into various shapes, allowing for innovative designs. They are generally resistant to corrosion and can handle moderate pressure levels.

Pros & Cons: The low cost and lightweight nature of plastic make it an attractive option for budget-conscious buyers. However, plastic may not withstand high-pressure applications as effectively as metal counterparts, limiting its use in more demanding environments.

Impact on Application: Plastic compressors are ideal for low to moderate pressure tasks, making them suitable for casual cyclists. However, they may not be suitable for professional or high-performance applications.

Considerations for International Buyers: Buyers should ensure that the plastic used meets safety standards, particularly in regions with stringent regulations. The environmental impact of plastic should also be considered, as some markets are moving towards more sustainable materials.

Illustrative image related to best air compressor for bicycle tires

Key Properties: Composite materials combine the benefits of various substances, offering high strength while remaining lightweight. They often have excellent resistance to corrosion and temperature fluctuations.

Pros & Cons: The main advantage of composites is their versatility and performance in various conditions. However, they can be more expensive to manufacture, which may increase the overall cost of the compressor.

Impact on Application: Composites are suitable for high-performance applications where weight and durability are critical, making them ideal for competitive cycling environments.

Illustrative image related to best air compressor for bicycle tires

Considerations for International Buyers: Compliance with international manufacturing standards is crucial, as is ensuring that the composites used are suitable for the specific environmental conditions of the buyer’s region.

| Material | Typical Use Case for best air compressor for bicycle tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable tire inflators for casual cyclists | Lightweight and corrosion-resistant | Higher cost, less impact resistance | Medium |

| Steel | Heavy-duty compressors for high-pressure applications | High durability and pressure rating | Heavier, prone to rust without treatment | Medium |

| Plastic | Budget-friendly options for low-pressure tasks | Cost-effective and lightweight | Limited pressure capacity | Low |

| Composite | High-performance compressors for competitive cycling | Versatile and high-performance | Higher manufacturing cost | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, helping them make informed decisions based on their specific needs and regional considerations.

The manufacturing process for air compressors designed specifically for bicycle tires involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers identify reliable suppliers and products that meet their quality standards.

Material preparation begins with sourcing high-quality components that can withstand the pressures and demands of tire inflation. Common materials include aluminum, steel, and high-density plastics. Suppliers typically evaluate raw materials for durability, weight, and resistance to corrosion. This stage may also involve pre-treatment processes such as anodizing or coating to enhance material properties.

The forming stage includes various techniques such as casting, machining, and molding. For metal components, casting techniques like die-casting or sand-casting are often used to create intricate parts. Machining processes—such as turning, milling, and drilling—are employed to achieve precise dimensions and tolerances, critical for the compressor’s performance. For plastic components, injection molding is a common method that allows for high-volume production with consistent quality.

Illustrative image related to best air compressor for bicycle tires

Once the components are formed, the assembly stage begins. This process may be manual or automated, depending on the manufacturer’s capabilities. Components such as motors, pressure gauges, and hoses are carefully assembled to ensure optimal performance. During this stage, manufacturers may also integrate electronic components, such as digital displays and pressure sensors, which require additional precision.

Finishing processes play a vital role in enhancing the aesthetic appeal and functionality of the final product. Techniques such as painting, powder coating, or polishing are commonly employed to protect against environmental factors and wear. Additionally, final assembly checks are performed to ensure that all components fit correctly and function as intended.

Quality assurance (QA) is essential in the manufacturing of air compressors, particularly for international B2B transactions. Suppliers should comply with various international standards, such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include CE marking for products sold in Europe, API standards for performance, and specific certifications for safety and environmental impact.

Illustrative image related to best air compressor for bicycle tires

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Suppliers check for conformity to specifications, ensuring that only high-quality materials enter production.

In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at various stages to monitor the production process. This may include checking dimensions, assembly accuracy, and testing for defects.

Final Quality Control (FQC): Once assembly is complete, the final product undergoes a rigorous testing phase. This may involve pressure testing, performance evaluation, and safety checks to ensure the compressor meets all necessary standards.

Testing methods for air compressors can include:

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Conducting supplier audits is an effective way to assess their manufacturing processes and QC protocols. During these audits, buyers can review documentation, inspect facilities, and observe manufacturing practices firsthand.

Buyers should request comprehensive quality assurance reports, including:

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control. Different countries may have varying regulations and standards that affect product compliance. For instance, products sold in Europe must meet stringent CE marking requirements, while other regions may have less stringent criteria.

Buyers should familiarize themselves with the regulatory landscape of their target markets. Collaborating with local experts or consultants can provide insights into compliance requirements. Additionally, establishing strong communication channels with suppliers can help address any concerns regarding quality and compliance.

Understanding the manufacturing processes and quality assurance measures for air compressors tailored for bicycle tires is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control practices, buyers can make informed decisions and select reliable suppliers. This knowledge not only enhances product quality but also builds strong partnerships in the global marketplace.

In today’s competitive marketplace, selecting the right air compressor for bicycle tires is essential for businesses aiming to provide efficient and reliable service. This guide offers a step-by-step checklist to assist B2B buyers in making informed procurement decisions.

Illustrative image related to best air compressor for bicycle tires

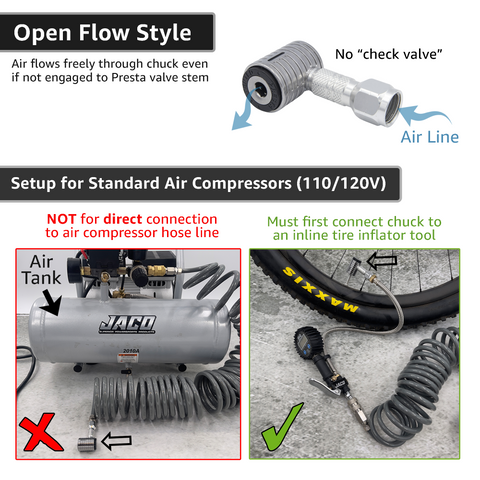

Establishing the technical requirements for your air compressor is critical. Consider factors such as the type of valves (Presta and Schrader compatibility), maximum PSI, and the intended use (e.g., for retail, workshops, or mobile services). Knowing these specifications will help you narrow down options that fit your operational needs.

Stay informed about the latest trends in air compressor technology. Innovations such as battery-powered electric pumps, compact designs, and integrated digital gauges are reshaping the market. Understanding these advancements can give you a competitive edge and enhance your product offerings.

Conduct thorough evaluations of potential suppliers. Request detailed company profiles, product catalogs, and case studies from buyers in your industry. Pay attention to supplier reputation, reliability, and their ability to meet your specific needs. This step is essential to ensure you partner with a trustworthy manufacturer.

Illustrative image related to best air compressor for bicycle tires

Before finalizing your order, request samples of the air compressors you are considering. Testing the products in real-world scenarios will allow you to assess performance, durability, and ease of use. This hands-on evaluation is crucial for understanding how well the compressor meets your operational demands.

Analyze the pricing structure and overall cost of ownership, including maintenance and warranty options. Look beyond the initial purchase price; consider factors such as energy efficiency, lifespan, and repair costs. A thorough cost analysis will help ensure that you make a financially sound decision.

Ensure that the air compressors comply with relevant industry standards and regulations. Check for certifications such as ISO, CE, or UL, which indicate adherence to safety and performance benchmarks. Compliance not only protects your business but also enhances your credibility with customers.

Consider the level of after-sales support and training provided by the supplier. A reliable supplier should offer installation assistance, maintenance training, and responsive customer service. Strong after-sales support is vital for maximizing the lifespan and effectiveness of your air compressors.

By following this checklist, B2B buyers can systematically evaluate their options, ensuring they select the best air compressor for bicycle tires that meets their business needs while providing excellent value.

Illustrative image related to best air compressor for bicycle tires

When evaluating the cost structure for sourcing air compressors designed for bicycle tires, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of materials directly influences the compressor’s durability and performance. High-quality plastics and metals, such as aluminum or stainless steel, are often used to enhance longevity and reduce weight. The cost of these materials can vary significantly based on global market trends and availability.

Labor: Labor costs are affected by the region of production. For example, manufacturers in Vietnam or Brazil may have lower labor costs compared to those in Europe. However, the skill level required for assembly and quality assurance can impact overall labor expenses.

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient production practices can help lower these costs, thereby impacting the final pricing of the compressors.

Tooling: Initial setup costs for molds and machinery can be substantial, particularly for customized products. This upfront investment is amortized over the production run, meaning larger volumes can reduce the per-unit tooling cost.

Quality Control: Ensuring that compressors meet performance and safety standards incurs costs related to testing and certification. International certifications can add to costs but are essential for market acceptance, particularly in regions with stringent regulations.

Logistics: Transportation and shipping costs vary based on distance, shipping method, and Incoterms. Import duties and tariffs can significantly affect landed costs, especially for international buyers.

Margin: The manufacturer’s margin is influenced by competitive dynamics and market demand. For air compressors, margins can range from 10% to 30%, depending on brand positioning and product differentiation.

Several factors can influence the pricing of air compressors in the B2B market:

Volume/MOQ: Buyers often encounter lower unit costs when ordering larger quantities. Minimum order quantities (MOQ) can vary significantly between suppliers, and negotiating these terms can lead to better pricing.

Specifications and Customization: Custom features, such as digital gauges or specific nozzle types, can increase costs. Buyers should balance their needs for customization with budget constraints.

Materials and Quality Certifications: The choice of premium materials and compliance with industry certifications can raise initial costs but may lead to lower total cost of ownership due to improved performance and reliability.

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge a premium for their products but often provide superior quality assurance and after-sales support.

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) can affect overall costs. Buyers should clarify who is responsible for shipping, insurance, and tariffs to avoid unexpected expenses.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

Negotiate Terms: Always negotiate pricing and payment terms with suppliers. Leverage volume purchases to secure discounts and favorable payment schedules.

Consider Total Cost of Ownership: Evaluate not just the purchase price but also the long-term costs associated with maintenance, repairs, and potential replacements. Higher upfront costs for quality products may result in lower overall expenditure.

Research Market Trends: Stay informed about fluctuations in material costs and labor markets, as these can impact pricing. Being aware of trends allows for strategic purchasing decisions.

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and exclusive access to new products.

Factor in Logistics and Tariffs: Assess the total landed cost, including shipping and potential tariffs, to make informed purchasing decisions. Utilizing local suppliers can sometimes mitigate these costs.

By understanding the cost structure and price influencers, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

When it comes to inflating bicycle tires, various solutions exist beyond the traditional air compressor. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and ease of use. This analysis provides a comparative overview of the best air compressor for bicycle tires against electric bike pumps and hand pumps, two viable alternatives in the market.

Illustrative image related to best air compressor for bicycle tires

| Comparison Aspect | Best Air Compressor For Bicycle Tires | Electric Bike Pump | Hand Pump |

|---|---|---|---|

| Performance | High PSI output; quick inflation | Moderate PSI; fast for small tires | Low PSI; requires manual effort |

| Cost | $100 – $300 | $50 – $100 | $20 – $60 |

| Ease of Implementation | Requires power source; less portable | Highly portable; battery-operated | Very portable; no setup required |

| Maintenance | Regular maintenance needed | Minimal maintenance | Minimal maintenance |

| Best Use Case | Workshop or home use; high-volume needs | On-the-go inflation; casual riders | Emergency use; lightweight setups |

Electric bike pumps have gained popularity due to their compact size and efficiency. They typically weigh around 150 grams and can inflate a flat tire in under a minute. The convenience of a built-in digital gauge allows for precise pressure adjustments, making them ideal for casual riders and those needing quick fixes during rides. However, their reliance on battery power can be a limitation; if the battery is drained, the pump becomes unusable until recharged. Additionally, while they are generally effective for standard tires, their performance may vary with larger or tubeless tires.

Hand pumps are the most traditional method of inflating bicycle tires, and their simplicity is a significant advantage. They are lightweight, highly portable, and require no power source, making them a reliable choice for emergency situations. However, hand pumps often require considerable physical effort and time to achieve the desired pressure, especially for larger tires. Furthermore, their performance can be inconsistent, and they may not reach the higher PSI levels that more serious cyclists often prefer.

Selecting the right tire inflation solution ultimately depends on the specific needs of the buyer and their target market. For businesses focusing on high-volume tire inflation or servicing, investing in a robust air compressor may be justified despite its higher cost and maintenance requirements. Conversely, if the target demographic consists of casual cyclists or those needing portable solutions, electric bike pumps offer an efficient and user-friendly alternative. Hand pumps can serve as a cost-effective backup for emergency use, appealing to budget-conscious buyers. By evaluating these alternatives based on performance, cost, and usability, B2B buyers can align their choices with their operational goals and customer preferences.

When evaluating air compressors for bicycle tires, several critical specifications can significantly impact performance, usability, and overall buyer satisfaction. Understanding these properties is essential for B2B buyers to make informed decisions.

Illustrative image related to best air compressor for bicycle tires

The maximum pressure an air compressor can deliver, measured in pounds per square inch (PSI), is crucial for effectively inflating different types of bicycle tires. Road bikes typically require higher pressures (up to 120 PSI), while mountain bikes may need lower pressures (around 30-50 PSI). Selecting an air compressor with an appropriate PSI range ensures compatibility with various tire types, enhancing customer satisfaction and reducing returns.

Flow rate, measured in cubic feet per minute (CFM), indicates how quickly the compressor can deliver air. A higher CFM allows for faster inflation, which is particularly beneficial for businesses that cater to high-volume tire servicing. Choosing a compressor with adequate flow rate helps streamline operations and improves service efficiency.

The tank size of an air compressor, often measured in gallons, determines the volume of air it can store for use. For bicycle tire inflation, a smaller tank (1-2 gallons) is typically sufficient, as tires require less air compared to larger vehicles. However, understanding tank size helps buyers assess whether the compressor can meet their operational needs without frequent refilling.

Air compressors can be powered by electricity, gas, or batteries. Electric compressors are generally preferred for indoor use due to their efficiency and lower emissions. In contrast, battery-powered models offer portability for mobile tire services. Identifying the right power source aligns with the specific business model and operational environment.

The weight of an air compressor is an important consideration, especially for businesses that require mobility. Lightweight models are easier to transport and set up, making them ideal for mobile service units. Understanding the balance between performance and portability can help businesses optimize their operational efficiency.

The materials used in the construction of the compressor, such as aluminum or reinforced plastic, affect its durability and lifespan. High-quality materials ensure that the compressor withstands frequent use and environmental factors, reducing maintenance costs and enhancing long-term reliability. Buyers should prioritize compressors that offer robust warranties, indicating confidence in material quality.

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some key terms to consider:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess product quality and compatibility, especially if they require specific components for their air compressors.

Illustrative image related to best air compressor for bicycle tires

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, as it affects initial investment and stock levels.

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. It helps buyers compare options and negotiate terms, ensuring they secure the best deal for their air compressor purchases.

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms ensures clarity in transactions, especially for international buyers, helping to avoid misunderstandings and additional costs.

Understanding the warranty and service terms associated with air compressors is crucial for B2B buyers. This knowledge ensures that they are aware of their rights regarding repairs, replacements, and maintenance, which can significantly impact long-term operational costs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market demands.

Illustrative image related to best air compressor for bicycle tires

The air compressor market for bicycle tires is evolving rapidly, driven by several global factors that affect sourcing and purchasing decisions for international B2B buyers. As cycling gains popularity as both a recreational activity and a sustainable mode of transport, the demand for efficient, portable, and user-friendly air compressors has surged. Key trends include the rise of electric bike pumps, which offer convenience and speed, as well as the growing consumer preference for digital gauges that enhance accuracy in tire inflation. This shift is particularly pronounced in emerging markets such as Africa and South America, where cycling is increasingly viewed as an eco-friendly alternative for urban mobility.

Moreover, technological advancements are reshaping product offerings. Manufacturers are investing in compact, lightweight designs that incorporate smart features, such as Bluetooth connectivity and mobile app integration, allowing users to monitor tire pressure and receive alerts directly on their smartphones. This trend aligns with the broader digital transformation across industries, making it crucial for B2B buyers to consider not just product specifications but also the technology behind them. Additionally, the competitive landscape is becoming more fragmented, with numerous brands entering the market, particularly from Asia, which can offer cost-effective solutions for international buyers.

Sustainability has emerged as a central concern for B2B buyers in the air compressor sector. The environmental impact of manufacturing processes and product life cycles is increasingly scrutinized, prompting companies to adopt greener practices. Ethical sourcing has become essential, as buyers seek suppliers that prioritize sustainable materials and manufacturing methods. Certifications such as ISO 14001 (Environmental Management) and the use of recyclable materials are becoming critical in supplier evaluation.

Moreover, eco-conscious consumers are driving demand for products that minimize their carbon footprint. This shift influences B2B purchasing decisions, as companies are pressured to align their product offerings with sustainability goals. Air compressors designed with energy-efficient technologies not only reduce operational costs but also appeal to environmentally aware buyers. Companies that can demonstrate their commitment to sustainability are likely to gain a competitive edge in the market, attracting international buyers who value ethical practices.

Illustrative image related to best air compressor for bicycle tires

The evolution of air compressors for bicycle tires reflects broader trends in cycling technology and consumer preferences. Historically, traditional floor pumps dominated the market due to their reliability and affordability. However, the advent of portable electric pumps has transformed the landscape, offering cyclists greater convenience and efficiency. The transition from manual to electric inflation methods has been particularly beneficial for competitive cyclists and casual riders alike, who prioritize speed and ease of use.

As the market has matured, manufacturers have focused on innovation, integrating features such as digital displays and rechargeable batteries into their products. This evolution not only enhances user experience but also aligns with the growing trend of smart cycling technology. As the demand for high-quality, sustainable, and efficient air compressors continues to rise, B2B buyers are encouraged to stay abreast of these developments to make informed sourcing decisions that meet their operational and sustainability objectives.

How do I choose the right air compressor for bicycle tires?

When selecting an air compressor for bicycle tires, consider factors like portability, inflation speed, power source (battery-operated vs. electric), and compatibility with valve types (Presta and Schrader). Look for models with built-in digital gauges for accuracy and convenience. Additionally, assess the compressor’s weight and size, especially if it will be used on the go. Finally, read customer reviews and conduct performance tests to ensure reliability and efficiency.

What is the best air compressor for inflating bicycle tires?

The best air compressor for bicycle tires typically combines portability, efficiency, and ease of use. Electric bike pumps that are compact, lightweight, and equipped with a digital gauge are highly recommended. Brands like Airbank, RockBros, and Flextail offer models that can inflate a flat tire to optimal pressure quickly and accurately. Evaluate the specifications based on your specific requirements, such as tire size and intended use.

What are the minimum order quantities (MOQs) for air compressors?

MOQs for air compressors can vary significantly based on the supplier and the type of compressor. Generally, manufacturers may set MOQs ranging from 50 to 500 units for B2B transactions. It’s essential to discuss your specific needs with potential suppliers to negotiate favorable terms. Some suppliers may offer lower MOQs for new buyers or for specific models, while others might provide discounts on larger orders.

What payment terms should I expect when sourcing air compressors internationally?

Payment terms for international sourcing can vary by supplier and region. Common options include advance payment, 30% deposit with the balance due before shipping, or letters of credit for larger orders. Always clarify payment terms upfront to avoid misunderstandings. Consider using secure payment methods like PayPal or escrow services to protect your investment, particularly with new suppliers.

How can I vet suppliers for air compressors effectively?

To vet suppliers, start by checking their business credentials, including registration and certifications. Look for reviews or testimonials from other B2B clients to gauge reliability. Consider requesting product samples and assessing their quality firsthand. Additionally, verify their production capabilities, lead times, and after-sales support. Engaging in direct communication can also provide insights into their professionalism and responsiveness.

What customization options are available for air compressors?

Many manufacturers offer customization options for air compressors, including branding, color choices, and specific features tailored to your target market. You can also request modifications in design or functionality to better suit local preferences. Discuss your customization needs with potential suppliers during the negotiation phase, as this can significantly enhance your product’s appeal in your target market.

What quality assurance (QA) measures should I consider?

When sourcing air compressors, ensure that the supplier adheres to quality assurance protocols. Request information about their QA processes, including inspections and testing procedures. Certifications such as ISO 9001 can indicate a commitment to quality. It’s also beneficial to establish a clear return policy and warranty terms to safeguard against defects and ensure customer satisfaction.

What logistics considerations should I keep in mind when importing air compressors?

Logistics are crucial when importing air compressors. Consider shipping methods (air vs. sea), as they can significantly impact delivery times and costs. Ensure that the supplier can accommodate your logistics requirements, including packaging and documentation for customs clearance. Additionally, factor in potential tariffs, taxes, and local regulations that may affect the import process in your country. Working with a reliable freight forwarder can streamline logistics and reduce complications.

Domain: roadbikeaction.com

Registered: 2006 (19 years)

Introduction: {“Park Tool INF-1”: {“type”: “Shop Inflator”, “weight”: “1 pound, 11 ounces”, “valve compatibility”: “Dual-head for Presta and Schrader valves”, “price”: “$130”, “features”: [“Heavy-duty build”, “Easier to use with one hand”, “Fixed dual-head design”]}, “Prestacycle Prestaflator”: {“type”: “Pistol-grip inflator”, “weight”: “13 ounces”, “valve compatibility”: “Presta (with removable head for Schrad…

In the evolving landscape of bicycle tire inflation solutions, strategic sourcing of the best air compressors is paramount for B2B buyers across diverse international markets. The shift from traditional manual pumps to electric bike pumps offers significant advantages, including enhanced efficiency, portability, and accuracy. These modern inflators not only streamline the tire maintenance process but also present a cost-effective solution when compared to the cumulative expense of conventional tools.

Illustrative image related to best air compressor for bicycle tires

As global demand for cycling products continues to rise, sourcing high-quality electric bike pumps from reputable manufacturers can ensure that businesses remain competitive. Buyers should prioritize suppliers that offer reliable performance, warranty support, and adaptability to different tire types. Engaging with manufacturers that emphasize sustainability and innovation will also resonate well with eco-conscious consumers.

Looking ahead, the future of bicycle tire inflation is bright, with technological advancements paving the way for even more efficient solutions. B2B buyers in regions such as Africa, South America, the Middle East, and Europe should seize this opportunity to enhance their product offerings. By strategically sourcing the best air compressors, businesses can not only meet customer needs but also position themselves as leaders in the cycling industry.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to best air compressor for bicycle tires

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.