In today’s competitive landscape, sourcing high-quality air inflators with gauge can pose a significant challenge for B2B buyers, especially when navigating diverse international markets. Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Brazil, often encounter varying standards of quality, price points, and supplier reliability. This guide aims to streamline the procurement process by providing a comprehensive overview of the types of air inflators available, their applications across different sectors, and best practices for supplier vetting.

By delving into critical aspects such as cost considerations, technological advancements, and industry-specific requirements, this guide equips international buyers with the knowledge necessary to make informed purchasing decisions. Whether you are looking for portable solutions for consumer use or robust inflators designed for heavy-duty applications, understanding the nuances of the market can significantly impact your operational efficiency and product reliability.

With actionable insights and strategic recommendations, this resource empowers you to navigate the complexities of sourcing air inflators with gauge, ensuring that you select products that meet your specific business needs while fostering strong supplier relationships. Ultimately, this guide serves as your roadmap to optimizing your procurement process in the global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Tire Inflator with Pressure Gauge | High accuracy, often features a digital display, programmable PSI settings | Automotive repair shops, fleet maintenance | Pros: Easy to read, precise; Cons: Requires batteries or power source. |

| Analog Tire Inflator with Pressure Gauge | Mechanical gauge, typically more durable, no power required | General automotive service, DIY workshops | Pros: Reliable, cost-effective; Cons: Can be less accurate than digital. |

| Portable Tire Inflator with Gauge | Compact design, often battery-operated or AC/DC compatible | Roadside assistance, personal use | Pros: Convenient for on-the-go; Cons: May have lower PSI output. |

| Heavy-Duty Tire Inflator with Gauge | Designed for rugged use, higher PSI ratings, often includes multiple attachments | Commercial fleets, off-road vehicle maintenance | Pros: Durable and versatile; Cons: Higher price point, bulkier. |

| Automatic Tire Inflator with Gauge | Automatically shuts off at set PSI, often features advanced technology | Automotive service centers, rental services | Pros: Reduces user error; Cons: More complex, potential for higher repair costs. |

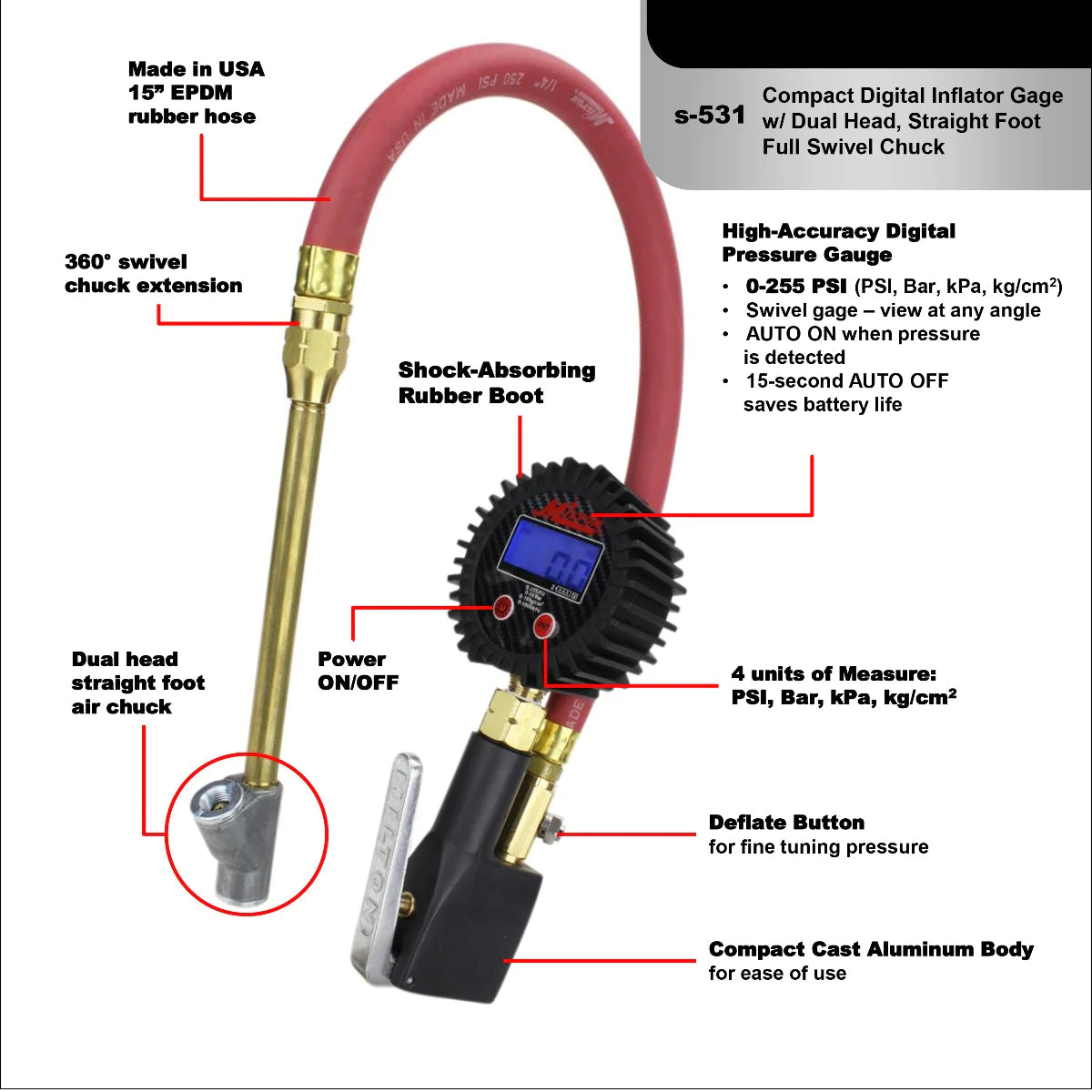

Digital tire inflators with pressure gauges are characterized by their high accuracy and user-friendly digital displays. They often come with programmable PSI settings that allow users to set their desired pressure level, making them ideal for automotive repair shops and fleet maintenance operations where precision is paramount. B2B buyers should consider the ease of use and the potential need for batteries or a power source, which can affect operational efficiency.

Illustrative image related to air inflator with gauge

Analog tire inflators with pressure gauges employ mechanical gauges, offering robust performance without the need for power sources. These tools are particularly suitable for general automotive services and DIY workshops where reliability is essential. While they are generally more cost-effective, B2B buyers should weigh their lower accuracy against the initial savings, especially in high-volume settings.

Portable tire inflators with gauges are designed for convenience, featuring compact designs that are often battery-operated or compatible with AC/DC power. They are perfect for roadside assistance and personal use, allowing users to address tire inflation needs quickly. Buyers should consider the PSI output and battery life, as these factors can significantly impact the tool’s effectiveness in emergency situations.

Heavy-duty tire inflators with gauges are built for rugged applications, providing higher PSI ratings and often including multiple attachments for various tire types. They are commonly used in commercial fleets and off-road vehicle maintenance due to their durability and versatility. Buyers should be prepared for a higher price point and bulkier design, which may require dedicated storage space.

Automatic tire inflators with gauges feature advanced technology that allows for automatic shut-off when the desired PSI is reached. This reduces user error and is beneficial in high-volume automotive service centers and rental services. While they tend to be more complex and may incur higher repair costs, the efficiency gains make them a valuable investment for businesses focused on improving workflow and minimizing downtime.

| Industry/Sector | Specific Application of air inflator with gauge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and pressure maintenance for vehicles | Enhances safety and performance through proper tire pressure | Accuracy, durability, compatibility with various tire types |

| Construction | Inflating pneumatic tools and equipment | Increases efficiency and reduces downtime on job sites | Portability, power options (AC/DC), and ruggedness |

| Agriculture | Inflation of agricultural vehicle tires | Ensures optimal vehicle performance on uneven terrains | High PSI capacity, ease of use, and adaptability to different vehicles |

| Sports and Recreation | Inflating sports equipment and recreational vehicles | Promotes safety and optimal performance for users | Versatility, ease of transport, and reliability under pressure |

| Logistics and Shipping | Maintenance of tire pressure for transport vehicles | Reduces fuel consumption and extends tire life | Quick inflation capabilities, accuracy, and bulk purchasing options |

In the automotive repair sector, air inflators with gauges are essential tools for ensuring proper tire inflation. Mechanics rely on these devices to maintain optimal tire pressure, which is critical for vehicle safety and efficiency. An accurate inflator helps avoid issues such as tire blowouts or uneven wear, which can lead to costly repairs. International buyers, particularly from regions like Africa and South America, should prioritize products that demonstrate durability and compatibility with diverse vehicle types to meet local demands.

In construction, air inflators with gauges are vital for inflating pneumatic tools and equipment, such as nail guns and air compressors. Properly inflated tools enhance performance and minimize the risk of malfunctions that can cause project delays. For international B2B buyers, sourcing inflators that are portable and capable of operating on various power sources (AC/DC) is crucial, particularly in remote or rugged job sites common in the Middle East and parts of Europe.

Agricultural vehicles, often used in challenging terrains, require consistent tire pressure for optimal performance. Air inflators with gauges are used to maintain the correct tire pressure on tractors and other farming equipment, ensuring they function efficiently. For buyers in the agricultural sector, high PSI capacity and ease of use are key considerations, as they often work in time-sensitive conditions. Reliability in various weather conditions is also essential for buyers from regions with diverse climates.

In the sports and recreation industry, air inflators with gauges are crucial for maintaining equipment such as bicycles, balls, and inflatable boats. Proper inflation is essential for safety and performance, as under-inflated equipment can lead to accidents or diminished functionality. International buyers should look for versatile inflators that can handle various types of equipment and are easy to transport. This is particularly important for businesses catering to outdoor enthusiasts across Europe and South America.

In logistics and shipping, maintaining the correct tire pressure for transport vehicles is essential for reducing fuel consumption and ensuring safe transport of goods. Air inflators with gauges allow fleet managers to quickly check and adjust tire pressure, thereby extending tire life and improving vehicle efficiency. For international B2B buyers, sourcing inflators that offer quick inflation capabilities and high accuracy is vital, particularly for companies operating in competitive markets across Africa and the Middle East.

The Problem: B2B buyers often face the challenge of ensuring that their air inflators with gauges provide accurate pressure readings. Inaccurate readings can lead to under-inflated or over-inflated tires, which not only affects vehicle performance but also compromises safety. This issue is particularly critical in industries such as logistics and transportation, where maintaining proper tire pressure is essential for safety, fuel efficiency, and tire longevity.

The Solution: To mitigate this problem, it is crucial to source high-quality air inflators with gauges that are certified for accuracy, such as those that meet ANSI B40.1 standards. Buyers should prioritize products that come with user reviews highlighting reliability and precision. Additionally, implementing a routine calibration schedule for the inflators can ensure ongoing accuracy. Regularly comparing the readings of the inflator against a known calibrated gauge can help maintain trust in the tool’s performance. It is also advisable to train staff on how to read gauges correctly and understand the importance of maintaining optimal tire pressure for safety and efficiency.

The Problem: A common pain point for B2B buyers is the challenge of inflating various tire types and sizes, from passenger vehicles to heavy-duty trucks. Many inflators may not accommodate the different valve types or pressure requirements, leading to inefficiencies and increased downtime. This issue is particularly prevalent in automotive service businesses and fleet operations where time is of the essence.

The Solution: To address this issue, businesses should invest in versatile inflators equipped with interchangeable attachments and adapters that can handle multiple tire types, including cars, trucks, motorcycles, and even specialized equipment. Opting for models with a wide PSI range, like those that offer up to 200 PSI, will ensure adaptability. Furthermore, creating a detailed inventory of all tire types and their specific pressure requirements can aid in selecting the right inflator for each job. Training staff on how to quickly change attachments and adjust settings for different tires can streamline operations and minimize delays in service.

The Problem: In many settings, particularly in large garages or field operations, mobility and accessibility can hinder the effective use of air inflators with gauges. Buyers often find that inflators with short power cords or limited portability can restrict their ability to reach certain vehicles or equipment, leading to inefficiencies and potential safety hazards.

The Solution: To overcome this challenge, B2B buyers should consider investing in portable air inflators that are lightweight and come with extended power cords or battery-operated options. Models that can operate on both AC and DC power sources are particularly beneficial for fieldwork, as they can be plugged into vehicles or power outlets as needed. Additionally, incorporating mobile storage solutions for inflators can enhance accessibility. Training staff to maintain a clear and organized workspace will also help ensure that inflators are readily available when needed, reducing delays and improving operational efficiency. Implementing a system where inflators are routinely checked for functionality and battery life can also help maintain consistent performance in various environments.

When considering the strategic selection of materials for air inflators with gauges, it is essential to evaluate their properties, advantages, and limitations. The choice of materials can significantly impact product performance, durability, and compliance with international standards, which is particularly relevant for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

Aluminum is a popular choice for the housing and components of air inflators due to its lightweight nature and excellent corrosion resistance. With a temperature rating that can handle typical operational conditions, aluminum inflators offer good durability. However, while aluminum is generally cost-effective, it may not withstand extreme pressures as well as other metals, which could limit its use in high-performance applications. For international buyers, aluminum components must comply with standards such as ASTM B221 for extrusions, ensuring quality and reliability.

Steel, particularly stainless steel, is another common material used in air inflators. It provides superior strength and pressure resistance, making it ideal for high-pressure applications. Stainless steel is also resistant to corrosion, which is crucial for products exposed to various environmental conditions. The downside is that steel components can be heavier and more expensive than aluminum, potentially increasing shipping costs. Buyers should ensure compliance with ISO 9001 standards for quality management to guarantee product reliability.

Polypropylene (PP) is frequently used for non-structural components such as handles and housings. This thermoplastic is lightweight, cost-effective, and resistant to various chemicals, making it suitable for different inflation tasks. However, it may not withstand high temperatures or pressures, which could limit its use in heavy-duty applications. B2B buyers should consider local regulations regarding plastic materials, as certain regions may have restrictions on specific types of plastics.

Polyvinyl Chloride (PVC) is another plastic option that offers good flexibility and chemical resistance. It is often used for hoses and tubing in air inflators. PVC is relatively inexpensive and easy to manufacture, making it a popular choice. However, its performance can degrade under UV exposure, which is a consideration for outdoor use. Buyers in regions with stringent environmental regulations should ensure compliance with standards like REACH in Europe, which governs the use of hazardous substances.

When selecting materials for air inflators with gauges, international buyers must also consider the supply chain implications, including availability and sourcing challenges in their respective regions. Additionally, understanding local market preferences and compliance with regional standards can facilitate smoother transactions and enhance product acceptance.

| Material | Typical Use Case for air inflator with gauge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Limited high-pressure performance | Medium |

| Stainless Steel | High-pressure components | Superior strength and durability | Heavier and more expensive | High |

| Polypropylene | Handles and non-structural parts | Cost-effective and lightweight | Limited temperature/pressure tolerance | Low |

| Polyvinyl Chloride | Hoses and tubing | Flexible and chemically resistant | Degrades under UV exposure | Low |

This material selection guide provides a comprehensive overview for B2B buyers, allowing for informed decisions that align with performance requirements and regulatory standards across various international markets.

Illustrative image related to air inflator with gauge

The manufacturing process of air inflators with gauges involves several critical stages that ensure the final product meets quality and performance standards.

The first step in manufacturing air inflators is the preparation of raw materials. Key components typically include metals such as aluminum or steel for the body and brass for fittings and nozzles. High-quality rubber is often used for seals to prevent air leaks. Suppliers of these materials are vetted for compliance with international standards to ensure durability and safety.

Once materials are procured, forming techniques are employed. This may include processes like extrusion for hoses, stamping for metal parts, and injection molding for plastic components. Advanced methods such as CNC machining may also be utilized to achieve precise dimensions. The choice of forming technique can significantly impact the performance and longevity of the inflator, so manufacturers often invest in state-of-the-art machinery.

The assembly stage combines all individual components into a cohesive unit. This typically involves a series of manual and automated processes, including the installation of gauges, pressure regulators, and air hoses. Attention to detail is crucial during assembly to ensure that all connections are secure, and components are aligned correctly. Quality checks are integrated at this stage to catch any potential issues early on.

The final stage in manufacturing involves surface finishing, which may include anodizing metal parts for corrosion resistance and applying protective coatings. Aesthetic elements, such as branding and labeling, are also added during this phase. This not only enhances the product’s appearance but also provides essential information for end-users regarding safety and operational guidelines.

Quality control (QC) is a cornerstone of manufacturing air inflators, ensuring that each product adheres to high standards of safety and performance.

Illustrative image related to air inflator with gauge

Manufacturers of air inflators often comply with international standards such as ISO 9001, which outlines criteria for a quality management system. Certification to this standard demonstrates a commitment to consistent quality and customer satisfaction. Additionally, products may need to meet specific industry standards, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

To ensure product quality, various QC checkpoints are established throughout the manufacturing process:

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials and components upon delivery to verify that they meet specified standards. Defective materials are rejected, ensuring that only high-quality inputs are used in production.

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor production processes. This can include measuring dimensions, testing for leaks, and ensuring that assembly is performed correctly. Any deviations from quality standards are addressed immediately to prevent defects from progressing to the next stage.

Final Quality Control (FQC): Once the product is assembled, a final inspection is conducted. This may involve functional testing of the inflator, calibration of gauges, and performance evaluations under various conditions. Products that pass these checks are packaged for shipment, while those that do not meet standards are reworked or discarded.

Several testing methods are employed to ensure that air inflators meet the required performance specifications:

Illustrative image related to air inflator with gauge

Pressure Testing: This involves subjecting the inflator to high pressure to ensure it can handle the maximum operational pressure without leaking or failing.

Durability Testing: Products are subjected to repeated use conditions to evaluate their longevity and performance over time. This may include testing the hose’s flexibility and the gauge’s accuracy after extensive usage.

Temperature and Humidity Testing: Given that air inflators may be used in various climates, testing is conducted to ensure they perform well in extreme temperatures and humidity levels.

For international B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential.

Buyers should conduct thorough audits of potential suppliers. This includes reviewing their quality management certifications, inspecting manufacturing facilities, and assessing their QC processes. Engaging third-party inspection services can provide additional assurance of compliance with international standards.

Buyers should request relevant documentation, such as:

Quality Control Reports: These should detail the results of various tests conducted during the manufacturing process.

Certificates of Compliance: Suppliers should provide certificates proving adherence to international standards like ISO 9001 and any specific industry regulations relevant to the product.

Traceability Records: It is beneficial to have records that trace the origin of materials and components used in the inflators, ensuring that they meet safety and quality benchmarks.

Understanding the nuances of quality control can help B2B buyers navigate the complexities of sourcing air inflators. Buyers should be aware that:

Regulatory Compliance: Different regions may have specific regulations regarding product safety and environmental impact. Familiarizing oneself with these can prevent compliance issues.

Cultural Differences in Quality Standards: Quality expectations can vary significantly between regions. Buyers should communicate clearly with suppliers about their quality requirements and ensure that these are understood and implemented.

After-Sales Support: Inquire about the supplier’s after-sales support and warranty policies. This can be a critical factor in maintaining quality assurance after the sale is made.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and ensure they source high-quality air inflators with gauges that meet their operational needs.

Illustrative image related to air inflator with gauge

When sourcing air inflators with gauges, it is essential to navigate the selection process strategically to ensure you procure a reliable and efficient product. This guide will equip you with a step-by-step checklist to make informed decisions that meet your business needs.

Before engaging suppliers, clarify the specific technical requirements for the air inflator with gauge. Consider factors such as maximum pressure (e.g., 100 PSI vs. 200 PSI), power source (AC, DC, or manual), and intended use (automotive, recreational, or industrial). Understanding these parameters will help you narrow down options that align with your operations.

Stay informed about the latest market trends and technological advancements in air inflators. Innovations such as digital gauges, automatic shut-off features, or portable designs are increasingly popular. Being knowledgeable about these trends will help you select products that not only meet current needs but also anticipate future demands.

Thoroughly vet potential suppliers to ensure they can deliver quality products. Request company profiles, certifications, and case studies that demonstrate their experience and reliability in the industry. Look for suppliers who can provide references from other businesses within your sector or region, as this can offer insights into their performance and customer service.

Ensure that the air inflators comply with relevant international safety and quality standards. This is particularly crucial if you are sourcing for markets in Europe, Africa, or South America, where regulatory compliance can impact product acceptance. Certifications such as ISO, CE, or local equivalents should be verified to avoid legal and operational issues.

Once you have shortlisted suppliers, request samples of the air inflators with gauges for hands-on evaluation. Testing the products will allow you to assess their performance, durability, and ease of use. Pay attention to the accuracy of the gauge, the quality of materials, and any additional features that may enhance functionality.

Gather detailed quotes from your selected suppliers and compare their pricing structures. Look beyond the initial cost; consider factors like bulk discounts, warranty terms, and after-sales support. Establishing a clear understanding of total costs will help you make a financially sound decision that supports your budget.

Once you have selected a supplier, ensure that the contract outlines all agreed-upon terms, including delivery timelines, payment conditions, and service level agreements. Having a comprehensive contract protects both parties and minimizes the risk of misunderstandings during the procurement process.

Following this checklist will enhance your sourcing strategy for air inflators with gauges, ensuring that you select products that meet your technical needs while fostering strong supplier relationships.

When sourcing air inflators with gauges, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Several price influencers can affect the final cost of air inflators with gauges.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

In conclusion, understanding the comprehensive cost and pricing structure for air inflators with gauges is crucial for B2B buyers. By analyzing cost components and price influencers, and employing strategic negotiation tactics, buyers can make informed decisions that enhance their procurement processes. Be mindful of the indicative prices available in the market as they can vary based on multiple factors, including location and market demand.

In the realm of tire maintenance, the air inflator with gauge is a popular choice for achieving optimal tire pressure. However, various alternative solutions exist, each with its own advantages and disadvantages. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding these alternatives can be crucial for making informed purchasing decisions.

Illustrative image related to air inflator with gauge

| Comparison Aspect | Air Inflator With Gauge | Manual Tire Pump | Portable Air Compressor |

|---|---|---|---|

| Performance | High accuracy and efficiency | Moderate; relies on manual effort | High; fast inflation rates |

| Cost | $30 – $70 | $15 – $40 | $50 – $150 |

| Ease of Implementation | Easy to use, requires air source | Requires physical effort | Generally plug-and-play |

| Maintenance | Low; occasional calibration | Low; simple mechanism | Moderate; requires electrical upkeep |

| Best Use Case | Regular vehicle maintenance | Emergency situations | Off-road or heavy-duty applications |

Manual tire pumps are simple devices that allow users to inflate tires through physical effort. They are typically less expensive than air inflators with gauges, making them an attractive option for budget-conscious buyers. However, the performance can be inconsistent, as it heavily depends on the user’s strength and stamina. Manual pumps are best suited for emergency situations where quick access to a power source may not be available. Their simplicity also translates to low maintenance requirements, but they may not provide the precision needed for regular tire maintenance.

Portable air compressors are a versatile solution for tire inflation, offering high performance and efficiency. These devices can inflate tires quickly, making them ideal for off-road or heavy-duty applications. While they are more expensive than manual pumps, their performance justifies the investment for businesses that require frequent tire maintenance. However, they typically require a power source, which may limit their usability in remote locations. Maintenance can be moderate, as users need to ensure the electrical components are functioning correctly. Overall, portable air compressors are excellent for businesses that prioritize speed and efficiency in tire maintenance.

When selecting the right tire inflation solution, B2B buyers should consider their specific needs, including the types of vehicles they service, their budget, and the typical environments in which they operate. An air inflator with gauge is ideal for regular maintenance where precision is critical. In contrast, manual pumps may suffice for occasional emergencies or less frequent use. For those who require robust performance and speed, particularly in off-road or demanding situations, a portable air compressor is likely the best choice. Assessing these factors will enable buyers to make an informed decision that aligns with their operational requirements.

When selecting an air inflator with a gauge for commercial purposes, understanding its technical specifications is crucial. Here are several key properties that B2B buyers should consider:

Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the inflator can handle. Common ratings range from 100 PSI to 200 PSI. This specification is vital for ensuring that the inflator meets the requirements for various applications, such as automotive, industrial, or recreational use. A higher PSI rating allows for versatility across different tire types and sizes.

Material Grade

The materials used in the construction of the inflator, such as brass, steel, or high-grade plastic, affect its durability and performance. Brass fittings, for instance, provide better resistance to corrosion and wear, which is essential for long-term use in diverse environments. Understanding material specifications helps buyers gauge the longevity and reliability of the inflator in their operations.

Hose Length and Flexibility

The length and flexibility of the hose determine the ease of use and accessibility during inflation. A longer hose allows for better reach to tires without repositioning the inflator, while a flexible hose facilitates maneuverability in tight spaces. This property is particularly important for businesses involved in mobile tire services or those operating in confined work areas.

Gauge Type

The type of pressure gauge—whether analog or digital—can influence precision and user experience. Digital gauges often provide more accurate readings and are easier to read, especially in low-light conditions. Understanding gauge specifications is essential for ensuring precise inflation and maintaining optimal tire pressure, which can impact vehicle safety and performance.

Power Source

Air inflators can be powered either by AC (alternating current) or DC (direct current), which influences their portability and usability in various settings. DC-powered inflators are typically used in vehicles and can be operated via a car’s power outlet, making them ideal for roadside emergencies. Knowing the power source helps businesses determine the appropriate inflator for their specific operational needs.

Inflation Speed (CFM)

The inflation speed, measured in cubic feet per minute (CFM), indicates how quickly the inflator can fill a tire. A higher CFM value means faster inflation, which is critical for businesses that require quick turnaround times, such as tire repair shops. Selecting an inflator with an appropriate CFM ensures efficiency in operations.

Familiarity with industry jargon is essential for effective communication and negotiations. Here are several common terms related to air inflators:

Illustrative image related to air inflator with gauge

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for specific inflator models that meet industry standards and compatibility with existing equipment.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budget-conscious buyers, especially when considering inventory levels and storage costs. This term helps in planning procurement strategies effectively.

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It is particularly important for B2B transactions to ensure that buyers receive competitive pricing and terms. Understanding the RFQ process can lead to better negotiation outcomes and cost savings.

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risks, and delivery obligations, which can greatly impact the overall cost of procurement.

Warranty Terms

Warranty terms outline the conditions under which a product can be returned or repaired. Knowledge of warranty coverage is critical for assessing the long-term value and reliability of an air inflator. This information helps buyers make informed decisions regarding maintenance and replacement costs.

By understanding these technical properties and trade terminologies, B2B buyers can make informed purchasing decisions that align with their operational needs and market demands.

The global air inflator with gauge market is witnessing significant growth driven by several factors, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The increasing prevalence of vehicle ownership, coupled with a rising awareness of the importance of tire maintenance for safety and efficiency, fuels demand. Moreover, technological advancements, such as the integration of digital pressure gauges and portable air compressors, have enhanced product functionality, appealing to both professional mechanics and everyday consumers.

In addition to traditional automotive applications, the versatility of air inflators with gauges is being recognized in other sectors, including sports equipment and DIY projects. International B2B buyers are increasingly seeking products that offer a blend of reliability, speed, and precision, reflecting a shift towards quality over cost. Furthermore, e-commerce platforms have transformed sourcing strategies, enabling buyers to access a broader range of products and suppliers, thus enhancing competition and driving innovation in the sector.

Illustrative image related to air inflator with gauge

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the air inflator with gauge sector. The environmental impact of manufacturing processes and the materials used in these products is under scrutiny, prompting many companies to adopt greener practices. For instance, sourcing from suppliers that utilize recyclable materials or renewable energy can significantly reduce the carbon footprint associated with production.

Moreover, the demand for certifications such as ISO 14001 (Environmental Management) is on the rise, as businesses look to align with global sustainability standards. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical labor practices and transparency in their supply chains. This shift not only appeals to environmentally conscious consumers but also enhances brand reputation and loyalty. By emphasizing sustainability in sourcing decisions, B2B buyers can differentiate themselves in a competitive market while contributing to a more sustainable future.

The air inflator with gauge has evolved significantly over the years, transitioning from manual pumps to sophisticated digital devices. Initially, these tools were simple, mechanical devices that required manual effort to inflate tires. However, advancements in technology have led to the development of electric and battery-operated inflators that offer convenience and efficiency.

The introduction of digital gauges has further transformed the landscape, providing users with precise pressure readings and enhancing the accuracy of inflation. The modern inflators often come equipped with features such as auto shut-off, programmable pressure settings, and compatibility with multiple power sources, catering to diverse user needs. This evolution reflects a broader trend towards automation and user-friendly designs in the automotive accessories market, making air inflators with gauges essential tools for both professionals and everyday consumers.

Understanding the market dynamics and sourcing trends in the air inflator with gauge sector is crucial for international B2B buyers. By keeping abreast of technological advancements and prioritizing sustainability, businesses can make informed sourcing decisions that align with both market demands and ethical standards. As the sector continues to evolve, those who adapt to these changes will be well-positioned to capitalize on emerging opportunities and drive growth.

Illustrative image related to air inflator with gauge

How do I ensure the air inflator with gauge meets international quality standards?

To ensure that the air inflator with gauge complies with international quality standards, request certifications such as ISO 9001, CE, or other relevant marks depending on your target market. It’s crucial to verify the supplier’s production processes and quality assurance measures. Conducting factory audits or third-party inspections can provide additional assurance. Furthermore, reviewing customer feedback and performance data can help gauge product reliability and compliance with industry standards.

What is the best air inflator with gauge for high-volume tire maintenance?

For high-volume tire maintenance, the best air inflator with gauge is one that offers fast inflation rates, durability, and a high PSI range. Look for models with automatic shut-off features and built-in pressure gauges for accuracy. Heavy-duty options with robust construction, such as those designed for commercial garages or fleet maintenance, are recommended. Evaluate specific features like portability, power source (AC/DC), and additional attachments that enhance usability for various tire types.

What are the typical minimum order quantities (MOQs) for air inflators with gauges?

Minimum order quantities (MOQs) for air inflators with gauges can vary significantly by supplier and product type. Generally, MOQs can range from 50 to 500 units for standard models, while customized or specialized inflators may require higher quantities. It’s advisable to discuss your requirements with potential suppliers to negotiate favorable terms. Keep in mind that larger orders may also lead to better pricing and shipping efficiencies.

How can I vet suppliers for air inflators with gauges?

Vetting suppliers involves researching their business credentials, manufacturing capabilities, and reputation in the industry. Start by checking references and reading reviews from other B2B buyers. Assess their certifications and compliance with international standards. Request samples to evaluate product quality firsthand. Additionally, consider conducting site visits or virtual audits to understand their operational practices and quality control processes better.

What payment terms are common in international transactions for air inflators with gauges?

Common payment terms for international transactions may include letters of credit, wire transfers, or payment upon delivery, depending on the supplier’s policies and buyer-seller relationship. It’s essential to clarify payment terms before finalizing contracts to avoid misunderstandings. Some suppliers might offer favorable terms like net 30 or 60 days, especially for long-term clients. Always ensure that terms are documented in the contract to protect both parties.

What logistics considerations should I keep in mind when importing air inflators with gauges?

When importing air inflators with gauges, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure you understand the import regulations of your destination country, including any tariffs. Working with a reliable freight forwarder can help streamline the process and ensure compliance with all necessary documentation.

Can I customize air inflators with gauges for my brand?

Yes, many manufacturers offer customization options for air inflators with gauges. Customization can include branding with your logo, specific color schemes, or tailored features that suit your market’s needs. When discussing customization, provide clear specifications and consider the associated costs and lead times. Be aware that customized products may have higher MOQs and require upfront payments or deposits.

What quality assurance measures should I expect from suppliers of air inflators with gauges?

Reputable suppliers should have comprehensive quality assurance measures in place, including regular product testing, adherence to international standards, and detailed inspection processes. Expect them to provide documentation of quality tests, such as pressure accuracy and durability assessments. It’s advisable to ask about their return policy and warranty options, as these can indicate their confidence in product quality and commitment to customer satisfaction.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Milton – Recommended for tire gauges. 2. Longacre – Offers analog and digital models, known for accuracy and temperature compensation, used by racers. 3. Astro – Suggested for tire inflators, priced around $80, noted for convenience. 4. Matco DT6 – Priced at $160, rebranded Astro 3018 at $90, similar in design.

Domain: steelmantools.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘STEELMAN # 75052 Straight Chuck Tire Inflator with Built-In Gauge and Green 12-Inch Hose’, ‘price’: ‘$29.99’, ‘availability’: ‘In stock’}, {‘name’: ‘STEELMAN # 75051 Straight Chuck Tire Inflator with Built-In Gauge and 12-Inch Hose’, ‘price’: ‘$21.99’, ‘availability’: ‘In stock’}, {‘name’: ‘STEELMAN # 97977 High Accuracy Digital Gauge Tire Inflator with Temperature Compensation and 15-I…

Domain: mactools.com

Registered: 1997 (28 years)

Introduction: This company, MacTools – Analog Tire Inflator Gauge, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In summary, the strategic sourcing of air inflators with gauges is essential for businesses aiming to enhance operational efficiency and customer satisfaction. These tools not only ensure optimal tire pressure, leading to improved fuel efficiency and tire longevity, but they also represent a significant value proposition for B2B buyers across diverse markets. The growing demand for reliable, portable, and user-friendly inflators highlights the importance of selecting high-quality products that cater to various inflation needs, whether for automotive, recreational, or industrial applications.

As international buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their supply chains, investing in top-tier inflators with gauges can provide a competitive edge. By leveraging strategic sourcing practices, businesses can access innovative solutions that meet evolving market demands while ensuring compliance with safety and performance standards.

Looking ahead, the landscape for air inflators is poised for growth, with advancements in technology and design. We encourage B2B buyers to engage with reputable suppliers and explore the latest offerings in this dynamic market. This proactive approach not only enhances product offerings but also strengthens partnerships that drive long-term success.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air inflator with gauge

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.