In the competitive landscape of the global transportation industry, sourcing an efficient Meritor tire inflation system (MTIS) can be a daunting challenge for businesses. With rising fuel costs and the growing emphasis on sustainability, tire maintenance has never been more critical. An effective tire inflation system not only enhances vehicle safety but also significantly improves operational efficiency by reducing downtime and increasing fuel economy. This guide serves as a comprehensive resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including emerging markets like Brazil and Vietnam.

Within this guide, we explore various types of Meritor tire inflation systems, their applications across different sectors, and the latest technological advancements that enhance their functionality. We provide actionable insights on supplier vetting processes, ensuring you can identify reliable partners who meet your quality standards. Additionally, we discuss cost considerations, helping you to make informed financial decisions that align with your business goals.

By equipping you with the necessary knowledge and strategies, this guide empowers you to navigate the complexities of sourcing a Meritor tire inflation system effectively. Whether you are looking to enhance fleet performance or reduce maintenance costs, understanding the nuances of this vital component will enable you to make informed purchasing decisions that drive your business forward.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MTIS® Standard System | Basic inflation control, manual monitoring required | Freight transport, construction vehicles | Pros: Cost-effective, simple installation. Cons: Requires manual checks, less automation. |

| MTIS® Advanced System | Automated inflation monitoring and adjustments | Long-haul trucking, logistics management | Pros: Reduces tire wear, enhances fuel efficiency. Cons: Higher initial investment. |

| MTIS® Dual System | Supports dual tire configurations for stability | Heavy-duty trucks, specialized vehicles | Pros: Improved handling, better load distribution. Cons: More complex installation, maintenance. |

| MTIS® Smart Tire Management | Integrated with telematics for real-time data | Fleet management, rental services | Pros: Data-driven insights, predictive maintenance. Cons: Requires compatible vehicle systems. |

| MTIS® Retrofit Kit | Upgrades existing systems to modern standards | Fleet upgrades, cost-effective solutions | Pros: Extends tire life, reduces downtime. Cons: Compatibility issues with older vehicles. |

The MTIS® Standard System is designed for basic tire inflation control. It involves manual monitoring, making it suitable for businesses that prioritize budget over automation. This system is ideal for freight transport and construction vehicles where cost-effective solutions are critical. While the initial investment is low and installation is straightforward, users must commit to regular manual checks, which can be a drawback for larger fleets needing efficiency.

The MTIS® Advanced System offers automated inflation monitoring and adjustments, significantly benefiting long-haul trucking and logistics management. This system minimizes tire wear and optimizes fuel efficiency through continuous monitoring and automatic adjustments. Although it requires a higher initial investment, the potential for reduced operational costs and improved vehicle performance makes it a compelling choice for businesses focused on long-term savings.

The MTIS® Dual System is specifically engineered for vehicles with dual tire configurations, enhancing stability and load distribution. This system is particularly advantageous for heavy-duty trucks and specialized vehicles that carry substantial loads. While it provides improved handling and safety, the complexity of installation and maintenance may deter some buyers, making it essential for businesses to assess their capabilities before investing.

The MTIS® Smart Tire Management system integrates with telematics for real-time data collection and analysis, making it an excellent choice for fleet management and rental services. This system enables businesses to gain data-driven insights and predictive maintenance capabilities, leading to proactive decision-making. However, its reliance on compatible vehicle systems may limit its applicability for some fleets, necessitating careful evaluation of existing infrastructure.

The MTIS® Retrofit Kit allows businesses to upgrade their existing tire inflation systems to modern standards without the need for complete vehicle replacement. This cost-effective solution is ideal for fleet upgrades, extending tire life and reducing downtime. However, compatibility issues with older vehicles can pose challenges, making it crucial for buyers to verify specifications before proceeding with the retrofit.

| Industry/Sector | Specific Application of meritor tire inflation system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Automatic tire pressure maintenance for fleet vehicles | Reduces tire wear and enhances fuel efficiency | Compatibility with various vehicle models and tire types |

| Mining & Construction | Tire inflation system for heavy-duty machinery | Increases operational uptime and safety | Ability to withstand harsh environments and heavy loads |

| Agriculture | Tire inflation for agricultural equipment | Improves traction and reduces soil compaction | Adaptability to different soil types and weather conditions |

| Public Transport | Centralized tire inflation for buses and coaches | Enhances passenger safety and comfort | Regulatory compliance and integration with existing systems |

| Waste Management | Tire inflation for waste collection vehicles | Decreases maintenance costs and downtime | Durability against debris and rough terrains |

In the transportation and logistics sector, the Meritor tire inflation system is essential for maintaining optimal tire pressure in fleet vehicles. This automated system not only reduces tire wear but also enhances fuel efficiency, leading to significant cost savings. International buyers must consider compatibility with various vehicle models and tire types, ensuring that the system can be seamlessly integrated into existing fleets.

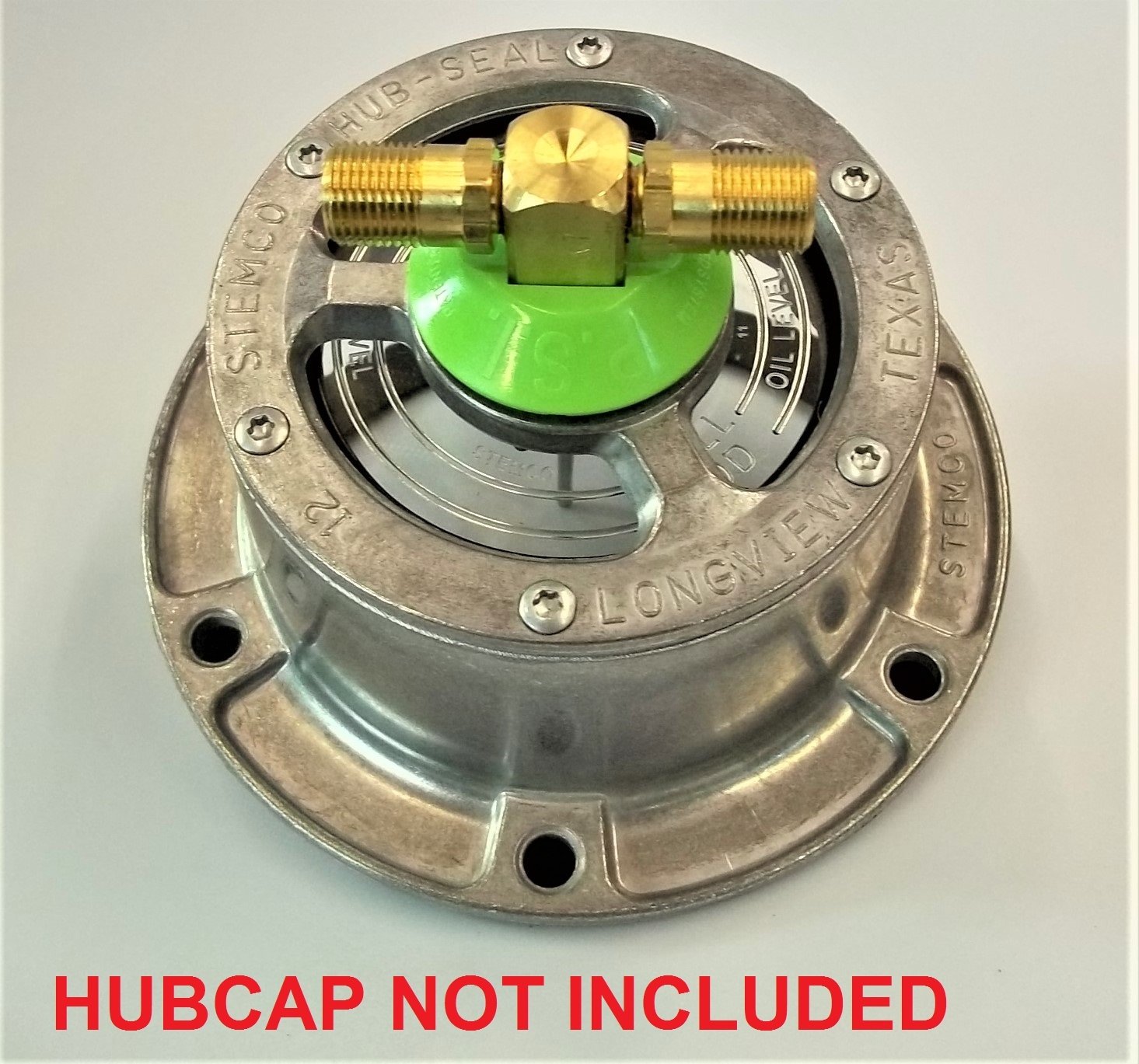

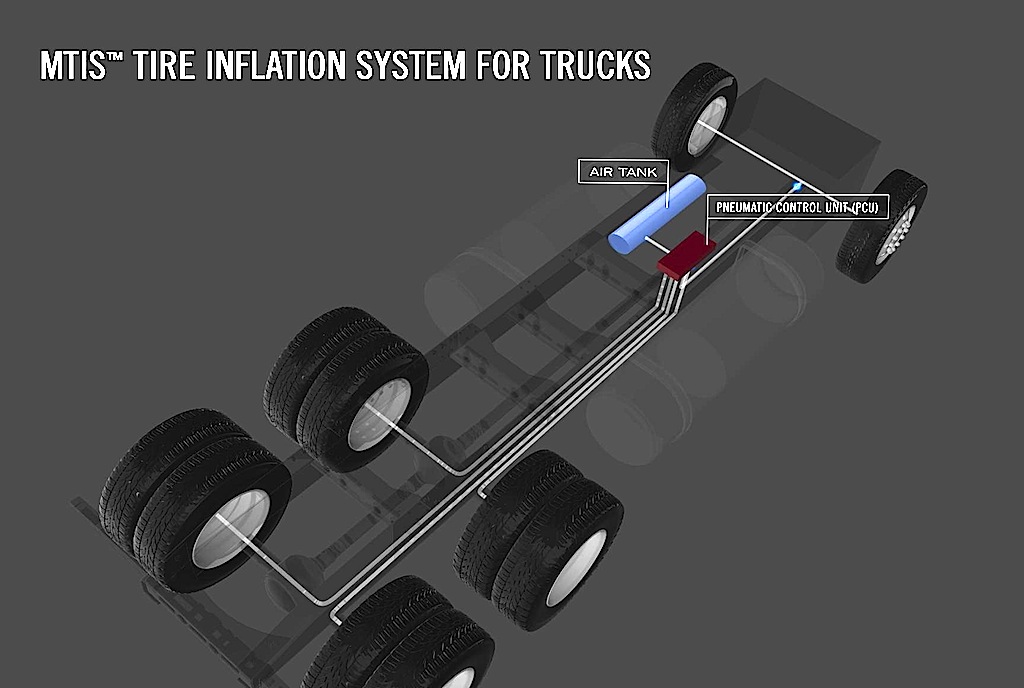

Illustrative image related to meritor tire inflation system

For mining and construction industries, the Meritor tire inflation system is utilized in heavy-duty machinery to maintain tire pressure under demanding conditions. This system increases operational uptime and enhances safety by preventing tire blowouts and ensuring better traction. Buyers in this sector should focus on the system’s ability to withstand harsh environments and heavy loads, as well as its reliability in remote locations.

In agriculture, the Meritor tire inflation system is applied to various farming equipment to optimize tire pressure. Maintaining proper tire pressure improves traction, which is crucial for plowing and harvesting, while also reducing soil compaction that can adversely affect crop yields. Buyers should consider the system’s adaptability to different soil types and weather conditions, ensuring it meets the specific needs of their agricultural practices.

Public transport systems leverage the Meritor tire inflation system for buses and coaches to ensure consistent tire pressure across their fleets. This not only enhances passenger safety and comfort but also improves vehicle performance and fuel efficiency. Key sourcing considerations include ensuring regulatory compliance and the system’s ability to integrate with existing fleet management technologies.

In the waste management sector, the Meritor tire inflation system is crucial for waste collection vehicles, helping to maintain tire pressure for optimal performance. By reducing maintenance costs and vehicle downtime, this system allows for more efficient operations. Buyers should prioritize durability against debris and rough terrains, as these vehicles often operate in challenging environments.

The Problem: B2B buyers managing fleets in remote or underdeveloped regions often face the challenge of tire deflation due to poor road conditions and limited access to maintenance services. In these areas, a sudden loss of tire pressure can lead to significant operational downtime, increased maintenance costs, and safety risks for drivers. Fleet managers may struggle to ensure that their vehicles remain roadworthy, which can result in lost revenue and damaged reputations.

The Solution: To combat this issue, fleet managers should implement the Meritor Tire Inflation System (MTIS), which automatically maintains optimal tire pressure. By equipping vehicles with MTIS, companies can significantly reduce the risk of tire deflation. When sourcing the system, it’s essential to specify the appropriate model that fits your fleet’s tire sizes and configurations. Additionally, investing in training for maintenance personnel on how to monitor and maintain the system will ensure its longevity and effectiveness. This proactive approach not only minimizes downtime but also enhances vehicle safety, ultimately leading to lower overall operating costs.

The Problem: Many B2B buyers are concerned about the impact of uneven tire wear on overall fuel efficiency and operating costs. This issue is particularly prevalent in industries such as logistics and transportation, where every cent counts. Tires that are not properly inflated can wear unevenly, leading to premature replacements and higher fuel consumption. Fleet operators often find themselves caught in a cycle of rising operational expenses due to these factors.

The Solution: Implementing the Meritor Tire Inflation System can be a game-changer for managing tire wear and improving fuel efficiency. The MTIS ensures that tires are consistently maintained at the manufacturer-recommended pressure levels, which directly contributes to even wear. When specifying MTIS for your fleet, consider integrating tire monitoring sensors that provide real-time data on tire health and pressure. This data can be used to schedule preventive maintenance, ensuring tires are rotated and replaced as necessary. By taking these steps, companies can not only prolong tire life but also enhance fuel efficiency, leading to significant savings in operational costs.

The Problem: Compliance with safety regulations regarding tire maintenance is a significant concern for B2B buyers, especially in industries subject to stringent transportation laws. Failing to meet these regulations can result in fines, penalties, and increased scrutiny from regulatory bodies. Fleet managers often face the challenge of keeping accurate records of tire pressures and maintenance schedules, which can be time-consuming and prone to human error.

The Solution: The Meritor Tire Inflation System simplifies compliance with safety regulations by automating tire pressure management. By integrating MTIS into your fleet, you can ensure that all vehicles maintain optimal tire pressure, reducing the risk of non-compliance. Moreover, MTIS can be connected to fleet management software, allowing for automatic reporting and record-keeping. When sourcing the system, choose a model that includes data logging features to track tire performance over time. Training staff on how to use this technology effectively can further streamline compliance efforts. By investing in MTIS, companies can not only enhance safety but also reduce administrative burdens related to regulatory compliance.

Illustrative image related to meritor tire inflation system

The Meritor Tire Inflation System (MTIS) utilizes various materials, each selected for specific properties that enhance the system’s performance. Understanding these materials is crucial for international B2B buyers looking to optimize their fleet operations. Here, we analyze four common materials used in the MTIS, focusing on their properties, advantages, disadvantages, and considerations for buyers in diverse markets.

Rubber is a primary material in the Meritor Tire Inflation System, especially in components like seals and hoses.

Aluminum is often used in the construction of valves and fittings in the MTIS due to its favorable properties.

Steel is frequently used for structural components in the MTIS, providing robustness and reliability.

Plastic materials, particularly high-density polyethylene (HDPE), are also utilized in the MTIS for certain components.

| Material | Typical Use Case for meritor tire inflation system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Seals and hoses | Excellent flexibility and durability | Degrades under UV exposure | Medium |

| Aluminum | Valves and fittings | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| Steel | Structural components | High tensile strength | Prone to corrosion without treatment | Medium |

| Plastic | Non-structural components | Lightweight and design flexibility | Lower temperature and pressure ratings | Low |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that enhance the performance and reliability of their Meritor Tire Inflation Systems.

The manufacturing process for Meritor Tire Inflation Systems (MTIS) involves several critical stages that ensure the final product meets stringent quality standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: The first step involves sourcing high-quality materials, including specialized plastics, metals, and electronic components. Suppliers must comply with international material standards to guarantee durability and performance. Material testing is conducted to verify specifications and ensure that they meet the necessary criteria for strength and resistance to environmental factors.

Forming: In this stage, the raw materials are shaped into components using various techniques such as injection molding for plastic parts and stamping or machining for metal components. Advanced manufacturing technologies, including CNC machining and robotic assembly, are commonly employed to enhance precision and reduce manufacturing time.

Assembly: Once the components are formed, they move to the assembly line. This process typically includes the integration of pneumatic and electronic systems that allow for automatic tire inflation. Each unit undergoes a systematic assembly protocol to ensure that all components fit perfectly and function as intended.

Finishing: The final stage involves surface treatments, such as painting, coating, or polishing, to enhance the aesthetic appeal and protect against corrosion. Additionally, quality control checks are performed at this stage to catch any defects before the product is packaged for shipment.

Quality assurance is paramount in the production of tire inflation systems. Manufacturers adhere to international and industry-specific standards to ensure that their products are safe, reliable, and of high quality.

International Standards Compliance: Many manufacturers follow ISO 9001, which outlines a framework for a quality management system. This certification ensures that the manufacturing process is consistently controlled, and that there is a focus on continuous improvement. Compliance with CE marking requirements is also essential for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

Quality Control Checkpoints: Quality control is integrated throughout the manufacturing process, with several critical checkpoints:

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide documentation that proves compliance with specifications.

In-Process Quality Control (IPQC): During the manufacturing stages, various tests are conducted to ensure that the production process remains within predefined limits. This includes monitoring machinery performance and conducting measurements on components.

Final Quality Control (FQC): After assembly, the entire system undergoes rigorous testing to ensure functionality. This may include pressure tests, electronic diagnostics, and performance evaluations under simulated conditions.

Testing methods for quality assurance in Meritor Tire Inflation Systems are diverse and tailored to evaluate the durability, performance, and safety of the product.

Pressure Testing: This method checks for leaks and ensures that the system can handle the pressures it will encounter during operation. It is critical for ensuring that the inflation system operates safely and effectively.

Functional Testing: The system is subjected to operational tests to verify that all components work as designed. This includes automated inflation and deflation cycles to assess responsiveness and reliability.

Environmental Testing: Products are exposed to various environmental conditions, such as extreme temperatures and humidity levels, to evaluate their performance and durability. This is especially important for systems used in diverse climates across regions like Africa and South America.

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability and compliance with regional regulations.

Supplier Audits: Conducting on-site audits of suppliers is one of the most effective ways to assess their quality control processes. This allows buyers to review manufacturing practices, quality management systems, and adherence to standards firsthand.

Quality Reports: Requesting detailed quality reports and certifications can provide insights into a supplier’s performance history. These documents should outline testing results, compliance with international standards, and any corrective actions taken in response to past quality issues.

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can conduct thorough evaluations of the manufacturing process and product quality, providing unbiased reports that buyers can trust.

International buyers need to be aware of specific quality control nuances when sourcing Meritor Tire Inflation Systems.

Regulatory Compliance: Different regions have unique regulatory requirements. For instance, products sold in Europe must meet CE marking standards, while those in the U.S. may require compliance with DOT regulations. Understanding these regulations is vital for ensuring market access.

Cultural and Logistical Considerations: Factors such as cultural differences, language barriers, and logistical challenges can impact communication and the flow of quality assurance information. Establishing clear channels of communication with suppliers can help mitigate these issues.

Long-term Partnerships: Building long-term relationships with reliable suppliers can enhance quality assurance. This collaboration allows for continuous improvement in manufacturing processes and adherence to evolving industry standards.

In summary, the manufacturing processes and quality assurance measures for Meritor Tire Inflation Systems are comprehensive and tailored to meet the demands of a global market. By understanding these processes and implementing diligent verification methods, international B2B buyers can ensure they are sourcing high-quality, reliable products that meet their operational needs.

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring the Meritor Tire Inflation System (MTIS). As tire maintenance is crucial for vehicle safety and efficiency, understanding how to effectively source this system will help ensure that your fleet operates smoothly and economically. Follow these steps to make informed purchasing decisions that align with your operational needs.

Before reaching out to suppliers, clearly outline your technical requirements for the MTIS. This includes understanding the vehicle types it will be used on, the desired inflation pressure range, and any specific features such as automatic adjustment capabilities or remote monitoring.

– Why It Matters: Clear specifications help streamline the sourcing process and ensure you receive products that meet your operational needs.

Conduct thorough research to identify potential suppliers of the Meritor Tire Inflation System. Look for companies with a strong reputation in the industry, relevant experience, and positive customer reviews.

– What to Consider: Focus on suppliers who specialize in tire management solutions and have a proven track record. Utilize online platforms, industry forums, and trade shows to gather insights.

Certifications can be a strong indicator of a supplier’s quality and reliability. Ensure that potential suppliers have relevant certifications, such as ISO 9001 for quality management systems and any industry-specific standards.

– Why This Is Important: Certified suppliers are more likely to adhere to stringent quality controls, which can reduce the risk of defects and enhance system reliability.

Once you’ve shortlisted suppliers, request detailed quotes that include pricing, delivery timelines, and warranty information. It’s essential to compare not only the costs but also the terms and conditions associated with each quote.

– What to Look For: Ensure that the quotes clearly outline all costs, including installation and support services. Hidden fees can significantly affect your overall budget.

Illustrative image related to meritor tire inflation system

Reliable after-sales support is critical for the effective operation of the MTIS. Inquire about the level of support offered, including training for your staff, maintenance services, and availability of spare parts.

– Why It Matters: Strong after-sales support can minimize downtime and enhance the longevity of the tire inflation system, leading to improved fleet performance.

Evaluate the risks associated with each supplier, including financial stability, delivery reliability, and potential supply chain disruptions.

– How to Proceed: Utilize tools like SWOT analysis to weigh the strengths and weaknesses of each supplier and consider their impact on your operations.

Once you have selected a supplier, ensure that all terms are clearly defined in the contract. This includes payment terms, delivery schedules, and clauses for warranty and service agreements.

– What to Ensure: A well-defined contract protects both parties and helps mitigate potential disputes in the future.

By following these steps, B2B buyers can make well-informed decisions when sourcing the Meritor Tire Inflation System, ensuring optimal performance and reliability for their fleet operations.

When considering the sourcing of the Meritor Tire Inflation System (MTIS), understanding the comprehensive cost structure and pricing elements is essential for B2B buyers. This analysis will cover the key cost components, influential price factors, and provide actionable buyer tips to navigate the procurement process effectively.

Illustrative image related to meritor tire inflation system

The total cost of acquiring the MTIS can be broken down into several critical components:

Materials: The raw materials used in the production of the MTIS significantly affect pricing. High-quality materials enhance durability and performance but can increase costs. Buyers should assess the balance between material quality and cost-effectiveness.

Labor: Labor costs are influenced by the skill level required for assembly and installation. In regions with higher labor costs, such as parts of Europe, overall pricing may reflect this. Conversely, sourcing from regions with lower labor costs may offer savings.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead, positively impacting pricing.

Tooling: The initial investment in tooling for the MTIS can be substantial, especially for custom configurations. Buyers should inquire about tooling costs and potential shared tooling arrangements for larger orders.

Quality Control (QC): Maintaining high standards through rigorous QC processes can add to the overall cost. However, it is crucial for ensuring the reliability of the system, particularly for critical applications in commercial vehicles.

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, shipping mode, and customs duties should be factored into the total cost.

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the industry standard margins can aid buyers in negotiating better deals.

Several factors can influence the pricing of the MTIS, including:

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to better pricing through economies of scale. Buyers should consider negotiating MOQs to optimize their purchase costs.

Specifications and Customization: Custom features or specific configurations can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

Material Quality and Certifications: Systems that meet specific industry certifications may command higher prices. Buyers should weigh the benefits of certified systems against their budget.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer better warranties and support, justifying a higher cost.

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial, as they dictate the responsibilities of buyers and sellers in shipping costs and risks.

To ensure cost-efficiency in sourcing the MTIS, buyers should consider the following strategies:

Effective Negotiation: Engage suppliers in discussions about pricing structures and potential discounts for bulk purchases. Negotiating terms can yield significant savings.

Total Cost of Ownership (TCO): Consider the TCO, which includes initial costs, maintenance, and operational efficiencies over the product’s lifecycle. A higher upfront cost may be justified by lower long-term operational expenses.

Understanding Pricing Nuances for International Purchases: For buyers in regions like Africa, South America, the Middle East, and Europe, fluctuations in currency and import duties can impact overall costs. Buyers should stay informed about these factors when negotiating prices.

In conclusion, a thorough understanding of the cost structure and price influences surrounding the Meritor Tire Inflation System will empower international B2B buyers to make informed purchasing decisions. While indicative prices may vary, leveraging the insights provided can lead to more strategic sourcing outcomes.

In the realm of tire management, various solutions exist to optimize tire performance and enhance safety. The Meritor Tire Inflation System (MTIS) is a well-regarded option, but businesses should also consider alternative technologies that may suit their unique operational needs. This analysis compares MTIS against two notable alternatives, providing insights into their strengths and weaknesses.

| Comparison Aspect | Meritor Tire Inflation System | Tire Pressure Monitoring System (TPMS) | Automatic Tire Inflation System (ATIS) |

|---|---|---|---|

| Performance | Consistent tire pressure maintenance; reduces blowouts and uneven wear. | Real-time tire pressure monitoring; alerts for low pressure. | Continuous inflation; maintains optimal pressure. |

| Cost | Higher initial investment; potential long-term savings on tire replacements. | Lower upfront cost; costs may accumulate from manual interventions. | Moderate initial cost; savings from reduced tire wear and fuel efficiency. |

| Ease of Implementation | Requires professional installation; may need retrofitting on existing vehicles. | Simple installation; often can be added to existing systems. | Can be complex to install; may require specialized training. |

| Maintenance | Low maintenance; periodic checks recommended. | Requires occasional sensor battery replacements; manual checks needed. | Minimal maintenance; automated system reduces manual checks. |

| Best Use Case | Ideal for fleets seeking reliability and safety in diverse conditions. | Best for smaller fleets or individual vehicles needing budget-friendly monitoring. | Suited for high-mileage fleets where constant tire pressure is critical. |

The Tire Pressure Monitoring System (TPMS) is designed primarily for real-time pressure monitoring. Its main advantage lies in its low cost and ease of installation. For businesses operating smaller fleets or individual vehicles, TPMS can provide sufficient oversight without the need for extensive investment. However, the reliance on manual checks and potential sensor failures can lead to oversight, making it less reliable for larger operations where tire pressure consistency is critical.

Automatic Tire Inflation Systems (ATIS) offer continuous tire pressure maintenance, similar to MTIS but often with a different operational approach. ATIS systems are designed to automatically inflate tires as needed, ensuring optimal pressure at all times. This technology is particularly beneficial for high-mileage fleets, as it can significantly reduce tire wear and improve fuel efficiency. However, the installation process can be more complex and may require specialized training for effective operation, which could be a drawback for some businesses.

Illustrative image related to meritor tire inflation system

When deciding between the Meritor Tire Inflation System and its alternatives, B2B buyers should assess their specific operational needs and budget constraints. For fleets that prioritize reliability and safety, MTIS may be the best option despite its higher initial cost. Conversely, smaller fleets or companies with budget limitations might find TPMS to be a more suitable choice. Those managing high-mileage operations should consider ATIS for its continuous maintenance capability. Ultimately, the right solution will depend on balancing initial investment against long-term savings and operational efficiency.

Understanding the essential specifications of the Meritor Tire Inflation System (MTIS) is crucial for B2B buyers, especially when making purchasing decisions that impact fleet efficiency and operational costs. Here are several critical technical properties to consider:

Material Grade

The MTIS components are typically constructed from high-grade materials, such as reinforced polymers and corrosion-resistant metals. These materials ensure durability and longevity, reducing the frequency of replacements. For buyers, selecting a system with superior material grade can lead to lower maintenance costs and improved performance under various environmental conditions.

Pressure Range

The MTIS is designed to operate within a specific pressure range, usually between 80 to 120 PSI. This range is vital for maintaining optimal tire performance and fuel efficiency. Understanding the required pressure range helps buyers ensure compatibility with their fleet’s operational needs and enhances tire lifespan, ultimately contributing to better cost management.

Tolerance Levels

Tolerance levels refer to the allowable deviation in dimensions of the system components. For instance, the tolerances in valve sizes and fittings are critical for ensuring airtight seals. Accurate tolerances prevent air leaks, which can lead to under-inflation and increased tire wear. B2B buyers should prioritize systems with precise tolerances to maximize efficiency and minimize operational disruptions.

Weight Capacity

The MTIS is engineered to support specific load capacities, which vary based on the vehicle type and intended use. Knowing the weight capacity ensures that the system can adequately handle the demands placed upon it, which is particularly important for logistics companies operating heavy-duty vehicles. This specification directly impacts safety and compliance with regulatory standards.

Installation Flexibility

The MTIS offers various installation options, making it adaptable for different vehicle models. This flexibility is advantageous for fleet operators looking to standardize their tire inflation systems across diverse vehicle types. Ensuring compatibility with existing fleets can reduce installation costs and downtime.

Familiarity with industry jargon is essential for effective communication between buyers and suppliers. Here are some common terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

An OEM refers to the company that manufactures the original product. In the context of the MTIS, understanding whether the system is produced by Meritor or a third-party supplier is critical. OEM parts are often preferred for their guaranteed compatibility and performance standards.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for MTIS components can help businesses plan their inventory and budgeting effectively, ensuring they do not overcommit resources while still meeting operational needs.

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to request pricing information from suppliers. When seeking the MTIS, submitting an RFQ allows buyers to compare offers and negotiate better terms, ensuring they receive value for their investment.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping costs, insurance, and delivery. Familiarity with Incoterms is crucial for B2B transactions involving the MTIS, as they dictate who is liable for various aspects of shipping, thus affecting overall cost and risk.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times for the MTIS is essential for fleet operators who rely on timely deliveries to maintain their operational schedules and avoid disruptions.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational goals and financial constraints, ultimately leading to more efficient fleet management.

Illustrative image related to meritor tire inflation system

The Meritor Tire Inflation System (MTIS) is witnessing significant growth driven by a variety of global factors. As businesses increasingly prioritize efficiency and cost savings, the demand for advanced tire inflation systems is on the rise. Key trends include the integration of IoT technologies, enabling real-time monitoring of tire pressure, which helps in reducing fuel consumption and extending tire life. This technology is particularly beneficial for industries such as transportation and logistics, where operational efficiency is critical.

International buyers from regions like Africa, South America, the Middle East, and Europe are focusing on sourcing suppliers that offer not only cost-effective solutions but also innovative technologies. The emergence of mobile applications that allow fleet managers to monitor tire health remotely is transforming the way businesses operate. Furthermore, as electric vehicles (EVs) gain traction, the need for tailored tire inflation solutions that cater to different vehicle types is becoming apparent.

In addition to technological advancements, regulatory pressures related to safety and environmental standards are shaping the market. Many countries are implementing stricter regulations regarding tire maintenance and efficiency, compelling companies to invest in systems like MTIS to ensure compliance and enhance operational reliability.

Sustainability is becoming increasingly crucial in the tire inflation system sector, particularly as environmental concerns rise globally. The production and maintenance of tire inflation systems can have a significant environmental impact, leading to a growing emphasis on reducing waste and enhancing energy efficiency. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials in their products and minimizing carbon footprints.

Ethical sourcing is another vital consideration. International buyers are looking for suppliers who adhere to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can enhance a supplier’s credibility and appeal in the global market. Additionally, employing ‘green’ materials in the production of tire inflation systems not only meets customer expectations but can also lead to cost savings through energy efficiency and reduced waste.

As businesses strive for greater sustainability, the demand for innovative products that balance performance with environmental responsibility is likely to continue growing. This trend presents an opportunity for suppliers to differentiate themselves in a competitive marketplace.

The Meritor Tire Inflation System has evolved significantly since its inception, driven by advancements in technology and changing industry needs. Initially developed to address the basic requirements of tire pressure maintenance, the system has transformed into a sophisticated solution integrating automation and smart technology. The introduction of automated systems marked a significant milestone, allowing for real-time monitoring and adjustments, which improved safety and efficiency in fleet operations.

Illustrative image related to meritor tire inflation system

Over the years, the focus has shifted from merely maintaining tire pressure to optimizing overall vehicle performance and sustainability. With increasing awareness of environmental impacts and the importance of efficient resource management, the MTIS has adapted to meet these evolving demands. Today, it stands as a critical component in modern transportation, reflecting broader trends in the automotive industry towards innovation, safety, and environmental stewardship.

This evolution highlights the importance of continuous improvement and adaptation in the tire inflation system sector, ensuring that suppliers remain competitive in a fast-changing global marketplace.

1. How can I troubleshoot issues with the Meritor Tire Inflation System (MTIS)?

To troubleshoot issues with the MTIS, start by checking for any visible leaks in the air lines or connections. Ensure that the system is receiving adequate air pressure from the compressor and that the sensors are functioning correctly. If the system is not inflating the tires to the specified pressure, inspect the control module and wiring for faults. Consult the user manual for diagnostic codes that can guide you in identifying specific problems. If issues persist, consider contacting Meritor’s customer support for professional assistance.

2. What are the key benefits of using the Meritor Tire Inflation System (MTIS)?

The Meritor Tire Inflation System offers several significant benefits, including improved fuel efficiency, extended tire life, and enhanced safety. By maintaining optimal tire pressure, the MTIS reduces rolling resistance, leading to lower fuel consumption. Additionally, consistent tire pressure helps prevent premature tire wear and blowouts, minimizing maintenance costs. The system also contributes to better vehicle handling and stability, particularly in challenging driving conditions, making it a valuable investment for fleet operators.

3. What customization options are available for the Meritor Tire Inflation System?

Meritor offers customization options for the MTIS to meet specific fleet requirements. Buyers can choose different configurations based on vehicle type, operating conditions, and specific tire sizes. Additionally, the system can be integrated with telematics for real-time monitoring and alerts. Discuss your unique needs with a Meritor representative to explore available modifications and ensure that the system fits seamlessly into your fleet’s operational framework.

4. What is the minimum order quantity (MOQ) for the Meritor Tire Inflation System?

The minimum order quantity for the MTIS can vary depending on the distributor and the specific configuration required. Generally, for bulk purchases, the MOQ is set to ensure cost-effectiveness for both the buyer and the supplier. It is advisable to contact your Meritor sales representative or local distributor to inquire about specific MOQ terms and any potential discounts for larger orders, especially if you are looking to equip an entire fleet.

5. What payment terms should I expect when purchasing the Meritor Tire Inflation System?

Payment terms for purchasing the MTIS typically vary based on the supplier and the size of the order. Common terms may include a deposit upfront with the balance due upon delivery or net 30/60 days payment options. It’s essential to discuss payment arrangements during negotiations to ensure clarity and agreement. Additionally, inquire about any financing options that may be available for larger purchases, which can ease cash flow management for your business.

6. How does Meritor ensure quality assurance for the Tire Inflation System?

Meritor employs rigorous quality assurance processes throughout the manufacturing and assembly of the MTIS. This includes thorough testing of individual components and the final system to ensure they meet industry standards and performance specifications. Regular audits and inspections are conducted to maintain high-quality standards. Buyers can request documentation on quality certifications and performance metrics to ensure that the system adheres to the required safety and operational guidelines.

7. What logistics considerations should I keep in mind when sourcing the MTIS internationally?

When sourcing the MTIS internationally, consider factors such as shipping costs, customs duties, and delivery timelines. Work with logistics providers experienced in handling automotive components to navigate potential challenges. Ensure that you understand the import regulations of your country and have all necessary documentation, including invoices and certificates of origin. Collaborate with your supplier to arrange reliable shipping methods that align with your operational schedules.

8. How can I vet suppliers of the Meritor Tire Inflation System to ensure reliability?

To vet suppliers of the MTIS, start by researching their reputation in the industry through reviews and testimonials. Verify their certifications and compliance with international standards. Request references from previous clients to gauge their reliability and service quality. Additionally, assess their customer support capabilities and responsiveness. Engaging in direct conversations with potential suppliers can also provide insights into their operational practices and commitment to service excellence.

Domain: meritorpartsxpress.com

Registered: 2016 (9 years)

Introduction: This company, Meritor – Tire Inflation System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: cummins.com

Registered: 1990 (35 years)

Introduction: The Meritor Tire Inflation System (MTIS) is designed to automatically maintain optimal tire pressure, enhancing tire life and improving fuel efficiency. It features a centralized inflation system that can be integrated with existing tire pressure monitoring systems (TPMS). The system is suitable for various vehicle types, including heavy-duty trucks and trailers. Key benefits include reduced tire …

Domain: rollofftrucktrailerparts.com

Registered: 2015 (10 years)

Introduction: {“name”:”Meritor H2712-22 PSI Tire Inflation System – Tandem Axle”,”manufacturer”:”Meritor”,”sku”:”AS114″,”price”:”$1,298.00 USD”,”features”:[“Keeps tires inflated when they leak due to nails or metal pieces”,”Senses overheating at axle bearings with THERMALERT”,”Reduces road service calls”,”Saves money due to fewer flat tires”,”Reduces DOT fines for flat tires”,”Reduces axle damage”,”Increases ti…

In today’s competitive landscape, strategic sourcing of the Meritor Tire Inflation System (MTIS) offers significant advantages for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The MTIS not only enhances tire performance through optimal inflation but also reduces operational costs and minimizes downtime, making it an essential investment for fleet operators. By prioritizing the integration of advanced tire inflation solutions, businesses can improve fleet efficiency and safety while aligning with sustainability goals.

As the demand for reliable and efficient transportation solutions continues to grow globally, sourcing MTIS becomes a pivotal strategy for companies looking to maintain a competitive edge. Embracing these systems can lead to enhanced productivity and a stronger return on investment.

Illustrative image related to meritor tire inflation system

Looking ahead, international B2B buyers are encouraged to explore partnerships with trusted suppliers of the Meritor Tire Inflation System. By leveraging this technology, businesses can position themselves for future success in an ever-evolving marketplace. Take the next step toward optimizing your fleet’s performance—invest in the Meritor Tire Inflation System today for a more efficient tomorrow.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to meritor tire inflation system