In the ever-evolving landscape of cycling accessories, sourcing the right air compressor for bike prices presents a significant challenge for B2B buyers across diverse markets. With a multitude of options available—from compact electric pumps to robust dual-function compressors—understanding the nuances of pricing, quality, and functionality is critical. This guide aims to illuminate the complexities of the global market for bike air compressors, providing insights into various types, their applications, and the essential factors to consider when vetting suppliers.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate this competitive landscape, they face unique challenges, including fluctuating prices and varying product availability. This comprehensive resource empowers decision-makers by detailing the range of products, offering strategies for effective supplier evaluation, and presenting a thorough analysis of cost considerations. By synthesizing data from reputable sources, this guide equips buyers with the knowledge needed to make informed purchasing decisions that align with their business needs and market demands.

Ultimately, understanding the dynamics of air compressor pricing for bikes is not just about cost; it’s about ensuring reliability and quality in every purchase. This guide will serve as your essential tool for successfully navigating the global market, enabling you to optimize your procurement strategy and enhance your product offerings.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Air Compressors | Compact, battery-operated, suitable for on-the-go inflation | Retailers, cycling events, mobile repair shops | Pros: Easy to transport, quick inflation; Cons: Limited power and battery life. |

| High-Pressure Compressors | Designed for tubeless tires, capable of high PSI outputs | Professional bike shops, racing teams | Pros: Fast inflation, durable; Cons: Higher cost, requires more maintenance. |

| Mini Hand Pumps | Manual operation, lightweight, and cost-effective | Small retailers, individual cyclists | Pros: Low price, portable; Cons: Labor-intensive, slower inflation time. |

| Digital Tire Inflators | Equipped with pressure gauges and automatic shut-off | Workshops, cycling clubs | Pros: Accurate pressure settings, user-friendly; Cons: Requires power source, potential for electronic failure. |

| Multi-Function Compressors | Versatile, can inflate various items (balls, mattresses) | Sports retailers, outdoor equipment suppliers | Pros: Multi-use, saves space; Cons: May lack specialized features for bikes. |

Portable electric air compressors are designed for convenience and mobility. They are typically compact and battery-operated, making them ideal for cyclists who need to inflate tires on the go. These compressors are suitable for small-scale B2B applications, such as retail environments and mobile repair services. When considering a purchase, B2B buyers should evaluate the battery life and inflation speed to ensure they meet customer demands.

High-pressure compressors are engineered for serious cycling applications, particularly for tubeless tires that require higher PSI levels. These units are commonly used in professional bike shops and by racing teams due to their rapid inflation capabilities and durability. B2B buyers should consider the total cost of ownership, including maintenance and potential repairs, as these units tend to be more expensive but offer superior performance.

Mini hand pumps are manual devices that are lightweight and affordable, making them an attractive option for individual cyclists and small retailers. While they require physical effort to operate, their low cost and portability are significant advantages. B2B buyers should weigh the trade-off between labor intensity and price, especially when targeting budget-conscious consumers.

Digital tire inflators come with built-in pressure gauges and often feature automatic shut-off capabilities, enhancing user convenience and safety. These compressors are ideal for workshops and cycling clubs, where accurate pressure settings are critical. B2B buyers should ensure these devices are compatible with their power sources and consider the reliability of electronic components.

Multi-function compressors can inflate a range of items, including sports balls and air mattresses, making them versatile for retailers dealing in various outdoor products. Their ability to serve multiple functions can save space and reduce inventory costs. However, B2B buyers should assess whether these compressors compromise on bike-specific features, as they may not deliver optimal performance for cycling needs.

| Industry/Sector | Specific Application of air compressor for bike prices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Quality control in tire inflation during assembly | Ensures optimal tire pressure for safety and performance | Durable compressors with precise PSI settings and maintenance support |

| Bike Rental Services | Rapid tire inflation for fleet maintenance | Reduces downtime, improving customer satisfaction and service speed | Portable compressors with quick inflation capabilities |

| Sports Equipment Retail | Providing inflation services for customers purchasing bikes | Enhances customer experience and increases sales opportunities | Compact, user-friendly models that can be offered as add-ons |

| Cycling Events & Competitions | On-site tire maintenance for participants | Ensures optimal performance and safety for cyclists | Lightweight, portable compressors with fast inflation times |

| Logistics and Delivery Services | Maintaining bike fleets for last-mile delivery | Increases fleet reliability and efficiency | Robust compressors capable of handling multiple tire types |

In the bicycle manufacturing industry, air compressors are essential for quality control, particularly in tire inflation during the assembly process. Proper tire pressure is critical for safety, performance, and compliance with industry standards. Manufacturers need compressors that can deliver precise PSI settings to ensure each bike is fully operational before reaching the market. For international buyers, it’s vital to consider the durability and maintenance support of the compressors to minimize operational disruptions.

Bike rental services rely heavily on quick maintenance turnaround to keep their fleets in optimal condition. Air compressors are used for rapid tire inflation, allowing rental companies to quickly address flat tires and maintain service availability. This reduces downtime, directly impacting customer satisfaction and service speed. When sourcing compressors, rental businesses should prioritize models that are portable and efficient, ensuring they can handle multiple bikes with varying tire pressures.

In sports equipment retail, particularly for bicycles, air compressors can provide added value by allowing customers to inflate tires immediately upon purchase. This service enhances the shopping experience and can lead to increased sales, as customers appreciate the convenience. Retailers should look for compact, user-friendly models that can be easily integrated into their store layout. Providing inflation services can differentiate retailers in a competitive market.

Illustrative image related to air compressor for bike prices

During cycling events and competitions, air compressors play a crucial role in on-site tire maintenance. Participants often require quick inflation to ensure their bikes are performance-ready. Compressors used in this context need to be lightweight and portable, with fast inflation times to accommodate the high-paced nature of events. Event organizers should consider models that are reliable and easy to transport, ensuring that they can meet the demands of a large number of cyclists efficiently.

For logistics and delivery services that utilize bikes for last-mile delivery, maintaining a reliable fleet is paramount. Air compressors are used to ensure that tires are always inflated to the correct pressure, which enhances the reliability and efficiency of the delivery process. When sourcing compressors for this application, businesses should focus on robust models capable of handling various tire types, ensuring that all bikes in the fleet remain operational and ready for use.

The Problem: B2B buyers often face significant challenges when it comes to price variability for air compressors intended for bike maintenance across different regions. For instance, a distributor in Nigeria might encounter inflated prices due to import tariffs and logistical costs, while a buyer in Brazil may benefit from local manufacturing but struggle with inconsistent supply. This disparity not only complicates budgeting but can also lead to lost sales if a company cannot offer competitive pricing.

The Solution: To effectively navigate these challenges, buyers should engage in comprehensive market research to understand the local supply chain dynamics. Establishing relationships with multiple suppliers can help in negotiating better rates and identifying the most cost-effective options. Additionally, leveraging technology such as price comparison tools can provide insights into pricing trends across regions. It’s also beneficial to explore bulk purchasing agreements, which can lower the per-unit cost and provide a buffer against price fluctuations.

Illustrative image related to air compressor for bike prices

The Problem: Another common issue is the difficulty in balancing quality and price when sourcing air compressors for bikes. B2B buyers may be tempted to opt for cheaper options, only to find that the compressors do not meet performance standards, leading to customer dissatisfaction and increased warranty claims. This situation can be particularly acute in markets where low-cost imports flood the market, making it hard to discern quality.

The Solution: To ensure that quality is not compromised for price, buyers should develop a rigorous vetting process for suppliers. This includes requesting samples, checking certifications, and gathering user reviews. Establishing a robust quality assurance protocol can also help; for instance, implementing a pilot program to test products in real-world scenarios before committing to larger orders. Furthermore, collaborating with trusted brands known for their durability and performance can provide a competitive edge, ensuring that the compressors meet the needs of end-users while maintaining price competitiveness.

The Problem: B2B buyers often overlook the total cost of ownership (TCO) associated with air compressors for bikes. While the initial purchase price may seem attractive, factors such as energy consumption, maintenance requirements, and the longevity of the product can lead to higher costs over time. This oversight can impact profitability and operational efficiency, particularly for businesses that rely on these compressors for daily operations.

Illustrative image related to air compressor for bike prices

The Solution: Buyers should adopt a holistic approach to evaluating air compressor options by calculating the total cost of ownership. This involves assessing not only the upfront costs but also estimating energy costs, maintenance expenses, and potential downtime due to equipment failure. Utilizing tools such as life cycle cost analysis can help buyers make informed decisions. Additionally, investing in compressors that come with warranties and service agreements can mitigate long-term costs, ensuring that the equipment remains operational and efficient throughout its lifespan. By prioritizing TCO in their purchasing decisions, businesses can achieve significant savings and maintain a higher level of service for their customers.

When selecting materials for air compressors designed for bike tire inflation, it is essential to consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the construction of air compressors, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Aluminum is a popular choice for air compressor components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C (302°F) and can withstand moderate pressure levels, making it suitable for portable applications. Furthermore, aluminum exhibits good corrosion resistance, especially when anodized, which enhances its durability in various environments.

Pros and Cons of Aluminum

The primary advantage of aluminum is its lightweight, which facilitates mobility for bike users. It also offers good strength-to-weight ratio and is relatively easy to manufacture. However, aluminum can be more expensive than some alternatives, and its lower tensile strength compared to steel can be a limitation in high-stress applications.

Illustrative image related to air compressor for bike prices

Steel, particularly stainless steel, is another common material for air compressor components. It boasts high tensile strength and can withstand high pressures and temperatures, making it ideal for robust applications. Steel components can typically handle pressures exceeding 200 PSI and temperatures up to 300°C (572°F). Additionally, stainless steel provides excellent corrosion resistance, especially in humid or wet environments.

Pros and Cons of Steel

The key advantage of steel is its durability and ability to withstand harsh conditions, making it suitable for long-term use. However, steel is heavier than aluminum, which may detract from portability. Furthermore, the manufacturing process for steel can be more complex and costly, impacting the overall price of the compressor.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in air compressor housings and components. These materials are lightweight and can be molded into complex shapes, making them suitable for compact designs. Plastics typically have lower temperature ratings (up to 80°C or 176°F) and pressure ratings, which limits their use in high-performance applications.

Illustrative image related to air compressor for bike prices

Pros and Cons of Plastic

The main advantage of plastic is its low cost and versatility in design. It is also resistant to corrosion and can be produced in various colors. However, plastics may not provide the same level of durability and strength as metals, which could lead to shorter lifespans in demanding applications.

Composite materials, such as fiberglass-reinforced plastics, combine the lightweight properties of plastics with the strength of fibers. These materials can withstand moderate pressures and temperatures, making them suitable for specific applications in air compressors. Composites can be engineered for enhanced performance, offering a balance of strength and weight.

Pros and Cons of Composite Materials

The primary advantage of composites is their ability to be tailored for specific performance characteristics, such as increased strength or improved thermal resistance. However, they can be more expensive to produce and may require specialized manufacturing techniques, which can complicate the supply chain.

| Material | Typical Use Case for air compressor for bike prices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable air compressors for casual cyclists | Lightweight and good thermal conductivity | Lower tensile strength than steel | Medium |

| Steel | Heavy-duty compressors for professional use | High durability and pressure resistance | Heavier and more complex to manufacture | High |

| Plastic | Budget-friendly, lightweight compressors | Low cost and corrosion-resistant | Limited durability and strength | Low |

| Composite | Specialized applications needing tailored properties | Customizable performance characteristics | Higher production costs | Medium to High |

In conclusion, selecting the appropriate material for air compressors involves balancing performance, durability, and cost. International B2B buyers should consider local standards and preferences, such as compliance with ASTM, DIN, or JIS, to ensure product suitability in their respective markets. Understanding these material properties will enable buyers to make informed decisions that align with their operational needs and market demands.

Illustrative image related to air compressor for bike prices

The manufacturing process of air compressors designed for bikes involves several critical stages, each essential for ensuring the final product’s functionality and quality.

The first step in the manufacturing process is material preparation. High-quality materials, such as aluminum alloys and high-strength plastics, are selected based on their durability and lightweight properties. These materials are then subjected to rigorous testing for strength and reliability. Suppliers often provide material certifications to verify compliance with international standards, which is crucial for B2B buyers to ensure they are sourcing high-quality components.

Once the materials are prepared, forming techniques come into play. This stage typically involves processes such as die casting, extrusion, or injection molding. For instance, aluminum parts may be die-cast to achieve precise shapes, while plastic components may be created through injection molding. These techniques not only influence the air compressor’s performance but also its weight and portability, factors that are particularly important for bicycle applications.

The assembly stage is where various components come together to create the finished product. This involves integrating the motor, compressor unit, pressure gauges, and electronic controls. Each assembly line usually follows a standardized protocol to ensure consistency. Automation plays a significant role in this stage, with robotic systems commonly used for tasks that require precision, such as fastening and wiring. Manual assembly might still be employed for complex components, ensuring that each air compressor is assembled to specifications.

Illustrative image related to air compressor for bike prices

The final stage involves finishing processes, which may include surface treatments like anodizing or powder coating to improve corrosion resistance and aesthetic appeal. This is also when quality checks are performed to ensure that the compressor meets performance standards before it is packaged for shipment. Finishing touches can significantly impact the long-term durability of the product, an important consideration for B2B buyers looking for reliable solutions.

Quality assurance (QA) is a critical component of the manufacturing process for air compressors. It ensures that products meet both regulatory and customer requirements, which is particularly important for international B2B transactions.

Most manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE (Conformité Européenne) for products sold in Europe. These certifications indicate that the products have undergone rigorous testing and meet safety and performance requirements. For B2B buyers, verifying these certifications is crucial, as it ensures that the products can be trusted for their intended use.

Illustrative image related to air compressor for bike prices

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components as they arrive at the facility. Ensuring that only high-quality materials enter the production line is fundamental for maintaining product integrity.

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to verify that each stage adheres to the predefined quality standards. This can include monitoring assembly line processes and conducting tests on components as they are produced.

Final Quality Control (FQC): Once the air compressors are fully assembled, they undergo final inspections and testing. This may include performance tests to check for air pressure accuracy, durability tests, and safety checks. Any units that do not meet the required specifications are either reworked or discarded.

B2B buyers should be aware of the various testing methods employed in the quality assurance process. These may include:

Documentation of these tests, including test reports and certification, should be made available to buyers, providing transparency and assurance of quality.

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable steps to ensure quality compliance:

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing practices and quality assurance processes. This can help identify any potential risks before placing large orders.

Requesting Documentation: Buyers should request quality assurance documentation, including certificates of compliance, test reports, and records of previous audits. This information can help assess the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and the final products. These agencies often conduct their own tests and verify compliance with international standards.

International buyers must navigate various nuances when dealing with quality control in manufacturing. Different countries may have specific regulations regarding product safety and quality, which can affect importation processes. Understanding these regulations is crucial for compliance and can prevent costly delays or rejections at customs.

Moreover, language barriers and cultural differences can complicate communication about quality standards. Establishing clear lines of communication with suppliers and ensuring that all parties understand the quality expectations can mitigate these challenges.

In conclusion, the manufacturing processes and quality assurance practices for air compressors designed for bikes are comprehensive and crucial for delivering reliable products. By understanding these processes and implementing robust verification methods, B2B buyers can make informed purchasing decisions that meet their quality and performance needs.

This guide provides a structured approach for B2B buyers seeking to procure air compressors specifically for bicycles. Understanding the complexities of pricing, features, and supplier reliability is essential in making informed purchasing decisions that align with business needs.

Illustrative image related to air compressor for bike prices

Before initiating the procurement process, clarify the technical specifications required for your air compressor. Consider factors such as pressure capacity (PSI), power source (electric or manual), and portability. This step ensures that the compressors you evaluate will meet the operational demands of your business or customers.

Conduct thorough research on the current market prices for various air compressors designed for bikes. Utilize online platforms and supplier catalogs to gather pricing data. This information will help you establish a budget and recognize competitive pricing, enabling you to negotiate effectively with suppliers.

When selecting suppliers, it’s crucial to assess their credibility and reliability. Look for suppliers with a proven track record in the industry, supported by positive reviews and case studies. Request certifications that demonstrate compliance with international quality standards, which can help mitigate risks associated with subpar products.

Illustrative image related to air compressor for bike prices

Before finalizing any orders, ask suppliers for product samples. Testing these samples allows you to evaluate the compressor’s performance, durability, and ease of use. This step is vital in ensuring that the products meet your quality standards and the expectations of your clientele.

Assess the warranty offered by suppliers on their air compressors. A robust warranty indicates the manufacturer’s confidence in their product and provides you with protection against defects. Additionally, inquire about after-sales support, including service availability and response times, as these factors can significantly affect your business operations.

For international procurement, familiarize yourself with shipping options and import regulations in your country. Analyze shipping costs, delivery times, and any tariffs or taxes that may apply. This understanding will help you avoid unexpected expenses and delays in receiving your products.

Once you have identified a suitable supplier, engage in negotiations to agree on favorable terms, including price, payment methods, and delivery schedules. Ensure all terms are documented in a formal contract to protect both parties. This final step solidifies your procurement process and establishes a professional relationship with the supplier.

Illustrative image related to air compressor for bike prices

By following this checklist, B2B buyers can navigate the complexities of sourcing air compressors for bikes effectively, ensuring that they make informed decisions that align with their operational needs and budget constraints.

When sourcing air compressors for bikes, B2B buyers must understand the various cost components involved in the product’s pricing structure. The primary cost elements include:

Materials: The choice of materials significantly affects the overall cost. High-quality components such as durable plastics and metals can increase initial costs but may result in better performance and longevity.

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing but could compromise on quality.

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

Tooling: The cost of molds and machinery used in production can be substantial, especially for customized or high-spec models. Buyers should consider the tooling costs when evaluating suppliers.

Quality Control (QC): Investing in QC processes ensures that products meet required standards. While this may add to costs, it ultimately protects against returns and enhances brand reputation.

Logistics: Transportation and shipping costs can vary significantly based on the supplier’s location and the buyer’s destination. Understanding these costs is essential for accurate pricing.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market demand, brand reputation, and product uniqueness.

Several factors influence the pricing of air compressors for bikes, making it essential for buyers to evaluate them closely:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit prices. Buyers should negotiate terms that allow for scalable purchasing to maximize cost efficiency.

Specifications and Customization: Customized products may incur additional costs for design and tooling. Buyers should assess whether the added features justify the price increase.

Materials and Quality Certifications: Premium materials and certifications (like ISO or CE) can raise costs but may be necessary for certain markets, especially in Europe and the Middle East, where quality standards are stringent.

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers may charge a premium for their proven quality and service.

Incoterms: Understanding the terms of shipping and delivery (such as FOB, CIF, or DDP) is crucial. These terms dictate who bears the risk and cost at various points in the shipping process, impacting total costs.

B2B buyers can leverage several strategies to optimize their sourcing of air compressors:

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing and terms. Consider volume commitments or long-term contracts to enhance negotiating power.

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and energy efficiency to assess the true value of the compressor over its lifespan.

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, import tariffs, and shipping delays can affect the final price. Buyers in regions like Africa and South America should be particularly mindful of these variables.

Conduct Market Research: Keeping abreast of market trends and competitor pricing can provide leverage in negotiations. Utilize resources like trade shows, industry reports, and peer networks to gather insights.

Evaluate Supplier Locations: Sourcing from suppliers closer to the target market can reduce shipping costs and lead times, enhancing overall efficiency.

Understanding the comprehensive cost structure and pricing dynamics of air compressors for bikes is crucial for B2B buyers. By carefully considering the cost components, pricing influencers, and employing strategic sourcing tactics, businesses can make informed purchasing decisions that align with their operational goals. Remember that prices can vary widely based on multiple factors, so it is advisable to request quotes from multiple suppliers and conduct thorough due diligence before finalizing any agreements.

In the quest for effective tire inflation solutions, businesses often consider a range of alternatives to traditional air compressors designed specifically for bikes. Understanding these alternatives helps B2B buyers make informed decisions that align with their operational needs, budget constraints, and maintenance capabilities. Below, we present a comparative analysis of air compressors against two viable alternatives: manual pumps and CO2 inflators.

| Comparison Aspect | Air Compressor For Bike Prices | Manual Bike Pumps | CO2 Inflators |

|---|---|---|---|

| Performance | High efficiency, quick inflation | Moderate efficiency, requires manual effort | Fast inflation but limited by CO2 cartridge size |

| Cost | $50 – $500 (varies widely) | $20 – $60 | $15 – $40 per inflator + cartridge costs |

| Ease of Implementation | Easy to use, plug-and-play for electric models | Requires physical effort, user skill varies | Simple to use, requires cartridge replacement |

| Maintenance | Requires periodic checks, battery or electrical maintenance | Minimal, primarily cleaning | Minimal, replacement of cartridges only |

| Best Use Case | Best for regular bike maintenance and high-volume needs | Ideal for casual cyclists and emergency situations | Suitable for quick fixes on the go, especially in racing |

Manual bike pumps are a traditional alternative that offers a reliable method for inflating tires without the need for electricity or cartridges. They are generally lightweight and portable, making them a great choice for cyclists who prefer to travel light. However, the manual effort required can be a downside, especially for high-pressure tires, which may require significant physical exertion. While the initial investment is low, the time taken to inflate tires can be longer compared to electric compressors, making them less suitable for businesses with high-frequency needs.

CO2 inflators are compact devices that utilize pressurized carbon dioxide cartridges to inflate tires quickly. These inflators are favored by competitive cyclists and those looking for a rapid solution in emergency situations. They are easy to use—simply attach the inflator to the tire valve and release the gas. However, the primary limitation lies in the finite number of inflations per cartridge, which can lead to higher ongoing costs if used frequently. Additionally, they may not be practical for regular maintenance as they require cartridge replacements.

When selecting an inflation solution, B2B buyers should consider their specific use case and operational requirements. If regular maintenance and high-volume inflations are critical, investing in an air compressor may be the best option despite the higher upfront costs. Conversely, for businesses catering to casual cyclists or those needing quick, portable solutions, manual pumps or CO2 inflators might suffice. Ultimately, understanding the performance, costs, ease of use, and maintenance needs of each option will empower buyers to choose the most effective solution tailored to their operational goals.

When sourcing air compressors for bikes, it is crucial to understand certain technical specifications that can significantly impact performance, reliability, and overall value. Below are some essential properties to consider:

Pressure Output (PSI)

The pressure output, measured in pounds per square inch (PSI), indicates how much air the compressor can deliver. For bike tires, a typical range is between 30 PSI to 100 PSI. Higher PSI ratings allow for faster inflation and compatibility with a broader range of bike tire types. Understanding the required PSI for your market ensures that the products you offer meet customer expectations and safety standards.

Flow Rate (CFM)

The flow rate, expressed in cubic feet per minute (CFM), measures the volume of air the compressor can produce. A higher CFM is beneficial for quickly inflating tires and other accessories. For B2B buyers, selecting a compressor with an adequate CFM rating ensures operational efficiency, particularly in high-demand environments such as repair shops or cycling events.

Power Source (Electric vs. Manual)

Air compressors can be powered by electricity, batteries, or manual pumps. Electric models are typically faster and more efficient, while manual pumps are portable and do not require a power source. Understanding the power source preferences in your target market can guide purchasing decisions and impact pricing strategies.

Durability and Material Quality

The materials used in the construction of air compressors, such as high-grade plastics, aluminum, or steel, affect durability and weight. Compressors made from high-quality materials are more resistant to wear and tear, which is essential for long-term use in various environments. B2B buyers should prioritize suppliers that provide robust product specifications to ensure longevity and reliability.

Size and Portability

The dimensions and weight of air compressors are critical for users who prioritize portability. Compact and lightweight designs are favored for on-the-go applications, particularly in regions where space is limited. Understanding the logistics of distribution and storage can influence your selection of models that align with consumer needs.

Familiarity with industry-specific jargon is vital for effective communication and negotiation in the B2B landscape. Here are some key terms to know:

Illustrative image related to air compressor for bike prices

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the air compressor sector, working with OEMs can provide access to high-quality components and ensure that the products meet industry standards. This is crucial for B2B buyers looking to maintain brand integrity and customer satisfaction.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B transactions, as it can impact inventory management and cash flow. Buyers should negotiate MOQs to align with their market demand and storage capabilities.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price for specific goods or services. This process is critical for B2B buyers to compare pricing, terms, and conditions from multiple suppliers, ensuring they secure the best deal for air compressors.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers. Familiarity with these terms helps avoid misunderstandings regarding shipping costs, risk, and delivery obligations. For international buyers, understanding Incoterms is vital for smooth logistics and compliance with global trade regulations.

Warranty and Service Agreements

Warranties provide assurance regarding the quality and longevity of products. Service agreements outline the support and maintenance options available for air compressors. Understanding these terms is crucial for B2B buyers to ensure they are protected against defects and can maintain operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs, ultimately leading to successful sourcing and customer satisfaction.

The global air compressor market, particularly for bicycles, is driven by several factors. The increasing popularity of cycling as a sustainable mode of transport is a significant contributor. Regions like Africa, South America, the Middle East, and Europe are witnessing a surge in cycling culture, fueled by urban congestion and a growing environmental consciousness. Moreover, advancements in technology have led to the development of compact, efficient, and user-friendly air compressors, appealing to both casual cyclists and professional riders.

Emerging trends include the integration of smart technology into air compressors, enabling features such as automatic pressure monitoring and mobile app connectivity. B2B buyers are increasingly looking for products that offer dual functionality, such as compressors that can serve both bike and vehicle needs, which enhances their value proposition. Additionally, competitive pricing is becoming crucial as companies seek to penetrate cost-sensitive markets in regions like Brazil and Nigeria, where affordability can dictate purchasing decisions.

Illustrative image related to air compressor for bike prices

Sustainability has become a non-negotiable aspect of B2B sourcing in the air compressor market. Buyers are increasingly aware of the environmental impact of their procurement choices, prompting a shift towards ethical sourcing practices. This includes selecting suppliers that prioritize sustainable materials and manufacturing processes. Certifications such as ISO 14001 for environmental management systems are gaining traction among suppliers, assuring buyers of their commitment to minimizing ecological footprints.

Furthermore, the demand for ‘green’ products is influencing design and production. Many manufacturers are focusing on lightweight, recyclable materials that reduce energy consumption during use and production. B2B buyers are encouraged to consider not just the initial purchase price but also the long-term sustainability and efficiency of air compressors. This trend is particularly relevant for buyers in regions heavily impacted by climate change, where sustainable practices can contribute to broader environmental goals.

The evolution of air compressors for bikes has seen significant advancements over the decades. Initially, bicycle pumps were manual and required considerable effort from the user, limiting their convenience. The introduction of electric air compressors marked a pivotal shift, providing faster and more efficient inflation solutions.

In recent years, the focus has shifted towards portability and multi-functionality, with products designed to be compact and easy to carry. Innovations in battery technology have also enhanced the performance of portable compressors, allowing for quicker inflation times and longer usage periods on a single charge. This evolution reflects a broader trend in the cycling industry towards convenience and efficiency, catering to the needs of modern cyclists who demand reliable and user-friendly equipment.

The combined impact of market dynamics, sustainability, and technological advancements positions the air compressor for bikes sector as a promising avenue for B2B buyers looking to invest in high-demand, eco-friendly products that meet the evolving needs of consumers globally.

Illustrative image related to air compressor for bike prices

How do I choose the right air compressor for bike tires?

When selecting an air compressor for bike tires, consider factors such as pressure capacity, portability, power source (battery-operated or plug-in), and ease of use. Look for models with a minimum PSI of 100, as this is typically sufficient for most bike tires. Additionally, assess the size and weight for portability, especially if the compressor will be used during rides or outdoor activities. Reading reviews and checking specifications from various suppliers can also provide insight into the performance and reliability of different models.

What is the best air compressor for bike tires on the market?

The best air compressor for bike tires often depends on specific needs, such as portability and inflation speed. Popular models include the Fanttik X9 Pro and VIAIR TLC series, known for their efficiency and compact size. These compressors are designed to quickly inflate tires, have multiple pressure settings, and often feature built-in lights for nighttime use. It’s advisable to compare several options based on features, price, and user reviews to find the best fit for your requirements.

What are the common price ranges for air compressors for bikes?

Air compressor prices for bikes typically range from $50 to $500, depending on the features and brand. Entry-level models may cost around $50 to $150, while high-performance or specialized compressors can exceed $300. Factors influencing price include pressure capacity, portability, and included accessories. For bulk purchases, negotiating with suppliers can yield discounts, making it essential to compare prices across different vendors to ensure competitive pricing.

What factors should I consider when vetting suppliers for air compressors?

When vetting suppliers for air compressors, consider their reputation, product quality, and customer service. Request samples to assess the quality of the compressors. Investigate their manufacturing processes and compliance with international standards. Additionally, check their financial stability, delivery times, and return policies. It’s beneficial to read reviews and testimonials from other buyers, particularly those in your region, to gauge their reliability and responsiveness.

What is the minimum order quantity (MOQ) for air compressors?

The minimum order quantity (MOQ) for air compressors can vary significantly by supplier and model. Typically, MOQs range from 10 to 100 units, depending on the manufacturer’s capacity and production schedule. Discussing your specific needs with potential suppliers can lead to more flexible terms, especially if you are looking to establish a long-term partnership. Some suppliers may offer lower MOQs for first-time buyers to encourage trial orders.

What payment terms should I expect when purchasing air compressors internationally?

Payment terms for international purchases of air compressors usually include options like wire transfers, letters of credit, or payment through platforms like PayPal. Most suppliers require a deposit (often 30% to 50%) upfront, with the balance due upon shipment or delivery. It’s essential to clarify payment terms and any potential additional costs, such as taxes and shipping fees, to avoid surprises. Establishing clear agreements in writing can help facilitate smoother transactions.

How can I ensure quality assurance (QA) for the compressors I purchase?

To ensure quality assurance for air compressors, request detailed specifications and certifications from your supplier. Consider implementing a quality control process that includes inspection of samples before bulk orders are finalized. You may also engage third-party inspection services to verify the quality during production and before shipment. Establishing a clear return policy in case of defective products is crucial to safeguard your investment.

What logistics considerations should I keep in mind when sourcing air compressors?

When sourcing air compressors, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose a shipping option that balances cost and delivery speed, whether by air or sea. Be aware of any import duties or taxes that may apply, and ensure that your supplier provides all necessary documentation for customs clearance. Planning for potential delays and establishing a reliable logistics partner can streamline the process and reduce risks.

Domain: cycplus.com

Registered: 2017 (8 years)

Introduction: {“products”:[{“name”:”AS2 Ultra Tiny E-pump for Bike”,”regular_price”:”$119.00″},{“name”:”AS2 Pro Tiny E-Pump For Bike”,”regular_price”:”$109.00″,”discount”:”12% OFF”,”sale_price”:”$114.00″},{“name”:”AS2 Pro Max Tiny E-Pump For Bike”,”regular_price”:”$129.00″,”sale_price”:”$114.00″},{“name”:”AS2 Tiny E-Pump For Bike”,”regular_price”:”$69.00″},{“name”:”Electric Air Pump A2 Pro”,”regular_price”:”$49…

Domain: lasfit.com

Registered: 2016 (9 years)

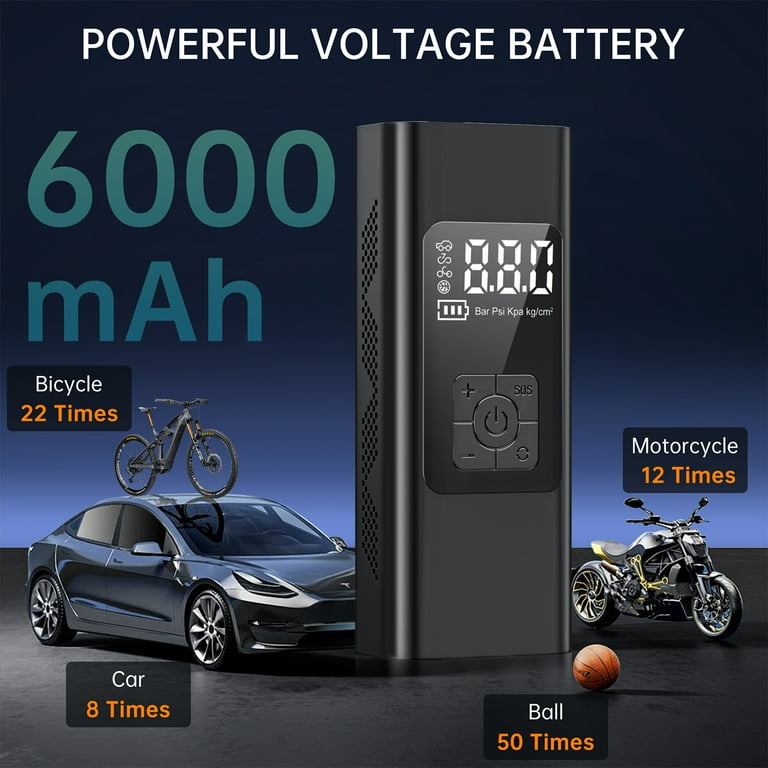

Introduction: {“product_name”: “LASFIT AIR Portable Cordless Tire Inflator Air Compressor Pump for Bike Bicycle Motorcycle Ball”, “model_number”: “LAP-BM1-R”, “price”: “$54.99”, “original_price”: “$79.99”, “discount”: “18% OFF”, “warranty”: “2-year hassle-free warranty”, “return_policy”: “45 days free return and money back, 90 days free return and money back for Lasfit club member”, “shipping”: “FREE U.S. shipp…

In the competitive landscape of air compressors for bikes, strategic sourcing emerges as a vital strategy for B2B buyers aiming to optimize costs and enhance operational efficiency. Understanding the diverse pricing structures across different markets—from the rugged terrains of Africa to the bustling streets of South America—allows buyers to make informed purchasing decisions. Key insights reveal that prices can vary significantly based on features, brand reputation, and regional availability.

Investing in high-quality, reliable air compressors not only ensures consistent product performance but also fosters customer loyalty in the long run. Buyers should prioritize suppliers that offer robust warranties and after-sales support, which can mitigate risks associated with equipment failure and service downtime.

As global trends lean towards sustainable and efficient cycling solutions, now is the time for international buyers to capitalize on this growing market. Engage with suppliers who prioritize innovation and customer-centric solutions to stay ahead of the curve. By leveraging strategic sourcing, businesses can not only enhance their product offerings but also secure a competitive edge in the evolving marketplace. Start exploring your options today to ensure you are well-positioned for future success in this dynamic industry.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air compressor for bike prices

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.