In today’s fast-paced automotive industry, sourcing a reliable portable tire inflator car can be a daunting challenge for B2B buyers. With the increasing demand for efficient and user-friendly inflation solutions, companies must navigate a diverse market filled with various models and features. This comprehensive guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—with the insights necessary to make informed purchasing decisions.

We will explore the different types of portable tire inflators available, their applications across various vehicle categories, and essential factors to consider when vetting suppliers. Additionally, we will delve into cost analysis, ensuring that you understand the pricing landscape and can negotiate effectively. By addressing common pain points, such as battery life, inflation speed, and multi-functionality, this guide empowers businesses to select products that not only meet their operational needs but also enhance customer satisfaction.

By leveraging the insights provided in this guide, B2B buyers can confidently navigate the global market for portable tire inflators, ensuring they invest in high-quality products that drive value and performance for their fleets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, compact, easy to use | Automotive repair shops, roadside assistance | Pros: Portable, no need for power outlet. Cons: Limited battery life for multiple tires. |

| 12V Plug-In Tire Inflators | Connect to vehicle’s 12V outlet, often includes long hose | Fleet management, vehicle maintenance | Pros: Convenient for on-the-go inflation. Cons: Requires vehicle power source; less portable. |

| Heavy-Duty Tire Inflators | Designed for larger tires, often with higher PSI capacity | Construction, off-road vehicle services | Pros: Fast inflation for large tires. Cons: Bulkier, may require direct battery connection. |

| Ultra-Compact Tire Inflators | Extremely portable, often fits in glove compartments | Motorcycles, bicycles, small vehicles | Pros: Highly portable, ideal for small spaces. Cons: Limited power and slower inflation. |

| Multi-Function Tire Inflators | Additional features like LED lights, USB ports, and adapters | General consumer markets, outdoor activities | Pros: Versatile for various applications. Cons: May be more expensive due to added features. |

Cordless tire inflators are battery-operated devices that offer significant portability and ease of use. They are particularly suitable for emergency situations where immediate inflation is required without access to power outlets. When purchasing, B2B buyers should consider battery capacity, charging options, and the time it takes to inflate a tire fully. These inflators are ideal for automotive repair shops and roadside assistance services, but their limited battery life may restrict their effectiveness for multiple tires in one session.

12V plug-in tire inflators connect directly to a vehicle’s 12V outlet, making them a reliable choice for fleet management and vehicle maintenance. These inflators typically feature longer hoses, allowing for easier access to all tires without moving the vehicle. Buyers should evaluate the hose length, ease of use, and overall durability. While convenient for on-the-go inflation, these models require the vehicle to be operational, which may limit their use in certain scenarios.

Heavy-duty tire inflators are built to handle larger tires, often seen in trucks and off-road vehicles, with a higher PSI capacity. They are particularly favored in construction and off-road vehicle services where rapid inflation is crucial. Key considerations for B2B buyers include the inflator’s speed, durability, and whether it requires a direct battery connection. While they can inflate large tires quickly, their bulkiness and connection requirements may deter some users.

Ultra-compact tire inflators are designed for maximum portability, often fitting easily into glove compartments or small bags. They are particularly suitable for motorcycles, bicycles, and small vehicles. Buyers should assess the inflator’s power limitations and inflation speed, as these models often have a smaller battery and may take longer to inflate tires. While they are highly portable, their capacity for larger tires is limited, making them best for specific applications.

Multi-function tire inflators come equipped with additional features such as LED lights, USB ports, and adapters for inflating various objects. These versatile tools are ideal for general consumer markets and outdoor activities, appealing to a broader audience. When considering these models, B2B buyers should weigh the added value of features against the price. While they offer a range of functionalities, the cost can be higher, which may not be justified for buyers focused solely on tire inflation.

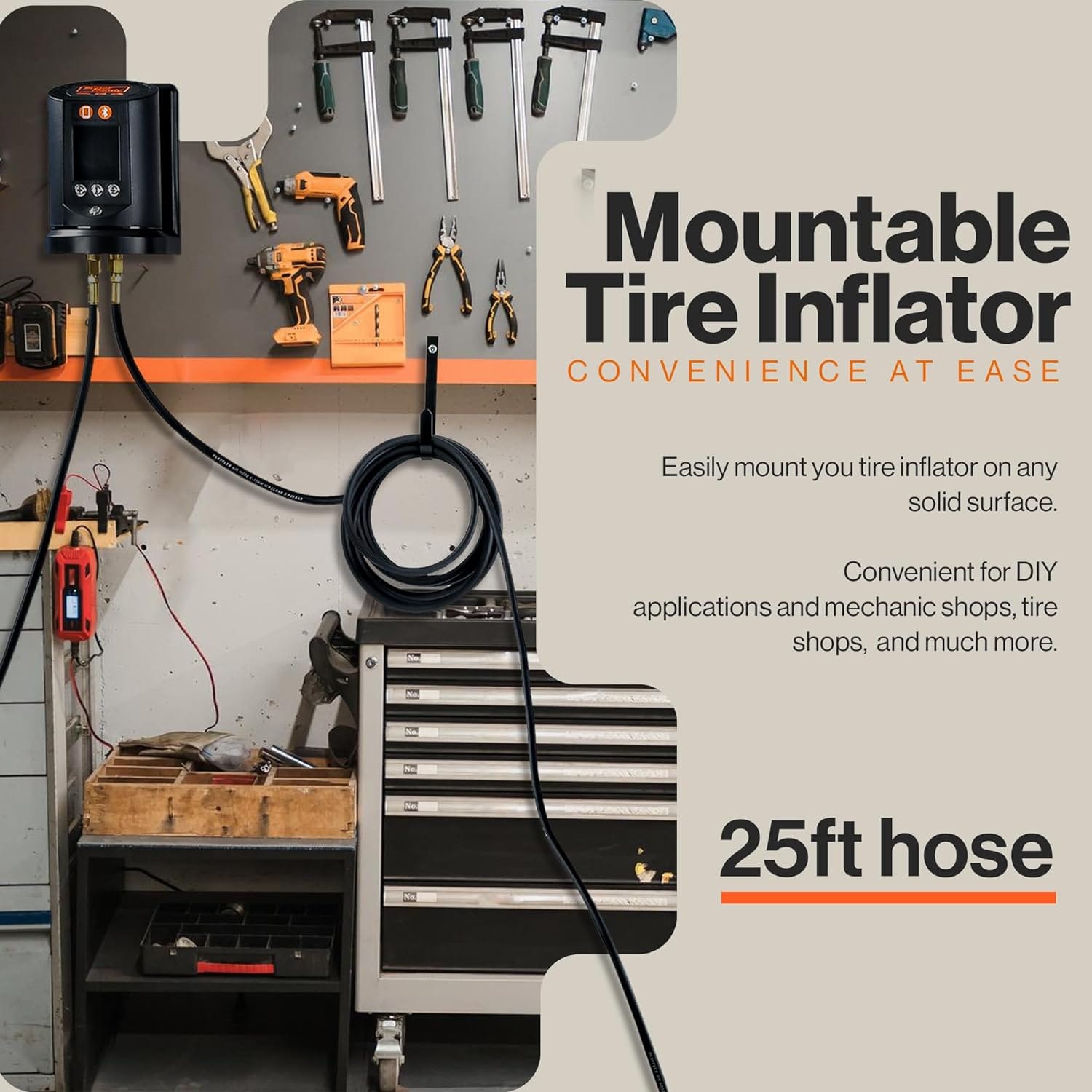

Illustrative image related to portable tire inflator car

| Industry/Sector | Specific Application of Portable Tire Inflator Car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Quick tire inflation for customer service | Enhances customer satisfaction and turnaround time | Reliability, ease of use, and portability |

| Transportation and Logistics | Maintenance of fleet vehicles | Reduces downtime and ensures safety on the road | Power options, durability, and capacity for multiple tires |

| Construction and Heavy Equipment | Inflation of heavy machinery tires | Prevents work delays and enhances equipment longevity | High-pressure capabilities and rugged construction |

| Emergency Services | Rapid response for flat tires in the field | Increases operational efficiency and response time | Compact design, battery life, and ease of use |

| Retail and Car Dealerships | Tire maintenance for inventory vehicles | Maintains vehicle readiness and customer trust | Cost-effectiveness, portability, and additional features |

In automotive repair shops, portable tire inflators are essential tools that facilitate quick tire inflation for customer service. When a customer arrives with low tire pressure, a reliable inflator can significantly enhance service speed, leading to higher customer satisfaction and quicker turnaround times. Buyers in this sector should prioritize inflators that are user-friendly, durable, and capable of handling various tire sizes.

For businesses in transportation and logistics, maintaining fleet vehicles is critical for operational efficiency. Portable tire inflators enable quick maintenance checks and inflation of tires, reducing downtime and ensuring vehicles are roadworthy. In this sector, buyers should consider inflators with multiple power options and the ability to inflate multiple tires in one session, ensuring they can respond promptly to any tire-related issues.

In the construction industry, portable tire inflators play a vital role in maintaining heavy machinery. These inflators help prevent work delays caused by flat tires, ensuring that equipment remains operational. Buyers from this sector should look for inflators with high-pressure capabilities and rugged construction to withstand tough job site conditions, ensuring reliability when it matters most.

Emergency services benefit greatly from portable tire inflators, which allow for rapid response to flat tires in the field. Quick inflation can be the difference between timely assistance and delays in critical situations. Buyers in this sector need compact, battery-operated inflators that are easy to use and have a long battery life, enabling them to perform under pressure.

Illustrative image related to portable tire inflator car

Retail businesses and car dealerships utilize portable tire inflators for tire maintenance on their inventory vehicles. Keeping these vehicles ready for test drives or customer delivery builds trust and enhances the customer experience. Key sourcing considerations for this application include cost-effectiveness, portability, and additional features like built-in pressure gauges or LED lights, which can further improve usability and service quality.

The Problem: B2B buyers, particularly those in sectors like logistics or transportation, often face situations where tire maintenance is critical yet time-sensitive. A portable tire inflator may run out of battery mid-operation, especially if multiple vehicles need servicing or if the inflator is required to handle high-pressure tires. This can lead to downtime, impacting delivery schedules and increasing operational costs.

The Solution: When sourcing portable tire inflators, prioritize models with robust battery life and dual power options, such as a rechargeable battery and a 12-volt car adapter. Look for inflators like the AstroAI Cordless Tire Inflator, which can inflate multiple tires on a single charge. Ensure that your procurement process includes testing these inflators in real-world scenarios, such as inflating multiple tires from low pressures. Providing training for staff on how to use the inflator efficiently—like pre-charging before anticipated use and understanding how to switch power sources—can significantly reduce downtime.

The Problem: Many portable tire inflators come with built-in pressure gauges that can be inaccurate, which poses a significant risk for businesses relying on vehicle safety. An inflator that fails to deliver the correct pressure can lead to under-inflated tires, resulting in increased fuel consumption, tire wear, and potential accidents, which can be costly both in terms of repairs and liability.

The Solution: Invest in inflators known for their reliable pressure gauges, such as those with digital readouts that offer real-time pressure monitoring. Before making a purchase, conduct thorough market research and compare user reviews, focusing on models that have been tested for accuracy. Additionally, consider integrating calibration practices into your routine maintenance schedule, where inflators can be regularly checked against a certified gauge to ensure ongoing accuracy. This proactive approach not only enhances safety but also extends tire life and promotes better fuel efficiency.

The Problem: In industries like construction or agriculture, where larger vehicles with high-pressure tires are common, many portable tire inflators struggle to meet inflation demands. Buyers often find that standard inflators are not powerful enough or take too long to inflate larger tires, which can lead to project delays and increased labor costs.

The Solution: Select tire inflators specifically designed for heavy-duty applications, such as the Viair 88P, which is capable of inflating larger tires quickly and efficiently. When evaluating options, prioritize features like maximum PSI capability and inflation speed. It’s also advisable to maintain a diverse fleet of inflators tailored for different vehicle sizes. Training operators on the specific requirements for inflating larger tires—like connecting directly to the vehicle’s battery for maximum power—can streamline operations and enhance productivity. By ensuring your inflators can handle the demands of larger tires, you mitigate the risk of delays and improve overall operational efficiency.

When selecting materials for portable tire inflators, various factors such as performance, durability, cost, and suitability for specific applications must be considered. Here, we analyze four common materials used in the construction of portable tire inflators: plastic, aluminum, rubber, and stainless steel.

Plastic is widely used in the housing and components of portable tire inflators due to its lightweight nature and versatility. Key properties include good temperature resistance (typically up to 80°C) and moderate pressure ratings, making it suitable for low-pressure applications.

Illustrative image related to portable tire inflator car

Pros: Plastic is cost-effective and easy to mold, allowing for complex shapes and designs. It also provides decent corrosion resistance, which is essential for products exposed to varying environmental conditions.

Cons: While plastic is durable, it can be less resistant to high temperatures and may degrade over time under UV exposure. Additionally, it may not be suitable for high-pressure components, which can limit its application in heavy-duty inflators.

Impact on Application: Plastic components are ideal for the outer casing and non-pressurized parts, but they may not be suitable for high-stress areas where durability is critical.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is crucial. Buyers in regions like Africa and South America should consider the availability of high-quality plastics that can withstand local environmental conditions.

Aluminum is often chosen for its excellent strength-to-weight ratio and resistance to corrosion, making it suitable for high-pressure applications. It can withstand temperatures up to 200°C, which is beneficial for inflators that may generate heat during operation.

Pros: Aluminum is lightweight yet strong, enhancing the portability of tire inflators. It is also recyclable, appealing to environmentally conscious buyers.

Cons: The manufacturing process can be more complex and costlier compared to plastic. Additionally, aluminum may require surface treatments to enhance corrosion resistance, adding to production costs.

Impact on Application: Aluminum is ideal for high-pressure components and internal mechanisms, providing reliability and performance in demanding situations.

Illustrative image related to portable tire inflator car

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards such as ASTM B221 for extruded aluminum. In regions like Europe and the Middle East, buyers may prioritize suppliers who adhere to stringent quality standards.

Rubber is primarily used for seals, hoses, and gaskets in portable tire inflators. Its key properties include excellent elasticity and temperature resistance, typically from -40°C to 100°C, which is essential for maintaining airtight seals.

Pros: Rubber provides excellent durability and flexibility, ensuring that seals remain intact under various conditions. It also has good wear resistance, which is vital for components subjected to friction.

Cons: Rubber can degrade over time due to ozone exposure and UV radiation, necessitating regular inspections and potential replacements. Additionally, it may not be suitable for high-temperature applications without specific formulations.

Impact on Application: Rubber is critical for ensuring the airtight integrity of inflators, making it indispensable for effective performance.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 for rubber materials is essential. Buyers in regions with extreme climates, like Nigeria or Brazil, should ensure that the rubber used can withstand local conditions.

Illustrative image related to portable tire inflator car

Stainless steel is often used in high-pressure components, such as fittings and valves, due to its exceptional strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, ensuring longevity. It can also handle extreme pressure conditions, providing reliability in critical applications.

Cons: The primary drawback is its higher cost compared to other materials, which can impact the overall price of the inflator. Additionally, stainless steel is heavier, which may affect the portability of the product.

Impact on Application: Stainless steel is ideal for components that require high strength and durability, ensuring safety and performance under pressure.

Considerations for International Buyers: Buyers should ensure that stainless steel components meet standards such as ASTM A240 for corrosion resistance. In markets like Europe and the Middle East, adherence to quality certifications is often a purchasing criterion.

Illustrative image related to portable tire inflator car

| Material | Typical Use Case for portable tire inflator car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-pressurized components | Lightweight and cost-effective | Less suitable for high pressure | Low |

| Aluminum | High-pressure components and internal mechanisms | Strong and corrosion-resistant | Higher manufacturing costs | Medium |

| Rubber | Seals, hoses, and gaskets | Excellent durability and flexibility | Degrades under UV exposure | Medium |

| Stainless Steel | High-pressure fittings and valves | Highly durable and corrosion-resistant | Higher cost and weight | High |

This analysis provides valuable insights for B2B buyers, helping them make informed decisions about material selection for portable tire inflators.

The manufacturing process of a portable tire inflator involves several key stages that ensure the product is functional, reliable, and safe for consumer use.

Material Preparation:

The first step involves sourcing high-quality materials that meet the specifications for durability and performance. Common materials include high-impact plastics for the casing, metal components for the internal mechanisms, and rubber for hoses and seals. Suppliers often conduct material testing to ensure compliance with relevant industry standards, which is crucial for the overall reliability of the inflator.

Forming:

This stage includes various techniques such as injection molding for plastic parts, die-casting for metal components, and extrusion for rubber hoses. Advanced forming methods ensure precision and consistency in the dimensions of each component, which is vital for the assembly process.

Assembly:

During assembly, the individual parts are brought together to form the complete inflator. This process typically involves both manual labor and automated machinery to enhance efficiency. Components such as the motor, battery, pressure gauge, and control circuitry are integrated carefully. Each unit may go through a preliminary inspection to ensure that all components are correctly fitted and functional.

Finishing:

The finishing stage involves cosmetic enhancements and protective coatings. This may include painting, applying decals, and adding protective seals to prevent moisture and dust ingress. The final product is then packaged for shipment, often including user manuals and safety information.

Quality control (QC) is a critical aspect of the manufacturing process for portable tire inflators, ensuring that each unit meets safety and performance standards.

International Standards Compliance:

Adhering to international standards such as ISO 9001 is crucial for manufacturers. This standard focuses on quality management systems and continuous improvement. Additionally, specific certifications like CE mark in Europe or API for certain components can enhance the product’s credibility and marketability.

Key QC Checkpoints:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon delivery to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted at various stages to identify defects early. This includes monitoring assembly accuracy and checking for proper component integration.

– Final Quality Control (FQC): After assembly, each inflator undergoes rigorous testing to confirm functionality. This includes pressure tests, performance evaluations, and safety checks to ensure compliance with standards.

Common Testing Methods:

Manufacturers typically employ a range of testing methods, including:

– Functional Testing: Verifying that the inflator operates correctly under various conditions.

– Pressure Testing: Ensuring the inflator can achieve and maintain specified pressure levels without failure.

– Durability Testing: Assessing the product’s resilience to impacts, temperature variations, and prolonged use.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks.

Supplier Audits:

Conducting on-site audits of manufacturing facilities can provide insights into the supplier’s operations, quality management systems, and adherence to standards. This enables buyers to assess the environment in which products are made and the processes followed.

Requesting Quality Reports:

Buyers should request detailed quality control reports that outline the testing methods used, results from previous batches, and any corrective actions taken. This documentation can serve as evidence of the supplier’s commitment to quality.

Third-Party Inspections:

Engaging third-party inspection services can further validate the quality of the inflators. These independent entities can conduct tests and evaluations, ensuring that the products meet international standards and specifications before shipment.

International B2B buyers must navigate specific challenges and nuances when it comes to quality control for portable tire inflators.

Understanding Regional Standards:

Different regions have distinct safety and quality standards. For instance, while CE certification is crucial in Europe, buyers in Africa or South America may need to consider local regulations that pertain to product safety and performance.

Logistical Challenges:

Importing products can introduce risks related to damage during transportation. Ensuring that suppliers use robust packaging and have quality checks before shipment can mitigate these risks.

Cultural Differences in Quality Expectations:

Quality perceptions can vary significantly between regions. Buyers should communicate their specific quality expectations clearly to suppliers to avoid misunderstandings.

Post-Purchase Support:

Consider the supplier’s ability to provide after-sales support and warranty services. A strong support system can enhance buyer confidence and ensure that any quality issues can be addressed promptly.

Manufacturing portable tire inflators involves a complex process that integrates precise engineering, rigorous quality control, and compliance with international standards. For B2B buyers, understanding these processes and verification methods is crucial for making informed purchasing decisions. By prioritizing quality assurance and supplier credibility, businesses can ensure they are investing in reliable, high-performance products that meet their operational needs.

This sourcing guide aims to assist B2B buyers in selecting the best portable tire inflators for automotive applications. By following this step-by-step checklist, you can ensure that your procurement process is thorough, efficient, and aligned with your organizational needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Before initiating the procurement process, clearly outline the technical specifications required for the portable tire inflators. Consider factors such as maximum PSI, power source options (battery-operated vs. corded), and size/weight constraints for ease of storage and transport. This step is crucial to ensure that the inflators meet your operational needs and customer expectations.

Stay informed about the latest developments in tire inflator technology. Research current trends such as cordless models, inflation speed, and multifunctional features like built-in pressure gauges and USB charging ports. Understanding market innovations can help you identify products that offer a competitive advantage and enhance user experience.

Thoroughly vet potential suppliers before making a commitment. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Look for suppliers with a proven track record in manufacturing high-quality inflators and ensure they adhere to relevant international standards.

Before finalizing your order, request samples of the inflators you are considering. Testing samples allows you to evaluate the performance, usability, and durability of the products firsthand. This step can prevent costly mistakes and ensure that the products align with your specifications.

Once you have selected potential suppliers and tested their products, negotiate pricing and payment terms. Consider bulk purchase discounts, warranty conditions, and after-sales support services. Effective negotiation can lead to cost savings and better overall value.

After agreeing on terms, finalize your purchase order and discuss logistics for shipping and delivery. Coordinate with the supplier to ensure that the inflators are delivered on time and in good condition. Proper logistics planning is vital for maintaining your supply chain efficiency.

Once the inflators arrive, conduct a quality control check to ensure that they meet the agreed specifications and standards. This step is essential to maintain product quality and customer satisfaction.

By following this checklist, B2B buyers can make informed decisions when sourcing portable tire inflators, ensuring product quality and supplier reliability.

Illustrative image related to portable tire inflator car

When sourcing portable tire inflators, international B2B buyers should consider several cost components that contribute to the overall pricing structure. The primary elements include:

Materials: The choice of materials significantly impacts the cost. High-quality plastic, durable metal components, and advanced battery technologies can raise manufacturing costs but also enhance the product’s longevity and performance. For example, inflators with lithium-ion batteries tend to be pricier than those with standard batteries due to their efficiency and longer life.

Labor: Labor costs can vary widely based on the manufacturing location. Regions with lower labor costs might offer more competitive pricing, but this can sometimes come at the expense of product quality. Understanding the labor rates in various countries can help buyers make informed decisions.

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, rent, and administrative expenses. Buyers should inquire about these costs to understand how they affect the final price.

Tooling: Customization often requires special tooling, which can be a significant initial investment. Buyers should assess if the tooling costs are included in the quoted price or if they will be charged separately.

Quality Control (QC): Investing in stringent QC processes ensures that the inflators meet safety and performance standards. While this may increase upfront costs, it can lead to reduced returns and increased customer satisfaction in the long run.

Logistics: Shipping costs, including freight, insurance, and handling, can vary significantly based on the shipping method and distance. Understanding the logistics involved is crucial for calculating the total cost of ownership.

Margin: Suppliers will add a markup to cover their operating costs and profit margins. The level of competition in the market can influence this margin, so buyers should compare quotes from multiple suppliers.

Several factors can influence the pricing of portable tire inflators, particularly for international buyers:

Volume/MOQ: Suppliers often provide better pricing for larger order quantities. Understanding the minimum order quantities (MOQs) can help buyers negotiate better terms and reduce per-unit costs.

Specifications and Customization: Custom features, such as specific pressure gauges or additional adapters, can increase costs. Buyers should evaluate whether the added features justify the higher prices.

Quality and Certifications: Products that meet international safety and quality certifications, such as ISO or CE markings, may command higher prices. Buyers should weigh the importance of these certifications against their budget constraints.

Supplier Factors: Reputation, reliability, and historical performance of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and customer service.

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is essential. They dictate the responsibilities of buyers and sellers in shipping, which can affect overall costs. For instance, terms like FOB (Free on Board) might shift more costs to the buyer compared to CIF (Cost, Insurance, and Freight).

International B2B buyers should adopt strategic approaches to improve their sourcing outcomes:

Negotiate Wisely: Leverage volume discounts and long-term contracts to negotiate better pricing. Building a good relationship with suppliers can also lead to favorable terms.

Focus on Cost-Efficiency: Consider the total cost of ownership, which includes not only the purchase price but also shipping, potential repairs, and product lifespan. A higher initial investment may lead to lower long-term costs.

Understand Pricing Nuances: Be aware of regional pricing variations and economic factors affecting costs, such as currency fluctuations or tariffs. This awareness can help in making informed sourcing decisions.

Research Supplier Markets: Investigate potential suppliers in different regions, such as Asia or Eastern Europe, where production costs might be lower, while maintaining acceptable quality standards.

Prices for portable tire inflators can vary significantly based on the factors outlined above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting the best value for their investment.

When considering solutions for maintaining optimal tire pressure, portable tire inflators are a popular choice for businesses and consumers alike. However, alternative methods and technologies can also effectively serve this purpose. Understanding the pros and cons of various options allows B2B buyers to make informed decisions that align with their specific operational needs and budget constraints.

| Comparison Aspect | Portable Tire Inflator Car | Air Compressor | Manual Tire Pump |

|---|---|---|---|

| Performance | Quick inflation, versatile for various tire sizes | High volume, suitable for heavy-duty applications | Slower, requires physical effort |

| Cost | Moderate ($40 – $90) | Higher ($100+) | Low ($20 – $50) |

| Ease of Implementation | Very user-friendly, typically plug-and-play | Requires setup and knowledge of operation | Simple but labor-intensive |

| Maintenance | Low, generally requires battery replacement | Moderate, needs regular checks and oiling | Very low, no maintenance required |

| Best Use Case | Roadside assistance, personal vehicles | Workshops, commercial fleets | Bicycles, emergency kits |

Air compressors are robust machines designed for heavy-duty applications and can inflate tires quickly and efficiently. They are ideal for businesses that manage large fleets or require high-volume air for various tools. While their performance is superior for inflating tires and other applications, the initial investment is higher, and they often require some setup and maintenance. Additionally, their size makes them less portable, which can be a disadvantage for businesses needing quick roadside assistance.

Manual tire pumps are a cost-effective solution for inflating tires, particularly for bicycles or as an emergency backup. They are lightweight and can be easily stored in vehicles or carried in backpacks. However, their effectiveness diminishes with larger tires, and they require physical effort, which may not be ideal for all users. While the low cost is appealing, the time and labor involved in using a manual pump can be a drawback for busy professionals or businesses that prioritize efficiency.

Selecting the right tire inflation solution depends on various factors, including the scale of operations, budget, and specific use cases. For businesses that require quick and versatile inflation capabilities, a portable tire inflator car is often the best choice. However, if the need for high-volume air and performance outweighs portability, investing in an air compressor may be more beneficial. On the other hand, for those seeking a budget-friendly option for occasional use, a manual tire pump can serve well. Evaluating these alternatives in light of your operational needs will ensure you choose the most effective solution for maintaining tire health and safety.

When selecting a portable tire inflator for automotive applications, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some key properties that B2B buyers should consider:

Illustrative image related to portable tire inflator car

Maximum Pressure (PSI)

– Definition: The highest air pressure that the inflator can deliver, measured in pounds per square inch (PSI).

– Importance: Different vehicles require different tire pressures; heavy-duty trucks may need higher PSI levels. An inflator with a maximum PSI of 100 or more is ideal for versatility, accommodating various vehicle types.

Duty Cycle

– Definition: The amount of time the inflator can operate continuously before needing to cool down, typically expressed in minutes.

– Importance: A longer duty cycle allows for more extensive use without overheating, which is particularly beneficial for users who need to inflate multiple tires or larger tires commonly found in SUVs and trucks.

Power Source

– Definition: The type of energy the inflator uses, which can include battery (cordless), 12-volt car adapter, or AC mains.

– Importance: The choice of power source affects portability and usability. Cordless models offer convenience, while those that plug into a vehicle’s power outlet are beneficial for users with limited battery life.

Inflation Time

– Definition: The duration required to inflate a tire from a specified PSI to another (e.g., from 25 to 35 PSI).

– Importance: Fast inflation times are essential for efficiency, especially in emergency situations. Buyers should look for inflators that can complete this task in under 10 minutes.

Pressure Gauge Type

– Definition: The method of displaying tire pressure, which can be analog or digital.

– Importance: Accurate pressure readings are crucial for safety and tire longevity. Digital gauges often provide clearer readings and more precision compared to analog models.

Size and Portability

– Definition: The dimensions and weight of the inflator when stored.

– Importance: Compact designs are easier to store in vehicles and carry during travel, making them more appealing for consumers who prioritize convenience.

Understanding industry jargon can help buyers navigate the procurement process more effectively. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing whether an inflator is OEM can assure buyers of its quality and compatibility with existing systems.

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding the MOQ is vital for managing inventory and ensuring that purchases align with business needs, especially for bulk orders.

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price bids from suppliers.

– Importance: An RFQ is essential for comparing prices and terms among different suppliers, enabling buyers to make cost-effective decisions.

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps businesses understand shipping costs, risks, and logistics, facilitating smoother international transactions.

Warranty Period

– Definition: The duration during which a product is guaranteed against defects in materials or workmanship.

– Importance: A longer warranty period can indicate higher product quality and offer peace of mind to buyers, making it an essential factor in purchasing decisions.

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Knowing the lead time helps businesses plan their inventory and operations, ensuring they have the necessary tools when needed.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when selecting portable tire inflators, ensuring they meet their operational needs and maintain vehicle safety.

The portable tire inflator market is experiencing significant growth, driven by several global factors. Increased vehicle ownership in emerging markets like Africa and South America is a primary driver. As more consumers and businesses rely on automobiles for transportation, the demand for effective maintenance tools, such as tire inflators, has surged. Additionally, rising fuel prices and a growing awareness of vehicle maintenance have prompted both consumers and businesses to invest in portable inflators to ensure optimal tire pressure, ultimately leading to fuel efficiency.

Illustrative image related to portable tire inflator car

Current and emerging B2B tech trends are reshaping the portable tire inflator sector. Innovations in battery technology, such as lithium-ion batteries, are making inflators more efficient and portable, appealing to a wider range of users, including those in remote areas. Additionally, the integration of smart technology, such as Bluetooth connectivity and mobile app compatibility, allows users to monitor tire pressure and receive alerts, enhancing user experience. For international B2B buyers, particularly from regions like Nigeria and Brazil, sourcing products that incorporate these advancements can create a competitive edge in the market.

Moreover, the market dynamics are influenced by fluctuating raw material costs and supply chain disruptions, necessitating strategic sourcing practices. Buyers must remain vigilant about market trends and adapt their sourcing strategies to mitigate risks associated with price volatility and availability of components. By understanding these dynamics, B2B buyers can make informed decisions that align with their operational needs and market demands.

The environmental impact of manufacturing portable tire inflators is an increasingly important consideration for B2B buyers. The production of these devices often involves materials like plastics and metals, which contribute to pollution and resource depletion. Therefore, companies are under pressure to adopt sustainable practices and minimize their ecological footprint. For B2B buyers, prioritizing suppliers that utilize eco-friendly materials and practices can enhance their brand reputation and appeal to environmentally-conscious consumers.

Ethical sourcing is equally vital in this sector. Buyers should seek out manufacturers committed to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to ethical practices. By selecting suppliers that prioritize sustainability and ethical sourcing, businesses can not only comply with regulatory standards but also foster trust and loyalty among their customer base.

Incorporating ‘green’ certifications and materials into the sourcing strategy can also provide a competitive advantage. Consumers increasingly prefer products that demonstrate a commitment to environmental sustainability. For instance, inflators made from recycled materials or designed for energy efficiency can attract a broader audience. As the market continues to evolve, B2B buyers must stay attuned to sustainability trends to ensure they remain relevant and responsible in their sourcing efforts.

Illustrative image related to portable tire inflator car

The portable tire inflator has evolved significantly since its inception. Originally designed as bulky, manually-operated devices, early models required considerable effort and time to inflate tires. The introduction of electric-powered inflators in the late 20th century marked a turning point, allowing for quicker and more efficient inflation processes.

As technology advanced, the focus shifted toward portability and user-friendliness, leading to the development of compact, battery-operated models that could easily be stored in a vehicle. The latest innovations incorporate smart features, such as digital pressure gauges and automatic shut-off mechanisms, enhancing safety and convenience for users. This evolution reflects a broader trend in consumer preferences for multifunctional, efficient tools that support modern lifestyles.

For B2B buyers, understanding this evolution is essential for identifying products that meet current market demands while anticipating future trends. By sourcing from manufacturers who embrace innovation and quality, businesses can ensure they remain competitive in a rapidly changing landscape.

How do I choose the right portable tire inflator for my business needs?

Selecting the right portable tire inflator involves evaluating your specific requirements, such as the types of vehicles you service and the frequency of use. Consider factors like maximum pressure capabilities, power sources (cordless vs. corded), and inflation speed. Look for features that enhance usability, such as built-in pressure gauges, compact design for storage, and additional functionalities like USB charging ports. Reviewing product specifications and user feedback can also provide insights into performance, ensuring you invest in a reliable tool that meets your operational demands.

What is the best portable tire inflator for high-pressure applications?

For high-pressure applications, the AstroAI Cordless Tire Inflator is an excellent choice, as it can inflate tires to a maximum pressure of 160 psi. This makes it suitable for heavy-duty vehicles and commercial use. Its cordless feature allows for flexibility in use, and it can efficiently inflate multiple tires on a single charge. Additionally, consider inflators like the Viair 88P for heavy-duty trucks, as it excels in quickly inflating larger tires, albeit requiring a connection to the vehicle’s battery.

What are common payment terms in international B2B transactions for tire inflators?

Payment terms in international B2B transactions typically include options like Letter of Credit (LC), advance payment, or net terms (e.g., 30, 60, or 90 days). A Letter of Credit provides security for both buyers and suppliers, ensuring that payment is made only upon compliance with agreed terms. Buyers should negotiate terms that align with their cash flow and risk management strategies. Understanding the supplier’s preferred payment methods can also facilitate smoother transactions and foster stronger business relationships.

How can I vet suppliers for portable tire inflators?

Vetting suppliers involves a thorough evaluation process that includes checking their credentials, certifications, and industry reputation. Request references from previous clients and examine customer reviews to assess reliability and product quality. Conducting a factory audit can provide insights into their manufacturing processes and quality control measures. Additionally, ensure that they comply with international standards and regulations relevant to your region, which can help mitigate risks associated with product quality and delivery reliability.

What is the minimum order quantity (MOQ) for portable tire inflators?

Minimum order quantities (MOQs) for portable tire inflators can vary significantly based on the supplier and product specifications. Typically, MOQs range from 50 to 500 units. It is essential to clarify MOQs during negotiations to align with your purchasing strategy and inventory management. Some suppliers may offer flexibility on MOQs for first-time orders or bulk purchases, so it’s advisable to discuss your requirements directly with the supplier to find a mutually beneficial arrangement.

What shipping options are available for portable tire inflators?

Shipping options for portable tire inflators typically include air freight, sea freight, and express courier services. Air freight is faster but generally more expensive, making it suitable for urgent orders. Sea freight is cost-effective for larger shipments but takes longer. Express couriers offer a balance of speed and reliability for smaller orders. When selecting a shipping method, consider factors such as delivery time, cost, and the nature of your products, as well as any applicable customs regulations in your region.

How can I ensure quality assurance (QA) for tire inflators sourced internationally?

To ensure quality assurance for internationally sourced tire inflators, implement a robust QA process that includes pre-production samples, in-line inspections, and final product audits. Collaborate with suppliers to establish clear quality standards and inspection criteria. Additionally, consider third-party inspection services to verify compliance with specifications before shipment. Having a well-defined QA process can help minimize defects, ensure product reliability, and maintain customer satisfaction.

What are the key features to look for in a portable tire inflator for commercial use?

When sourcing portable tire inflators for commercial use, key features to consider include maximum psi capabilities, inflation speed, power options (battery or corded), and built-in pressure gauges for accuracy. Durability and ease of portability are also critical, especially for businesses requiring frequent transportation of equipment. Additional features like LED lights, multiple attachments for different inflatables, and compact storage solutions can enhance usability and make the inflator a versatile tool for various applications.

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Best Portable Tire Inflators:

1. **AstroAI Tire Inflator Portable Air Compressor**

– Type: 12-Volt Plug-In

– Price: $40.49 (currently $31.98 at Amazon)

– Pros: Durable, easy to use, multiple connections, digital pressure gauge, compact storage.

– Cons: Power cable can be a hassle to use and store.

2. **EMSON Bullseye Pro Digital Tire Inflator**

– Type: Battery-Operated …

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: This company, AstroAI – Portable Tire Inflator Air Compressor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In today’s competitive automotive market, the strategic sourcing of portable tire inflators is paramount for B2B buyers seeking high-quality, reliable products. The demand for efficient tire maintenance solutions is escalating, particularly in regions such as Africa, South America, the Middle East, and Europe, where varied terrain and climate conditions necessitate durable and effective inflators.

Illustrative image related to portable tire inflator car

Key takeaways include the importance of selecting inflators that balance performance with portability, ensuring they meet the diverse needs of end-users. Products like the AstroAI Cordless Tire Inflator and Craftsman 12V Max highlight the trend toward multifunctionality, offering features that extend beyond simple inflation—such as built-in pressure gauges and charging ports.

As international buyers consider their sourcing strategies, it’s crucial to prioritize suppliers who demonstrate quality assurance, innovative design, and customer support. By investing in reliable tire inflators, businesses can enhance customer satisfaction and reduce operational downtime.

Looking ahead, the market for portable tire inflators is poised for growth. B2B buyers are encouraged to explore partnerships with manufacturers who can provide cutting-edge solutions that cater to evolving consumer demands. Engaging with suppliers now will position businesses favorably in this expanding sector.

Illustrative image related to portable tire inflator car

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to portable tire inflator car