In the rapidly evolving landscape of the global market, sourcing reliable truck tyre pumps presents a significant challenge for B2B buyers. With the diverse demands of various regions, including Africa, South America, the Middle East, and Europe, it becomes crucial to identify high-quality inflators that not only meet performance standards but also adapt to the specific needs of local markets. This comprehensive guide delves into the multifaceted world of truck tyre pumps, covering essential topics such as the different types of pumps available, their various applications, and key factors to consider when vetting suppliers.

Understanding the nuances of the truck tyre pump market is vital for making informed purchasing decisions. This guide empowers international buyers by providing actionable insights into cost considerations, quality assessments, and supplier credibility checks. Whether you’re in Vietnam, Saudi Arabia, or beyond, our expert analysis will equip you with the knowledge needed to navigate supplier landscapes and optimize your procurement strategies.

By addressing common pain points and highlighting best practices, this guide ensures that B2B buyers can confidently select the right truck tyre pumps tailored to their operational needs. The right choice can enhance fleet efficiency, reduce downtime, and ultimately contribute to a more profitable bottom line. Let’s embark on this journey to discover the best solutions for your truck tyre pump requirements.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Tire Inflator | Compact design, powered by 12V outlet or battery | Fleet maintenance, emergency roadside kits | Pros: Easy to use, versatile; Cons: Limited power for heavy-duty use. |

| Heavy-Duty Air Compressor | High PSI capability, often requires AC power | Workshops, large fleet operations | Pros: Quick inflation, durable; Cons: Bulky, less portable. |

| Dual-Cylinder Air Pump | Faster inflation rates, suitable for larger tires | Off-road vehicle maintenance, heavy trucks | Pros: Efficient for large tires; Cons: Higher price point. |

| Cordless Tire Inflator | Battery-operated, portable, suitable for light tasks | Emergency kits, small fleet operations | Pros: Convenient and portable; Cons: Limited battery life. |

| Multi-Purpose Inflator | Includes multiple attachments for different inflatables | General maintenance, sports equipment | Pros: Versatile usage; Cons: May not perform as well on heavy-duty tasks. |

Portable electric tire inflators are designed for convenience, typically powered by a 12V outlet or a rechargeable battery. These inflators are compact and lightweight, making them ideal for emergency roadside assistance or routine tire maintenance in fleet operations. When considering a purchase, B2B buyers should focus on features such as inflation speed, pressure accuracy, and the ability to handle various tire sizes. While they are easy to store and transport, their power limitations may not be suitable for heavy-duty applications.

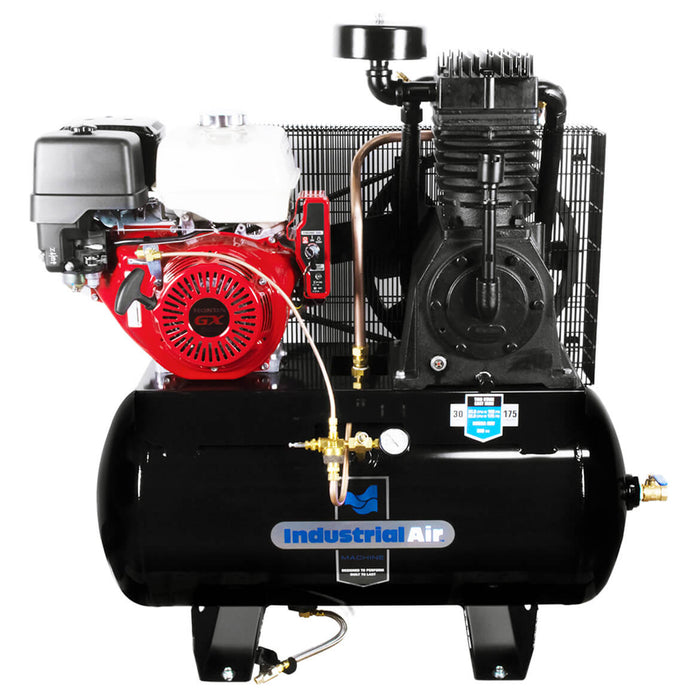

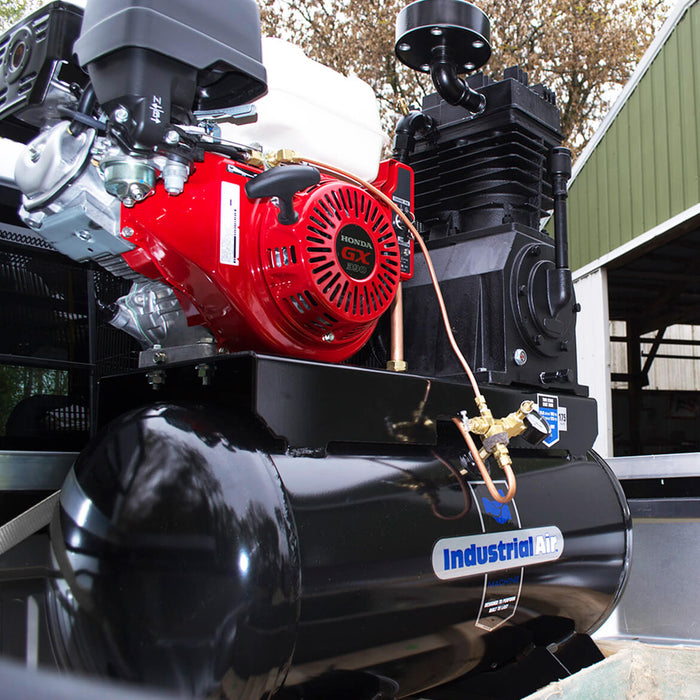

Heavy-duty air compressors are built for high-performance tasks, capable of inflating tires to high PSI levels quickly. These compressors often require AC power and are suited for workshops and large fleet operations where efficiency is paramount. B2B buyers should evaluate the compressor’s PSI capability, duty cycle, and overall durability. The investment may be higher, but the efficiency and reliability for heavy-duty applications can justify the cost, especially in environments where time is critical.

Illustrative image related to truck tyre pump

Dual-cylinder air pumps are engineered to provide faster inflation rates, making them particularly effective for larger tires found on trucks and off-road vehicles. These pumps typically have higher PSI capabilities and can inflate tires in a fraction of the time compared to single-cylinder models. For B2B buyers, the key considerations include the pump’s weight, portability, and speed. While they may come at a premium, their efficiency can significantly reduce downtime in operations that rely on heavy vehicles.

Cordless tire inflators are battery-operated devices that offer unparalleled portability and ease of use, making them suitable for emergency kits or small fleet operations. They can be used without needing an external power source, which is beneficial in remote locations. Buyers should assess battery life, charging time, and overall inflation speed when selecting a cordless model. While they are convenient, the limitation in power and inflation capacity may not meet the demands of larger vehicles.

Multi-purpose inflators come with various attachments, enabling them to inflate not just truck tires but also sports equipment, air mattresses, and more. This versatility makes them a valuable addition to any maintenance toolkit, especially for businesses that require flexibility. When purchasing, B2B buyers should consider the range of attachments included, the performance on different items, and overall durability. While they may not excel in heavy-duty tasks, their multifunctionality can provide significant value in everyday operations.

| Industry/Sector | Specific Application of truck tyre pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Routine maintenance of fleet vehicles | Ensures optimal tire pressure, enhancing fuel efficiency and safety | Compatibility with various vehicle types, durability, and ease of use |

| Construction | Inflating tires on heavy machinery and transport trucks | Reduces downtime by ensuring equipment is operational and safe | High PSI capabilities, robust design, and mobility for site use |

| Agriculture | Maintaining tires on agricultural vehicles | Increases productivity by minimizing tire-related delays | Portability, ruggedness for rough terrain, and ease of storage |

| Mining | Tire inflation for mining trucks and equipment | Enhances safety and operational efficiency in harsh environments | Ability to handle high-pressure requirements and rugged conditions |

| Emergency Services | Quick tire inflation for emergency response vehicles | Ensures readiness and rapid response in critical situations | Reliability, quick inflation time, and compact design for storage |

In the logistics and transportation sector, truck tyre pumps are essential for the routine maintenance of fleet vehicles. Companies rely on these pumps to ensure that all tires are inflated to the correct pressure, which significantly enhances fuel efficiency and vehicle safety. For international buyers, particularly in regions like Africa and South America, sourcing durable, high-performance pumps that are compatible with various vehicle types is crucial. Additionally, ease of use and maintenance are key considerations to minimize downtime.

In the construction industry, truck tyre pumps are vital for inflating tires on heavy machinery and transport trucks. Regularly maintaining tire pressure helps reduce downtime, allowing equipment to operate at peak performance. Buyers in this sector should focus on pumps that offer high PSI capabilities and robust designs to withstand the rigors of construction sites. Mobility is also a key factor, as pumps must be easily transportable across various locations.

Illustrative image related to truck tyre pump

Agricultural operations utilize truck tyre pumps to maintain the tires on tractors and other agricultural vehicles. Proper tire inflation is crucial for maximizing productivity and minimizing delays caused by tire issues. For B2B buyers in the agriculture sector, considerations include the portability of the pump, its ruggedness for rough terrain, and ease of storage. These features ensure that farmers can quickly address tire inflation needs during busy planting or harvesting seasons.

In the mining industry, truck tyre pumps are indispensable for tire inflation on mining trucks and heavy equipment. Maintaining the correct tire pressure is essential for safety and operational efficiency, particularly in harsh environments. Buyers in this sector should prioritize pumps that can handle high-pressure requirements and are designed for rugged conditions. Reliability and ease of use are also critical, as any delays in tire maintenance can lead to significant productivity losses.

Emergency services rely on truck tyre pumps for quick tire inflation of response vehicles, ensuring they are always ready for action. In critical situations, having a reliable and efficient pump can make a significant difference in response times. For B2B buyers in this field, sourcing pumps that offer reliability, quick inflation times, and compact designs for easy storage is essential. This ensures that emergency responders can maintain their vehicles effectively, enhancing their operational readiness.

Illustrative image related to truck tyre pump

The Problem: In the fast-paced environment of logistics and transportation, maintaining optimal tire pressure is critical for safety, fuel efficiency, and tire longevity. Many B2B buyers struggle with tire inflators that provide inaccurate pressure readings. This can lead to under-inflated or over-inflated tires, resulting in costly delays, increased fuel consumption, and even tire blowouts. Furthermore, in regions with varying climate conditions, the pressure can fluctuate, making it imperative to have reliable inflators that can adapt to different scenarios.

The Solution: To overcome this challenge, B2B buyers should prioritize tire inflators with built-in, high-quality digital pressure gauges. When sourcing a truck tire pump, look for models that feature automatic shut-off capabilities and preset pressure settings. This ensures that the pump will stop inflating once the desired PSI is reached, eliminating the risk of over-inflation. Additionally, buyers should invest in a model that can accommodate the specific tire pressure requirements of their fleet, ensuring versatility across various vehicle types. Regular calibration of the inflator’s gauge is also recommended to maintain accuracy, particularly before long trips or seasonal changes.

The Problem: Logistics and transportation companies often operate under tight schedules, leaving little room for extended tire maintenance. B2B buyers frequently encounter traditional air compressors that are bulky, require extensive setup, or take a long time to inflate tires. This inefficiency can lead to downtime, affecting service delivery and customer satisfaction. In competitive markets, every minute counts, and ineffective tire pumps can become a costly bottleneck.

The Solution: To address time constraints, businesses should consider investing in portable, high-capacity tire inflators designed specifically for trucks. Look for models that feature fast inflation rates—capable of inflating a standard truck tire within a few minutes. Dual-cylinder compressors can significantly reduce inflation time and are ideal for larger tires. Additionally, choose inflators with extended power cords or those that can be powered by both 12V outlets and rechargeable batteries, allowing flexibility in various settings. For maximum efficiency, ensure that the inflator is easily accessible within the vehicle and conduct regular maintenance checks to keep it in optimal working condition.

Illustrative image related to truck tyre pump

The Problem: Many B2B buyers in the transport sector may lack comprehensive knowledge about tire maintenance best practices, which can lead to improper use of tire pumps and inflated tires causing premature wear. This knowledge gap can be especially pronounced in regions where tire maintenance education is limited, further exacerbating the risk of vehicle breakdowns and additional costs.

The Solution: To mitigate this issue, companies should invest in training programs for their staff that focus on tire maintenance and the proper use of tire inflators. This includes educating employees on the importance of checking tire pressure regularly, understanding the specific PSI requirements for their fleet, and using the inflator correctly. Suppliers can assist by providing instructional materials, videos, or even in-person demonstrations on how to use their products effectively. Additionally, consider sourcing inflators that come with user-friendly manuals and digital interfaces that make operation intuitive. This proactive approach not only enhances safety but also prolongs tire life and reduces overall operational costs.

When selecting materials for truck tyre pumps, it is crucial to consider the performance, durability, and cost-effectiveness of each option. This analysis will focus on four common materials: aluminum, steel, plastic, and rubber. Each material has unique properties that affect the pump’s performance and suitability for various applications, particularly in diverse international markets.

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. It can withstand moderate pressure and temperature variations, making it suitable for portable tyre inflators. The key advantage of aluminum is its low weight, which enhances portability, especially for users in regions where mobility is essential.

Illustrative image related to truck tyre pump

Pros: Aluminum is durable and resistant to rust, which is particularly beneficial in humid or coastal environments. It is also relatively easy to manufacture and can be extruded into complex shapes, allowing for innovative designs.

Cons: While aluminum is strong, it may not withstand very high pressures as effectively as steel. Additionally, the cost of aluminum can be higher than that of some plastics, which may deter budget-conscious buyers.

Impact on Application: Aluminum pumps are generally compatible with a wide range of media, including air and nitrogen. However, users should ensure that the specific aluminum alloy used is appropriate for high-pressure applications.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is essential. Buyers in regions like Africa and South America should consider local availability and cost of aluminum, as well as potential tariffs.

Steel is another common material, particularly favored for its strength and durability. It can handle high pressures and is often used in heavy-duty applications, making it ideal for truck tyre pumps that require robust construction.

Illustrative image related to truck tyre pump

Pros: Steel’s high tensile strength allows it to withstand significant pressure, making it suitable for inflating large tyres. It also has excellent wear resistance, which extends the lifespan of the pump.

Cons: The primary drawback of steel is its susceptibility to corrosion unless treated or coated. This can lead to increased maintenance costs and reduced reliability, particularly in humid or saline environments.

Impact on Application: Steel pumps are typically used for high-pressure applications, but corrosion-resistant coatings are necessary for compatibility with various environments.

Considerations for International Buyers: Buyers should ensure that the steel used meets local and international standards for safety and performance. In the Middle East and Europe, for instance, compliance with EN standards can be critical.

Illustrative image related to truck tyre pump

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in the manufacture of truck tyre pumps due to their lightweight and corrosion-resistant properties.

Pros: Plastic pumps are typically less expensive to produce and can be designed for easy portability. They are also resistant to many chemicals, making them suitable for various applications beyond just tyre inflation.

Cons: While plastic is lightweight, it may not withstand high pressures as effectively as metals. This can limit its use in heavy-duty applications, which are common in truck tyre pumps.

Illustrative image related to truck tyre pump

Impact on Application: Plastic pumps are often used for lower-pressure applications and are ideal for consumer-grade products. However, they may not be suitable for commercial or industrial use where high durability is required.

Considerations for International Buyers: Buyers should verify that the plastic materials used comply with relevant safety and environmental regulations, particularly in Europe where standards can be stringent.

Rubber is primarily used in seals and hoses within tyre pumps. Its elasticity and resilience make it an ideal choice for components that require flexibility and durability.

Pros: Rubber components can withstand a wide range of temperatures and pressures, providing excellent sealing capabilities that prevent air leakage.

Cons: Rubber can degrade over time, especially when exposed to ozone or UV light, which may necessitate more frequent replacements.

Illustrative image related to truck tyre pump

Impact on Application: The use of rubber in pumps ensures reliable performance, particularly in high-pressure situations. However, the longevity of rubber components can be a concern in harsh environments.

Considerations for International Buyers: Buyers should consider the quality of rubber used, ensuring it meets international standards for durability and safety. In regions with extreme climates, selecting high-grade rubber can enhance pump performance.

| Material | Typical Use Case for truck tyre pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable inflators for light to moderate use | Lightweight and corrosion-resistant | Limited high-pressure capability | Medium |

| Steel | Heavy-duty pumps for high-pressure applications | High strength and durability | Susceptible to corrosion | High |

| Plastic | Consumer-grade pumps for low-pressure applications | Cost-effective and lightweight | Limited pressure resistance | Low |

| Rubber | Seals and hoses in tyre pumps | Excellent sealing and flexibility | Degrades over time in harsh conditions | Medium |

This strategic material selection guide provides insights into the various materials used in truck tyre pumps, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

Illustrative image related to truck tyre pump

The manufacturing process for truck tyre pumps involves several key stages, each critical to ensuring the final product’s performance and reliability.

The first stage begins with the careful selection and preparation of materials. High-quality plastic, metals, and rubber are common components in truck tyre pumps. Suppliers must ensure that these materials meet specific industry standards for durability and safety. For example, metals should be corrosion-resistant to withstand various environmental conditions. Rigorous testing of raw materials is essential, involving both visual inspections and material property assessments to confirm compliance with international standards.

Once materials are prepared, the next step is forming. This includes processes such as injection molding for plastic components, metal stamping, and die-casting for metal parts. Advanced techniques like CNC machining may also be employed to achieve precise dimensions and complex shapes. The choice of forming technique often depends on the design specifications and the intended use of the pump. For instance, dual-cylinder inflators may require more intricate metal components to facilitate high-pressure performance.

Illustrative image related to truck tyre pump

The assembly stage brings together all the components into a functional unit. This may involve manual assembly or automated processes, depending on the scale of production. Quality control during assembly is vital; each component must fit accurately to ensure the pump operates effectively. Common assembly techniques include fastening, welding, and sealing. For high-pressure pumps, attention must be paid to the sealing methods used to prevent air leaks, which could compromise performance.

After assembly, pumps undergo finishing processes, including surface treatment, painting, or coating. These processes not only enhance aesthetics but also improve durability and corrosion resistance. Quality assurance checks at this stage ensure that any defects in the finish or assembly are identified and rectified. Final inspection often includes testing the pump’s functionality and pressure capabilities, ensuring it meets specified performance standards.

Quality assurance (QA) is an integral part of the manufacturing process for truck tyre pumps, ensuring that the final products meet stringent safety and performance standards.

For manufacturers, compliance with international standards like ISO 9001 is crucial. ISO 9001 outlines requirements for a quality management system (QMS) that helps organizations ensure they meet customer and regulatory requirements consistently. Additionally, specific certifications such as CE marking for products sold in Europe and API standards for industrial equipment provide further assurance of quality and safety.

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process, typically categorized into three main areas:

Illustrative image related to truck tyre pump

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins. Material testing may include physical inspections and performance assessments.

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor quality at various stages. This may involve checking dimensions, functionality, and assembly integrity to catch defects early.

Final Quality Control (FQC): After assembly and finishing, pumps undergo comprehensive testing to verify their performance against industry standards. This may include pressure testing, operational testing, and safety checks.

Common testing methods for truck tyre pumps include:

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to mitigate risks.

Conducting supplier audits is one effective way to assess quality control practices. Buyers should establish a clear audit process that includes:

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services often include:

International buyers should be aware of specific nuances in quality control when sourcing truck tyre pumps.

Different regions may have varying standards and regulations that affect product compliance. For instance, products sold in the European market must meet CE marking requirements, while North American buyers may prioritize compliance with the American National Standards Institute (ANSI). Understanding these regional nuances is crucial for ensuring that the products meet local regulations.

Buyers should assess a supplier’s capacity to adapt to changing quality requirements or production volumes. This flexibility is particularly important in industries like transportation, where demand can fluctuate significantly. Suppliers with robust quality control systems are often better equipped to manage these changes without compromising product quality.

In conclusion, the manufacturing processes and quality assurance practices for truck tyre pumps are multifaceted and critical for ensuring product reliability. B2B buyers must engage in thorough due diligence to verify supplier capabilities, maintain compliance with international standards, and ensure the quality of the products they procure. By understanding these processes, buyers can make informed decisions that support their operational needs and enhance their supply chain reliability.

To aid B2B buyers in effectively sourcing truck tyre pumps, this guide provides a structured checklist that outlines the essential steps to ensure a successful procurement process. By following these steps, buyers can make informed decisions, minimize risks, and secure high-quality products that meet their operational needs.

Clearly outline the specifications required for your truck tyre pumps. Consider factors such as the pump’s maximum pressure, power source (12V, cordless, etc.), and compatibility with various tyre types. This step is crucial because it sets the foundation for identifying suitable products and suppliers.

Illustrative image related to truck tyre pump

Investigate current market trends and reputable brands in the tyre pump industry. Understanding which brands are recognized for quality and reliability can guide your sourcing decisions.

Before committing to a supplier, conduct thorough evaluations. This includes checking their company profile, production capabilities, and customer feedback from businesses in similar sectors.

Obtain samples of the tyre pumps you are considering. Testing the product firsthand allows you to evaluate its performance, durability, and ease of use.

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Ensure that the costs align with your budget while considering the value offered.

Engage in negotiations to finalize the terms of your purchase. Clearly outline the delivery schedules, payment methods, and any other conditions pertinent to the agreement.

Illustrative image related to truck tyre pump

After procurement, it’s essential to monitor the supplier’s performance. Regular assessments will help ensure that the product meets your expectations and that the supplier remains reliable for future purchases.

Following this structured checklist will empower B2B buyers to source truck tyre pumps effectively, ensuring they select the best products that meet their operational requirements while fostering strong supplier relationships.

When analyzing the cost structure for sourcing truck tyre pumps, several components contribute to the overall price. These include:

Illustrative image related to truck tyre pump

Materials: The primary materials for truck tyre pumps typically involve high-grade plastics, metals (like aluminum or steel), and rubber for seals. The choice of materials directly impacts durability and performance, which can vary significantly in price.

Labor: Labor costs encompass the wages paid to workers involved in manufacturing and assembly. These costs can fluctuate based on the region, labor laws, and the skill level required for assembling more complex inflators.

Manufacturing Overhead: This includes the costs of utilities, equipment maintenance, and other indirect expenses incurred during production. Overhead can vary based on the manufacturing facility’s location and operational efficiency.

Tooling: The initial investment in tooling for molds and machinery is substantial, especially for custom designs. This cost is amortized over the production run, affecting the unit price for smaller orders.

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and compliance with safety standards. The costs associated with testing and certification can be significant, particularly for buyers in regions with stringent regulations.

Logistics: Shipping costs depend on the distance, weight, and dimensions of the pumps. International shipping can add complexity, with tariffs and customs duties also influencing the final price.

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s business model.

Several factors influence the pricing of truck tyre pumps, particularly for international B2B buyers:

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect unit pricing. Larger orders typically yield better pricing due to economies of scale, while smaller orders may incur higher per-unit costs.

Specifications and Customization: Custom features (e.g., specific PSI ratings, digital displays) can increase costs. Buyers should weigh the benefits of customization against additional expenses.

Materials: The choice of materials not only impacts durability but also the cost. Premium materials may ensure better performance but will also raise the price point.

Quality and Certifications: Products with certifications (such as CE or ISO) may command higher prices due to their assurance of quality and safety, which can be crucial for markets with strict compliance requirements.

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers with a track record may charge a premium, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential, as they determine who bears the costs and risks during transport. This can significantly impact the total landed cost of the pumps.

B2B buyers can enhance cost-efficiency through strategic sourcing approaches:

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders or long-term contracts. Building relationships can lead to better terms and conditions.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential failure costs. A cheaper pump may lead to higher long-term expenses if it requires frequent replacement.

Pricing Nuances for International Buyers: Different regions may have varying price structures due to local economic conditions, tariffs, and currency fluctuations. Buyers should conduct thorough market research to understand regional pricing dynamics.

Leverage Technology: Utilize online platforms and marketplaces to compare prices and specifications across suppliers. This can provide leverage during negotiations and ensure competitive pricing.

Evaluate Supplier Capabilities: Assess suppliers based on their ability to meet specifications, delivery timelines, and after-sales service. A slightly higher price might be justified by superior service or product quality.

It is important to note that the prices mentioned for truck tyre pumps are indicative and can fluctuate based on market conditions, supplier pricing strategies, and other external factors. Always consult with suppliers for the most accurate and current pricing information tailored to your specific requirements.

In today’s competitive landscape, B2B buyers in industries reliant on transport must carefully evaluate the tools they employ for maintenance and safety. Among these tools, the truck tyre pump is essential for maintaining optimal tire pressure, but various alternative solutions exist that can also serve this purpose. This analysis will compare the truck tyre pump with two viable alternatives: portable electric tire inflators and air compressor systems.

| Comparison Aspect | Truck Tyre Pump | Portable Electric Tire Inflator | Air Compressor System |

|---|---|---|---|

| Performance | High; designed for heavy-duty use | Moderate; suitable for light to moderate inflation tasks | Very high; capable of inflating multiple tires quickly |

| Cost | Moderate; typically ranges from $50 to $150 | Low to moderate; prices range from $30 to $100 | High; initial investment often exceeds $300 |

| Ease of Implementation | Simple; plug-and-play operation | Very simple; often battery-operated or plugs into vehicle | Requires setup; may need professional installation |

| Maintenance | Low; minimal upkeep required | Low; mostly battery management | Moderate; regular maintenance needed for longevity |

| Best Use Case | Ideal for commercial fleets and heavy-duty vehicles | Best for personal use or light-duty applications | Best for workshops or facilities needing continuous use |

Portable electric tire inflators are compact and designed for convenience, making them a popular choice for personal vehicles. They are typically lightweight and easy to store, allowing drivers to maintain tire pressure on the go. Most models feature digital displays and automatic shut-off functions, which simplify the inflation process. However, their performance may be limited compared to truck tyre pumps, particularly when dealing with larger tires or multiple inflations in quick succession. Additionally, battery life can be a concern for frequent users.

Illustrative image related to truck tyre pump

Air compressor systems are known for their high performance and versatility. They can inflate multiple tires quickly and are often used in commercial settings where time efficiency is crucial. These systems can also power pneumatic tools, making them a valuable addition to workshops. However, the initial investment is significantly higher, and they require a dedicated space and maintenance to ensure optimal functionality. For businesses with limited budgets or space, this may not be the most practical solution.

When selecting the right solution for tire inflation, B2B buyers should consider several factors, including the scale of their operations, budget constraints, and specific use cases. For heavy-duty applications and commercial fleets, a truck tyre pump provides reliability and performance. However, businesses with lighter demands may benefit from the cost-effectiveness and portability of electric tire inflators. Meanwhile, organizations with extensive maintenance needs might find air compressor systems to be the best long-term investment despite their higher upfront costs. By thoroughly evaluating these factors, businesses can make informed decisions that enhance operational efficiency and safety.

Understanding the essential specifications of truck tyre pumps is crucial for B2B buyers, as these properties directly impact performance, reliability, and overall value. Here are several critical specifications to consider:

Pressure Capacity (PSI)

– The maximum pressure a tyre pump can achieve, typically measured in pounds per square inch (PSI). For truck tyre pumps, this often ranges from 80 to 150 PSI. High-pressure capacity is essential for heavy-duty vehicles, ensuring that tires are inflated to optimal levels for safety and efficiency.

Power Source

– Truck tyre pumps may be powered by various sources, including 12V DC from vehicle batteries or rechargeable lithium-ion batteries. Understanding the power source is vital for determining where and how the pump can be used. For instance, a portable battery-operated pump offers flexibility, while a 12V model may be more suitable for continuous use in a workshop setting.

Flow Rate (CFM)

– The flow rate, measured in cubic feet per minute (CFM), indicates how quickly a pump can inflate a tire. A higher CFM means faster inflation, which is particularly beneficial for commercial operations where time is critical. For truck applications, a flow rate of 2.0 to 5.0 CFM is typically desirable.

Duty Cycle

– This specification refers to the amount of time a pump can operate continuously before needing to cool down. For example, a 50% duty cycle means the pump can run for 5 minutes and then requires a 5-minute rest. Understanding the duty cycle is essential for ensuring that the pump can handle the demands of frequent use without overheating.

Weight and Portability

– The weight of the pump affects its portability. Lightweight models are easier to transport, making them ideal for roadside assistance or emergency situations. However, heavier pumps may offer more robust construction and higher performance, which can be a trade-off depending on the buyer’s needs.

Material and Build Quality

– The materials used in the pump’s construction (e.g., aluminum, high-grade plastic) impact durability and performance. Pumps made from high-quality materials are typically more resistant to wear and tear, ensuring longevity, especially in harsh environments.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms you should know:

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tyre pumps, an OEM might supply components for a branded pump. Buyers often seek OEM products for quality assurance and compatibility.

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they can meet their inventory needs without overcommitting capital. This is particularly important in markets with fluctuating demand.

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and other details for specific products. It is a standard practice in B2B transactions that allows buyers to compare options and negotiate terms effectively.

Incoterms (International Commercial Terms)

– These are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps in determining who is responsible for shipping, insurance, and tariffs, which is essential for cost management.

Warranty Period

– The warranty period is the duration during which a product is covered for defects and malfunctions. Knowing the warranty terms is vital for buyers to understand their rights and the level of support they can expect from the manufacturer.

Lead Time

– This term refers to the time it takes from placing an order until the product is delivered. Understanding lead time is critical for inventory management, especially in industries that rely on timely access to equipment like truck tyre pumps.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right truck tyre pump for their operational needs while effectively navigating the procurement process.

Illustrative image related to truck tyre pump

The truck tyre pump sector is witnessing significant growth driven by the increasing demand for efficient and reliable tire maintenance solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are influenced by several global drivers. One of the primary factors is the rising awareness of vehicle safety and maintenance, which has prompted fleet operators and individual truck owners to invest in high-quality tire pumps. Additionally, the ongoing expansion of the logistics and transportation industries necessitates reliable equipment, further fueling demand.

Emerging technologies such as smart tire inflators equipped with digital pressure gauges and automated shut-off features are transforming the market. These innovations not only enhance convenience but also ensure optimal tire performance. Furthermore, the trend towards portable and battery-operated models is gaining traction, especially in remote regions where access to power sources may be limited. B2B buyers are increasingly seeking products that offer versatility, enabling them to cater to various vehicle types, from light trucks to heavy-duty commercial vehicles.

Sourcing strategies are also evolving, with a greater emphasis on direct relationships with manufacturers. International buyers are looking for suppliers who can provide customized solutions that meet specific regional needs. This shift towards direct sourcing helps in reducing costs and improving supply chain efficiency, enabling buyers to respond swiftly to market demands.

Sustainability and ethical sourcing are becoming pivotal in the truck tyre pump sector. The environmental impact of production processes and materials used in manufacturing is under scrutiny, compelling companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials in their products.

The importance of ethical supply chains cannot be overstated. Buyers are more likely to choose suppliers who uphold labor rights, ensure fair wages, and promote safe working conditions throughout their supply chains. This ethical approach not only enhances brand reputation but also fosters customer loyalty, particularly among consumers who are increasingly conscious of the social implications of their purchases.

In terms of certifications, products made from recycled materials or those that achieve recognized environmental certifications are gaining popularity. Buyers are encouraged to seek out truck tyre pumps that are certified by reputable organizations, as these certifications can serve as indicators of a product’s commitment to sustainability. As the industry progresses, the demand for ‘green’ products will likely increase, making it essential for suppliers to align with these values.

The evolution of the truck tyre pump market reflects broader technological advancements and changing consumer needs. Initially, tire pumps were basic manual devices that required significant physical effort to operate. However, as the automotive industry evolved in the mid-20th century, so did the technology behind tire inflation. The introduction of electric and portable air compressors marked a significant turning point, making tire maintenance more convenient and efficient.

By the late 20th century, the focus shifted towards enhancing safety and performance, leading to the development of more sophisticated inflators with integrated pressure gauges and automatic shut-off mechanisms. This evolution has been instrumental in shaping the current market landscape, where convenience, efficiency, and safety are paramount. As the sector continues to grow, understanding this historical context allows B2B buyers to appreciate the advancements that have led to today’s diverse offerings in the truck tyre pump market.

Illustrative image related to truck tyre pump

How do I choose the right truck tyre pump for my fleet?

Choosing the right truck tyre pump involves assessing your specific needs, including the size of your fleet, the types of vehicles, and the typical operating conditions. Look for pumps with high PSI ratings suitable for heavy-duty trucks and ensure they can handle the volume of usage required. Additionally, consider features such as portability, power source (cordless vs. corded), and whether the pump has automatic shut-off functions to prevent overinflation. Reading reviews and consulting with suppliers about performance under similar conditions can also provide valuable insights.

What is the best portable tyre pump for heavy-duty trucks?

For heavy-duty trucks, the best portable tyre pumps typically have a high PSI capacity and robust build quality. Models like the Viair 88P are recommended for their ability to inflate larger tires quickly and efficiently. Features to look for include a durable design, long hose length, and a reliable power source, such as battery clamps or a 12-volt outlet. Additionally, consider pumps with built-in pressure gauges for accuracy and ease of use.

What are the key factors to consider when sourcing tyre pumps from international suppliers?

When sourcing tyre pumps internationally, key factors include the supplier’s reputation, compliance with international quality standards, and their ability to provide certifications. Evaluate their manufacturing capabilities, lead times, and after-sales support. It’s also essential to understand the payment terms, shipping logistics, and any applicable tariffs or customs regulations. Conducting a thorough vetting process, including requesting samples and reviews from other buyers, will help ensure you partner with a reliable supplier.

What is the minimum order quantity (MOQ) for truck tyre pumps?

Minimum order quantities (MOQ) for truck tyre pumps can vary significantly by supplier and product specifications. Typically, MOQs may range from 50 to several hundred units, depending on the manufacturer’s production capabilities and your customization requirements. It’s advisable to discuss your needs directly with potential suppliers to negotiate MOQs that align with your purchasing strategy, especially if you are looking to test the market with a smaller initial order.

How can I ensure the quality of the tyre pumps I purchase?

To ensure the quality of tyre pumps, request product certifications and quality assurance documentation from suppliers. Implementing a quality control process, such as inspecting samples before bulk purchase and establishing clear specifications, can help mitigate risks. Additionally, consider working with suppliers that offer warranties and after-sales support, which can provide peace of mind regarding product performance and reliability.

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary greatly among international suppliers. Common terms include a percentage deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within 30-90 days after receiving the goods. It is crucial to clarify these terms early in negotiations and consider using secure payment methods, such as letters of credit or escrow services, to protect your investment.

How do logistics and shipping impact the sourcing of truck tyre pumps?

Logistics and shipping play a critical role in the sourcing process, influencing both cost and delivery timelines. Consider factors such as shipping method (air vs. sea), transit times, and the reliability of the chosen freight forwarder. Additionally, be aware of customs regulations and potential delays at borders, especially when importing into regions like Africa or South America. Collaborating with suppliers who have experience in your target markets can help streamline the logistics process.

Can I customize the tyre pumps for my specific branding needs?

Many manufacturers offer customization options for tyre pumps, allowing you to add your branding, colors, or specific features tailored to your market. Customization can enhance brand recognition and ensure the product meets your operational requirements. When discussing customization, provide clear specifications and inquire about any additional costs or changes to lead times. Engaging early with the supplier on these aspects can facilitate a smoother development process.

Could not verify enough suppliers for truck tyre pump to create a list at this time.

In navigating the complexities of sourcing truck tyre pumps, international B2B buyers must prioritize quality, efficiency, and reliability. The rising demand for robust inflators in regions such as Africa, South America, the Middle East, and Europe underscores the importance of selecting suppliers who can deliver advanced features, such as fast inflation times, accuracy, and user-friendly designs. By leveraging strategic sourcing, businesses can not only enhance their operational capabilities but also ensure they meet the diverse needs of their customer base.

Investing in high-performance tyre pumps can significantly impact fleet maintenance and operational costs, ultimately leading to improved safety and productivity. As companies look to streamline their supply chains, focusing on manufacturers with strong reputations for durability and service support will be paramount.

Looking ahead, it is crucial for buyers to stay informed about technological advancements in tyre inflation solutions. By actively seeking partnerships with innovative suppliers, businesses can position themselves at the forefront of the market. Engage with trusted manufacturers today to secure a competitive edge and elevate your fleet’s performance in the evolving global landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.