In the global marketplace, sourcing essential vehicle maintenance information, such as where to find tire inflation in a 2022 Sienna XLE, can pose significant challenges for B2B buyers. Proper tire inflation is crucial not only for vehicle safety but also for optimizing fuel efficiency, reducing operational costs, and enhancing overall vehicle performance. This guide comprehensively addresses the nuances of tire maintenance, including the recommended tire pressure specifications, the functionality of the Tire Pressure Monitoring System (TPMS), and the location of tire inflation points in the Sienna XLE.

International buyers from regions such as Africa, South America, the Middle East, and Europe (including Germany and Vietnam) will find actionable insights tailored to their unique market conditions. The guide delves into various tire types and their applications, ensuring buyers can make informed decisions based on vehicle requirements and local regulations. Additionally, we provide a thorough supplier vetting process, enabling buyers to identify reputable sources for tire maintenance equipment and services.

By equipping B2B buyers with the knowledge to maintain tire inflation effectively, this guide empowers them to optimize vehicle performance, enhance safety, and ultimately drive down costs in their operations. Whether you are managing a fleet or catering to individual customers, understanding tire inflation in the 2022 Sienna XLE is a pivotal step towards achieving operational excellence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Tire Pressure Check | Utilizes a standard tire pressure gauge for accurate readings. | Fleet maintenance, automotive services | Pros: High accuracy; Cons: Labor-intensive, time-consuming. |

| TPMS Monitoring System | Integrated sensor system that alerts drivers of pressure changes. | Automotive manufacturing, vehicle rental | Pros: Real-time monitoring; Cons: Battery replacement needed. |

| On-Board Display Access | Access tire pressure information through the vehicle’s dashboard. | Vehicle leasing, fleet management | Pros: Convenient, easy access; Cons: May require user training. |

| Mobile Tire Pressure Apps | Smartphone applications that connect to TPMS for readings. | Automotive aftermarket, fleet operators | Pros: User-friendly, remote monitoring; Cons: Dependent on smartphone compatibility. |

| Tire Pressure Calibration Kits | Specialized tools for calibrating tire pressure sensors. | Automotive repair shops, manufacturers | Pros: Ensures accuracy; Cons: High initial investment cost. |

Manual tire pressure checks involve using a handheld gauge to measure the air pressure in each tire. This method is favored for its accuracy, making it ideal for fleet maintenance or automotive services where precision is paramount. Buyers should consider the labor costs associated with manual checks, as they can be time-consuming, especially for larger fleets. However, the reliability of manual gauges can make them a worthwhile investment for businesses prioritizing safety and performance.

A Tire Pressure Monitoring System (TPMS) uses sensors installed in each tire to monitor air pressure continuously. This system is particularly beneficial for automotive manufacturers and vehicle rental companies, as it enhances safety by alerting drivers to potential tire issues. While TPMS provides real-time data, businesses must account for the eventual need to replace sensor batteries, which can add to maintenance costs. Overall, the convenience and safety benefits make TPMS a strong choice for modern fleets.

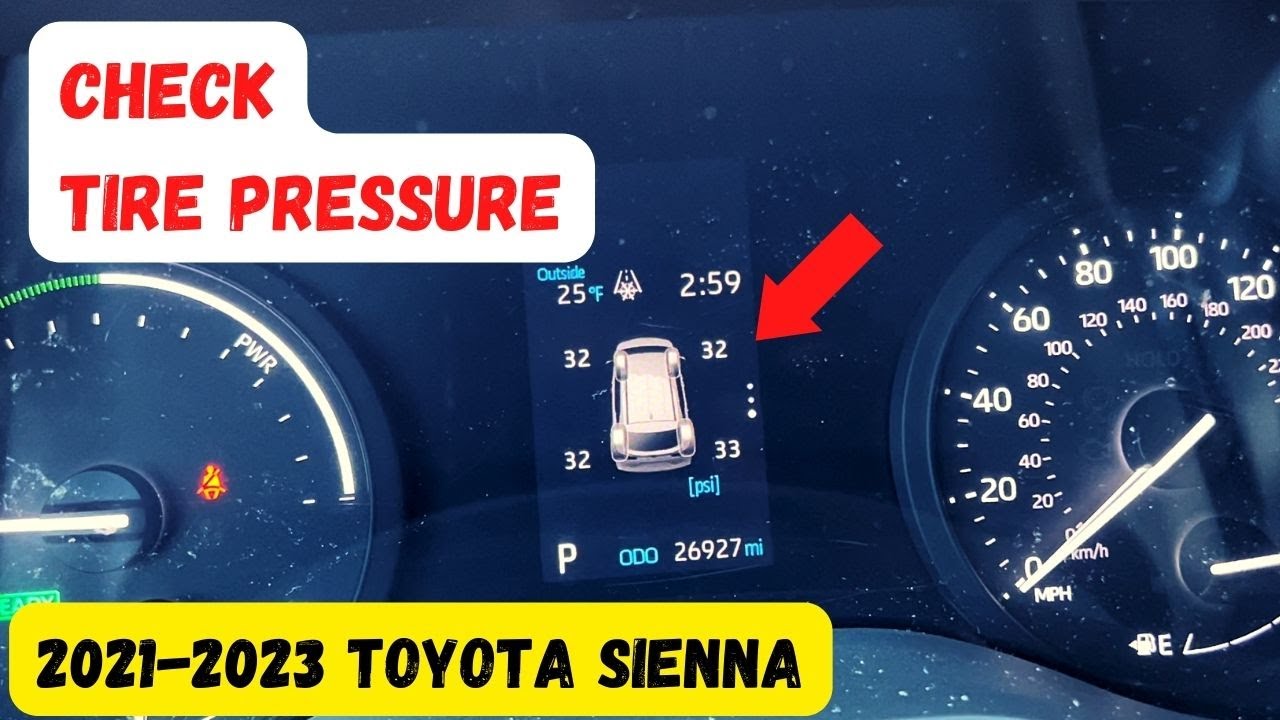

On-board display access allows drivers to view tire pressure readings directly from the vehicle’s dashboard. This feature is especially useful for vehicle leasing and fleet management operations, where quick access to information can streamline maintenance processes. While it offers convenience, companies must ensure that their drivers are adequately trained to navigate the vehicle’s interface. The ease of access to tire information can lead to better maintenance practices and improved vehicle safety.

Mobile tire pressure applications connect with the vehicle’s TPMS to provide tire pressure data on smartphones. This modern solution is gaining traction among automotive aftermarket businesses and fleet operators who value remote monitoring capabilities. The user-friendly nature of these apps makes them appealing; however, compatibility with smartphones can be a limiting factor. Businesses should evaluate the technological readiness of their workforce before investing in mobile solutions.

Tire pressure calibration kits are specialized tools used to ensure the accuracy of tire pressure sensors. They are essential for automotive repair shops and manufacturers that prioritize precision in tire management. Although the initial investment can be significant, the long-term benefits of maintaining accurate tire pressure can lead to improved vehicle performance and safety. Businesses should weigh the cost against the potential reduction in tire-related issues and enhanced customer satisfaction.

| Industry/Sector | Specific Application of where is the tire inflation in a 2022 sienna xle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Regular tire pressure checks for fleet maintenance | Improved vehicle safety and reduced operational costs | Availability of TPMS diagnostic tools and tire pressure gauges |

| Logistics & Transport | Ensuring optimal tire pressure for delivery vehicles | Enhanced fuel efficiency and reduced tire wear | Reliable suppliers of tire inflation equipment and monitoring systems |

| Car Rental Services | Pre-rental tire pressure verification for customer safety | Increased customer satisfaction and reduced liability risks | Access to accurate tire pressure monitoring systems |

| Fleet Management | Monitoring tire pressure across multiple vehicles in a fleet | Streamlined maintenance processes and improved vehicle uptime | Integration with fleet management software for real-time monitoring |

| Automotive Manufacturing | Quality control in tire pressure settings during production | Consistency in product quality and enhanced safety standards | Partnerships with tire manufacturers and quality assurance protocols |

For automotive repair businesses, regularly checking tire pressure is crucial for fleet maintenance. The 2022 Toyota Sienna XLE is equipped with a Tire Pressure Monitoring System (TPMS), allowing technicians to easily access tire pressure data. This ensures that vehicles are operating safely and efficiently, minimizing risks associated with underinflated or overinflated tires. International buyers must consider sourcing reliable TPMS diagnostic tools and manual gauges to maintain accuracy in their services, especially in regions with diverse climatic conditions.

In logistics and transport, maintaining optimal tire pressure is vital for delivery vehicles. Properly inflated tires enhance fuel efficiency, which is a significant cost driver in the industry. By leveraging the tire inflation data from the 2022 Sienna XLE, logistics companies can reduce tire wear and improve overall vehicle performance. Businesses should focus on sourcing high-quality tire inflation equipment and monitoring systems to ensure consistent tire pressure across their fleet, particularly in regions with varying road conditions.

Car rental services can significantly benefit from pre-rental tire pressure checks using the 2022 Sienna XLE’s TPMS features. Ensuring that vehicles are safe and ready for customers enhances satisfaction and reduces liability risks. Accurate tire pressure data helps rental companies maintain their fleet effectively, avoiding potential accidents caused by tire failures. When sourcing equipment, rental agencies should prioritize reliable tire pressure monitoring systems that can easily integrate into their existing fleet management practices.

For fleet management, monitoring tire pressure across multiple vehicles is crucial for operational efficiency. The 2022 Sienna XLE offers a user-friendly interface for accessing tire pressure information, allowing fleet managers to streamline maintenance processes. By ensuring that all vehicles are properly inflated, businesses can enhance vehicle uptime and reduce maintenance costs. Key sourcing considerations include integrating tire pressure monitoring systems with fleet management software for real-time data analysis, particularly in markets with high vehicle utilization rates.

In automotive manufacturing, maintaining consistent tire pressure settings during production is essential for quality control. The 2022 Sienna XLE’s tire inflation specifications can serve as a benchmark for manufacturers, ensuring that all vehicles meet safety standards. By establishing partnerships with tire manufacturers and implementing stringent quality assurance protocols, businesses can enhance the safety and reliability of their vehicles. International buyers should ensure that they have access to the latest tire technology and production equipment to maintain these standards.

The Problem:

B2B buyers, particularly those managing fleets or car rental services, often face challenges in locating critical information about tire inflation for the 2022 Sienna XLE. This is especially true when vehicles are used in diverse geographical locations where proper tire maintenance is essential for safety and performance. Many users report confusion regarding where to find the correct tire pressure specifications, often leading to inconsistent tire maintenance practices that can affect vehicle safety and longevity.

The Solution:

To effectively address this issue, B2B buyers should familiarize themselves with the vehicle’s owner manual, which provides comprehensive information regarding tire pressure specifications. Additionally, a sticker located on the driver’s side door jamb indicates the recommended tire pressure for the 2022 Sienna XLE. Regular training sessions for fleet personnel can enhance their understanding of these locations, ensuring that they know how to check tire pressures accurately. Implementing a standardized checklist for tire maintenance that includes checking pressure at the start of each day can further mitigate the risk of oversight.

The Problem:

Many buyers, particularly those new to managing vehicle fleets, often misunderstand how the Tire Pressure Monitoring System (TPMS) in the 2022 Sienna XLE operates. There can be confusion regarding the indicators shown on the dashboard, leading to either overinflation or underinflation of tires. This situation is compounded by the fact that some users report that the TPMS light may illuminate without a clear understanding of the severity of the issue, causing unnecessary anxiety and potential mismanagement of tire health.

The Solution:

To alleviate this problem, B2B buyers should invest in comprehensive training on the TPMS functionality. This can include workshops on how to interpret dashboard indicators and when to take corrective actions. Furthermore, equipping fleet managers with resources that explain the TPMS—such as detailed guides and visual aids—will enable them to respond appropriately to warnings. Regular inspections should also be scheduled to confirm that TPMS sensors are functioning correctly and that tire pressures are manually checked using reliable gauges, ensuring a comprehensive approach to tire management.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

The Problem:

B2B buyers managing vehicle fleets often encounter discrepancies between manual tire pressure gauges and the readings displayed on the Sienna XLE’s onboard system. Such inconsistencies can lead to confusion and mistrust in the accuracy of either the onboard system or the manual gauges, resulting in improper tire inflation that can affect vehicle performance and safety.

The Solution:

To combat this issue, it is essential for buyers to standardize the type of tire pressure gauges used across their fleet. Investing in high-quality, calibrated digital gauges can help ensure accurate readings that are consistent with the TPMS. Additionally, conducting regular audits of tire pressures using both the onboard display and manual gauges can help identify any discrepancies. Implementing a protocol where both readings are compared and corrected as necessary will foster a culture of diligence in tire maintenance, thereby enhancing the overall safety and efficiency of the fleet. Regular training sessions to reinforce the importance of accurate tire pressure monitoring can also be beneficial.

When considering tire inflation systems for the 2022 Toyota Sienna XLE, several materials are commonly used in the manufacturing of components such as valves, sensors, and hoses. Each material presents unique properties, advantages, and limitations that can significantly affect performance and suitability for international markets.

Rubber is often used for tire valves and sealing components due to its excellent elasticity and ability to maintain airtight seals. It can withstand a temperature range of -40°C to 100°C, making it suitable for various climates. Additionally, rubber exhibits good resistance to wear and tear, which is crucial for maintaining functionality over time.

Pros and Cons: Rubber is durable and cost-effective, making it a popular choice for manufacturers. However, it can degrade under extreme UV exposure and may require replacements more frequently in harsh environments. This degradation can lead to leaks, which is a critical concern for tire inflation systems.

Impact on Application: Rubber is compatible with air and nitrogen, commonly used in tire inflation. However, it may not be suitable for applications involving corrosive gases.

Considerations for International Buyers: Buyers in regions with high UV exposure, such as parts of Africa and the Middle East, should consider the longevity of rubber components. Compliance with international standards like ASTM and ISO can also guide material selection.

Aluminum is frequently used in tire pressure monitoring systems (TPMS) due to its lightweight nature and excellent corrosion resistance. It can withstand pressures up to 300 psi, making it suitable for tire inflation applications.

Pros and Cons: Aluminum is highly durable and lightweight, which enhances vehicle efficiency. However, it is generally more expensive than rubber and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Aluminum components are ideal for high-performance vehicles where weight savings are critical. They are compatible with various media, including air and nitrogen.

Considerations for International Buyers: In markets like Europe and Germany, where lightweight materials are preferred for performance vehicles, aluminum may be more appealing. Compliance with DIN standards is crucial for ensuring quality and performance.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

Stainless steel is often utilized for tire inflation valves and fittings due to its exceptional strength and corrosion resistance. It can handle high pressures and extreme temperatures, making it suitable for various environmental conditions.

Pros and Cons: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it is more expensive than both rubber and aluminum, which could impact overall production costs.

Impact on Application: Stainless steel is compatible with air and nitrogen and is often used in heavy-duty applications where reliability is paramount.

Considerations for International Buyers: Buyers in regions with high humidity or corrosive environments, such as coastal areas in South America, may find stainless steel components beneficial. Compliance with ASTM standards can help ensure the quality of these materials.

Composite materials, often a blend of plastics and fibers, are increasingly used in tire inflation systems for their lightweight and flexible properties. They can withstand pressures similar to aluminum and offer good resistance to environmental factors.

Pros and Cons: Composites are generally less expensive than metals and can be molded into complex shapes, reducing manufacturing complexity. However, they may not offer the same level of durability as metals, which could be a concern in high-stress applications.

Impact on Application: Composites are suitable for non-structural components where weight reduction is essential, such as in TPMS housings.

Considerations for International Buyers: In markets where cost is a significant factor, such as parts of Africa and South America, composites may provide a budget-friendly alternative. Compliance with local standards is vital for ensuring performance.

| Material | Typical Use Case for where is the tire inflation in a 2022 sienna xle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Tire valves and sealing components | Cost-effective and durable | Degrades under UV exposure | Low |

| Aluminum | Tire pressure monitoring systems (TPMS) | Lightweight and corrosion-resistant | Higher manufacturing complexity | Med |

| Stainless Steel | Tire inflation valves and fittings | Exceptional strength and durability | Higher cost | High |

| Composite | Non-structural components like TPMS housings | Lightweight and flexible | Lower durability compared to metals | Low |

This analysis aims to provide B2B buyers with actionable insights into material selection for tire inflation systems in the 2022 Toyota Sienna XLE, considering performance, cost, and regional preferences.

The manufacturing process for tire inflation systems in vehicles like the 2022 Toyota Sienna XLE involves several critical stages, ensuring that the system is efficient, reliable, and safe. Understanding these processes can help B2B buyers assess suppliers and ensure quality in their procurement strategies.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

The first stage of the manufacturing process involves selecting high-quality materials for the tire inflation system. Common materials include rubber for tires, steel for rims, and various polymers for valves and seals. In this phase, suppliers focus on sourcing materials that meet international quality standards. This is crucial for ensuring the durability and performance of the tire inflation system.

Once the materials are prepared, the next step is forming. For tires, this involves processes such as extrusion and molding, where rubber is shaped into the desired form. This stage may include the application of tread patterns and sidewall designs, which are critical for performance and safety. For rims, stamping and forging techniques are used to create a robust yet lightweight structure. Ensuring precision in this stage is vital, as any defects can lead to compromised safety and performance.

The assembly stage brings together all components of the tire inflation system. This includes attaching the tire to the rim and integrating the valve stem. In the case of the 2022 Sienna XLE, the assembly process may also involve integrating the Tire Pressure Monitoring System (TPMS) sensors, which provide real-time data on tire pressure. The assembly must be conducted in a controlled environment to minimize contamination and defects.

After assembly, the finishing stage involves inspection and testing of the tire inflation systems. This includes balancing the tires, checking for leaks, and ensuring that the TPMS is functioning correctly. A thorough finishing process is crucial for meeting safety standards and ensuring long-term performance.

Quality assurance in manufacturing tire inflation systems is critical for maintaining safety and performance. For international B2B buyers, understanding these standards can aid in selecting reputable suppliers.

ISO 9001 is a widely recognized international standard for quality management systems (QMS). Suppliers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements. For tire inflation systems, compliance with this standard can indicate a commitment to quality and continuous improvement.

Additionally, other standards such as CE marking in Europe signify that a product meets specific safety and environmental requirements. For buyers in regions like Africa and South America, understanding local certifications can also be crucial, as these may vary significantly from international standards.

Quality control (QC) checkpoints throughout the manufacturing process help ensure that each component meets the necessary specifications. Key checkpoints include:

Incoming Quality Control (IQC): This involves inspecting raw materials before they are used in production. Ensuring that materials meet specified standards is essential for preventing defects down the line.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect issues early. This proactive approach helps in maintaining high-quality standards throughout production.

Final Quality Control (FQC): This final inspection stage assesses the completed product before it leaves the manufacturing facility. It includes rigorous testing of tire pressure sensors and inflation systems to ensure they function as intended.

Various testing methods are employed to validate the quality of tire inflation systems. These methods may include:

Pressure Testing: This tests the integrity of tire components and ensures they can withstand the necessary pressure without failure.

Leak Testing: Ensures that there are no leaks in the valve stems or other components, which is vital for maintaining proper tire pressure.

Functional Testing: For TPMS, functional tests verify that sensors accurately report tire pressure readings.

B2B buyers should conduct thorough due diligence when selecting suppliers for tire inflation systems. Several strategies can enhance this process:

Supplier Audits: Regular audits of suppliers can help verify that they adhere to quality standards. These audits should assess both manufacturing processes and quality assurance practices.

Requesting Quality Reports: Buyers should ask for documentation regarding QC processes, including test results and compliance certifications. This transparency can provide insights into the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality assurance processes. This is particularly important for international buyers who may not have direct oversight.

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification can be critical. Different regions may have varying requirements for compliance and certification, which can impact procurement strategies.

Regional Standards: Buyers should familiarize themselves with regional standards and certifications, such as those required by the European Union or specific local regulations in African countries.

Cultural Considerations: Understanding cultural attitudes towards quality and safety can also influence supplier relationships. In some regions, there may be a stronger emphasis on compliance with international standards, while in others, local certifications may hold more weight.

Supply Chain Transparency: Establishing clear communication and transparency with suppliers regarding their quality assurance processes can lead to stronger partnerships and better product quality.

By understanding the manufacturing processes and quality assurance standards for tire inflation systems in the 2022 Toyota Sienna XLE, B2B buyers can make informed decisions that align with their quality expectations and regulatory requirements.

This guide serves as a practical checklist for B2B buyers who need to understand the tire inflation process for the 2022 Toyota Sienna XLE. Proper tire inflation is essential for vehicle safety, fuel efficiency, and tire longevity. Knowing where to find the tire pressure specifications and how to adjust them is crucial for maintaining the performance of this vehicle.

Begin by identifying the location of the tire pressure information. This is typically found on a sticker inside the driver’s side door frame. It provides the manufacturer’s recommended tire pressure, which is essential for optimal performance and safety.

Familiarize yourself with the TPMS, which alerts the driver when tire pressure is below the recommended levels. In the Sienna XLE, the TPMS light will illuminate on the dashboard if the pressure is low.

Make sure to adhere to the recommended tire pressure for the Sienna XLE, which may differ from the maximum pressure listed on the tire sidewall. Correct tire pressure not only enhances fuel efficiency but also prolongs tire life.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

Establish a routine for checking tire pressure, ideally once a month or before long trips. This practice helps identify slow leaks and ensures all tires are inflated to the correct levels.

When tire pressure is found to be below the recommended level, add air to bring it back to specification. This can be done at a service station or using a portable air compressor.

Inspect the tires for visible signs of wear or damage, such as cracks, bulges, or uneven tread wear. Proper tire inflation is only one part of tire maintenance; the overall condition must also be assessed.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

If you operate a fleet of vehicles, ensure that your maintenance team is well-versed in tire inflation practices specific to the Sienna XLE. Training on the importance of tire pressure can enhance safety and operational efficiency.

By following this checklist, B2B buyers can ensure they maintain optimal tire inflation for the 2022 Toyota Sienna XLE, enhancing safety and performance while reducing operational costs.

When sourcing tire inflation solutions for the 2022 Toyota Sienna XLE, understanding the comprehensive cost structure is essential for B2B buyers. This analysis highlights various cost components and pricing influencers, along with actionable tips to ensure cost-efficiency in procurement.

Materials: The primary material costs are linked to the tire inflation equipment, including air compressors, tire pressure monitoring systems (TPMS), and inflation hoses. The quality of materials can vary significantly, impacting both performance and durability. Selecting high-quality materials may increase initial costs but can reduce long-term expenses associated with replacements and repairs.

Labor: Labor costs encompass the installation and maintenance of tire inflation systems. Depending on the complexity of the system, skilled technicians may be required, which can increase labor expenses. For international buyers, consider the local labor market’s wage rates, as they can differ significantly from one region to another.

Manufacturing Overhead: This includes costs related to the production process, such as utilities and facility expenses. Efficient manufacturing processes can lower overhead costs, which is beneficial for buyers seeking competitive pricing.

Tooling: Investment in specialized tooling for tire inflation systems can influence the overall cost. Custom tooling may be necessary for specific applications, which can drive up initial costs but may result in better efficiency and product quality.

Quality Control (QC): Implementing robust QC measures ensures that the tire inflation systems meet safety and performance standards. This might add to the overall costs, but it is crucial for maintaining reliability and reducing warranty claims.

Logistics: Transportation and storage costs can vary based on the supplier’s location and the final destination. Buyers should consider logistics costs when evaluating suppliers, especially for international shipments where tariffs and customs may apply.

Margin: Supplier margins will vary based on competition, market demand, and brand reputation. Understanding the margin structure can help buyers negotiate better terms.

Volume/MOQ: Pricing often decreases with higher order volumes. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to achieve better pricing.

Specifications/Customization: Custom specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses related to modifications.

Quality/Certifications: Products with certifications (e.g., ISO, CE) may command higher prices due to increased assurance of quality and compliance. Buyers should weigh the importance of certifications against the potential cost benefits.

Supplier Factors: The reliability and reputation of the supplier can significantly impact pricing. Established suppliers may charge more but offer better quality assurance and service, which can lead to lower total costs over time.

Incoterms: Understanding Incoterms is crucial for international transactions as they dictate shipping responsibilities and costs. Buyers should negotiate Incoterms that minimize their risk and costs.

Negotiate Terms: Effective negotiation can lead to improved pricing and terms. Buyers should leverage their purchasing power, especially if they have the potential for repeat business.

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, repairs, and replacements. A lower upfront cost may not always be the best choice if it leads to higher TCO.

Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, the Middle East, and Europe, it’s essential to consider currency fluctuations, import tariffs, and regional demand. Establishing long-term relationships with suppliers can help mitigate some of these risks.

Prices for tire inflation solutions can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

In the realm of tire maintenance, ensuring optimal inflation is crucial for vehicle safety, performance, and fuel efficiency. The 2022 Toyota Sienna XLE provides a built-in Tire Pressure Monitoring System (TPMS) that aids in monitoring tire inflation. However, various alternative methods and technologies exist that can also help in achieving accurate tire pressure management. This analysis delves into these alternatives, comparing them with the Sienna XLE’s approach.

| Comparison Aspect | Where Is The Tire Inflation In A 2022 Sienna XLE | Portable Tire Pressure Gauge | Tire Pressure Monitoring System (TPMS) App |

|---|---|---|---|

| Performance | Integrated TPMS provides real-time alerts for low pressure. | Manual checking; requires user intervention. | Offers real-time data via smartphone; may vary in accuracy. |

| Cost | Included with vehicle purchase. | $10 – $30 per unit. | Free or subscription-based, depending on app features. |

| Ease of Implementation | No installation needed; built into vehicle. | Simple to use; just check manually. | Requires setup and Bluetooth connection; user-friendly apps available. |

| Maintenance | Minimal; requires occasional sensor battery checks. | No maintenance; replace as needed. | Regular app updates; potential need for recalibration. |

| Best Use Case | Ideal for proactive monitoring while driving. | Best for manual checks in remote locations. | Excellent for tech-savvy users wanting detailed analytics. |

Portable tire pressure gauges are widely used for their simplicity and affordability. They offer a straightforward solution for checking tire pressure manually. Users can easily carry them in their vehicles, ensuring they can check tire pressure at any time, especially in remote locations where access to service stations is limited. However, this method requires users to remember to perform checks regularly, which may lead to oversight. Additionally, readings can be less consistent if not calibrated correctly.

TPMS apps provide a modern solution to tire inflation monitoring. These applications, when connected to compatible sensors installed in the tires, can relay real-time tire pressure data directly to a smartphone. The convenience of having tire pressure information at one’s fingertips enhances proactive maintenance. However, the effectiveness of these apps can vary based on the quality of the sensors and the app itself. Users may also face challenges with setup, including Bluetooth connectivity issues, which could hinder their experience.

Selecting the appropriate tire inflation monitoring method hinges on the specific needs and preferences of the B2B buyer. For those who prioritize convenience and seamless integration, the TPMS in the 2022 Sienna XLE offers an excellent solution, requiring minimal user intervention. Conversely, businesses operating in remote areas may find portable tire pressure gauges more practical, as they provide a reliable backup for manual checks. Tech-savvy buyers may appreciate the detailed analytics offered by TPMS apps, enabling them to maintain optimal tire conditions effectively. Ultimately, understanding each alternative’s pros and cons will empower buyers to make informed decisions that enhance their vehicle maintenance strategies.

When discussing tire inflation for the 2022 Toyota Sienna XLE, several technical properties and specifications are critical for understanding and maintaining optimal vehicle performance. Here are some essential properties:

Illustrative image related to where is the tire inflation in a 2022 sienna xle

Understanding industry jargon is essential for effective communication and decision-making. Here are some key terms:

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding tire inflation for the 2022 Sienna XLE, ultimately enhancing vehicle safety and operational efficiency.

The tire inflation sector for vehicles like the 2022 Toyota Sienna XLE is increasingly influenced by global trends such as rising fuel costs, regulatory changes regarding vehicle emissions, and advancements in tire technology. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are navigating these dynamics by seeking suppliers who can offer innovative solutions for tire maintenance and monitoring. The adoption of smart tire technologies, including tire pressure monitoring systems (TPMS) and inflation systems, is on the rise. These systems not only enhance safety but also improve fuel efficiency, which is a crucial factor for cost-conscious businesses.

Moreover, the focus on vehicle safety regulations is driving demand for accurate tire pressure monitoring, as underinflated tires can lead to accidents and increased wear and tear. This has led to an uptick in the sourcing of high-quality sensors and monitoring systems that can provide real-time data to drivers. Additionally, the growing trend of vehicle electrification is prompting manufacturers to rethink tire designs and inflation strategies, making it imperative for B2B buyers to stay informed about the latest technological advancements and market shifts.

Sustainability has become a central theme in the automotive industry, with tire inflation systems being no exception. The environmental impact of tire production and disposal is significant, prompting B2B buyers to prioritize suppliers who adhere to sustainable practices. This includes sourcing materials that have lower environmental footprints, such as recycled rubber and eco-friendly manufacturing processes.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who demonstrate commitment to ethical labor practices and transparency in their sourcing methods. Certifications like ISO 14001 for environmental management and other green certifications are becoming essential criteria for B2B partnerships. The demand for ‘green’ materials not only contributes to corporate social responsibility goals but also aligns with the growing consumer preference for environmentally friendly products, creating a competitive advantage for businesses that prioritize sustainability.

The evolution of tire inflation technology has been marked by significant advancements over the past few decades. Initially, tire inflation was a manual process reliant on basic gauges, but the introduction of TPMS has revolutionized how tire pressure is monitored and maintained. This technology provides real-time updates to drivers, ensuring that tire pressure is always optimal.

For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions. Suppliers who offer advanced tire inflation systems can provide a competitive edge, particularly as businesses seek to enhance fleet safety and efficiency. As tire technologies continue to evolve with innovations such as self-inflating tires and integrated monitoring systems, buyers must stay abreast of these trends to leverage new opportunities and mitigate risks associated with tire management.

In summary, the tire inflation sector for the 2022 Toyota Sienna XLE presents numerous opportunities for international B2B buyers. By focusing on market dynamics, sustainability, and the evolution of technology, businesses can make strategic sourcing decisions that align with their operational goals and consumer demands.

How do I check the tire inflation on a 2022 Sienna XLE?

To check the tire inflation on a 2022 Toyota Sienna XLE, open the driver’s side door to locate the tire pressure label. This label indicates the recommended tire pressure for both front and rear tires. It’s best to check the tire pressure in the morning or after driving less than a mile to get an accurate reading. Additionally, the Sienna is equipped with a Tire Pressure Monitoring System (TPMS) that alerts you if the tire pressure is low. Regularly checking and maintaining the correct tire pressure is crucial for vehicle safety and fuel efficiency.

What should I do if the tire pressure warning light is on?

If the tire pressure warning light illuminates on your dashboard, it indicates that one or more tires may be underinflated. First, check the tire pressures with a manual gauge to confirm the readings. Inflate any low tires to the recommended pressure as indicated on the tire label inside the driver’s side door. After inflating, drive the vehicle for a few miles to allow the TPMS to reset. If the light remains on, consult a professional to check for potential sensor issues or tire damage.

What are the potential risks of driving with underinflated tires?

Driving with underinflated tires poses several risks, including decreased fuel efficiency, increased tire wear, and compromised handling. Underinflated tires can lead to overheating and blowouts, especially during long journeys or high-speed driving. This not only endangers the safety of the vehicle occupants but can also result in costly repairs and downtime. Regular tire maintenance, including pressure checks, is essential for safe and efficient vehicle operation.

What is the best way to source replacement tires for a 2022 Sienna XLE?

When sourcing replacement tires for a 2022 Sienna XLE, it is essential to consider the tire specifications outlined in the owner’s manual or the tire pressure label. Look for reputable suppliers who offer OEM or high-quality aftermarket tires that meet the necessary standards. Ensure that the supplier can provide a warranty and has a solid reputation for customer service. Additionally, consider logistics and shipping costs, especially if importing tires to regions such as Africa or South America.

How can I verify the reliability of a tire supplier?

To verify the reliability of a tire supplier, conduct thorough research by checking customer reviews, ratings, and testimonials. Look for suppliers with a strong track record in the industry, especially those who specialize in the specific tire type you need. Ask for references or case studies from other B2B clients. Additionally, assess their certifications, quality assurance processes, and return policies to ensure they meet international standards and can accommodate your specific requirements.

What are typical payment terms for international tire suppliers?

Payment terms for international tire suppliers can vary widely based on the supplier’s policies, the order size, and the buyer’s creditworthiness. Common terms include upfront payment, a deposit with the balance due upon delivery, or net 30/60/90 days payment terms. It’s crucial to negotiate these terms before finalizing an order to ensure clarity and avoid any potential disputes. Additionally, consider using secure payment methods that offer buyer protection, especially for large transactions.

What should I consider regarding logistics when importing tires?

When importing tires, consider factors such as shipping costs, delivery times, and customs regulations in your destination country. Work with logistics providers experienced in handling automotive products to ensure compliance with local import laws. Additionally, factor in potential tariffs and taxes that may apply. It’s also advisable to schedule deliveries to align with your inventory management practices to avoid stock shortages or excess inventory.

How can I customize tire orders for specific market needs?

Customizing tire orders for specific market needs involves understanding the unique requirements of your target market, such as climate conditions, road types, and consumer preferences. Collaborate with suppliers who offer flexible manufacturing options, such as tread patterns and sizes tailored to local conditions. Communicate clearly about your specifications and ensure the supplier can meet your minimum order quantities (MOQ). Additionally, consider branding options if you plan to sell the tires under your own label in your market.

Domain: carcarekiosk.com

Registered: 2007 (18 years)

Introduction: Tire pressure for 2022 Toyota Sienna LE 2.5L 4 Cyl. is crucial for vehicle maintenance and fuel economy. The correct tire pressure is found on a sticker inside the driver side door, not on the tire sidewall. It’s recommended to check tire pressure in the morning or after driving less than a mile for accurate readings. The vehicle may have a Tire Pressure Monitoring System (TPMS) that alerts the dr…

In conclusion, understanding the tire inflation system of the 2022 Toyota Sienna XLE is crucial for optimizing performance and ensuring safety. Key takeaways include the importance of adhering to the manufacturer’s recommended tire pressure, which can be found on the driver’s side door jamb, rather than relying on the maximum pressure indicated on the tire sidewall. Regular checks using the onboard Tire Pressure Monitoring System (TPMS) provide real-time data, but physical gauges remain a reliable method for accuracy.

Illustrative image related to where is the tire inflation in a 2022 sienna xle

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic sourcing of automotive parts and services is essential. Engaging with reliable suppliers ensures access to quality components that enhance vehicle safety and efficiency. As the automotive market evolves, staying informed about best practices and technological advancements will position your business competitively.

Investing in effective tire management solutions not only enhances fleet performance but also aligns with sustainability goals by improving fuel efficiency. As you consider your sourcing strategies, prioritize partnerships that offer innovative solutions tailored to your operational needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to where is the tire inflation in a 2022 sienna xle