The global market for flat tire inflators presents a unique challenge for B2B buyers seeking reliable and efficient solutions. As vehicles become an essential part of daily operations, the ability to swiftly address tire-related issues can significantly impact productivity and safety. This guide serves as a comprehensive resource for international buyers, exploring various types of flat tire inflators, their applications, and key considerations for supplier vetting. Whether you are sourcing products for automotive retailers in South America, fleet operators in Africa, or service providers in Europe and the Middle East, understanding the landscape of flat tire inflators is crucial.

Throughout this guide, we delve into critical aspects such as cost structures, performance metrics, and emerging trends in tire inflator technology. By examining the diverse range of products available—from compact portable inflators to heavy-duty models designed for larger vehicles—we equip you with the knowledge necessary to make informed purchasing decisions. Additionally, we highlight the importance of selecting suppliers who adhere to quality standards and provide robust customer support, ensuring that your investment translates into long-term value.

Navigating this market effectively will not only enhance your operational capabilities but also position your business to meet the evolving needs of your clientele. Empower yourself with the insights contained within this guide and take confident steps towards optimizing your tire maintenance solutions.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

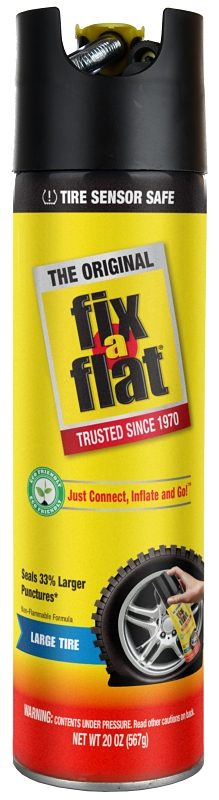

| Aerosol Tire Sealants | Quick application, seals punctures, compact size | Automotive repair shops, fleets | Pros: Fast, easy to use. Cons: Temporary fix, limited puncture size. |

| Cordless Electric Inflators | Battery-operated, portable, often includes built-in gauges | Roadside assistance, mobile service | Pros: Convenient, rechargeable. Cons: Limited battery life, slower inflation. |

| Plug Kits | Manual repair method, requires tools for installation | Tire shops, DIY enthusiasts | Pros: Permanent solution, cost-effective. Cons: Requires skill, time-consuming. |

| Heavy-Duty Air Compressors | High PSI capabilities, suitable for larger vehicles | Construction, transportation fleets | Pros: Fast inflation, durable. Cons: Bulky, requires a power source. |

| 12V Tire Inflators | Powered by vehicle’s battery, compact design | Automotive emergency kits | Pros: Versatile, easy to store. Cons: Limited power for larger tires. |

Aerosol tire sealants are designed for quick and easy application in emergency situations. They work by sealing small punctures and inflating the tire simultaneously, making them ideal for automotive repair shops and fleet management. B2B buyers should consider the size of the punctures they typically encounter, as these products are generally effective for holes up to 1/4 inch in diameter. However, they are not a permanent solution and should be followed by a professional repair.

Cordless electric inflators offer the convenience of portability and ease of use, making them suitable for roadside assistance and mobile service providers. They often come with built-in pressure gauges and can inflate multiple tires on a single charge, which is a key consideration for B2B buyers. While they provide a quick inflation solution, the battery life can be a limitation, particularly for larger vehicles or multiple tire inflations.

Plug kits are a more traditional method of tire repair that involves inserting a rubber plug into a puncture. They are ideal for tire shops and DIY enthusiasts who seek a permanent solution to flat tires. B2B buyers should note that while plug kits can be cost-effective, they require a certain level of skill and time to implement correctly. This method is best suited for businesses that can provide proper training and tools for their staff.

Heavy-duty air compressors are essential for businesses dealing with larger vehicles, such as construction or transportation fleets. They can inflate tires to high PSI levels quickly and are built for durability. When purchasing, B2B buyers should consider the compressor’s size and power requirements, as these units can be bulky and may need a dedicated power source. While they offer speed and efficiency, they may not be practical for smaller operations.

12V tire inflators are compact and powered by the vehicle’s battery, making them a popular choice for automotive emergency kits. They are easy to store and can be used in various situations, providing versatility for roadside repairs. B2B buyers should evaluate the inflator’s maximum PSI and overall performance, especially if they cater to larger vehicles. While they are convenient, their power limitations can affect their effectiveness on larger tires.

| Industry/Sector | Specific Application of Flat Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Emergency roadside assistance for fleet vehicles | Reduces downtime and operational costs during tire emergencies | Reliability, ease of use, and compatibility with various vehicle types |

| Automotive Repair | Tire repair services in workshops | Enhances service efficiency and customer satisfaction | Portability, repair effectiveness, and eco-friendliness |

| Construction | On-site tire maintenance for heavy machinery | Minimizes equipment downtime and boosts productivity | Durability, pressure capacity, and ease of operation |

| Agriculture | Tire inflation for agricultural machinery | Ensures optimal performance and reduces crop loss due to machinery failures | Robustness, compatibility with large tires, and quick inflation capabilities |

| Event Management | Quick tire inflation for mobile event setups | Facilitates smooth logistics and operational continuity | Compact design, multi-use capability, and ease of transport |

In the transportation and logistics sector, flat tire inflators are vital for emergency roadside assistance for fleet vehicles. When a tire goes flat, the inflator allows drivers to quickly seal punctures and reinflate the tire, minimizing downtime. This is particularly crucial for logistics companies operating in regions with limited access to repair services. Buyers in this sector should prioritize inflators that are reliable, easy to use, and compatible with various vehicle types, as efficiency directly impacts operational costs.

Illustrative image related to flat tire inflator

Automotive repair workshops utilize flat tire inflators to enhance their tire repair services. These inflators can quickly seal and inflate tires, allowing technicians to serve more customers efficiently. The ability to handle larger punctures and provide a temporary fix is essential for customer satisfaction. B2B buyers in this industry should look for portable models that are effective in repair and eco-friendly, ensuring compliance with environmental regulations.

On construction sites, flat tire inflators are crucial for maintaining heavy machinery. Equipment downtime due to flat tires can significantly hinder productivity and lead to increased costs. By equipping teams with reliable inflators, operators can quickly address tire issues and keep machinery running smoothly. Buyers should consider the durability of the inflator, its pressure capacity, and ease of operation, especially in rugged environments typical of construction sites.

Agricultural machinery often faces tire issues due to rough terrain. Flat tire inflators are used to maintain optimal tire pressure, ensuring that tractors and harvesters operate effectively. Quick inflation capabilities can prevent losses during critical farming periods. Buyers in agriculture should seek robust inflators that can handle the larger tires common in this sector, ensuring that they can quickly respond to tire emergencies.

For event management companies, flat tire inflators are essential for ensuring that mobile setups, such as food trucks or portable stages, operate without interruption. Quick inflation allows for seamless logistics, especially when moving equipment between locations. Compact and multi-use inflators are ideal for this sector, as they can be easily transported and utilized in various scenarios, enhancing operational continuity.

The Problem: B2B buyers often struggle with sourcing flat tire inflators that are reliable and suitable for varying vehicle types across diverse markets, especially in regions like Africa and South America where vehicle models can differ significantly. Discrepancies in quality, performance, and compatibility with local vehicles can lead to unsatisfied customers and potential losses. Buyers may also face challenges in understanding the regulatory standards for products in different regions, further complicating their procurement processes.

Illustrative image related to flat tire inflator

The Solution: To effectively source reliable flat tire inflators, B2B buyers should engage with manufacturers that offer a comprehensive range of products specifically designed for different vehicle types and market conditions. Conduct thorough research on suppliers and prioritize those that have experience in international markets. Request samples to assess performance and compatibility before making bulk purchases. Additionally, consider manufacturers who provide detailed product specifications and user manuals in multiple languages, ensuring ease of understanding for local consumers. Establishing direct communication with suppliers can help clarify regulatory compliance and quality assurance processes, leading to more informed purchasing decisions.

The Problem: A common pain point for B2B buyers is the lack of adequate training and user guidance for flat tire inflators, which can lead to improper use and customer dissatisfaction. This is particularly critical in markets with less technical expertise or where end-users may not be familiar with inflator technology. Misuse can result in inflated tires, equipment damage, or even safety hazards, ultimately harming the reputation of the business.

The Solution: To mitigate this issue, B2B buyers should prioritize partnerships with suppliers who offer comprehensive training programs and user-friendly resources. Suppliers should provide not only detailed written instructions but also video tutorials that demonstrate the correct usage of flat tire inflators. Organizing training sessions for staff and end-users can enhance product understanding and ensure safe operation. Additionally, consider creating multilingual support materials to cater to diverse customer bases. This proactive approach will empower users, reduce the likelihood of misuse, and bolster customer confidence in the product.

The Problem: After-sales support is often a significant concern for B2B buyers of flat tire inflators. Many companies face challenges when products malfunction or do not meet performance expectations, and they find themselves without adequate support or warranty coverage. This lack of assistance can lead to prolonged downtimes, increased operational costs, and ultimately, loss of customer trust.

Illustrative image related to flat tire inflator

The Solution: B2B buyers should thoroughly evaluate the after-sales support policies of potential suppliers before making a purchase. Look for manufacturers that offer comprehensive warranty packages and responsive customer service. Establish clear channels of communication for troubleshooting and support, ensuring that buyers can quickly resolve issues. It’s also advisable to inquire about the availability of spare parts and repair services. Building relationships with suppliers who are committed to customer satisfaction will lead to a more reliable partnership and can enhance the overall experience for end-users. Additionally, consider implementing a feedback loop where users can report issues or suggest improvements, which can help suppliers enhance their products and support services over time.

When selecting materials for flat tire inflators, it is essential to consider properties that affect performance, durability, and user safety. The following analysis covers four common materials: plastic, aluminum, rubber, and steel. Each material has unique characteristics that can influence the overall effectiveness and marketability of the product.

Plastic is widely used in the outer casing and components of flat tire inflators due to its lightweight nature and resistance to corrosion. Common types include polypropylene and polycarbonate, which can withstand moderate temperature ranges and pressures.

Pros: Plastic is generally low-cost, easy to mold, and offers good insulation properties, making it suitable for various designs. It is also resistant to corrosion, which is critical for products exposed to environmental factors.

Cons: While plastic is durable, it may not withstand extreme temperatures or high pressures as effectively as metals. Additionally, certain plastics can become brittle over time, particularly when exposed to UV light.

Impact on Application: Plastic components are compatible with air and some sealant chemicals, but care must be taken to ensure they do not degrade when in contact with specific materials.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with international standards such as ASTM and REACH regulations, particularly in regions like Europe where environmental regulations are stringent.

Aluminum is often used for the internal components of inflators due to its excellent strength-to-weight ratio and resistance to corrosion. It can handle higher pressures, making it ideal for inflators designed for heavy-duty applications.

Pros: Aluminum is lightweight, durable, and offers good thermal conductivity. It can be easily machined and formed into complex shapes, allowing for innovative designs.

Cons: The primary drawback is cost; aluminum is generally more expensive than plastic. Additionally, while it is resistant to corrosion, it can still oxidize if not properly treated.

Impact on Application: Aluminum is suitable for high-pressure applications and can handle a wide range of temperatures, making it versatile for different tire types.

Considerations for International Buyers: Buyers should consider the availability of aluminum in their region and ensure compliance with relevant standards, such as DIN or JIS, which may dictate specific alloy compositions.

Rubber is primarily used in the seals and hoses of tire inflators due to its flexibility and resilience. It can withstand a variety of pressures and temperatures, making it suitable for sealing applications.

Pros: Rubber provides excellent sealing capabilities and is resistant to wear and tear. It can also absorb vibrations, which enhances user comfort during operation.

Cons: Rubber can degrade over time when exposed to ozone and UV light, which may limit its lifespan. Additionally, it can be more challenging to manufacture than plastic.

Impact on Application: The compatibility of rubber with various gases and sealants is crucial, as it must not react adversely with the materials it seals.

Considerations for International Buyers: Buyers should ensure that the rubber used meets international safety and environmental standards, particularly in markets like Africa and South America, where local regulations may vary.

Steel is often used for structural components and high-pressure fittings due to its strength and durability. Stainless steel is particularly favored for its corrosion resistance.

Illustrative image related to flat tire inflator

Pros: Steel offers exceptional strength and durability, making it suitable for high-stress applications. It is also resistant to deformation under pressure.

Cons: The main disadvantage is weight; steel inflators can be heavier than those made from other materials. Additionally, steel is more expensive and may require more complex manufacturing processes.

Impact on Application: Steel components can handle high pressures and are suitable for heavy-duty inflators, but they may not be ideal for portable models due to weight considerations.

Considerations for International Buyers: International buyers should be aware of the varying standards for steel quality, such as ASTM A36 or A992, and ensure compliance with local regulations regarding metal products.

| Material | Typical Use Case for Flat Tire Inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Outer casing and components | Lightweight and corrosion-resistant | May become brittle over time | Low |

| Aluminum | Internal components for high-pressure applications | Strong, durable, and lightweight | Higher cost and potential oxidation | Medium |

| Rubber | Seals and hoses | Excellent sealing and vibration absorption | Degrades with UV exposure | Medium |

| Steel | Structural components and high-pressure fittings | Exceptional strength and durability | Heavier and more expensive | High |

This analysis provides actionable insights into material selection for flat tire inflators, helping international B2B buyers make informed decisions that align with their market needs and regulatory requirements.

The manufacturing process of flat tire inflators typically comprises four main stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets the performance and safety standards required by the market.

The first stage involves sourcing and preparing the materials needed for production. Common materials include:

Manufacturers must ensure that all materials meet international safety and quality standards. This often includes certifications from recognized bodies to confirm the materials are free from hazardous substances.

In the forming stage, various techniques are employed to shape the materials into usable components.

After forming, components are often subjected to a deburring process to remove sharp edges and ensure safety during handling and assembly.

The assembly stage is where individual components come together to form the final product.

Each inflator is typically assembled with a focus on ease of use, ensuring that the end-user can operate the device without complications.

Illustrative image related to flat tire inflator

Finishing processes are crucial for the aesthetic appeal and functionality of flat tire inflators.

This stage may also include packaging, where products are carefully packed to prevent damage during shipping.

Quality assurance (QA) in the manufacturing of flat tire inflators is critical, particularly for B2B buyers who require reliable products. Several international standards apply:

To maintain high-quality standards, manufacturers implement various quality control checkpoints throughout the production process:

Illustrative image related to flat tire inflator

Testing methods for flat tire inflators include:

B2B buyers looking to ensure quality from suppliers can employ several strategies:

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it is crucial to understand the local regulations and certifications required for importing tire inflators.

By understanding the manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing flat tire inflators, ensuring they receive products that meet their operational needs and regulatory requirements.

In today’s fast-paced business environment, having reliable tools for vehicle maintenance is essential. This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure flat tire inflators. Whether for a fleet of vehicles or retail purposes, this guide will help you make informed decisions to ensure you select the right product that meets your needs.

Establishing clear technical specifications is the first step in the procurement process. Determine the types of vehicles that will use the inflators and the typical tire sizes you will encounter. Consider specifications such as maximum psi, power sources (cordless or corded), and additional features like built-in pressure gauges or lights.

Conduct thorough research to identify potential suppliers. Look for manufacturers with a strong reputation in the market and a history of delivering quality products. Compare various suppliers based on product range, pricing, and customer service.

Different inflators come with varying features that can enhance usability. Evaluate the inflators based on their ease of use, speed of inflation, and additional functionalities such as digital displays or built-in battery packs.

Ensure that the inflators comply with relevant safety and environmental regulations in your target market. Certifications can indicate quality standards and safety measures taken by the manufacturer.

Before making a bulk purchase, request samples of the inflators to test their performance. This hands-on evaluation will help you assess the ease of use and reliability of the products.

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and terms that align with your budget and operational needs.

Assess the after-sales support offered by the supplier, including warranty terms and customer service availability. Reliable support is essential for addressing potential issues post-purchase.

By following this checklist, B2B buyers can confidently source flat tire inflators that meet their operational requirements and enhance vehicle maintenance efficiency.

When sourcing flat tire inflators, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly affects the overall cost. High-quality plastics, metals for the body, and eco-friendly sealing agents can drive up expenses but enhance durability and performance.

Labor: Labor costs vary by region. In countries with lower labor costs, such as some in South America and Africa, manufacturers can offer competitive pricing. However, skilled labor for quality control and assembly might be higher.

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Overhead costs can fluctuate based on location and operational efficiency.

Tooling: Initial tooling costs for molds and specialized equipment can be substantial, particularly for custom designs. These costs are often amortized over larger production runs.

Quality Control (QC): Investing in rigorous QC processes ensures product reliability. While this can add to upfront costs, it reduces long-term warranty claims and enhances brand reputation.

Logistics: Shipping costs vary based on distance, mode of transportation, and Incoterms. Import tariffs and duties can also influence final pricing, especially for international buyers.

Margin: Suppliers typically add a profit margin that reflects their business strategy and market positioning. This margin can be negotiable depending on order volume.

Several factors influence the pricing of flat tire inflators in the B2B market:

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Higher quantities can lead to significant discounts, making it crucial for buyers to assess their needs accurately.

Specifications and Customization: Custom designs or specific features (like digital gauges or eco-friendly materials) can increase costs. Buyers should weigh the benefits of customization against budget constraints.

Materials Quality and Certifications: Products made from premium materials or those that meet specific certifications (like ISO or CE) may command higher prices but often justify the cost through enhanced performance and safety.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality and service may charge more but offer better peace of mind.

Incoterms: Understanding Incoterms is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, directly affecting the total landed cost.

To maximize cost-efficiency when sourcing flat tire inflators, consider the following strategies:

Negotiation: Engage in open discussions with suppliers about pricing. Highlight your potential for repeat business or bulk orders to negotiate better terms.

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, warranty support, and potential downtime. A slightly higher upfront cost may lead to lower overall expenses.

Pricing Nuances for International Buyers: Understand currency fluctuations, import regulations, and local market conditions that may affect pricing. Establishing a strong relationship with suppliers can also facilitate smoother transactions.

Research and Benchmarking: Conduct thorough market research to compare prices and specifications across different suppliers. Benchmarking against similar products can help identify fair pricing.

Evaluate Supply Chain Logistics: Optimize logistics by considering local suppliers or those with established distribution networks. This can reduce shipping times and costs.

By understanding these components, influencers, and strategies, B2B buyers can make informed decisions, ensuring they source flat tire inflators that meet their needs while optimizing costs. Always remember that prices can vary widely based on numerous factors, and it’s advisable to seek multiple quotes before making a final decision.

Illustrative image related to flat tire inflator

When faced with a flat tire, immediate and effective solutions are essential for minimizing downtime, especially in commercial settings. While flat tire inflators offer a reliable means to address this issue, various alternatives exist that can also serve the purpose of inflating tires. This section explores these alternatives, comparing their performance, costs, ease of implementation, maintenance, and best use cases to help B2B buyers make informed decisions.

| Comparison Aspect | Flat Tire Inflator | Portable Air Compressor | Tire Sealant Spray |

|---|---|---|---|

| Performance | Quickly inflates and seals small punctures | Can inflate tires to higher pressures and volume | Seals small punctures but limited inflation |

| Cost | $15 – $20 per can | $40 – $100 depending on size and features | $10 – $20 per can |

| Ease of Implementation | Simple: connect, inflate, and go | Requires setup and power source | Easy: spray into valve, wait for sealing |

| Maintenance | Minimal, single-use | Requires regular maintenance | Minimal, single-use |

| Best Use Case | Emergency roadside assistance | Routine maintenance for multiple vehicles | Temporary fix until proper repair |

Portable air compressors are versatile tools that can quickly inflate tires to higher pressures, making them suitable for a variety of vehicles, including trucks and SUVs. They typically come with multiple power options, such as battery and car charger capabilities. While they are slightly more expensive than flat tire inflators, their durability and ability to handle larger tires make them a valuable investment for businesses with diverse fleet requirements. However, they require more setup time and maintenance, which can be a drawback in emergency situations.

Tire sealant sprays provide a quick solution for sealing small punctures without the need for inflation. These products are typically less expensive and easy to use; users simply spray the sealant into the tire valve. However, they offer limited inflation capability and are often seen as a temporary fix. Their effectiveness can vary based on the size and location of the puncture, and they may not work in all situations. Businesses that prioritize immediate, albeit temporary, solutions may find this option appealing, but it is crucial to follow up with a proper tire repair.

When selecting the best tire inflation solution, B2B buyers should consider their specific needs, including the type of vehicles in their fleet, the typical conditions they encounter, and their budget constraints. Flat tire inflators are excellent for quick, emergency fixes, while portable air compressors offer greater versatility for routine maintenance. Tire sealant sprays can serve as a cost-effective temporary measure but should be followed by a proper tire repair. By assessing the trade-offs of each option, businesses can choose the solution that best aligns with their operational requirements and enhances their efficiency on the road.

When evaluating flat tire inflators for B2B procurement, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest inflation capacity of the tire inflator. Most flat tire inflators can range from 80 to 160 PSI. This specification is vital for B2B buyers as it determines the tool’s capability to service various vehicle types, from compact cars to heavy-duty trucks. Ensuring the inflator meets the pressure requirements of your fleet can enhance operational efficiency.

The duty cycle refers to the amount of time the inflator can operate continuously before requiring a cooldown period. For instance, a duty cycle of 25 minutes on and 30 minutes off is common. This property is essential for businesses that need to inflate multiple tires in quick succession. A longer duty cycle can reduce downtime and improve productivity in high-demand scenarios.

Flat tire inflators can be powered by various sources, including rechargeable batteries, 12-volt vehicle outlets, or AC power. Knowing the power source is critical for B2B buyers to ensure compatibility with their operations. For mobile service providers, battery-operated models offer portability, while those that plug into vehicles are ideal for roadside assistance.

Illustrative image related to flat tire inflator

Inflation time indicates how quickly an inflator can restore a tire to its proper pressure. For example, a model might take 5 minutes to inflate a tire from flat to 35 PSI. Faster inflation times are advantageous for businesses aiming to minimize service times and enhance customer satisfaction.

Modern inflators often come equipped with additional features such as digital pressure gauges, LED lights, and multi-nozzle adapters. These added functionalities can provide significant value in diverse situations, making the inflator more versatile for various applications. B2B buyers should assess which features align with their specific needs.

Understanding industry jargon can greatly assist B2B buyers in navigating procurement processes effectively. Here are several key terms:

Illustrative image related to flat tire inflator

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, knowing whether a product is OEM can assure buyers of quality and compatibility with existing systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure they meet supplier requirements without overstocking.

An RFQ is a document that a buyer sends to suppliers to request price quotes for specific products. This process helps buyers compare costs and negotiate better terms, making it a critical step in the procurement cycle for flat tire inflators.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with Incoterms is crucial for B2B buyers, especially when importing tire inflators from overseas, as they clarify shipping, insurance, and delivery obligations.

This term refers to the guarantee provided by the manufacturer regarding the product’s performance and the conditions under which repairs or replacements will be made. Understanding warranty terms is vital for B2B buyers to protect their investment and ensure service continuity.

Illustrative image related to flat tire inflator

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing flat tire inflators, ensuring they meet operational needs and expectations.

The flat tire inflator market is experiencing significant growth driven by several global factors. Increasing vehicle ownership rates across emerging economies in Africa, South America, and parts of Europe have heightened the demand for convenient tire maintenance solutions. As urbanization continues, the necessity for rapid roadside assistance tools, such as flat tire inflators, has become paramount. Additionally, the rise of e-commerce platforms has facilitated easier access for B2B buyers to procure these products from international suppliers.

Emerging technologies are also reshaping the flat tire inflator landscape. Innovations such as cordless models with rechargeable batteries and built-in smart pressure gauges are becoming increasingly popular. These features cater to the needs of modern consumers who prioritize convenience and efficiency. Furthermore, the integration of IoT technology is paving the way for smart inflators that can monitor tire pressure in real-time and alert users via mobile applications, creating new avenues for product development and marketing strategies.

For international B2B buyers, understanding regional preferences is crucial. For instance, buyers from the Middle East may prioritize heavy-duty inflators capable of managing larger vehicle tires, while buyers in Europe might focus on compact, portable solutions. Establishing strong relationships with manufacturers that can adapt to these diverse market needs will be vital for success in this sector.

Sustainability and ethical sourcing are becoming increasingly important in the flat tire inflator industry. As environmental concerns grow, B2B buyers are more inclined to seek out products that are not only effective but also eco-friendly. Manufacturers are responding by developing inflators using sustainable materials and eco-friendly propellants, which minimize environmental impact. This trend aligns with global initiatives aimed at reducing carbon footprints and promoting responsible consumption.

Additionally, certifications such as Green Seal or EcoLabel are gaining traction among suppliers. These certifications help buyers identify products that adhere to strict environmental standards, fostering transparency in the supply chain. By prioritizing suppliers with green certifications, businesses can enhance their brand reputation and appeal to a growing demographic of eco-conscious consumers.

Ethical sourcing practices are also crucial. Ensuring that products are manufactured under fair labor conditions and that materials are sourced responsibly can help mitigate risks associated with unethical practices. B2B buyers should conduct thorough due diligence on their supply chains to ensure compliance with international labor standards and environmental regulations.

The flat tire inflator market has evolved significantly over the decades. Initially, the focus was primarily on manual pumps and basic aerosol inflators, which required significant physical effort and technical knowledge. The introduction of portable electric inflators revolutionized the market, providing a more user-friendly solution for everyday consumers.

In recent years, advancements in battery technology and materials science have led to the development of highly efficient, compact inflators with enhanced performance capabilities. The rise of digital pressure gauges and automatic shut-off features has further improved the user experience, making tire maintenance accessible to a broader audience. This evolution reflects the changing demands of consumers and the continuous innovation within the automotive accessory market. As the industry progresses, B2B buyers should remain vigilant for emerging technologies that promise to redefine the flat tire inflator landscape once again.

How do I choose the right flat tire inflator for my business needs?

When selecting a flat tire inflator, consider factors such as the types of vehicles you service, the average tire sizes, and the inflator’s maximum pressure capacity. For businesses dealing with larger vehicles like trucks and SUVs, opt for inflators that can handle higher PSI levels and larger tire volumes. Additionally, assess the inflator’s portability, power source options (cordless vs. corded), and user-friendliness. Reviews and performance tests can provide valuable insights into the reliability and efficiency of various models.

What is the best flat tire inflator for international shipping?

The best flat tire inflator for international shipping should be compact, lightweight, and durable. Models like the AstroAI Cordless Tire Inflator are excellent due to their robust construction and versatility, which makes them suitable for various tire types. Ensure that the inflator meets international safety and environmental regulations, as well as the electrical standards of the destination country. Additionally, consider the availability of spare parts and support services in the regions you plan to operate.

What are the common payment terms for purchasing flat tire inflators from international suppliers?

Payment terms can vary widely among suppliers, but common practices include payment in advance, 30-60 days after shipment, or a letter of credit. For larger orders, negotiating favorable terms such as partial upfront payment and the balance upon delivery can be beneficial. Always ensure that payment methods are secure and consider using escrow services for high-value transactions. Understanding the supplier’s payment policies and any associated fees is crucial to avoid surprises.

What should I look for in a supplier of flat tire inflators?

When vetting suppliers, prioritize those with a proven track record in the industry and positive customer reviews. Evaluate their production capabilities, quality assurance processes, and certifications (e.g., ISO, CE). Request samples to assess product quality firsthand and inquire about their ability to meet your specific customization needs. Additionally, consider their responsiveness and willingness to provide after-sales support, which is essential for long-term business relationships.

What are the minimum order quantities (MOQs) for flat tire inflators?

Minimum order quantities can vary based on the supplier and the specific product line. Some manufacturers may have MOQs as low as 100 units, while others may require 500 or more. When negotiating with suppliers, inquire about the possibility of lower MOQs for first-time orders or trial runs. Understanding the MOQ is vital for budgeting and inventory planning, especially for businesses entering new markets.

How can I ensure quality assurance when sourcing flat tire inflators?

To guarantee quality, request detailed specifications and certifications from suppliers. Conduct factory audits, if feasible, to inspect production processes and materials used. Implementing a quality control plan that includes pre-shipment inspections can help identify potential defects before products are shipped. Establish clear return and warranty policies with suppliers to safeguard against defective items and maintain customer satisfaction.

What logistics considerations should I keep in mind when importing flat tire inflators?

Key logistics considerations include shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more cost-effective for your needs, and factor in transit times when planning inventory. Ensure compliance with import duties and taxes in your country, and work with a reliable freight forwarder to navigate customs processes efficiently. Having a clear logistics strategy will minimize delays and additional costs.

Are there customization options available for flat tire inflators?

Many suppliers offer customization options, such as branding, color variations, and specific features tailored to your business needs. Discuss your requirements with potential suppliers to explore available options and associated costs. Customization can enhance your brand’s visibility and cater to specific market demands, making it a valuable aspect of your procurement strategy. Always verify the supplier’s ability to meet your customization requests within your desired timeline.

Domain: fixaflat.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Fix-a-Flat 16 oz.”, “suitable_for”: “Standard Tires (Sedan | Coupe)”, “price”: “$15.49”, “description”: “Fix-a-Flat aerosol tire inflators are the easiest and quickest way to repair a flat tire in an emergency. Designed to seal small tire punctures in seconds and provide enough inflation to lift the rim off the ground.”, “puncture_sealing_capacity”: “Seals tread area punctures up…

In the rapidly evolving landscape of tire maintenance solutions, strategic sourcing of flat tire inflators emerges as a critical factor for international B2B buyers. By understanding the diverse range of products available—from aerosol inflators like Fix-A-Flat to advanced portable inflators such as the AstroAI and Viair models—businesses can cater to varying customer needs and preferences across regions, including Africa, South America, the Middle East, and Europe.

Illustrative image related to flat tire inflator

Key takeaways emphasize the importance of product reliability, speed of inflation, and eco-friendly features. Buyers should prioritize partnerships with suppliers who offer innovative, high-quality inflators that meet stringent safety and environmental standards. Additionally, understanding regional demands and specifications can enhance inventory management and customer satisfaction.

As the market for tire inflators continues to grow, now is the time for B2B buyers to leverage strategic sourcing to optimize their supply chains. By investing in superior inflator solutions, businesses can not only improve operational efficiency but also position themselves as leaders in customer service and sustainability. Embrace this opportunity to enhance your product offerings and drive growth in the tire maintenance sector.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to flat tire inflator

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.