In today’s fast-paced global market, sourcing an effective central tire inflation system (CTIS) is crucial for businesses aiming to optimize vehicle performance and reduce operational costs. Many international B2B buyers face the challenge of ensuring tire maintenance while navigating diverse terrains, especially in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide addresses those challenges by exploring various types of CTIS, their applications across different industries, and strategies for supplier vetting.

From construction and agriculture to military and commercial transport, a reliable CTIS can significantly enhance tire longevity, improve fuel efficiency, and minimize downtime caused by tire-related issues. By delving into aspects such as installation costs, maintenance requirements, and technological advancements, this guide empowers decision-makers to make informed purchasing choices.

Additionally, it highlights key considerations for evaluating suppliers, ensuring that businesses can secure high-quality products tailored to their specific needs. As the demand for efficient tire management solutions grows, understanding the intricacies of CTIS will enable international buyers to stay ahead of the competition and drive operational excellence. This guide serves as a vital resource for those looking to enhance their fleet’s performance while effectively managing costs and resources.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic CTIS | Automatically adjusts tire pressure based on terrain and load | Military, construction, mining | Pros: Enhances mobility, reduces tire wear. Cons: Higher initial investment. |

| Manual CTIS | Requires manual adjustment of tire pressure | Agriculture, off-road vehicles | Pros: Lower cost, straightforward operation. Cons: Time-consuming and less precise. |

| Onboard Air Systems | Allows for inflation/deflation of multiple tires simultaneously | Off-road, recreational vehicles | Pros: Quick tire management, versatile. Cons: Dependent on compressor quality. |

| Portable Tire Inflation Kits | Compact systems for individual tire inflation on-the-go | Fleet management, emergency services | Pros: Convenient, easy to transport. Cons: Limited to single tire at a time. |

| Integrated Fleet Management CTIS | Combines tire inflation with vehicle diagnostics and monitoring | Logistics, transportation fleets | Pros: Comprehensive data insights, reduces downtime. Cons: Complex installation and maintenance. |

Automatic Central Tire Inflation Systems (CTIS) are designed to adjust tire pressure dynamically based on real-time data regarding vehicle load and terrain conditions. This system is particularly beneficial for military and heavy-duty vehicles, where optimal tire performance is critical for mobility and safety. B2B buyers should consider the initial investment versus long-term operational efficiency, as these systems can significantly reduce tire wear and improve fuel efficiency.

Manual CTIS requires operators to adjust tire pressures manually, making it a simpler, more cost-effective solution for applications such as agriculture and off-road vehicles. While it provides less precision and can be time-consuming, it offers a straightforward solution for businesses on a budget. Buyers should assess their operational needs and the trade-offs between cost and efficiency when considering manual systems.

Onboard Air Systems enable users to inflate or deflate all tires simultaneously, making them ideal for off-road and recreational applications. These systems streamline tire management, allowing for quick adjustments without the need for separate equipment. B2B buyers must evaluate compatibility with existing compressors and consider the system’s durability and ease of installation when making a purchasing decision.

Portable Tire Inflation Kits are compact, easy-to-use solutions designed for on-the-go tire management, making them suitable for fleet management and emergency services. While they offer convenience and mobility, they typically inflate one tire at a time, which can be a drawback for high-volume operations. Buyers should weigh the portability against the potential need for multiple kits to ensure efficiency.

Integrated Fleet Management CTIS combines tire inflation with diagnostic capabilities, providing fleet operators with valuable insights into tire health and performance. This system is particularly advantageous for logistics and transportation fleets, as it minimizes downtime and enhances operational efficiency. However, the complexity of installation and ongoing maintenance should be carefully considered by B2B buyers looking to implement these advanced systems.

| Industry/Sector | Specific Application of Central Tire Inflation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy Equipment Mobility on Job Sites | Enhanced traction, reduced downtime, improved fuel efficiency | Compatibility with diverse terrain, ease of installation, reliability |

| Agriculture | Agricultural Vehicles for Field Operations | Reduced soil compaction, optimized tire life | Durability in harsh conditions, adaptability to various vehicles |

| Military | Tactical Military Vehicles in Varied Terrain | Increased mobility and safety in challenging environments | Proven reliability, rapid response capabilities, and ease of use |

| Mining | Off-Road Mining Trucks Operating in Extreme Conditions | Minimized tire failures, improved operational efficiency | Robust design for harsh terrains, compatibility with mining equipment |

| Transportation and Logistics | Fleet Management for Long-Haul Trucks | Cost savings through fuel efficiency and reduced maintenance | Integration with fleet management systems, scalability, and support |

In the construction sector, Central Tire Inflation Systems (CTIS) are employed to enhance the mobility of heavy equipment on job sites. These systems allow operators to adjust tire pressure on-the-fly, ensuring optimal traction and stability on varied terrains. This capability is essential for reducing downtime due to tire-related issues, which can significantly impact project timelines. B2B buyers in this industry should prioritize systems that offer compatibility with different machinery types and ease of installation to minimize disruptions during deployment.

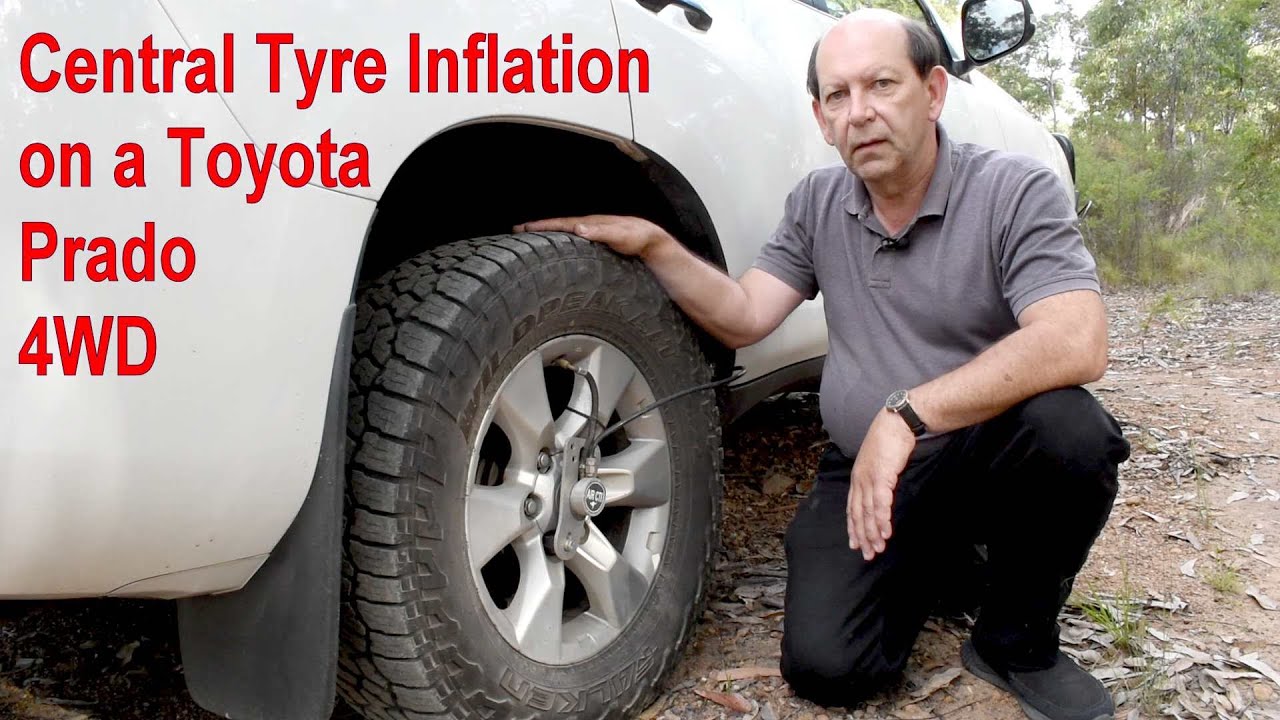

Illustrative image related to central tire inflation

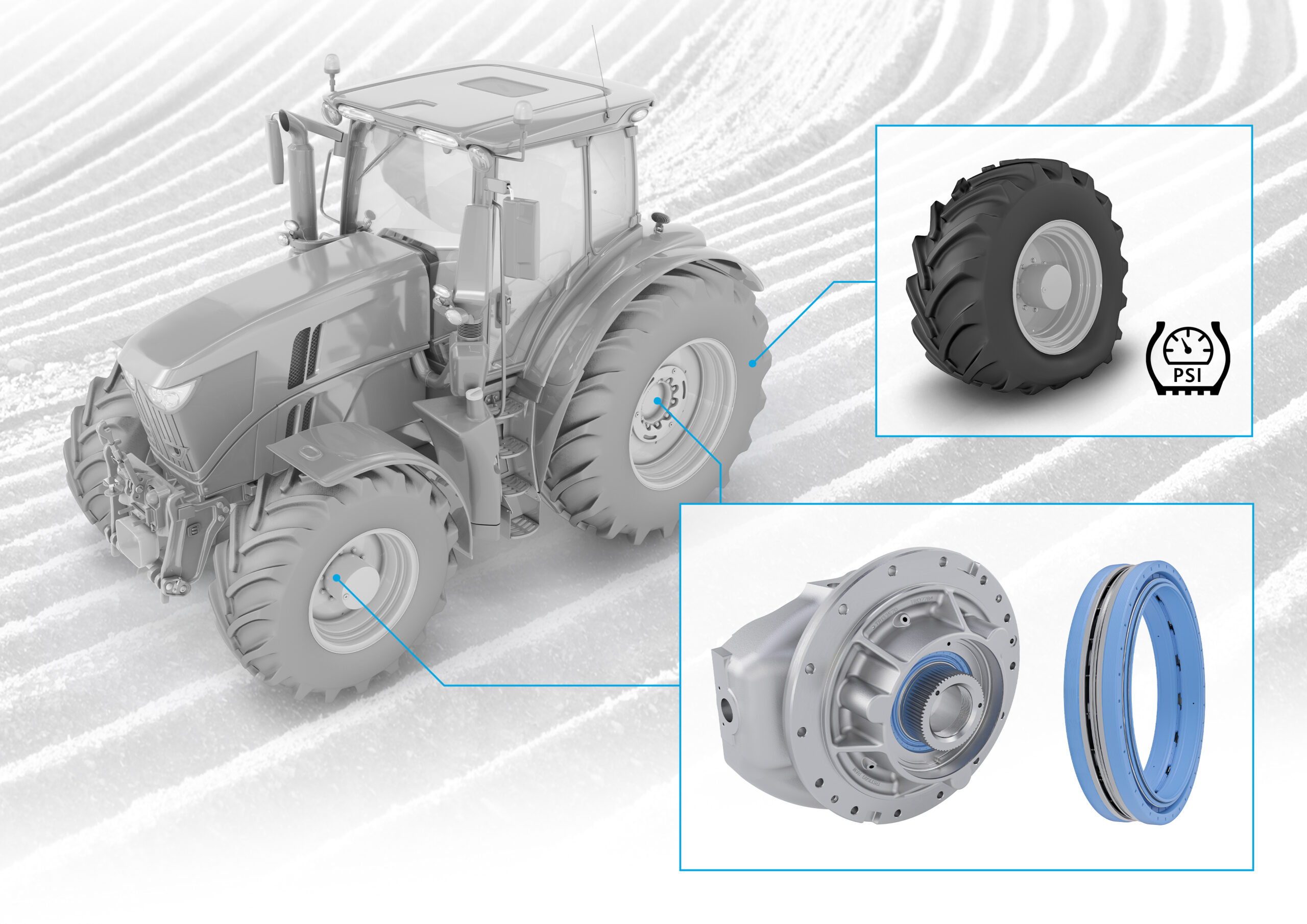

Agricultural vehicles, such as tractors and harvesters, utilize central tire inflation to adapt to changing field conditions. By optimizing tire pressure, farmers can reduce soil compaction and enhance fuel efficiency, which is critical for maintaining crop health and maximizing yield. International buyers, particularly in regions with diverse agricultural practices, need systems that are durable and can withstand challenging environments. Additionally, ease of maintenance and the ability to interface with existing equipment are key considerations for agricultural applications.

In military applications, CTIS technology is vital for ensuring tactical vehicles can navigate difficult terrains while maintaining safety. The ability to adjust tire pressure allows military units to maneuver effectively under pressure, whether escaping threats or traversing rugged landscapes. For B2B buyers in defense sectors, sourcing reliable systems that offer rapid response capabilities and user-friendly interfaces is crucial. The systems should also be tested for durability in extreme conditions, ensuring they meet the rigorous demands of military operations.

Mining operations depend heavily on off-road trucks that can handle extreme conditions. Central Tire Inflation Systems help minimize tire failures, which can lead to costly downtime and safety hazards. By allowing operators to adjust tire pressure based on the terrain, these systems enhance operational efficiency and vehicle lifespan. Buyers in the mining sector should consider robust designs that are specifically engineered for harsh environments and ensure compatibility with existing mining equipment.

In the transportation and logistics industry, CTIS contributes to fleet management by improving fuel efficiency and reducing maintenance costs associated with tire wear. Fleet operators can manage tire pressure across multiple vehicles simultaneously, leading to significant operational savings. B2B buyers in this sector should look for systems that integrate seamlessly with fleet management software, offering scalability and robust support. Reliability and ease of use are also critical factors that can influence purchasing decisions.

Illustrative image related to central tire inflation

The Problem: B2B buyers in industries such as construction or agriculture often face the challenge of managing tire pressure effectively across varying terrains. For example, a fleet manager might oversee a diverse fleet of vehicles that frequently transition between paved roads, gravel paths, and muddy fields. Inadequate tire pressure not only affects vehicle stability and traction but also accelerates tire wear, resulting in increased operational costs and downtime due to tire failures. The need for a reliable system that can automatically adjust tire pressure based on terrain type is critical to maintaining productivity and safety.

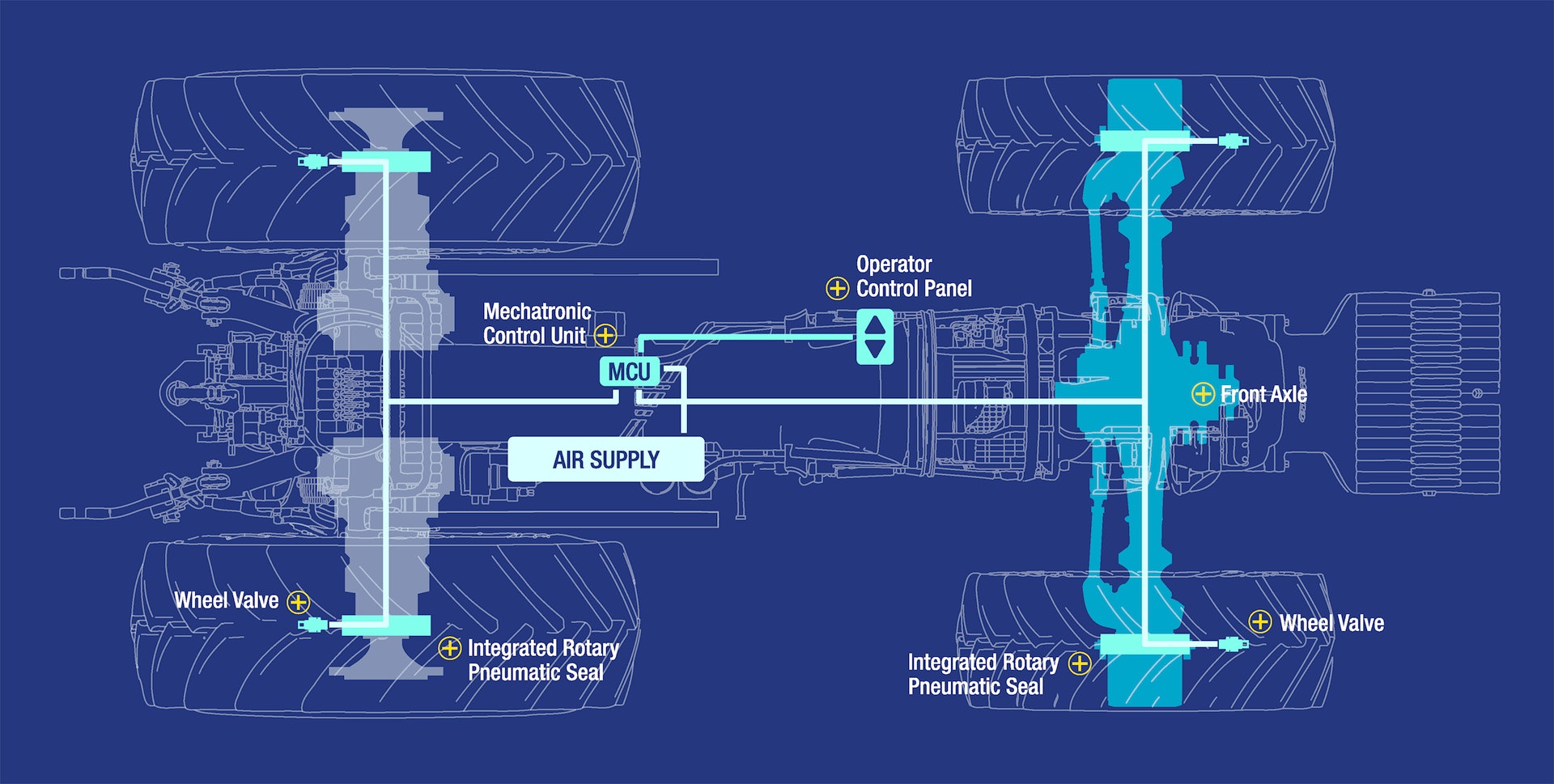

The Solution: Implementing a Central Tire Inflation System (CTIS) can significantly alleviate this issue. Fleet managers should source a CTIS that offers automatic pressure adjustment capabilities tailored to specific terrain conditions. Look for systems that provide integrated diagnostics and alerts for tire issues, allowing drivers to respond proactively to potential problems. When selecting a CTIS, ensure it has user-friendly controls—ideally, a simple push-button interface from within the cab. This feature allows operators to adjust tire pressures quickly and safely while on the move, enhancing vehicle performance and reducing the risk of accidents caused by improper tire management.

The Problem: For international B2B buyers operating in remote or harsh environments, the risk of tire failure due to punctures or leaks can be a significant concern. In many cases, drivers may not have the ability to monitor tire pressure continuously, leading to unexpected downtimes and costly repairs. This scenario is particularly pressing for companies with heavy-duty vehicles that require constant mobility, such as those involved in mining or oil exploration, where tire integrity is crucial for operational success.

The Solution: Investing in a CTIS equipped with real-time monitoring and automatic leak detection is essential. Such systems can alert drivers to tire pressure drops before they lead to significant problems. When sourcing a CTIS, prioritize those with advanced diagnostics that provide continuous feedback on tire health. Implementing training for drivers on how to interpret these alerts will also ensure that they can take timely action, such as adjusting tire pressure or inspecting for leaks. Additionally, consider establishing a routine maintenance schedule that includes checking the CTIS to ensure optimal functionality and reliability.

Illustrative image related to central tire inflation

The Problem: In many industries, fuel costs represent a significant portion of operational expenses. B2B buyers often find that incorrect tire pressure can lead to increased rolling resistance, directly impacting fuel efficiency. For logistics companies or transportation fleets, this inefficiency can translate into higher fuel costs, reduced profit margins, and an increased carbon footprint. The challenge lies in maintaining the correct tire pressure across a diverse fleet, especially when vehicles are frequently loaded with varying weights.

The Solution: To combat fuel inefficiencies related to tire pressure, B2B buyers should consider a CTIS that allows for on-the-fly adjustments based on load weight and road conditions. When specifying a CTIS, look for features that enable dynamic pressure adjustments, optimizing fuel consumption without compromising safety or performance. Additionally, implementing a comprehensive training program for drivers on the importance of maintaining proper tire pressure can enhance awareness and accountability. Regularly reviewing fuel consumption data in conjunction with tire performance metrics will provide insights into how well the CTIS is contributing to operational efficiency, allowing for continuous improvement.

Central Tire Inflation Systems (CTIS) rely on various materials to ensure efficient performance, durability, and reliability. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, particularly those operating in diverse climates and terrains across Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in CTIS components.

Rubber is a primary material used in tire valves, hoses, and seals within CTIS. Its key properties include excellent flexibility, a high-temperature rating (typically up to 120°C), and good resistance to wear and tear.

Pros: Rubber is relatively inexpensive and easy to manufacture, making it a popular choice for mass production. Its elasticity allows for a secure fit in various applications, ensuring airtight seals that prevent leaks.

Cons: However, rubber can degrade over time when exposed to UV light and certain chemicals, which may limit its lifespan in harsh environments. Additionally, it may not perform well in extreme temperature conditions beyond its rating.

Impact on Application: Rubber’s compatibility with air and various gases makes it suitable for tire inflation applications. However, buyers should consider the local climate and potential exposure to elements that may accelerate degradation.

Considerations for International Buyers: Compliance with local standards such as ASTM or DIN is essential. Buyers in regions like Germany may prioritize materials that meet stringent quality regulations, while those in Africa might focus on cost-effectiveness and availability.

Aluminum is often used in the construction of valves and fittings due to its lightweight and corrosion-resistant properties. It can withstand high pressure (up to 300 PSI) and performs well in various environmental conditions.

Pros: The lightweight nature of aluminum reduces overall system weight, which is beneficial for fuel efficiency. Its resistance to corrosion makes it ideal for use in humid or saline environments.

Cons: While aluminum is durable, it can be more expensive than rubber and may require specialized manufacturing processes, which can increase production costs.

Impact on Application: Aluminum’s compatibility with high-pressure systems enhances the performance of CTIS, especially in heavy-duty applications such as mining and military vehicles.

Considerations for International Buyers: Buyers should ensure that aluminum components meet international standards for pressure ratings and corrosion resistance, particularly in regions with extreme climates like the Middle East.

Stainless steel is frequently used for components that require high strength and corrosion resistance, such as wheel valves and quick-release fittings. Its temperature and pressure ratings can exceed 500°F and 1,000 PSI, respectively.

Pros: The durability of stainless steel ensures a long service life, reducing the need for frequent replacements. Its resistance to rust and corrosion makes it suitable for use in harsh environments.

Cons: The primary drawback is cost; stainless steel is more expensive than both rubber and aluminum. Additionally, its weight can be a concern for applications where minimizing vehicle weight is critical.

Illustrative image related to central tire inflation

Impact on Application: Stainless steel is ideal for heavy-duty applications where reliability is paramount, making it a preferred choice for military and industrial vehicles.

Considerations for International Buyers: Compliance with international standards is crucial. Buyers in Europe and North America often seek stainless steel components that meet ASTM or JIS standards for quality assurance.

Composite materials, often a blend of polymers and fibers, are increasingly used in CTIS components for their lightweight and high-strength properties. They can effectively manage pressures up to 200 PSI while offering good resistance to chemicals.

Illustrative image related to central tire inflation

Pros: Composites are lightweight, reducing overall vehicle weight, and can be manufactured in various shapes and sizes, providing design flexibility. They also have excellent fatigue resistance.

Cons: The manufacturing process can be complex and costly, making composites less accessible for lower-budget projects. Additionally, their long-term durability under extreme conditions is still being evaluated.

Impact on Application: Composites can be used in specialized applications where weight savings are critical, such as in racing or high-performance vehicles.

Considerations for International Buyers: Buyers should verify that composite materials meet local and international standards, as well as consider the availability of these materials in their regions.

| Material | Typical Use Case for Central Tire Inflation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Valves, hoses, seals | Cost-effective and flexible | Degrades under UV exposure | Low |

| Aluminum | Valves, fittings | Lightweight and corrosion-resistant | Higher cost and specialized manufacturing | Medium |

| Stainless Steel | Heavy-duty valves, fittings | High strength and durability | Expensive and heavier | High |

| Composite | Specialized applications | Lightweight and design flexibility | Complex manufacturing and durability concerns | Medium |

This material selection guide provides B2B buyers with actionable insights to make informed decisions regarding the components of Central Tire Inflation Systems, ensuring they choose the most suitable materials for their specific applications and regional requirements.

Central Tire Inflation Systems (CTIS) are integral to the efficiency and safety of vehicles operating in demanding environments. Understanding the manufacturing processes and quality assurance measures behind these systems is crucial for B2B buyers looking to source reliable products. This section will provide insights into the manufacturing stages, key techniques, quality control standards, and verification methods that buyers should consider when selecting a supplier.

Illustrative image related to central tire inflation

The manufacturing process for CTIS typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the components meet rigorous performance and durability standards.

Material preparation is the first step in the manufacturing process. High-quality materials, such as advanced polymers and metals, are selected based on their performance characteristics, such as resistance to wear, temperature fluctuations, and corrosion. Suppliers often conduct material tests to verify that the materials meet industry standards. For instance, using materials that comply with international specifications ensures that components can withstand harsh conditions, which is vital for applications in diverse climates across Africa, South America, the Middle East, and Europe.

The forming stage involves shaping raw materials into specific components. Techniques such as injection molding, extrusion, and machining are commonly employed. Injection molding is often used for producing complex shapes with high precision, particularly for plastic components. Machining ensures that metal parts meet exact specifications and tolerances. Each technique is chosen based on the material properties and the required design of the component, ensuring that the final product performs optimally in real-world applications.

The assembly process is crucial for ensuring that all components fit together correctly and function as intended. This stage often involves automated assembly lines for efficiency, as well as manual assembly for more complex parts. During this phase, components such as valves, pressure regulators, and sensors are integrated into the system. Proper assembly techniques are essential to avoid leaks and ensure reliable operation under varying conditions.

Illustrative image related to central tire inflation

Finishing processes include surface treatments, coatings, and quality checks that enhance the durability and aesthetic appeal of the components. Treatments such as anodizing, galvanizing, or applying specialized coatings can improve corrosion resistance and overall longevity. These processes also help in achieving compliance with international standards, which is particularly important for B2B buyers in different regions.

Quality assurance (QA) is a critical aspect of CTIS manufacturing, ensuring that each product meets stringent safety and performance standards. The following QA measures are commonly implemented:

B2B buyers should prioritize suppliers that adhere to international quality management standards, such as ISO 9001. This certification indicates a commitment to quality processes and continuous improvement. Additionally, industry-specific certifications such as CE marking for compliance with European health, safety, and environmental protection standards, and API standards for oil and gas applications, may also be relevant depending on the intended application of the CTIS.

Illustrative image related to central tire inflation

Quality control (QC) is typically conducted at various checkpoints throughout the manufacturing process:

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers:

Conducting supplier audits is an effective way to assess the manufacturing capabilities and quality assurance practices of a supplier. Audits can reveal insights into the supplier’s adherence to quality standards, employee training programs, and overall production environment. Buyers can request documentation of previous audits or certifications to ensure compliance with relevant standards.

Quality control reports provide valuable information on the performance and reliability of CTIS products. Buyers should request detailed QC reports that outline inspection results, test methodologies, and any corrective actions taken. Additionally, third-party inspections can provide an unbiased assessment of the manufacturing process and product quality, further enhancing trust in the supplier.

Illustrative image related to central tire inflation

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware that QC certifications can vary significantly between countries. For example, while ISO certifications are globally recognized, specific regional standards may apply, such as the Gulf Cooperation Council (GCC) standards in the Middle East or the European Union’s regulations. Buyers should ensure that suppliers understand and comply with the regulatory requirements specific to their target markets.

In summary, understanding the manufacturing processes and quality assurance measures for Central Tire Inflation Systems is crucial for B2B buyers. By focusing on the stages of production, quality control standards, and verification methods, buyers can make informed decisions and select reliable suppliers that meet their operational needs.

The purpose of this guide is to assist B2B buyers in effectively sourcing Central Tire Inflation Systems (CTIS) for their fleets. This checklist outlines critical steps to ensure that you select a system that meets your operational needs while optimizing performance and cost-efficiency.

Start by outlining the technical requirements for your CTIS. Consider factors such as vehicle type, load capacity, and the terrains your vehicles will navigate. This clarity will help you communicate your needs effectively to suppliers and ensure that the systems you evaluate are suitable for your specific applications.

Investigate various CTIS solutions available in the market. Look for systems that offer features such as automatic pressure adjustment, diagnostic alerts, and emergency modes for leak handling. Understanding the range of options will empower you to make informed comparisons.

Before making a commitment, conduct thorough evaluations of potential suppliers. Request detailed company profiles, case studies, and references from other clients in similar industries or regions. This step is crucial in ensuring you partner with a reputable supplier capable of delivering quality products.

Verify that the CTIS systems meet relevant international standards and certifications. This is especially important in regions like Europe and the Middle East where compliance with safety and environmental regulations is mandatory. Ensuring compliance protects your investment and enhances operational reliability.

Whenever possible, arrange for product demonstrations or trials. This firsthand experience will allow you to assess the system’s performance, ease of use, and integration with your existing fleet management practices. Observing the system in action can also highlight potential operational challenges.

Illustrative image related to central tire inflation

Evaluate the total cost of ownership for the CTIS, which includes initial purchase price, installation costs, maintenance, and potential savings from improved tire longevity and fuel efficiency. A thorough TCO analysis helps in understanding the long-term financial implications of your investment.

Confirm the after-sales support offered by the supplier, including warranty terms and availability of replacement parts. Reliable support is crucial for minimizing downtime and ensuring that your CTIS operates effectively throughout its lifecycle.

By following this step-by-step checklist, you can ensure a strategic approach to sourcing Central Tire Inflation Systems, ultimately enhancing your operational efficiency and vehicle performance.

When analyzing the cost structure for Central Tire Inflation Systems (CTIS), several components must be considered:

Materials: The materials used in CTIS can significantly affect pricing. Components such as valves, hoses, and electronic controls require high-quality materials to ensure durability and reliability under various conditions. The choice of materials directly influences both the initial cost and the long-term performance of the system.

Labor: Labor costs encompass both the manufacturing and assembly processes. Skilled technicians are required to assemble CTIS units, and their wages can vary significantly by region. In countries with lower labor costs, such as some parts of Africa and South America, the overall labor component may be lower, impacting the final pricing for buyers.

Manufacturing Overhead: This includes costs related to the facilities, utilities, and equipment necessary for production. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

Tooling: Initial investment in tooling and machinery is essential for producing CTIS components. This cost is typically amortized over the production volume; therefore, higher volumes can lead to lower per-unit tooling costs.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and adherence to safety standards, which is crucial in sectors like automotive and military applications. However, these processes add to the overall cost, which must be considered in pricing.

Logistics: Transportation and distribution costs can vary widely based on the supplier’s location and the destination market. International shipping, customs duties, and local delivery charges are all part of the logistics equation that can affect final pricing.

Margin: Suppliers typically include a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market position, brand reputation, and the perceived value of their products.

Several factors influence the pricing of CTIS, particularly for international B2B buyers:

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding MOQ can help buyers negotiate better pricing, especially for fleet purchases.

Specifications and Customization: Customized systems tailored to specific operational needs may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) can justify a higher price point, as they often correlate with enhanced performance and longevity.

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge a premium for their products due to perceived reliability and service support.

Incoterms: The choice of Incoterms can influence the total cost. Understanding whether costs such as shipping, insurance, and duties are included in the quoted price is crucial for accurate budget planning.

To maximize value when sourcing CTIS, buyers should consider the following negotiation strategies:

Research and Benchmarking: Understand the market rates for CTIS by comparing quotes from multiple suppliers. This knowledge can empower buyers during negotiations.

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider the long-term costs associated with maintenance, fuel savings, and potential downtime. Presenting a TCO analysis can strengthen negotiation positions.

Leverage Volume Discounts: If purchasing for a fleet, use the volume to negotiate better pricing or terms. Suppliers are often willing to offer concessions for larger contracts.

Be Transparent About Needs: Clearly communicating specifications and expectations can lead to more tailored proposals and better alignment between buyer and supplier.

Explore Payment Terms: Flexible payment options can ease cash flow constraints, making it easier to finalize deals without compromising on quality or service.

While this analysis provides a framework for understanding costs and pricing dynamics in Central Tire Inflation System sourcing, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotations and engage in discussions with suppliers to achieve the best possible outcomes.

When considering tire pressure management solutions, it is essential to evaluate various options available in the market. Central Tire Inflation Systems (CTIS) offer significant advantages in controlling tire pressure automatically based on terrain and load. However, alternative methods exist that can also serve the needs of businesses in different sectors. This analysis compares CTIS against two viable alternatives: manual tire inflation systems and universal tire inflation systems.

| Comparison Aspect | Central Tire Inflation | Manual Tire Inflation System | Universal Tire Inflation System |

|---|---|---|---|

| Performance | Automated pressure adjustment; optimal for varying terrains | Manual adjustment; time-consuming | Quick inflation/deflation; simultaneous control |

| Cost | Higher initial investment due to technology | Lower upfront cost, but labor-intensive | Moderate cost; varies by components |

| Ease of Implementation | Requires professional installation | Simple installation; no special tools needed | Requires some setup; compatible with existing systems |

| Maintenance | Low maintenance; automated diagnostics | High maintenance; dependent on user diligence | Moderate maintenance; parts may wear over time |

| Best Use Case | Off-road, military, and heavy-duty applications | Light-duty vehicles; low-frequency use | Off-road and overlanding; diverse vehicle compatibility |

Manual tire inflation systems involve using handheld pumps or compressors to adjust tire pressure. These systems are often less expensive initially and easier to install, making them appealing for small-scale operations or light-duty vehicles. However, they require significant time and effort from drivers to monitor and adjust tire pressures manually, especially in fluctuating conditions. This can lead to inconsistent tire pressure management, potentially impacting vehicle performance and safety.

Universal tire inflation systems, such as the Overland Vehicle Systems Gen2 Air Delivery System, allow for the simultaneous inflation or deflation of multiple tires. These systems are designed for ease of use, with components that work well with both permanent onboard compressors and portable pumps. While these systems are moderately priced and effective for off-road enthusiasts, they may not offer the same level of precision as CTIS in adjusting tire pressure based on real-time conditions. Additionally, they require some installation effort and regular maintenance to ensure optimal performance.

Selecting the right tire pressure management solution hinges on understanding specific operational needs and environmental factors. For businesses operating in rugged terrains or requiring high mobility, Central Tire Inflation Systems provide unmatched performance and reliability, albeit at a higher cost. Conversely, manual and universal tire inflation systems offer viable alternatives that may suit lighter applications or budget-conscious operations. By evaluating performance, cost, ease of implementation, and maintenance, B2B buyers can make informed decisions that align with their operational goals and enhance vehicle efficiency.

Understanding the technical specifications of Central Tire Inflation Systems (CTIS) is crucial for B2B buyers looking to enhance vehicle performance, safety, and operational efficiency. Below are key technical properties that influence system effectiveness:

Illustrative image related to central tire inflation

The pressure range indicates the minimum and maximum tire pressure that the system can manage. Typically, CTIS systems operate between 10 to 120 PSI. This flexibility allows for optimal tire pressure adjustment based on varying loads and terrains, which is essential for maximizing traction and minimizing tire wear. For B2B buyers, selecting a system with an appropriate pressure range ensures compatibility with diverse vehicle types and operational demands.

The materials used in CTIS components, such as valves and hoses, significantly affect durability and performance. High-grade materials, often reinforced with synthetic fibers or metals, resist wear and tear from harsh environments. Buyers should prioritize systems utilizing robust materials, as this directly impacts longevity and reduces maintenance costs, essential for companies operating fleets in challenging conditions.

Response time measures how quickly the system can adjust tire pressure. A typical CTIS should achieve pressure changes within seconds. Fast response times are vital for maintaining vehicle stability and safety, especially in dynamic environments like construction sites or off-road conditions. B2B buyers must consider this property to ensure their vehicles can adapt swiftly to changing terrains.

CTIS can be controlled through manual or automated systems. Manual systems require driver intervention, while automated systems adjust pressure based on real-time data. Automated systems often integrate with vehicle diagnostics to alert drivers of potential issues. For businesses, investing in automated systems can lead to enhanced operational efficiency and reduced downtime due to tire-related problems.

The weight and size of the CTIS components are critical, especially for heavy-duty vehicles. Lighter systems contribute to overall vehicle efficiency, while compact designs facilitate easier installation and less impact on vehicle dynamics. Buyers should evaluate the balance between performance and weight to ensure optimal vehicle operation.

Familiarity with industry-specific terminology is essential for effective communication and decision-making in the B2B sector. Here are some common terms relevant to central tire inflation:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of CTIS, OEM parts are designed to meet specific vehicle standards. B2B buyers should consider OEM components for guaranteed compatibility and reliability.

MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers, as it can affect inventory management and procurement strategies. Understanding MOQ helps companies plan their purchases effectively, ensuring they meet their operational needs without overcommitting resources.

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. In the context of CTIS, submitting an RFQ allows buyers to compare pricing and service terms, enabling informed purchasing decisions.

Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers in global trade transactions. They clarify issues such as shipping, insurance, and tariffs. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding Incoterms is crucial for managing logistics and ensuring smooth international transactions.

This term refers to the capability of CTIS to connect with vehicle diagnostic systems to monitor tire conditions continuously. Systems with diagnostics integration can alert drivers to pressure irregularities or system malfunctions, which is essential for maintaining fleet safety and performance.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions regarding Central Tire Inflation Systems, ultimately leading to enhanced vehicle performance and reduced operational costs.

Illustrative image related to central tire inflation

The global central tire inflation system (CTIS) market is evolving rapidly, driven by the increasing need for efficient tire management in various sectors, including transportation, agriculture, and military applications. As international B2B buyers look for advanced solutions, key trends have emerged. Firstly, the integration of smart technology into CTIS is gaining traction. Systems now come equipped with real-time monitoring, allowing for instant alerts on tire pressure and potential issues, which significantly reduces downtime and enhances safety.

Moreover, sustainability is becoming a pivotal factor in sourcing decisions. Buyers are increasingly seeking products that not only improve operational efficiency but also contribute to environmental preservation. Innovations such as eco-friendly materials and energy-efficient manufacturing processes are becoming important criteria for supplier selection.

Geographically, regions such as Africa and South America are witnessing significant growth in the adoption of CTIS, driven by the expansion of the mining and agricultural sectors, which require robust tire management solutions. In contrast, Europe, particularly Germany, is focusing on high-tech CTIS that aligns with stringent environmental regulations and enhances vehicle performance. The Middle East, particularly Saudi Arabia, is also investing in CTIS as part of broader infrastructure development initiatives, making it a key market for international suppliers.

Sustainability is reshaping the landscape of B2B sourcing in the central tire inflation sector. Environmental concerns are prompting buyers to prioritize products that minimize their carbon footprint and promote responsible resource management. For instance, systems that use recyclable materials or have a lower environmental impact during production are increasingly favored.

Moreover, ethical sourcing is gaining importance as companies recognize the value of transparency in their supply chains. Buyers are more inclined to partner with suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 or LEED, which signify adherence to environmental management standards.

In addition, the adoption of green technologies in CTIS not only supports sustainability goals but also enhances operational efficiency. For example, systems designed to optimize tire pressure can reduce fuel consumption and extend tire life, resulting in lower emissions and operational costs. As international buyers from regions like Europe and North America push for greener practices, suppliers who can demonstrate their commitment to sustainability will likely have a competitive advantage.

Illustrative image related to central tire inflation

The evolution of central tire inflation technology reflects significant advancements in engineering and materials science. Initially developed for military applications to enhance vehicle mobility in challenging terrains, CTIS has transitioned into civilian use across various industries, including agriculture and logistics.

In the early stages, CTIS focused primarily on manual inflation methods. However, modern systems feature automated controls, allowing for real-time adjustments based on load and terrain. This not only improves performance but also enhances safety by reducing the risk of tire-related incidents.

The integration of diagnostic features has further transformed the landscape, enabling predictive maintenance and immediate alerts for potential issues like leaks or punctures. As technology continues to evolve, the future of CTIS will likely see even more sophisticated systems that leverage artificial intelligence and IoT connectivity, paving the way for smarter, more efficient tire management solutions in the global market.

In conclusion, understanding the dynamics of the CTIS market, the impact of sustainability on sourcing, and the historical evolution of technology can empower B2B buyers to make informed decisions that align with their operational needs and ethical standards.

How can I effectively address tire pressure issues in my fleet?

To tackle tire pressure issues efficiently, consider implementing a Central Tire Inflation System (CTIS). This technology allows for real-time adjustments based on load and terrain, enhancing tire longevity and vehicle performance. Additionally, systems equipped with diagnostic alerts notify drivers of potential problems, reducing downtime. By investing in a CTIS, you can ensure optimal tire pressure management, which directly translates to improved safety and reduced operational costs in your fleet.

What is the most effective Central Tire Inflation System for off-road vehicles?

For off-road vehicles, look for a CTIS that offers versatility in pressure settings and robust performance in diverse terrains. Systems like the Spicer® CTIS are designed for extreme conditions, enabling vehicles to operate with lower tire pressures without compromising safety. Features such as automatic pressure adjustments and emergency modes for leaks enhance vehicle mobility and reduce wear. When selecting a system, ensure it meets the specific demands of your operational environment.

How do I choose a reliable supplier for Central Tire Inflation Systems?

Selecting a trustworthy supplier involves evaluating their industry reputation, product quality, and customer service. Look for manufacturers with a proven track record in CTIS technology and positive reviews from other B2B buyers. Request samples or case studies to assess product performance in real-world applications. Additionally, ensure the supplier offers comprehensive support, including installation assistance and warranty options, to safeguard your investment.

What customization options are available for Central Tire Inflation Systems?

Many suppliers offer customization options to tailor CTIS to your specific needs. This can include modifications in system components, pressure settings, and integration with existing vehicle technology. Discuss your requirements with potential suppliers to explore available options, such as compatibility with different tire sizes and types. Custom solutions can enhance performance and ensure that the system aligns with your operational goals.

What are typical minimum order quantities (MOQs) for Central Tire Inflation Systems?

MOQs for CTIS can vary significantly based on the supplier and the scale of your order. Generally, larger orders may yield better pricing and more favorable terms. It’s advisable to communicate directly with suppliers to understand their MOQ policies. In some cases, suppliers may offer flexibility, especially for first-time buyers or bulk purchases, allowing you to negotiate terms that align with your purchasing strategy.

What payment terms should I expect when sourcing Central Tire Inflation Systems?

Payment terms can differ among suppliers, but common practices include upfront deposits, net 30 or net 60 days for payment, and options for letter of credit. It’s crucial to clarify payment expectations early in negotiations to avoid misunderstandings. Additionally, consider the implications of payment terms on your cash flow and overall budget, and choose a supplier whose terms align with your financial planning.

How is quality assurance handled in Central Tire Inflation Systems?

Quality assurance is critical in CTIS production. Reputable manufacturers implement rigorous testing protocols to ensure reliability and performance under various conditions. Inquire about the supplier’s quality control processes, including certifications and compliance with international standards. A strong QA program not only enhances product reliability but also minimizes the risk of operational disruptions due to equipment failures.

What logistics considerations should I keep in mind when importing Central Tire Inflation Systems?

When importing CTIS, logistics planning is essential. Consider factors such as shipping methods, lead times, and customs regulations specific to your region. Work closely with your supplier to understand packaging requirements and ensure that all components are compliant with local laws. Additionally, factor in the cost of shipping and potential tariffs, as these can impact your overall budget and timeline for deployment.

Domain: ti.systems

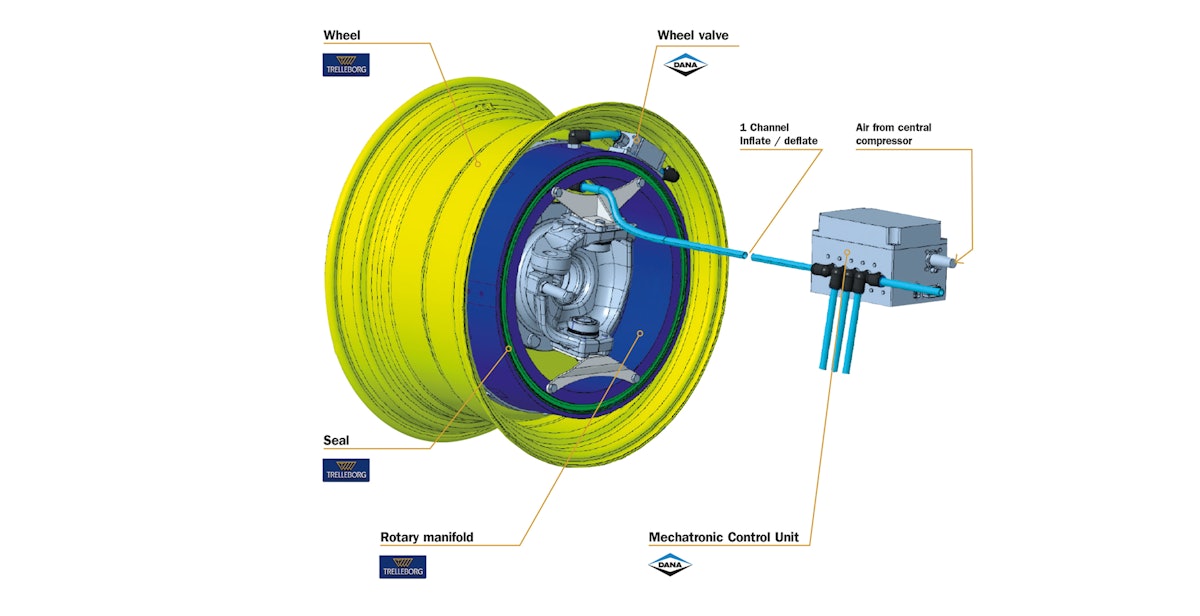

Introduction: CTIS | Central Tire Inflation System

– Precise tire pressure adjustment on the go

– Mechanically Operating

– Immediate Inflating and Deflating after Turning ON

– No restrictions regarding Tire Pressure and Driving Speed

– Pressureless when Turned OFF

– Adjust tire pressure while vehicle is moving

– Internal air lines through axles (prepared axles required)

**ti.systems Wheel Valve (TISWV)**

– Air…

Domain: spicerparts.com

Registered: 2004 (21 years)

Introduction: Product Name: Central Tire Inflation System (CTIS™) – Axle

Key Features:

– Automatic emergency mode for handling leaks

– Allows adjustment of tire pressure based on vehicle load

– Enhances traction, extends tire life, and reduces fuel consumption

– Convenient push-button operation for optimum pressure selection

– Integrated diagnostics for alerting drivers of potential tire problems

– Reduces dow…

Domain: ntstiresupply.com

Registered: 2007 (18 years)

Introduction: Central Tire Inflation Systems (CTIS) help solve soil compaction issues on farms, which is a major profit stealer. CTIS allows for optimized tire pressure adjustments throughout the day for improved machine performance. Key suppliers include AgriBrink (since 2010) and PTG (since 1991, now owned by Michelin). The system consists of three main components: Air Supply (compressor), Air Control (in-cab…

Domain: fst.com

Registered: 1995 (30 years)

Introduction: Freudenberg Sealing Technologies has developed a new double-lipped sealing component for Central Tire Inflation Systems (CTIS) aimed at enhancing safety and efficiency in heavy-duty vehicles. This innovative seal reduces friction and power loss, improving the functionality and lifespan of CTIS. It allows for the development of more sophisticated, automatic tire pressure systems controlled by a sin…

In conclusion, the implementation of Central Tire Inflation Systems (CTIS) presents significant operational advantages for businesses across various sectors, from agriculture to construction and military applications. By enabling precise tire pressure adjustments on-the-go, these systems not only enhance vehicle mobility but also contribute to extended tire life, improved fuel efficiency, and reduced downtime due to tire-related issues.

For international B2B buyers, particularly in emerging markets such as Africa and South America, as well as established regions like Europe and the Middle East, strategic sourcing of CTIS technology is essential. It allows companies to optimize their fleet management and operational costs while ensuring safety and reliability in diverse terrain conditions.

As you consider your procurement strategies, prioritize partnerships with reliable suppliers that offer cutting-edge CTIS solutions tailored to your specific needs. The future of tire management is evolving rapidly; by investing in these systems today, your business can stay ahead of the curve, ensuring both sustainability and operational excellence. Embrace the opportunity to enhance your fleet’s performance through strategic sourcing of Central Tire Inflation Systems and position your organization for long-term success.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.