Navigating the complexities of the global market for tire maintenance solutions can be challenging for B2B buyers, particularly when sourcing reliable products like the Slime tire inflator. With the increasing demand for efficient and effective tire inflation solutions across regions such as Africa, South America, the Middle East, and Europe, understanding how to use these tools effectively is crucial. This comprehensive guide addresses key considerations, including the various types of Slime tire inflators available, their specific applications, and essential tips for supplier vetting.

By offering insights into operational features such as Inflate-Right Technology, ease of use, and maintenance requirements, this guide empowers international B2B buyers to make informed purchasing decisions. It emphasizes the importance of aligning product capabilities with regional needs, ensuring that businesses can enhance their service offerings while minimizing operational downtime.

Additionally, we will explore cost considerations, potential return on investment, and the implications of tire maintenance on overall vehicle performance. With this knowledge, B2B buyers will be better equipped to evaluate their options and select the most suitable Slime tire inflator for their specific markets and applications. This guide aims to serve as a valuable resource, transforming tire maintenance from a reactive task into a proactive strategy for business efficiency and customer satisfaction.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12V Digital Tire Inflator | Compact design, automatic shut-off, LED light, digital display | Automotive service centers, fleet management | Pros: Quick inflation, easy to use; Cons: Limited to 12V power sources. |

| Cordless Tire Inflator | Battery-operated, portable, no power outlet required | Roadside assistance, remote locations | Pros: High portability, no cords; Cons: Battery life may limit usage. |

| 120V Home/Garage Inflator | AC-powered, higher performance, suitable for home use | Garages, workshops, home mechanics | Pros: Fast inflation, high power; Cons: Limited to indoor use. |

| Multi-Purpose Inflator | Includes adapters for various inflatables, versatile applications | Sports facilities, event organizers | Pros: Versatile, can inflate multiple items; Cons: May lack tire-specific features. |

| Pro Power Inflator | Heavy-duty, high CFM output, designed for professional use | Automotive repair shops, heavy-duty vehicles | Pros: Fast and efficient, durable; Cons: Higher price point. |

The 12V Digital Tire Inflator is designed for everyday use, making it an essential tool for automotive service centers and fleet management operations. It features a compact design and an easy-to-read digital display that allows users to set the desired tire pressure. The automatic shut-off function ensures that tires are inflated to the correct pressure without the risk of over-inflation. This model is particularly suitable for businesses that require a reliable and efficient tire inflation solution on the go, although it is limited to 12V power sources.

Cordless Tire Inflators offer the ultimate in portability, making them ideal for roadside assistance teams and businesses operating in remote locations. These battery-operated models eliminate the need for a power outlet, allowing for quick inflation of tires anywhere. While they provide convenience and ease of use, buyers should consider the battery life, as it may limit the number of inflations possible on a single charge. This type is particularly suitable for companies that prioritize mobility and require quick service response times.

The 120V Home/Garage Inflator is designed for high-performance applications, making it suitable for garages and workshops where power supply is readily available. This model typically inflates tires faster than its portable counterparts due to its higher power output. Businesses that perform regular tire maintenance or repairs will find this type particularly beneficial. However, it is important to note that this model is limited to indoor use, which may not be ideal for all B2B applications.

Multi-Purpose Inflators are versatile tools that come with various adapters, allowing them to inflate not just tires but also sports equipment and other inflatables. This makes them an excellent choice for sports facilities and event organizers who need a single device for multiple tasks. While they offer flexibility, they may lack some tire-specific features found in dedicated tire inflators. Businesses should consider their specific needs when choosing this type, particularly if they require frequent tire inflation.

The Pro Power Inflator is designed for professional use, featuring a high CFM output that allows for rapid inflation of larger tires commonly found on heavy-duty vehicles. This model is ideal for automotive repair shops and businesses that require a durable and efficient tire inflation solution. While it provides excellent performance, buyers should be prepared for a higher price point compared to standard inflators. This investment is justified for businesses that prioritize speed and reliability in tire maintenance.

| Industry/Sector | Specific Application of how to use slime tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | On-site tire inflation for vehicles in repair shops | Reduces downtime, enhances customer service | Ensure compatibility with various tire sizes and types |

| Transportation & Logistics | Emergency tire inflation for fleets | Minimizes vehicle downtime, improves operational efficiency | Look for durability and ease of use in rugged environments |

| Agriculture | Tire maintenance for agricultural machinery | Prevents costly delays during harvest seasons | Consider inflator power and portability for remote locations |

| Construction | Tire inflation for heavy equipment and machinery | Ensures operational readiness and safety on-site | Evaluate pressure range and reliability under heavy loads |

| Sports & Recreation | Inflating tires for bicycles and recreational vehicles | Enhances user experience and safety for customers | Multi-purpose capabilities for various inflatables required |

In the automotive repair sector, the Slime tire inflator is an essential tool for quick and efficient tire inflation. Repair shops can use it to address customer needs immediately, minimizing the time vehicles spend in the shop. This not only enhances service quality but also improves customer satisfaction and retention. Buyers in this sector should prioritize inflators that can handle diverse tire sizes and offer reliable performance, as rapid service is critical in a competitive market.

For transportation and logistics companies, the Slime tire inflator serves a crucial role in fleet maintenance. It allows for quick tire inflation during roadside emergencies, significantly reducing vehicle downtime. This capability is vital for maintaining schedules and ensuring timely deliveries. When sourcing, businesses should consider the inflator’s durability and ease of use in various weather conditions, as well as its compatibility with different vehicle types.

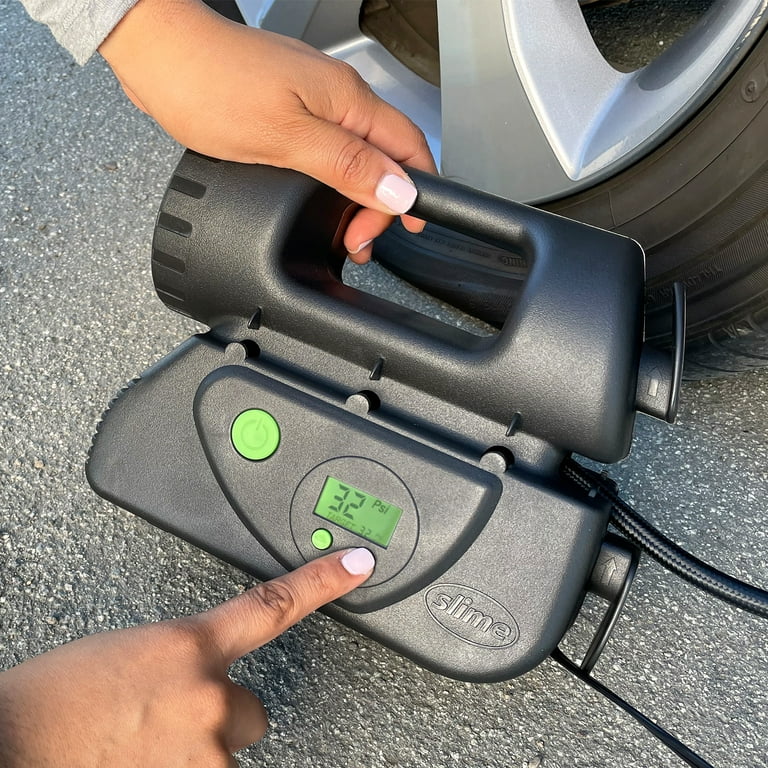

Illustrative image related to how to use slime tire inflator

In agriculture, the Slime tire inflator is used to maintain the tires of farm machinery, which is essential during peak operational periods like harvest. By preventing tire issues, it helps avoid costly delays that could impact productivity. Buyers in this sector must look for inflators that are portable and powerful enough to handle the larger tires found on agricultural equipment, ensuring they can operate effectively in remote and rugged locations.

On construction sites, the Slime tire inflator is vital for ensuring that heavy machinery and vehicles are always ready for use. Quick tire inflation contributes to operational efficiency and enhances safety, as properly inflated tires reduce the risk of accidents. Construction firms should evaluate the inflator’s pressure range and reliability under heavy loads, as these factors are critical for maintaining productivity in demanding environments.

In the sports and recreation industry, the Slime tire inflator is commonly used to inflate tires for bicycles and other recreational vehicles. This convenience enhances the user experience, ensuring that customers can enjoy their activities without delay. When sourcing for this application, businesses should seek inflators that offer multi-purpose capabilities, allowing them to handle various inflatables beyond just tires, catering to a broader range of customer needs.

The Problem: B2B buyers often encounter challenges when it comes to accurately setting the desired tire pressure on the Slime tire inflator. This issue can stem from a lack of familiarity with tire specifications or the specific model of the inflator being used. In commercial settings, where multiple vehicles with varying tire pressures are involved, this can lead to improper inflation, affecting vehicle safety and fuel efficiency.

The Solution: To mitigate this issue, B2B buyers should first ensure they have access to the tire pressure specifications for each vehicle, which can typically be found on a sticker inside the driver’s side door or in the owner’s manual. It’s essential to train staff on how to use the Slime tire inflator’s Inflate-Right Technology, which allows users to set the desired pressure digitally. A practical tip is to create a quick-reference guide that includes the recommended pressures for all vehicles in the fleet, affixing it near the inflator for easy access. This way, users can swiftly adjust the inflator settings without second-guessing, ensuring each tire is inflated correctly for optimal performance.

Illustrative image related to how to use slime tire inflator

The Problem: In regions with extreme temperatures, such as parts of Africa or the Middle East, the performance of tire inflators can be inconsistent. B2B buyers may find that their Slime tire inflator overheats or struggles to inflate tires efficiently, particularly when used frequently in a short time frame. This situation can lead to downtime, which is detrimental for businesses relying on their vehicles for logistics or transportation.

The Solution: To overcome performance issues in high temperatures, it is advisable to implement a cooling strategy. Users should allow the inflator to rest between uses, particularly after inflating multiple tires. Additionally, sourcing a model with built-in heat dissipation features can significantly improve durability. Buyers should also consider investing in multiple inflators to distribute usage among them during peak periods, reducing the risk of overheating. Regular maintenance checks, such as cleaning the air intake and ensuring the hose is free from obstructions, can also help maintain optimal functionality.

The Problem: B2B buyers in sectors like recreational vehicle rentals or automotive repair may struggle with using the correct adapters that come with the Slime tire inflator for various inflatable items, such as sports equipment or pool accessories. Misunderstandings can lead to wasted time and frustration, especially when a quick response is needed, such as during an emergency roadside assistance situation.

Illustrative image related to how to use slime tire inflator

The Solution: To streamline the process, businesses should categorize and label the included adapters for specific uses clearly. Creating an instructional guide or video demonstrating how to use each adapter can further enhance understanding. Additionally, organizing the adapters in a dedicated storage compartment within the inflator’s carrying case can prevent confusion and ensure that users have quick access to the correct tool. Establishing a standard operating procedure for inflator usage, including a checklist of items to inflate, can also help staff respond efficiently in various scenarios, ensuring customer satisfaction and operational efficiency.

When considering the materials used in the construction of Slime tire inflators, it’s essential to focus on those that enhance performance, durability, and user safety. Here, we analyze four common materials: plastic, rubber, metal, and electronic components, each with unique properties and implications for international B2B buyers.

Key Properties: Plastic is lightweight, resistant to corrosion, and can withstand a range of temperatures, making it suitable for various environments. Common plastics used include ABS (Acrylonitrile Butadiene Styrene) and polypropylene, which offer good impact resistance.

Pros & Cons: The primary advantages of plastic include its low cost and ease of manufacturing, allowing for complex shapes and designs. However, plastics may not withstand extreme temperatures or heavy mechanical stress, leading to potential failures in harsh conditions.

Impact on Application: Plastic components are typically used in housing and casing, providing protection for internal mechanisms. However, they may not be suitable for high-pressure applications where metal alternatives are preferred.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers in regions like Africa and South America should also consider the availability of recycled materials, which can influence sustainability practices.

Key Properties: Rubber is known for its excellent elasticity and resilience, making it ideal for seals and hoses. It can withstand a wide range of temperatures and pressures, which is critical for tire inflation applications.

Pros & Cons: The primary advantage of rubber is its durability and ability to maintain performance under pressure. However, it can degrade over time due to exposure to ozone and UV light, necessitating regular inspections and replacements.

Impact on Application: Rubber components are essential for ensuring airtight seals in the inflator’s hose and valve connections, directly impacting the efficiency of tire inflation.

Considerations for International Buyers: Buyers should ensure that the rubber used meets regional standards for automotive applications. In markets like the Middle East, where temperatures can be extreme, selecting high-quality rubber is essential for long-term reliability.

Key Properties: Metals such as aluminum and steel provide high strength and durability, with excellent pressure ratings. They are resistant to deformation under stress, making them ideal for critical components like the inflator’s body and connectors.

Pros & Cons: The advantages of metal include long-lasting performance and resistance to wear and tear. However, metal components can be heavier and more expensive to manufacture, which may impact the overall cost of the inflator.

Illustrative image related to how to use slime tire inflator

Impact on Application: Metal parts are crucial in high-pressure areas, ensuring the inflator can safely handle the pressures required for effective tire inflation.

Considerations for International Buyers: Compliance with metal standards such as JIS or DIN is vital for ensuring safety and reliability. Buyers in Europe and the Middle East should prioritize suppliers who adhere to these standards to avoid potential liabilities.

Key Properties: Electronic components, including microcontrollers and sensors, are essential for features like digital displays and automatic shut-off mechanisms. They operate effectively within a wide range of temperatures and are designed to be energy-efficient.

Illustrative image related to how to use slime tire inflator

Pros & Cons: The main advantages of electronic components include enhanced functionality and user convenience. However, they can be sensitive to environmental conditions, such as moisture and extreme temperatures, which may affect their reliability.

Impact on Application: Electronics enable features like Inflate-Right Technology, which automatically shuts off the inflator once the desired pressure is reached, enhancing user safety and convenience.

Considerations for International Buyers: Buyers should ensure that electronic components comply with international safety standards, particularly in regions with strict regulations like Europe. Additionally, understanding the warranty and service options for electronic parts is crucial for long-term use.

| Material | Typical Use Case for how to use slime tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and casing | Lightweight and cost-effective | Limited temperature resistance | Low |

| Rubber | Seals and hoses | Excellent elasticity and durability | Degrades under UV exposure | Medium |

| Metal | Body and connectors | High strength and durability | Heavier and more expensive | High |

| Electronic | Control systems and displays | Enhanced functionality | Sensitive to environmental factors | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to understand the implications of material choices in the performance and reliability of Slime tire inflators, especially in diverse international markets.

The manufacturing process for Slime tire inflators involves several critical stages, each designed to ensure efficiency and product reliability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the careful selection of raw materials, which typically include high-quality plastics for the casing, metal components for the internal mechanisms, and rubber for seals. Suppliers are often vetted to meet specific material standards, ensuring durability and performance.

Forming: In this stage, components are shaped using techniques such as injection molding for plastic parts and stamping for metal components. Advanced machinery is employed to guarantee precision and consistency, which is crucial for the overall functionality of the inflator.

Assembly: After forming, the components are assembled in a clean environment to prevent contamination. Automated assembly lines are often utilized to enhance speed and accuracy. Each unit undergoes initial testing for basic functionality before moving to the quality control stage.

Finishing: The final stage involves surface treatments and packaging. This may include painting, labeling, and the application of protective coatings. Finished products are prepared for shipment, ensuring they meet aesthetic and functional standards.

Quality assurance (QA) is integral to the manufacturing of Slime tire inflators, adhering to various international standards and industry-specific regulations.

International Standards: Slime products are manufactured in compliance with ISO 9001, a global standard that focuses on quality management systems. This certification ensures that companies consistently meet customer and regulatory requirements. Additional certifications like CE mark for compliance with European safety standards are also common in the production of inflators.

Industry-Specific Standards: Depending on the target market, Slime may also adhere to specific standards such as those set by the American Petroleum Institute (API) for products used in automotive applications. Compliance with these standards not only boosts product credibility but also assures buyers of the safety and reliability of the inflators.

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival. This includes testing for material integrity and conformity to specifications.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken at various stages to ensure that production processes are followed correctly and that any deviations are addressed immediately.

– Final Quality Control (FQC): After assembly, each tire inflator undergoes rigorous testing, including functional tests to verify inflation performance and pressure accuracy. This is where the effectiveness of features like Inflate-Right Technology is evaluated.

To ensure that each Slime tire inflator performs reliably, several common testing methods are employed:

Illustrative image related to how to use slime tire inflator

Functional Testing: Each unit is tested to ensure it inflates tires to the set pressure accurately. This involves measuring the time taken to inflate to a specific PSI and confirming the automatic shut-off feature works correctly.

Durability Testing: Inflators are subjected to stress tests simulating extreme conditions to evaluate how they perform under high usage scenarios. This helps identify any potential failure points.

Electrical Safety Testing: For electric models, tests are conducted to ensure electrical components meet safety standards, reducing the risk of short circuits or overheating.

B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality control processes:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, processes, and adherence to quality standards. This is crucial for understanding the supplier’s commitment to quality.

Quality Assurance Reports: Requesting documentation such as quality assurance reports and certifications can provide insight into the supplier’s compliance with international standards.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the product quality and compliance with agreed specifications before shipment. This can be particularly useful for international transactions.

For international B2B buyers, understanding the nuances of quality control and certification is vital to ensure product safety and compliance:

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers must be aware of local requirements, such as safety certifications in the EU or specific automotive standards in the Middle East.

Cultural and Market Differences: Quality expectations may vary across markets. For instance, European buyers might prioritize environmental sustainability, while buyers in the Middle East may focus on durability under extreme conditions.

Logistics and Supply Chain Considerations: The ability to meet quality standards can also be affected by the logistics of getting products from the manufacturer to the buyer. Buyers should ensure that the supplier has robust logistics in place to maintain quality during transportation.

Understanding the manufacturing processes and quality assurance measures for Slime tire inflators is essential for B2B buyers aiming to make informed purchasing decisions. By recognizing the key stages in manufacturing, the importance of quality control, and methods for verifying supplier reliability, businesses can ensure they select high-quality products that meet their operational needs.

This guide serves as a practical checklist for B2B buyers interested in procuring and effectively utilizing the Slime Tire Inflator. By following these steps, businesses can ensure they are making informed decisions, optimizing their tire maintenance processes, and ultimately enhancing operational efficiency.

Illustrative image related to how to use slime tire inflator

Before using a tire inflator, it’s vital to know the correct tire pressure for your vehicles. This information is typically found on a sticker inside the driver’s side door or in the vehicle’s manual. Proper tire pressure is crucial not only for vehicle safety but also for fuel efficiency and tire longevity.

Slime offers various models, including digital and cordless options. Assess your specific needs based on vehicle type and usage frequency. For instance, the 12V Digital Tire Inflator is suitable for everyday use, while a more robust model may be necessary for commercial vehicles.

Research potential suppliers thoroughly. Verify their certifications, industry experience, and customer reviews to ensure reliability. A reputable supplier will provide comprehensive product information and after-sales support.

Check the warranty terms for the Slime Tire Inflator and what support services are available. A solid warranty can protect your investment, while responsive customer support can assist with any operational issues.

Illustrative image related to how to use slime tire inflator

Once procured, it’s crucial to train your staff on how to use the tire inflator effectively. This ensures safety and maximizes the inflator’s benefits, reducing the risk of operational disruptions.

Regular maintenance of the inflator itself is essential for longevity and performance. Set a schedule to check the device for any wear and tear, ensuring that it remains functional and reliable for your tire maintenance needs.

After implementation, continually assess the performance of the Slime Tire Inflator within your operations. Gather feedback from users to identify any areas for improvement in usage or training.

By adhering to this checklist, B2B buyers can streamline their procurement process and enhance their operational capabilities with the Slime Tire Inflator.

When evaluating the cost structure of sourcing a Slime tire inflator, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

Materials: The primary materials for a tire inflator include plastics for the casing, metal components for the motor, and electronic parts for the display and controls. Sourcing high-quality materials can significantly impact the overall cost.

Labor: Labor costs vary depending on the region of production. In countries with higher labor costs, the manufacturing expenses will increase, whereas sourcing from regions with lower labor costs can lead to significant savings.

Manufacturing Overhead: This includes utilities, factory rent, and other operational costs associated with production. Efficient manufacturing processes can minimize overhead costs, thereby reducing the final price.

Tooling: The initial investment in tooling and molds can be substantial, especially for custom designs. These costs are typically amortized over production volume, influencing the unit price.

Quality Control: Implementing rigorous QC processes ensures product reliability and compliance with international standards. While this adds to the cost, it can reduce returns and increase customer satisfaction, making it a worthwhile investment.

Logistics: Transportation costs can vary widely based on the shipping method, distance, and Incoterms. Understanding these factors is crucial for accurate cost estimation.

Margin: Finally, suppliers will incorporate a profit margin into the pricing structure. This can vary significantly based on market demand and competition.

Several factors can influence the pricing of Slime tire inflators, particularly for international B2B buyers.

Volume/MOQ: Minimum order quantities (MOQs) can lead to discounts; larger orders often result in lower per-unit costs. Buyers should assess their needs and negotiate accordingly.

Specifications and Customization: Custom features or specifications can significantly increase the price. Buyers should weigh the necessity of these customizations against their budget.

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO) can enhance product reliability but may also raise costs. Buyers should ensure that the quality justifies the expense.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while newer suppliers might offer lower prices to gain market share.

Incoterms: The chosen Incoterms can affect the total landed cost of the product. Buyers should carefully select terms that align with their logistics capabilities and financial strategies.

Navigating the cost structure and pricing nuances of Slime tire inflators can be challenging, especially for international buyers from diverse regions.

Illustrative image related to how to use slime tire inflator

Negotiate Effectively: Leverage your purchasing power and market knowledge to negotiate better terms. Suppliers may be more willing to offer discounts for larger orders or long-term contracts.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential savings from improved fuel efficiency due to properly inflated tires. This broader perspective can help justify higher upfront costs.

Understand Pricing Nuances in Different Regions: International buyers should be aware of currency fluctuations, tariffs, and import duties that can affect pricing. It is advisable to conduct thorough market research to mitigate these risks.

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, improved service, and access to exclusive products. Long-term partnerships often yield the best value.

Evaluate After-Sales Support: Ensure that suppliers provide adequate support, including warranty terms and customer service. This can save costs in the long run by minimizing downtime and repair expenses.

By considering these aspects, B2B buyers can make informed decisions, ensuring they source Slime tire inflators that meet their needs while optimizing costs.

Exploring alternatives to the Slime tire inflator can provide valuable insights for B2B buyers looking for effective tire inflation solutions. With various technologies and methods available in the market, understanding their advantages and limitations is crucial for making an informed decision. Below, we compare the Slime tire inflator with two viable alternatives: a traditional air compressor and a CO2 tire inflator.

| Comparison Aspect | How To Use Slime Tire Inflator | Traditional Air Compressor | CO2 Tire Inflator |

|---|---|---|---|

| Performance | Inflates a standard car tire in approximately 6 minutes. Equipped with digital pressure settings. | Typically faster, inflating a tire in 2-4 minutes, depending on the model. | Can inflate a tire in under 2 minutes but may require multiple cartridges for larger tires. |

| Cost | Generally priced around $99.99, often found on sale. | Ranges from $50 to $200, depending on features and brand. | Each cartridge costs around $5-$10, with multiple cartridges needed for larger tires. |

| Ease of Implementation | Simple setup: plug into a 12V socket, set pressure, and start. | Requires more setup and may involve connecting to a power outlet or car battery. | Very portable and easy to use, but limited to a number of uses per cartridge. |

| Maintenance | Minimal maintenance required; just keep it clean and check for wear. | Regular maintenance needed, including oiling and filter changes. | No maintenance, but cartridges must be replaced after use. |

| Best Use Case | Ideal for everyday use and emergencies; compact and easy to store. | Best for workshops and frequent users needing high volume. | Suitable for off-road or emergency use; lightweight and portable. |

A traditional air compressor is a robust alternative that can deliver higher volume air quickly, making it suitable for frequent users, such as automotive workshops. The main advantage is its speed and versatility, as it can power multiple pneumatic tools. However, it often requires regular maintenance, which can lead to additional costs and downtime. Furthermore, its size and need for a power source can limit portability.

The CO2 tire inflator offers a highly portable solution for tire inflation, particularly beneficial in off-road scenarios or emergencies. It is lightweight and easy to use, allowing users to quickly inflate tires without needing an electrical source. However, the primary drawback is the need to carry multiple cartridges for larger tires or multiple uses, which can become expensive and cumbersome. Additionally, it lacks the precision of digital inflators like the Slime model.

Illustrative image related to how to use slime tire inflator

When selecting a tire inflation solution, B2B buyers should consider their specific needs and usage patterns. The Slime tire inflator is an excellent choice for those requiring convenience and ease of use in everyday situations. In contrast, traditional air compressors are better suited for high-volume applications, while CO2 inflators excel in portability and emergency scenarios. Evaluating performance, cost, and maintenance will help businesses choose the most suitable option for their tire inflation requirements.

When considering the purchase of a Slime tire inflator for your business, understanding its technical specifications is critical. Here are some key properties that influence performance and usability:

Inflation Time

The average inflation time for a standard mid-sized car tire is approximately 6 minutes. This property is crucial for businesses that require efficiency in operations, especially in automotive service or roadside assistance. A faster inflation time reduces downtime and enhances customer satisfaction.

Pressure Range and Accuracy

Slime tire inflators typically feature a digital display that measures pressure from 0 to 99 psi. This range allows users to inflate various tire sizes accurately. The precision of the pressure gauge is vital in ensuring optimal tire performance, which can lead to improved fuel efficiency and tire longevity—a key consideration for fleet management.

Power Source

Most Slime inflators operate on a 12-volt power supply, connecting to the vehicle’s accessory socket. Understanding the power requirements is essential for businesses operating in regions with varying electrical standards. Knowing whether the inflator can work with both AC and DC sources can also expand its usability across different applications.

Built-in Safety Features

Many models come with features like automatic shut-off when the desired pressure is reached, often referred to as “Inflate-Right Technology.” This safety measure prevents over-inflation and potential tire damage. For businesses, this reduces liability and enhances operational efficiency.

Size and Portability

Compact designs (e.g., 8.5 x 6.0 x 4.5 inches) make the inflators easily transportable. This is particularly beneficial for mobile service providers and those with limited storage space. Portability can be a deciding factor for companies looking to optimize their service offerings.

Versatility with Adaptors

Slime inflators often come with multiple adaptors for inflating various items such as sports equipment and inflatable products. This feature enhances the inflator’s usability, making it a valuable tool for businesses beyond just automotive applications.

Understanding industry terminology can enhance communication and negotiations with suppliers. Here are several key terms relevant to purchasing Slime tire inflators:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Knowing whether Slime products are OEM can affect purchasing decisions, particularly in terms of quality assurance and compatibility.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This is crucial for B2B buyers to understand, as it impacts inventory levels and cash flow management. Negotiating MOQs can lead to cost savings and better inventory turnover.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other terms for specific products or services. Businesses can use RFQs to gather competitive pricing for Slime tire inflators, ensuring they obtain the best value.

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers importing Slime products, as they dictate shipping costs, risks, and responsibilities.

Warranty and Service Terms

Warranty details outline the conditions under which repairs or replacements will be provided. For B2B buyers, understanding warranty terms can mitigate risks associated with product failures and enhance customer satisfaction.

Lead Time

This term refers to the time taken from placing an order to delivery. Knowing lead times is vital for inventory planning and ensuring that businesses have the necessary inflators on hand to meet customer demand.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, optimize their procurement processes, and enhance their operational efficiencies when utilizing Slime tire inflators.

Illustrative image related to how to use slime tire inflator

The global market for tire inflators, particularly Slime tire inflators, is experiencing significant growth driven by increasing vehicle ownership and the rising need for roadside assistance. In regions like Africa, South America, the Middle East, and Europe, the demand for reliable and efficient tire maintenance solutions is heightened due to varying road conditions and climatic challenges. Emerging markets are witnessing a surge in automobile sales, leading to a higher necessity for tire maintenance products.

Current B2B tech trends include the adoption of digital displays and automated pressure settings, as seen in Slime’s Inflate-Right Technology. This innovation not only enhances user experience but also reduces the risk of over-inflation, a common concern among users. Furthermore, the integration of smart technology, such as connectivity features for mobile apps, is emerging, offering businesses opportunities to enhance customer engagement and satisfaction.

Market dynamics are shifting as buyers seek value-added services, including warranties and customer support. Companies are increasingly focusing on sourcing high-quality products that can withstand harsh conditions while being easy to use. This trend is particularly relevant in regions with less reliable roadside assistance, where having a dependable inflator can be critical.

Sustainability is becoming a cornerstone for businesses in the tire inflator sector. The environmental impact of manufacturing processes and product life cycles is under scrutiny, leading companies to seek eco-friendly materials and production methods. For example, Slime is focusing on reducing waste by promoting reusable sealants and recyclable packaging, which not only appeals to environmentally conscious consumers but also aligns with global sustainability goals.

Ethical sourcing is equally important as international buyers increasingly prioritize suppliers that adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade can help businesses identify partners that meet these ethical standards. By investing in sustainable and ethically sourced products, companies can enhance their brand reputation and appeal to a broader customer base.

Additionally, the use of ‘green’ materials in manufacturing tire inflators, such as recyclable plastics and non-toxic sealants, is gaining traction. This shift not only mitigates environmental impact but also responds to regulatory pressures and consumer demand for sustainable products.

The evolution of tire inflators has been marked by significant technological advancements. Initially, tire inflators were bulky, manual devices requiring substantial physical effort to operate. Over the decades, the introduction of electric and portable models revolutionized the market, making tire inflation more accessible and efficient.

Slime, as a brand, has played a pivotal role in this transformation by integrating innovative features such as digital displays and automatic shut-off mechanisms. These advancements have not only improved usability but have also set new industry standards. The focus has shifted from merely inflating tires to providing comprehensive solutions that enhance safety and convenience for drivers worldwide.

As tire inflators continue to evolve, the emphasis on smart technology and user-friendly design will likely shape future developments, catering to the increasing demands of international B2B buyers who prioritize efficiency and reliability in their sourcing decisions.

Illustrative image related to how to use slime tire inflator

1. How do I solve tire inflation issues with the Slime tire inflator?

To effectively solve tire inflation problems using the Slime tire inflator, start by ensuring your inflator is plugged into a 12V power source. Check the tire’s recommended pressure, which can be found on a sticker inside the vehicle or in the owner’s manual. Set the desired pressure on the digital display using the controls, attach the hose to the tire valve, and power on the inflator. It will automatically shut off once the preset pressure is reached, allowing you to inflate tires efficiently and accurately.

2. What is the best practice for maintaining the Slime tire inflator?

To maintain the Slime tire inflator, store it in a dry, cool place to prevent moisture and heat damage. Regularly check the power cable and hose for any signs of wear or damage. Clean the nozzle after each use to ensure a proper seal during inflation. Additionally, periodically test the inflator to ensure it functions correctly, particularly before long trips or seasonal changes, to guarantee it will perform when needed.

3. How can I customize the Slime tire inflator for my business needs?

Customization options for the Slime tire inflator may include branding with your company logo or selecting specific accessories that cater to your target market. When sourcing from suppliers, inquire about bulk orders that allow for customization. Many manufacturers are open to discussing unique features or packaging that align with your business goals, ensuring that the product meets the specific requirements of your clientele.

4. What are the minimum order quantities (MOQs) for purchasing Slime tire inflators?

Minimum order quantities (MOQs) for Slime tire inflators can vary by supplier. Generally, MOQs are set to ensure cost-effectiveness in manufacturing and shipping. When negotiating with suppliers, clarify the MOQ upfront, and consider discussing the potential for lower MOQs if you are a new customer or if you are willing to pay a premium. This approach can help you manage inventory and minimize financial risk.

5. What payment terms should I expect when sourcing Slime tire inflators internationally?

When sourcing Slime tire inflators internationally, payment terms can vary significantly among suppliers. Common terms include payment in advance, 30% deposit with the remainder before shipping, or net payment after delivery. Be sure to negotiate terms that suit your cash flow needs while ensuring that they are competitive and secure. It’s also wise to utilize trusted payment methods to mitigate risks in international transactions.

6. How do I vet suppliers for Slime tire inflators in international markets?

Vetting suppliers for Slime tire inflators involves researching their business credentials, reviewing customer feedback, and verifying their manufacturing processes. Request references from other B2B clients and assess their responsiveness and professionalism during initial communications. Consider conducting background checks or using third-party services to ensure they are reputable. It’s crucial to establish clear communication to address any concerns before placing large orders.

7. What quality assurance (QA) measures should I implement when sourcing tire inflators?

Implementing quality assurance (QA) measures is essential when sourcing tire inflators. Start by requesting certifications that verify compliance with international safety and performance standards. Conduct sample testing of the inflators to assess their functionality and durability. Establish clear QA protocols with your supplier that include regular inspections, audits, and performance testing to ensure that the products meet your specifications consistently.

8. What logistics considerations should I keep in mind when importing Slime tire inflators?

When importing Slime tire inflators, logistics considerations include shipping methods, lead times, and customs regulations specific to your country. Evaluate the total landed cost, including shipping fees, taxes, and potential tariffs. Collaborate with a logistics provider experienced in international shipping to streamline the process and ensure timely delivery. Additionally, stay informed about import regulations to avoid delays or additional costs during customs clearance.

Illustrative image related to how to use slime tire inflator

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Tire Inflation Adapter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: manuals.plus

Introduction: Slime 40050 Tire Inflator; Steps to inflate a tire: 1. Attach the valve connector to the tire’s valve stem. 2. Plug the power cord into the 12-volt accessory power outlet in your vehicle. 3. Press the on/off button to turn on the inflator. 4. Inflate the tire to the manufacturer’s recommended air pressure (found in the vehicle owner’s manual or on the driver’s side door jamb). 5. Press the on/off …

Domain: thedrive.com

Registered: 2000 (25 years)

Introduction: Product Name: Slime Digital Pro Power Tire Inflator

Retail Price: $99.99 (often found on sale for $89.99)

Dimensions: 8.5 x 6.0 x 4.5 inches

Power Source: 12V socket

Output: 1.23 CFM without load

Hose Length: 15 feet coiled hose

Included Accessories: Adaptors for sports balls and pool floaties

Inflation Time: 1 minute, 54 seconds to inflate a tire from 9 psi to 35 psi

Key Features: Digital preset …

Incorporating Slime tire inflators into your operations offers significant advantages, particularly in ensuring vehicle readiness and minimizing downtime. The ease of use, facilitated by features such as the Inflate-Right Technology and a digital pressure display, allows for quick and efficient tire maintenance—critical for businesses that rely on transportation. Furthermore, these inflators can enhance overall safety, reduce fuel costs through proper tire inflation, and demonstrate a commitment to proactive vehicle management.

Strategic sourcing is essential when selecting tire inflators for your fleet or retail offerings. By leveraging supplier relationships and understanding market dynamics, businesses can secure favorable pricing and terms, ensuring that they obtain high-quality products that meet their specific operational needs. This approach not only maximizes value but also aligns with broader sustainability goals by promoting reliable, long-lasting equipment.

As you look to the future, consider the potential of Slime tire inflators to streamline your operations across diverse markets, including Africa, South America, the Middle East, and Europe. Emphasizing quality and efficiency in your procurement strategy will position your business for success. Engage with suppliers who understand local market nuances and can provide tailored support. Equip your fleet with Slime tire inflators today to enhance operational efficiency and drive long-term value in your business.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to use slime tire inflator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.