In the realm of recreational vehicle (RV) maintenance, sourcing a reliable RV tire inflator is a critical yet often overlooked challenge for international B2B buyers. With the unique demands of RV travel, including varying tire pressures and the need for portability, selecting the right inflator can significantly impact both safety and operational efficiency. This comprehensive guide delves into the diverse types of RV tire inflators available in the global market, examining their applications, features, and the specific needs they address for RV owners across different regions, including Africa, South America, the Middle East, and Europe, such as Germany and Nigeria.

Understanding the nuances of RV tire inflators is essential for making informed purchasing decisions. This guide not only highlights various models tailored for different RV types but also provides insights on supplier vetting processes, cost considerations, and essential performance metrics. By equipping B2B buyers with the knowledge to evaluate options critically, this resource aims to empower them to choose inflators that enhance safety, reliability, and convenience for their customers. Whether you are a distributor, retailer, or fleet manager, navigating the complexities of the RV tire inflator market becomes a streamlined process, ultimately ensuring that your clients can enjoy their adventures without the worry of tire-related issues.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Compressors | Compact size, powered by 12V, easy to store | RV maintenance, roadside assistance | Pros: Lightweight, easy to use; Cons: Limited power for larger tires. |

| High-Pressure Compressors | Capable of inflating up to 150 PSI, durable build | Heavy-duty RVs, commercial vehicles | Pros: Fast inflation, suitable for larger RVs; Cons: Higher cost, heavier. |

| Onboard Air Systems | Permanently installed, multi-functional capabilities | Long-term RV users, commercial fleets | Pros: Convenience, continuous air supply; Cons: Installation complexity, higher upfront cost. |

| Dual-Voltage Compressors | Operable on both 110V AC and 12V DC | Versatile usage in various locations | Pros: Flexibility in power source; Cons: Bulkier design, potential compatibility issues. |

| Battery-Operated Compressors | Rechargeable, completely portable | Emergency kits, remote locations | Pros: No need for external power; Cons: Limited run time, may require frequent charging. |

Portable electric compressors are designed for ease of use and storage, making them ideal for routine RV maintenance and roadside assistance. These compressors typically operate on a 12V power supply, allowing them to be connected directly to the RV’s battery. Their compact size makes them suitable for businesses that provide roadside assistance services or RV maintenance, as they can be easily transported and stored without taking up much space. However, their power limitations may restrict their effectiveness in inflating larger tires.

High-pressure compressors are essential for businesses dealing with heavy-duty RVs or commercial vehicles that require inflation pressures of up to 150 PSI. These compressors are built to withstand rigorous use, making them a reliable choice for tire shops and fleet maintenance companies. Their ability to inflate tires quickly is a significant advantage, but the cost and weight may deter some buyers. Investing in a high-pressure compressor can enhance operational efficiency for businesses that prioritize performance.

Onboard air systems are permanently installed in RVs and are equipped to provide a continuous air supply. They are particularly beneficial for long-term RV users or businesses managing commercial fleets, as they eliminate the need for portable solutions. While these systems offer unparalleled convenience, they require a higher upfront investment and can involve complex installation processes. Businesses should evaluate their long-term needs to determine if the benefits outweigh the initial costs.

Dual-voltage compressors offer the flexibility of operating on both 110V AC and 12V DC power, making them suitable for a variety of applications. This versatility is advantageous for businesses that operate in different environments, such as RV parks or remote job sites. However, their bulkier design may pose storage challenges, and potential compatibility issues could arise depending on the power sources available. Companies should assess their operational contexts to maximize the benefits of dual-voltage compressors.

Battery-operated compressors are entirely portable and rechargeable, making them an excellent addition to emergency kits for RV owners and businesses. They provide the convenience of inflation without the need for external power sources, which is critical in remote locations. However, their run time may be limited, necessitating frequent recharging. Businesses should consider the balance between portability and performance when selecting battery-operated compressors for their needs.

| Industry/Sector | Specific Application of RV Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| RV Manufacturing | Quality Control in Tire Inflation | Ensures safety and performance of RVs, reducing recalls and warranty claims. | Compliance with international safety standards; reliability under various climatic conditions. |

| Outdoor Adventure Rentals | Maintenance of Rental Fleet Tires | Enhances customer satisfaction by ensuring vehicles are road-ready and safe. | Portable design for easy transport; efficiency in inflating various tire sizes. |

| Logistics & Transport | Tire Maintenance for Delivery Vehicles | Reduces downtime and enhances the safety of transport operations. | Compatibility with different vehicle types; ability to handle high PSI requirements. |

| Camping & Recreational Services | Emergency Tire Inflation for Customers | Increases service reliability and customer trust during outdoor excursions. | Durability for rugged use; ease of use for non-technical customers. |

| Automotive Repair Shops | Tire Inflation Services for Various Vehicles | Expands service offerings, attracting a broader customer base. | Versatility in tire inflation; compact size for shop efficiency. |

In RV manufacturing, tire inflators are critical for quality control. They ensure that tires are inflated to the correct pressure before vehicles leave the assembly line, which is vital for safety and performance. This proactive approach helps manufacturers avoid costly recalls and warranty claims. Buyers in this sector should consider inflators that comply with international safety standards and can operate efficiently in diverse climatic conditions, particularly in regions like Africa and the Middle East where temperatures can vary significantly.

For businesses that rent out RVs and outdoor equipment, maintaining the tire pressure of rental vehicles is essential for customer satisfaction and safety. A reliable RV tire inflator allows operators to quickly check and adjust tire pressure before each rental, reducing the likelihood of breakdowns. When sourcing inflators, companies should prioritize portable designs that are easy to transport and capable of inflating tires to the required pressure levels efficiently, especially in remote locations common in South America and Africa.

In the logistics and transport industry, maintaining the correct tire pressure in delivery vehicles is crucial for safety and efficiency. An RV tire inflator enables fleet managers to perform regular tire maintenance, minimizing downtime caused by flat tires. When sourcing inflators, businesses should look for models that are compatible with various vehicle types and can handle high PSI requirements, ensuring they can service all vehicles in their fleet, whether operating in Europe or the Middle East.

Camping and recreational service providers can enhance their offerings by equipping their vehicles with RV tire inflators. These inflators allow for quick tire inflation in case of emergencies, ensuring that customers can continue their outdoor adventures without significant interruptions. Durability and ease of use are essential factors for buyers in this sector, especially when catering to customers who may not have technical knowledge, making it important to source robust and user-friendly inflators.

Automotive repair shops can expand their service offerings by incorporating RV tire inflators into their operations. These inflators facilitate tire inflation for a variety of vehicles, attracting a broader customer base. When selecting an inflator, repair shops should consider versatility in tire inflation capabilities and compact size for efficient use in limited workshop spaces, ensuring they can cater to the diverse needs of their clientele across different regions, including Europe and Africa.

The Problem: B2B buyers often struggle to identify tire inflators that can handle the specific high-pressure requirements of various RV models. Many standard air compressors lack the necessary pressure capacity, particularly for larger RV tires, which can reach up to 110 PSI or more. This mismatch can lead to safety hazards during travel, as improperly inflated tires can result in blowouts, reduced fuel efficiency, and increased wear and tear on tires.

The Solution: When sourcing RV tire inflators, it is critical to prioritize models specifically designed for high-pressure applications. For instance, the Viair 450P-RVS is engineered to inflate RV tires efficiently and can handle pressures up to 150 PSI. Buyers should ensure that the inflator they choose has a robust duty cycle, allowing for extended use without overheating. Additionally, investing in models that come with longer hoses and specialized attachments can enhance usability, enabling easy access to all tires, regardless of their positioning on the vehicle. When making a purchase, it’s advisable to verify the compressor’s specifications against the tire pressure requirements of the RV to ensure compatibility.

The Problem: Many B2B buyers face challenges regarding the storage and portability of tire inflators within RVs. Given the limited space in most RVs, bulky compressors can be cumbersome, leading to difficulties in both storage and transport. This situation can discourage RV owners from carrying a tire inflator, increasing the risk of being unprepared during a roadside emergency.

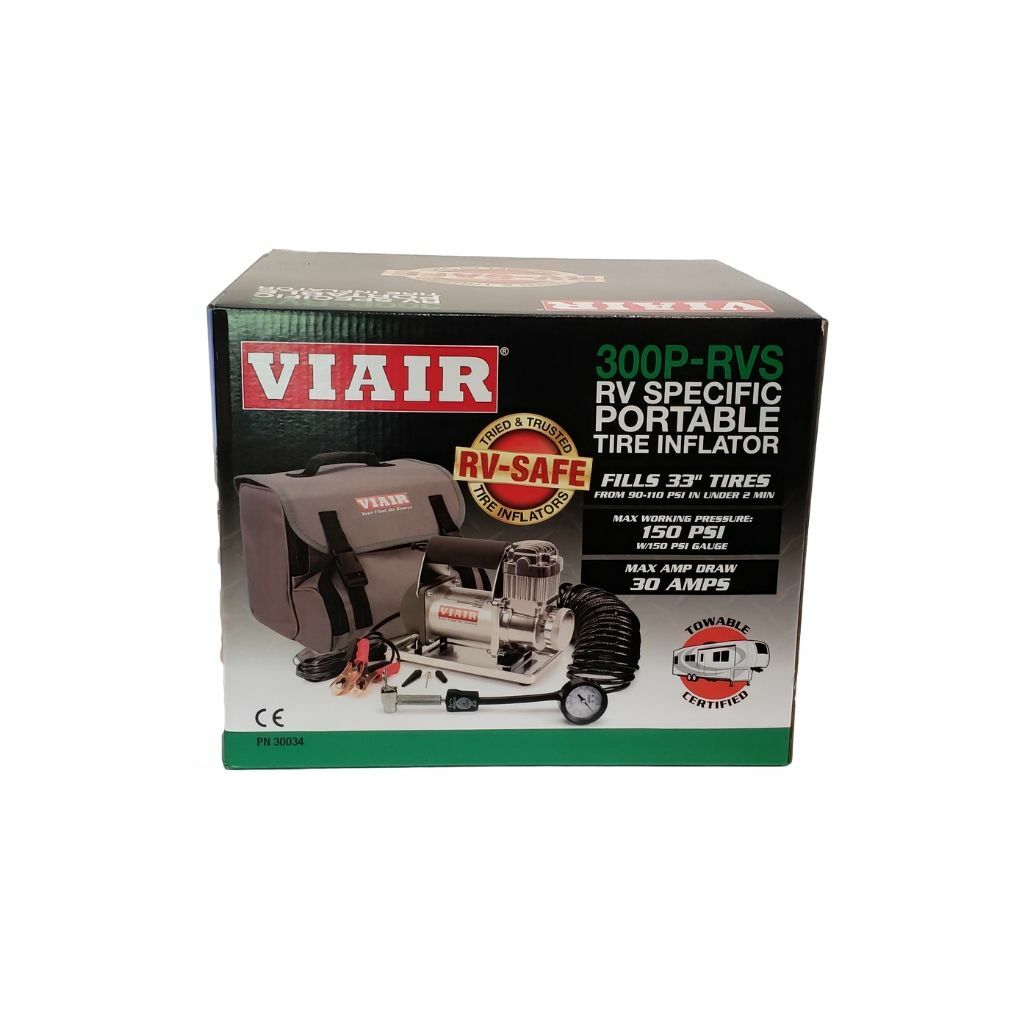

The Solution: To address storage issues, buyers should focus on purchasing compact and lightweight tire inflators specifically designed for RVs. Models like the Viair 300P RVS are known for their portability and efficiency without sacrificing performance. A good practice is to select inflators that come with a carrying case to keep all components organized and easily accessible. Furthermore, evaluate the inflator’s weight and dimensions to ensure it fits within the designated storage areas in the RV. Implementing organizational solutions, such as dedicated storage compartments or bags, can also streamline the process of keeping the inflator handy for quick use.

The Problem: B2B buyers frequently report issues with the reliability and accuracy of tire inflators, particularly those that are not specifically tailored for RVs. Many inflators, especially those found at gas stations, provide inaccurate pressure readings, which can lead to over-inflation or under-inflation of tires. This not only poses safety risks but can also lead to unnecessary expenses due to tire damage or premature wear.

The Solution: Buyers should prioritize purchasing RV tire inflators that feature built-in pressure gauges for real-time monitoring of tire pressure. Opting for brands like Viair, which are designed for RV applications, can provide peace of mind, as these models are rigorously tested for accuracy and reliability. When using the inflator, it’s advisable to check the tire pressure when the tires are cold, as hot tires can give misleading readings. Additionally, regular calibration of the inflator’s pressure gauge is essential to maintain accuracy over time. Establishing a routine for checking tire pressure before and during trips can significantly enhance the safety and performance of the RV.

When selecting materials for RV tire inflators, it is essential to consider their properties, advantages, and limitations. The choice of materials not only impacts the performance but also the durability and compliance with international standards. Below, we analyze four common materials used in the construction of RV tire inflators: aluminum, steel, plastic, and rubber.

Aluminum is frequently used in the body and components of RV tire inflators due to its lightweight and corrosion-resistant properties. It typically has a temperature rating up to 400°F and can withstand pressures of around 150 PSI, making it suitable for the high demands of RV tire inflation.

Pros: Aluminum is durable and resistant to rust, which is particularly beneficial in humid or coastal environments. Its lightweight nature makes it easy to transport and handle, which is a significant advantage for RV owners.

Cons: While aluminum is generally cost-effective, it can be more expensive than some plastic options. Additionally, it may not be as strong as steel under extreme conditions, leading to potential deformation.

Impact on Application: Aluminum is compatible with various media, including air and nitrogen, which are commonly used in tire inflation. It is also a preferred material for international buyers due to its compliance with ASTM standards.

Steel is another common material used in the construction of RV tire inflators, particularly for components that require additional strength, such as the housing and pressure vessels.

Pros: Steel offers superior strength and durability, making it ideal for high-pressure applications. It can handle temperatures exceeding 500°F and is resistant to wear and tear.

Cons: The primary drawback of steel is its weight, which can make the inflator cumbersome. Additionally, steel is prone to rust if not properly coated or maintained, which can be a concern in humid climates.

Impact on Application: Steel inflators are often used in heavy-duty applications where high pressure and durability are essential. Buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings to enhance longevity.

Plastic is often utilized in the manufacturing of hoses and some external components of RV tire inflators due to its lightweight and cost-effective nature.

Pros: Plastic is resistant to corrosion and can be molded into various shapes, allowing for design flexibility. It is also significantly lighter than metal options, making it easier to handle.

Cons: The main limitation of plastic is its lower pressure and temperature tolerance compared to metals. It can become brittle over time, especially under UV exposure or extreme temperatures.

Impact on Application: Plastic components are suitable for low-pressure applications and can be used in conjunction with metal parts for added durability. International buyers should ensure that the plastic used meets relevant standards, such as DIN or JIS.

Rubber is primarily used for seals and hoses in RV tire inflators due to its flexibility and resilience.

Pros: Rubber provides excellent sealing capabilities and can withstand a range of temperatures and pressures. It is also resistant to wear and tear, making it ideal for frequent use.

Cons: Over time, rubber can degrade due to exposure to ozone and UV light, which may lead to leaks. It is also less effective in extremely high-temperature applications.

Impact on Application: Rubber components are essential for ensuring airtight seals in inflators. Buyers should look for high-quality rubber that complies with international standards to ensure reliability and safety.

| Material | Typical Use Case for rv tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body and components | Lightweight and corrosion-resistant | More expensive than plastic | Medium |

| Steel | Housing and pressure vessels | Superior strength and durability | Prone to rust without coating | High |

| Plastic | Hoses and external components | Cost-effective and flexible | Lower pressure tolerance | Low |

| Rubber | Seals and hoses | Excellent sealing capabilities | Degrades over time due to exposure | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their RV tire inflator products. Understanding the properties and implications of each material will aid in making informed purchasing decisions that align with regional standards and customer expectations.

The manufacturing process for RV tire inflators involves several critical stages, each designed to ensure the product meets safety, performance, and durability standards. Understanding these stages can help B2B buyers assess the quality and reliability of suppliers.

The initial stage involves sourcing high-quality materials, such as durable plastics, metals, and rubber components. Suppliers often conduct rigorous assessments of raw materials to ensure they meet specific standards, including resistance to wear and tear, temperature fluctuations, and pressure ratings. Materials are typically tested for tensile strength and flexibility, ensuring they can withstand the demanding conditions of RV usage.

Once materials are prepared, they undergo forming processes, which may include injection molding for plastic components and metal stamping or casting for structural parts. Advanced techniques like CNC machining can also be employed for precision parts, ensuring that every component fits together seamlessly. This stage is crucial for maintaining the integrity of the inflator’s design, impacting both functionality and safety.

After forming, components are assembled into the final product. This stage often involves automated assembly lines that enhance efficiency and consistency. Key components, such as motors, hoses, and pressure gauges, are integrated, with a focus on ensuring that all parts function harmoniously. Quality control checkpoints are established during assembly to catch any defects early.

Illustrative image related to rv tire inflator

The finishing stage includes processes such as painting, coating, and quality inspection. Finishing not only improves the aesthetic appeal of the inflator but also provides protective layers against environmental factors. This stage often includes testing for airtightness and pressure resistance to ensure the product can handle the rigorous demands of inflating RV tires.

Quality control (QC) is an essential aspect of the manufacturing process, particularly for products that must adhere to strict safety and performance standards. B2B buyers should be aware of the various QC measures that suppliers implement.

Manufacturers often align their QC processes with international standards such as ISO 9001, which provides a framework for quality management systems. Compliance with this standard ensures a consistent approach to quality across all production stages. Additionally, industry-specific certifications, such as CE (European Conformity) and API (American Petroleum Institute), may apply, particularly for inflators used in commercial applications.

Quality control checkpoints are integrated throughout the manufacturing process. These typically include:

Common testing methods for RV tire inflators include:

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are effective strategies to conduct due diligence:

Illustrative image related to rv tire inflator

Buyers can conduct supplier audits, either internally or through third-party organizations. Audits should focus on evaluating the supplier’s compliance with international standards and their internal QC processes. Buyers may also request documentation of past audits and certifications to understand the supplier’s commitment to quality.

Requesting detailed reports on quality control metrics can provide insights into a supplier’s performance. This includes data on defect rates, test results, and corrective actions taken in response to quality issues. Suppliers that maintain transparent records demonstrate a commitment to quality assurance.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can occur at various stages, including pre-shipment inspections, ensuring that products meet agreed-upon specifications before reaching the buyer.

International buyers must navigate various quality control nuances based on regional standards and regulations. For example, European buyers may prioritize CE certifications, while those in the Middle East might focus on compliance with local safety standards.

Each region may have distinct regulations affecting the manufacturing and testing of RV tire inflators. B2B buyers should familiarize themselves with these regulations to ensure compliance and avoid potential legal issues. This is particularly important in regions like Africa and South America, where local regulations may differ significantly from international standards.

Illustrative image related to rv tire inflator

Maintaining open lines of communication with suppliers is essential for addressing quality concerns promptly. Buyers should establish clear expectations regarding quality standards and testing requirements, ensuring that suppliers are aligned with their needs.

Understanding the manufacturing processes and quality assurance measures for RV tire inflators is critical for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming, assembly, and finishing stages, as well as implementing robust quality control measures, suppliers can deliver high-quality products that meet international standards. Buyers should actively engage in supplier audits, request detailed reports, and stay informed about regional regulations to ensure they make informed purchasing decisions.

The following practical sourcing guide aims to assist B2B buyers in procuring RV tire inflators, ensuring they make informed decisions that enhance safety and efficiency for their operations.

Understanding the technical requirements of the RV tire inflator is crucial. Consider the maximum PSI needed for your RV tires, as different models cater to varying pressure levels. Additionally, assess the type of power supply (12V DC vs. 110V AC) that aligns with your usage scenarios—whether on the road or stationary.

Conduct thorough research to identify potential suppliers of RV tire inflators. Look for established companies with a solid reputation in the industry, such as VIAIR, known for its specialized RV models. Pay attention to customer reviews, case studies, and testimonials that reflect the supplier’s reliability and product effectiveness.

Before finalizing your choice, evaluate the specific features of the inflators available. Look for models that include:

– Long hoses for easy reach to all tires.

– Compact design for convenient storage within RVs.

– Duty cycle ratings to ensure the compressor can handle extended use without overheating.

Illustrative image related to rv tire inflator

Ensure that the products comply with international safety and quality standards. Check for certifications such as ISO or CE, which indicate adherence to industry regulations. This step is vital as it guarantees the inflator’s safety and reliability during operation.

Before making a bulk purchase, ask suppliers for product samples or demonstrations. This allows you to test the inflator’s performance firsthand, checking for ease of use, speed of inflation, and overall functionality. Observing the product in action can help you confirm that it meets your operational needs.

Gather quotes from multiple suppliers and compare pricing structures. Look for warranties or guarantees that come with the inflators, as these can protect your investment against defects or performance issues. A good warranty reflects the manufacturer’s confidence in their product quality.

Illustrative image related to rv tire inflator

Once you’ve selected a supplier and product, negotiate the terms of your purchase agreement. Ensure clarity on pricing, delivery timelines, and after-sales support. A well-defined agreement will help avoid misunderstandings and ensure that you receive the best possible service.

By following these steps, B2B buyers can confidently source RV tire inflators that enhance their operations while ensuring safety and efficiency on the road.

When evaluating the cost structure for sourcing RV tire inflators, several critical components contribute to the overall price. These include:

Illustrative image related to rv tire inflator

Materials: The quality and type of materials used in manufacturing significantly affect the price. High-grade metals and durable plastics that can withstand the rigors of outdoor use are often more expensive but enhance product longevity and reliability.

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this may impact product quality. It’s essential to balance cost and quality when selecting suppliers.

Manufacturing Overhead: This encompasses utilities, rent, and other operational expenses necessary for production. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

Tooling: The initial investment in molds and machinery for production can be substantial. Suppliers may require a minimum order quantity (MOQ) to cover these costs, which can influence pricing strategies.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which can be an additional cost but is essential for maintaining brand reputation and minimizing returns.

Logistics: Transportation and warehousing costs are vital considerations, especially for international shipments. These costs can fluctuate based on fuel prices, shipping methods, and distances involved.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and perceived value of the product.

Several factors can influence the pricing of RV tire inflators, particularly for international buyers:

Volume/MOQ: Bulk purchases often lead to discounts. Establishing a long-term relationship with suppliers can also result in better pricing and terms.

Specifications and Customization: Custom features such as specialized connectors or unique design elements can increase costs. Buyers should consider whether these features are necessary for their market.

Materials: The choice of materials affects both performance and price. High-performance materials may come at a premium but can offer better durability and efficiency.

Quality Certifications: Products that meet international safety and quality standards may have higher upfront costs. However, they can reduce liability risks and increase customer trust.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

B2B buyers should consider several strategies to optimize their sourcing process:

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility, especially for large orders or long-term contracts.

Focus on Cost-Efficiency: Look beyond the initial purchase price. Consider the total cost of ownership, including maintenance, warranty, and potential replacement costs.

Understand Pricing Nuances for International Markets: Different regions may have varying expectations regarding pricing and quality. For instance, European buyers often prioritize certifications, while buyers in Africa may focus on durability and cost-effectiveness.

Request Samples: Before committing to a large order, request samples to evaluate quality and performance. This can help ensure that the product meets your specifications and expectations.

Build Relationships: Developing strong relationships with suppliers can lead to better pricing, improved service, and priority access to new products.

Prices for RV tire inflators can fluctuate based on market conditions, supplier strategies, and regional economic factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the long-term implications of your sourcing decisions to maximize value.

When it comes to maintaining proper tire pressure for recreational vehicles (RVs), a reliable tire inflator is essential. However, RV owners have several options available, each with its unique benefits and drawbacks. This section explores the RV tire inflator in comparison with other solutions, helping international B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | RV Tire Inflator | Portable Electric Air Compressor | Gas Station Air Pump |

|---|---|---|---|

| Performance | High PSI capability; efficient for RV tires | Moderate PSI, suitable for smaller tires | Variable PSI; often unreliable |

| Cost | $300 – $500 depending on model | $50 – $150 | Typically free or minimal fee |

| Ease of Implementation | Simple to use; direct connection to battery | Plug-and-play; requires power source | Requires travel to location |

| Maintenance | Low maintenance; durable design | Moderate; may require hose replacement | None; no ownership responsibility |

| Best Use Case | Best for RV owners needing consistent tire pressure | Ideal for occasional use or smaller vehicles | Quick inflation when traveling or in emergencies |

A portable electric air compressor offers a convenient alternative for inflating tires, particularly for smaller vehicles or for RVs requiring less frequent inflation. These compressors are generally easy to use—simply plug them into a power outlet or vehicle’s power port. However, they may not provide the high PSI needed for larger RV tires, making them less suitable for heavy-duty applications. Additionally, their performance can vary based on the model, and they may require more frequent maintenance compared to specialized RV tire inflators.

Gas station air pumps are a familiar option for tire inflation, often available at little to no cost. While they can be useful in emergencies, their reliability is questionable. Many users report inconsistent PSI readings, which can lead to under-inflation or over-inflation of tires. Furthermore, using these pumps requires travel, which may not be convenient for RV owners who frequently check their tire pressure. In contrast, RV tire inflators are designed specifically for the high pressures associated with RV tires, ensuring accurate and safe inflation.

Choosing the right tire inflation solution involves considering several factors, including the type of vehicles in your fleet, frequency of use, and budget. For businesses that operate RVs or heavy-duty vehicles, investing in a specialized RV tire inflator ensures reliability and performance, minimizing the risk of tire failure during critical journeys. Conversely, for businesses that manage smaller vehicles or require an occasional inflation solution, portable electric air compressors may suffice. Gas station air pumps can serve as a backup, but they should not be relied upon as a primary solution due to their inconsistencies. Ultimately, understanding your specific needs will guide you to the most suitable option for your operations.

When considering RV tire inflators, several technical specifications are critical for ensuring optimal performance and reliability. Understanding these properties can help B2B buyers make informed purchasing decisions.

Illustrative image related to rv tire inflator

The pressure rating indicates the maximum air pressure the inflator can deliver, typically measured in pounds per square inch (PSI). For RV tires, which often require higher pressure (up to 110 PSI or more), selecting an inflator with a suitable PSI rating is essential. This ensures that the inflator can adequately service all types of RVs, from smaller trailers to larger motorhomes.

The duty cycle represents the duration an inflator can operate before needing to cool down. For example, a 100% duty cycle means the inflator can run continuously without overheating. This feature is particularly important for B2B buyers who require reliable performance during extended use, such as inflating multiple tires or servicing larger RV fleets.

Most RV tire inflators operate on either 12V DC or 110V AC power. A 12V DC inflator can be powered directly from the RV’s battery, making it more convenient for roadside assistance or camping trips. Understanding the power source is crucial for ensuring compatibility with the intended usage environment, especially for international buyers who may have varying access to power supply types.

Measured in cubic feet per minute (CFM), the air flow rate indicates how quickly the inflator can fill a tire. A higher CFM rating allows for faster inflation, which is beneficial for businesses needing to service multiple vehicles in a short time. Evaluating the air flow rate can help buyers determine the efficiency of the inflator for their operational needs.

The length and design of the air hose impact how easily the inflator can reach all tire valves on an RV. Longer hoses provide greater flexibility, especially for larger vehicles where access may be limited. Additionally, features such as a 90-degree twist-on chuck can simplify the inflation process, reducing the time and effort required for maintenance.

Compact and lightweight designs enhance the portability of RV tire inflators, making them easier to store in limited space within an RV. For businesses that require mobile solutions, investing in a portable inflator can facilitate on-the-go maintenance, which is especially valuable for rental companies or service fleets.

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms relevant to RV tire inflators:

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can be crucial for buyers looking to source reliable and compatible components for their inflator systems.

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budgeting and inventory planning, ensuring they meet supplier requirements while managing stock effectively.

An RFQ is a document used by buyers to solicit price bids from suppliers. Including detailed specifications in an RFQ can lead to more accurate pricing and service proposals, helping businesses secure the best deals for RV tire inflators.

Illustrative image related to rv tire inflator

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and risk. Familiarity with these terms is essential for international buyers to understand their obligations and rights during the procurement process.

These terms outline the conditions under which a supplier will repair or replace a faulty product. Understanding warranty terms is vital for B2B buyers to ensure they are covered for potential defects or operational issues, protecting their investment in RV tire inflators.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the RV tire inflator market more effectively, ensuring they make well-informed purchasing decisions that meet their operational needs.

The RV tire inflator market is experiencing significant growth, driven by the rising popularity of recreational vehicle travel, particularly in regions such as Africa, South America, the Middle East, and Europe. The increasing number of RV owners and the growing trend of domestic tourism are propelling demand for reliable tire maintenance solutions. B2B buyers are particularly keen on portable and efficient inflators that can handle high-pressure requirements, as RV tires typically demand inflation pressures between 80-110 PSI.

Emerging technologies in tire inflators are focused on automation and smart features. For instance, many new models are equipped with digital pressure gauges, automatic shut-off functions, and longer hoses designed for easier access to all tires. This shift towards technologically advanced products is appealing to B2B buyers looking for innovative solutions that enhance user convenience and safety. Additionally, the trend of integrating mobile apps with inflators for real-time monitoring is gaining traction, particularly among tech-savvy consumers in Europe and North America.

Illustrative image related to rv tire inflator

International buyers should also be aware of regional market dynamics. In Africa and South America, where road conditions can be challenging, the demand for robust and portable inflators is high. Conversely, European markets, particularly in Germany, favor compact and energy-efficient models that comply with strict environmental regulations. Understanding these regional preferences can guide B2B buyers in selecting the right products that meet local market demands.

Sustainability has become a critical consideration in the RV tire inflator sector. As environmental awareness grows, B2B buyers are increasingly prioritizing products that minimize ecological impact. Manufacturers are responding by developing inflators with energy-efficient designs and recyclable materials. This shift is not just about compliance with regulations; it’s also about meeting the expectations of environmentally conscious consumers.

Ethical sourcing is another important factor. Buyers are seeking suppliers who can demonstrate transparency in their supply chains and adherence to ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential for suppliers looking to gain a competitive edge in the market.

Furthermore, the adoption of “green” certifications is vital for B2B buyers aiming to enhance their brand reputation. By sourcing products that comply with environmental standards, companies can appeal to a broader customer base that values sustainability. This trend is particularly pronounced in Europe, where green consumerism is reshaping purchasing decisions across various sectors.

Illustrative image related to rv tire inflator

The RV tire inflator sector has evolved significantly over the past few decades. Initially dominated by manual pumps and basic air compressors, the market has transitioned towards more sophisticated and automated solutions. Early models were often bulky and inefficient, leading to user frustration and safety concerns.

With technological advancements, manufacturers began introducing portable, battery-operated inflators capable of delivering higher pressures with ease. The introduction of features such as digital gauges and automatic shut-offs has further enhanced safety and convenience, making these tools indispensable for modern RV owners.

Today, the sector is characterized by a focus on portability, efficiency, and sustainability, aligning with the broader trends in consumer preferences. As RV travel continues to rise globally, the demand for high-quality, reliable tire inflators is set to grow, presenting significant opportunities for B2B buyers in diverse markets.

How do I choose the right RV tire inflator for my needs?

Choosing the right RV tire inflator involves assessing your specific requirements, such as the tire pressure you need to achieve and the type of RV you own. Look for inflators specifically designed for RVs, like those from brands such as Viair, which offer models tailored for different RV types and tire sizes. Consider features like duty cycle, portability, hose length, and ease of storage. Additionally, ensure the inflator can reach the necessary PSI for your tires, which often range from 80 to 150 PSI, depending on the RV model.

What is the best portable air compressor for RV tires?

The best portable air compressor for RV tires is typically one that is specifically engineered for RV use, such as the Viair 450P-RVS. This model is known for its high capacity, allowing it to inflate RV tires efficiently within minutes. It features a 12-volt power source, extended hoses for easy access to all tires, and a compact design for convenient storage. Always compare specifications and user reviews to find a model that meets your operational needs and budget.

What should I consider when sourcing RV tire inflators from international suppliers?

When sourcing RV tire inflators from international suppliers, consider factors such as product quality, compliance with safety standards, and the supplier’s reputation. Vet suppliers through trade platforms, industry referrals, and customer reviews. Ensure they offer products that meet the regulatory requirements of your target market. Additionally, assess their ability to provide after-sales support, warranty terms, and responsiveness to inquiries, which are crucial for ongoing business relationships.

What are the typical minimum order quantities (MOQs) for RV tire inflators?

Minimum order quantities (MOQs) for RV tire inflators can vary significantly by supplier and region. Typically, MOQs can range from 100 to 1,000 units, depending on the manufacturer and the specific model. For B2B buyers, negotiating MOQs is common, especially if you are willing to place a larger order or are a first-time customer. Always clarify MOQs during initial discussions to ensure they align with your purchasing capabilities.

What payment terms should I expect when sourcing RV tire inflators?

Payment terms for RV tire inflators can vary based on the supplier and your negotiation. Common arrangements include payment in full upfront, a deposit with the balance due upon shipment, or net payment terms extending 30 to 90 days. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always request detailed payment terms before finalizing any agreements.

How can I ensure quality assurance for RV tire inflators?

To ensure quality assurance for RV tire inflators, request certifications and test reports from suppliers that demonstrate compliance with international safety and performance standards. Conduct factory audits if feasible, or utilize third-party inspection services to verify product quality before shipment. Additionally, inquire about warranty policies and the supplier’s return or exchange processes to safeguard your investment and ensure product reliability.

What logistics considerations should I keep in mind for importing RV tire inflators?

When importing RV tire inflators, logistics considerations include shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost-effective bulk shipments. Understand the import duties and taxes applicable in your country to avoid unexpected costs. Collaborate with a reliable freight forwarder who can navigate customs clearance and provide real-time tracking of your shipment to ensure timely delivery.

Can I customize RV tire inflators for my brand?

Yes, many manufacturers offer customization options for RV tire inflators, such as branding with your logo, color variations, or specific packaging designs. Discuss your customization needs during initial supplier conversations to understand the available options and any associated costs. Customization can enhance your brand visibility and differentiate your products in the market, making it a valuable consideration for B2B buyers looking to establish a unique presence.

Domain: rollinontv.com

Registered: 2010 (15 years)

Introduction: Product Name: Viair 450P-RVS Portable Air Compressor

Type: Automatic 12 volt portable tire inflator

Designed For: Class A motorhomes, also suitable for smaller tires

Key Features:

– Compact size for easy storage in RV

– Equipped with hoses long enough to reach all RV tires

– Comes with a convenient carry bag and necessary accessories

– 40-inch, 90 degree twist-on chuck for easier filling

– Capable…

Domain: forestriverforums.com

Registered: 2006 (19 years)

Introduction: 1. Viair 400P: A 12 VDC compressor, pricier than pancake compressors, known for being quiet. Recommended with a 50′ hybrid air hose.

2. Viair Constant Duty Universal: Costs over $300, can inflate completely flat truck tires without overheating. Suitable for blowing out water lines in travel trailers.

3. Hyper Tough 120v Air Compressor: Purchased for $50, has a small 1-gallon tank, works well but…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The DeWalt air inflator is compatible with 20V batteries and has two additional power sources. It can fill tires to the desired pressure and automatically shuts off when that pressure is reached. It is noted to be reasonably quick and quiet for a portable tool, taking about a minute for every 5 PSI on larger truck tires. It also has a toy inflater function for inflating beach or pool toys.

Domain: technorv.com

Registered: 2009 (16 years)

Introduction: [{“name”:”VIAIR 300P-RVS Tire Inflator for Towables”,”sale_price”:”$179.96″,”regular_price”:”$199.95″,”discount”:”10%”,”reviews”:”42 Reviews”},{“name”:”VIAIR 89P-RVS Tire Inflator for Class B Motorhomes”,”sale_price”:”$94.46″,”regular_price”:”$104.95″,”discount”:”10%”,”reviews”:”23 Reviews”},{“name”:”VIAIR Winterization Kit (Compatible with 400 and 450 models ONLY)”,”price”:”$55.95″,”reviews”:”8 R…

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Viair – 450RV & 400RV Air Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the competitive landscape of RV accessories, strategic sourcing for tire inflators is essential for maximizing operational efficiency and ensuring customer satisfaction. Key takeaways highlight the importance of selecting products specifically designed for RV applications, such as the Viair portable air compressors, which cater to various RV models and tire pressures. By investing in high-quality inflators that combine portability, efficiency, and durability, businesses can enhance their service offerings and build customer loyalty.

Illustrative image related to rv tire inflator

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe explore sourcing opportunities, it is crucial to prioritize suppliers who understand the unique demands of the RV market. Establishing partnerships with manufacturers that provide reliable, RV-specific inflators will not only improve safety and performance but also streamline inventory management and reduce long-term costs.

Looking ahead, the demand for innovative and efficient tire inflators is set to grow as the RV market expands globally. Now is the time to take action—connect with reputable suppliers, evaluate your sourcing strategies, and invest in high-quality RV tire inflators that meet the evolving needs of your customers. Together, we can drive the future of RV travel forward, ensuring a safe and enjoyable journey for adventurers around the world.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.