Navigating the global market for the Airshot tubeless tire inflator presents a unique challenge for B2B buyers, particularly those seeking efficient solutions for tire maintenance in diverse terrains and climates. Sourcing reliable tools that streamline the inflation process for tubeless tires is essential for businesses aiming to enhance operational efficiency and reduce downtime. The Airshot inflator stands out as a premier option, combining ease of use, durability, and compatibility with various valve types, making it an indispensable asset for workshops and retail operations alike.

This comprehensive guide will delve into various aspects of the Airshot tubeless tire inflator, including its types, applications, and the nuances of supplier vetting. Buyers will gain insights into cost structures and the factors influencing pricing in different regions, ensuring they make informed purchasing decisions. Additionally, we will explore best practices for integrating the Airshot inflator into existing workflows, enhancing productivity while minimizing service interruptions.

By equipping international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—with actionable insights, this guide empowers them to source the best products tailored to their specific needs. Investing in the right tools not only improves service quality but also fosters customer satisfaction and loyalty in an increasingly competitive landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Airshot Original Inflator | Aluminum construction, tool-free operation, compatible with Presta valves | Bike shops, cycling events, mobile repair services | Pros: Reliable, easy to use, durable. Cons: Initial cost may be higher than basic models. |

| Airshot Valve Core Adapter | Adapter for compatibility with non-Presta valves | Workshops, multi-sport facilities | Pros: Expands usability, cost-effective. Cons: Additional component to manage. |

| Airshot Spare Filling Valve | Replacement valve for maintenance | Retailers, bike repair shops | Pros: Ensures longevity, easy to replace. Cons: Minimal added expense. |

| Airshot Tubeless Repair Kit | Includes sealant and tools for emergency repairs | Mobile mechanics, cycling tours | Pros: Comprehensive solution, promotes customer loyalty. Cons: Requires additional storage space. |

| Airshot Professional Kit | Complete package with multiple inflators and adapters | Large bike retailers, event organizers | Pros: Versatile, accommodates various tire sizes. Cons: Higher upfront investment. |

The Airshot Original Inflator is designed for ease of use, featuring an aluminum body that withstands wear and tear. Its tool-free operation allows users to inflate tubeless tires quickly, making it ideal for bike shops and mobile repair services. The compatibility with Presta valves ensures broad applicability in the cycling industry. B2B buyers should consider its reliability and durability, as these features can enhance customer satisfaction and reduce long-term costs.

The Airshot Valve Core Adapter is a specialized accessory that allows the inflator to be used with non-Presta valves. This versatility makes it a valuable addition for workshops and multi-sport facilities that cater to a diverse clientele. While it expands the inflator’s usability, B2B buyers should be aware that it adds an extra component to manage, which may require additional training for staff.

Illustrative image related to airshot tubeless tire inflator

The Airshot Spare Filling Valve serves as a replacement part for the original inflator, ensuring its longevity and consistent performance. This product is particularly useful for retailers and bike repair shops that prioritize offering reliable services to their customers. The straightforward replacement process makes it easy to maintain, though it represents a minimal added expense that buyers should factor into their overall budget.

The Airshot Tubeless Repair Kit includes essential tools and sealant for emergency tire repairs, making it suitable for mobile mechanics and cycling tours. This comprehensive solution not only addresses immediate repair needs but also fosters customer loyalty by providing a one-stop-shop experience. However, B2B buyers should consider the need for additional storage space to accommodate the kit’s components.

The Airshot Professional Kit is a complete package that includes multiple inflators and adapters, catering to large bike retailers and event organizers. Its versatility allows it to accommodate various tire sizes, making it a worthwhile investment for businesses that handle high volumes of tire installations. While the higher upfront investment may be a consideration, the potential for increased efficiency and customer satisfaction can justify the cost.

| Industry/Sector | Specific Application of Airshot Tubeless Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Assisting in the assembly of tubeless bike tires | Reduces assembly time and minimizes the need for external air compressors | Ensure compatibility with various tire and rim sizes |

| Automotive Repair Shops | Quick tire installations for tubeless tires | Enhances service efficiency and customer satisfaction | Durability and ease of use in a high-paced environment |

| Outdoor Adventure Retail | Customer demonstrations for tubeless tire setups | Increases customer confidence in tubeless systems | Lightweight and portable design for easy transport |

| Bicycle Rental Services | Routine maintenance of tubeless tires in fleet bikes | Lowers operational costs and improves turnaround time | Reliable performance under diverse environmental conditions |

| Sporting Goods Retailers | Retail displays and workshops for tubeless tire products | Educates consumers, driving sales of tubeless systems | Availability of spare parts and accessories for customers |

In the bicycle manufacturing industry, the Airshot tubeless tire inflator is utilized during the assembly process of tubeless tires. By allowing manufacturers to quickly seat tire beads without the need for bulky air compressors, the Airshot significantly reduces assembly time. This efficiency not only speeds up production but also minimizes reliance on external air sources, making the manufacturing process more streamlined. For international buyers, sourcing considerations should include compatibility with various tire and rim sizes to ensure a versatile application.

Automotive repair shops benefit from the Airshot tubeless tire inflator by using it for quick tire installations and repairs of tubeless tires. The inflator allows technicians to efficiently seat tire beads, which enhances service efficiency and improves customer satisfaction. By eliminating the need for time-consuming trips to the compressor, repair shops can serve more customers in less time. Buyers should consider the durability and ease of use of the device, especially in high-paced environments.

Outdoor adventure retailers can leverage the Airshot tubeless tire inflator for customer demonstrations, showcasing the ease of setting up tubeless tires. This hands-on experience helps to build customer confidence in tubeless systems, ultimately driving sales. By providing workshops or live demonstrations, retailers can educate consumers about the benefits of tubeless tires, including puncture resistance and lower maintenance. Key sourcing considerations include ensuring the inflator’s lightweight and portable design for easy transport during events.

Bicycle rental services utilize the Airshot tubeless tire inflator for routine maintenance of fleet bikes. The inflator allows staff to quickly and efficiently maintain tubeless tires, which lowers operational costs and improves turnaround time for bike rentals. By ensuring that all bikes are ready for use without lengthy maintenance periods, rental services can enhance customer satisfaction. Buyers in this sector should focus on the inflator’s reliable performance under diverse environmental conditions to accommodate various terrains.

Sporting goods retailers can incorporate the Airshot tubeless tire inflator into retail displays and workshops dedicated to tubeless tire products. This strategy not only educates consumers about the benefits of tubeless systems but also drives sales of related products. By providing customers with easy access to the inflator and its accessories, retailers can enhance the shopping experience. Availability of spare parts and accessories is a key sourcing consideration for retailers looking to support their customers effectively.

Illustrative image related to airshot tubeless tire inflator

The Problem: B2B buyers in the cycling industry often encounter significant challenges when attempting to install tubeless tires. Traditional methods, such as using floor pumps or CO2 cartridges, can be time-consuming and ineffective, leading to frustrations among mechanics and customers alike. This problem is compounded when dealing with stubborn tires that refuse to bead properly, resulting in wasted time and increased operational costs. Shops may find themselves losing business as customers opt for competitors who can provide more reliable tire installation services.

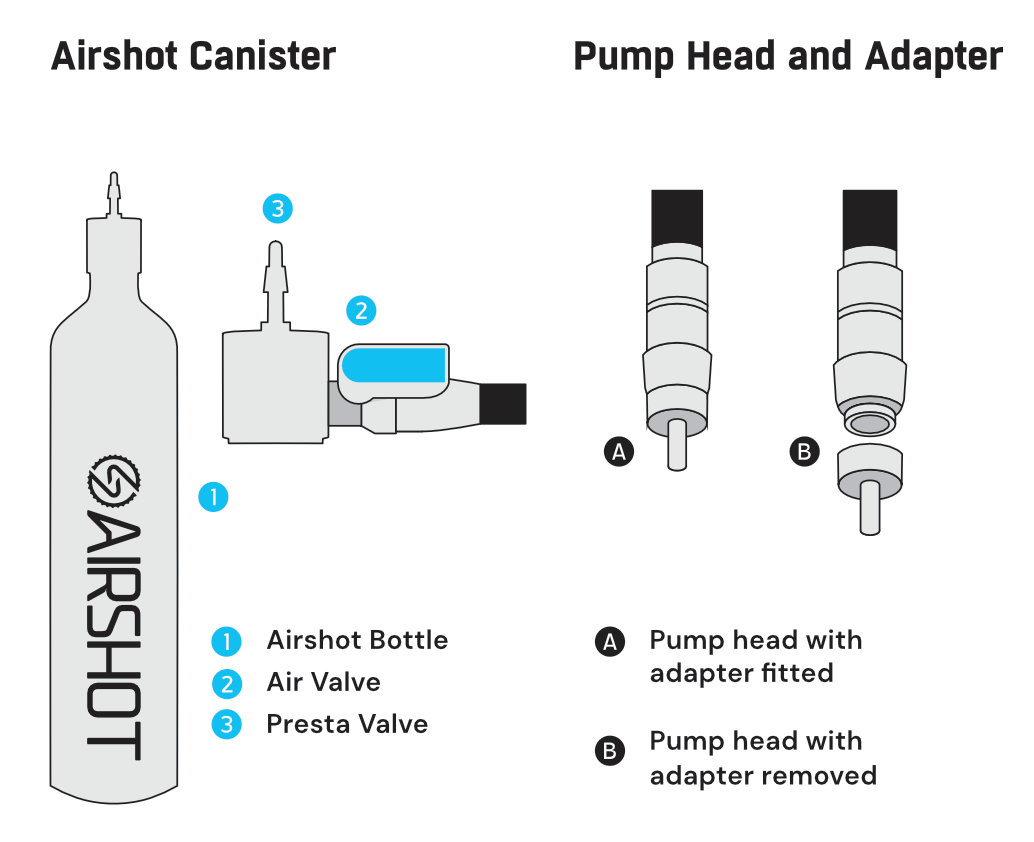

The Solution: To mitigate these challenges, businesses should invest in the Airshot Tubeless Tire Inflator, which is specifically designed to simplify the tubeless tire installation process. By utilizing an ordinary track pump to pressurize the Airshot, users can release a powerful burst of air that effectively seats the tire bead against the rim. This tool is not only easy to use but also compatible with both Presta and Schrader valves, ensuring versatility across various bike models. B2B buyers should consider sourcing multiple units for their workshops to streamline tire installation, reduce customer wait times, and enhance overall service quality.

The Problem: Many B2B buyers may struggle with the proper usage of the Airshot Tubeless Tire Inflator due to a lack of familiarity with the product or insufficient training. This can lead to improper setup, ineffective inflation, and ultimately, customer dissatisfaction. For instance, if a mechanic fails to ensure that the air valve is in the closed position before pressurizing the Airshot, they risk damaging the inflator or failing to inflate the tire entirely. Such errors can tarnish a business’s reputation and result in costly repairs or replacements.

The Solution: To address this issue, businesses should invest in comprehensive training programs for their staff, focusing on the correct usage of the Airshot Tubeless Tire Inflator. This can include workshops, instructional videos, and hands-on practice sessions that cover everything from setup to troubleshooting common problems. Additionally, providing easy-to-follow guides or quick-reference cards at workstations can help mechanics quickly recall essential procedures. By ensuring that all team members are well-versed in using the Airshot, businesses can improve their operational efficiency and enhance the customer experience.

The Problem: B2B buyers may have reservations about the durability and reliability of the Airshot Tubeless Tire Inflator, particularly in high-volume environments where equipment is subjected to frequent use. Concerns about product longevity can be a significant barrier to purchase, especially for companies looking to make a long-term investment. If the inflator fails prematurely or requires frequent repairs, it can disrupt operations and lead to increased costs and lost revenue.

The Solution: To alleviate these concerns, buyers should conduct thorough research on the quality and reliability of the Airshot Tubeless Tire Inflator before making a purchase. Seeking out user reviews, case studies, and testimonials can provide valuable insights into the product’s performance in real-world scenarios. Additionally, establishing a relationship with the manufacturer for ongoing support and warranty options can further assure buyers of the product’s durability. By prioritizing quality and sourcing products known for their reliability, B2B buyers can minimize the risk of operational disruptions and enhance their service offerings.

Illustrative image related to airshot tubeless tire inflator

When selecting materials for the Airshot tubeless tire inflator, it is essential to consider properties that impact performance, durability, and cost-effectiveness. Here, we analyze four common materials: aluminum, high-density polyethylene (HDPE), rubber, and brass. Each material has distinct advantages and disadvantages, making them suitable for specific applications in the inflator’s design.

Aluminum is the primary material used in the Airshot tubeless tire inflator’s body. It has excellent strength-to-weight ratio, allowing for a lightweight yet robust design. Aluminum can withstand high pressures, typically rated up to 200 psi, making it ideal for the rapid air release needed to seat tubeless tires. Additionally, it exhibits good corrosion resistance, especially when anodized.

Pros: Aluminum is durable, lightweight, and offers excellent pressure tolerance. It is also relatively easy to manufacture and can be formed into complex shapes.

Cons: The primary drawback is its cost, which can be higher than some plastics. Additionally, while it resists corrosion, it can still be susceptible to scratches and dents if not handled properly.

Illustrative image related to airshot tubeless tire inflator

Impact on Application: Aluminum’s compatibility with high-pressure applications makes it suitable for inflators, while its lightweight nature enhances portability.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should verify that the aluminum used meets these standards, especially in regions with stringent regulations like Europe.

High-density polyethylene (HDPE) is often used for parts such as seals and adapters in the Airshot inflator. HDPE is known for its excellent chemical resistance, making it suitable for use with tire sealants and other media. It has a moderate temperature tolerance, typically ranging from -40°C to 80°C.

Pros: HDPE is lightweight, cost-effective, and highly resistant to impact and moisture. It is also easy to mold into various shapes, which is advantageous for manufacturing.

Cons: While HDPE is durable, it may not withstand extreme temperatures as well as metals. Its pressure rating is lower than aluminum, which could limit its use in high-pressure applications.

Impact on Application: HDPE’s chemical resistance makes it suitable for components that come into contact with tire sealants, ensuring compatibility and longevity.

Considerations for International Buyers: Buyers should ensure that HDPE components comply with local regulations regarding plastics, especially in regions like South America and Africa, where environmental standards may differ.

Illustrative image related to airshot tubeless tire inflator

Rubber is commonly used for seals and gaskets in the Airshot inflator. Its elasticity and ability to create airtight seals are crucial for maintaining pressure within the inflator. Rubber can typically withstand temperatures from -30°C to 100°C, making it versatile for various climates.

Pros: Rubber is excellent for sealing applications due to its flexibility and resilience. It is also relatively inexpensive and widely available.

Cons: Over time, rubber can degrade due to exposure to UV light and ozone, which may limit its lifespan. Additionally, it may not perform well in extreme temperature conditions.

Illustrative image related to airshot tubeless tire inflator

Impact on Application: Rubber’s sealing capabilities are vital for maintaining pressure and ensuring the effective operation of the inflator.

Considerations for International Buyers: Buyers should check for compliance with standards such as JIS and ASTM, particularly in regions with varying climate conditions that may affect rubber performance.

Brass is often used for fittings and valves in the Airshot inflator due to its excellent corrosion resistance and durability. It can withstand high pressures and is less likely to fail under stress compared to plastic alternatives.

Pros: Brass is highly durable and offers good resistance to corrosion, making it suitable for parts exposed to air and moisture. It also has a high-temperature tolerance.

Cons: Brass can be more expensive than other materials like plastic. Additionally, its weight may be a consideration for portable applications.

Illustrative image related to airshot tubeless tire inflator

Impact on Application: The use of brass in fittings ensures reliable connections and long-term durability, critical for high-pressure applications.

Considerations for International Buyers: Compliance with international standards for brass components is essential, especially in regions like the Middle East, where metal quality can vary significantly.

| Material | Typical Use Case for airshot tubeless tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body of the inflator | Lightweight and high pressure tolerance | Higher cost, susceptible to scratches | High |

| High-Density Polyethylene (HDPE) | Seals and adapters | Excellent chemical resistance | Lower temperature tolerance | Medium |

| Rubber | Seals and gaskets | Excellent sealing capabilities | Degrades over time with UV exposure | Low |

| Brass | Fittings and valves | Corrosion resistance and durability | Higher cost, heavier than plastic | Medium |

This strategic material selection guide provides insights into the materials used in the Airshot tubeless tire inflator, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

Illustrative image related to airshot tubeless tire inflator

The manufacturing process of the Airshot Tubeless Tire Inflator involves several key stages that ensure the final product is not only functional but also reliable and durable. Understanding these stages can help B2B buyers assess the quality and efficiency of their suppliers.

The first stage involves selecting high-quality materials that can withstand high pressure and environmental stressors. Common materials include aluminum for the body, which provides strength without adding excessive weight, and durable plastics for various components. Suppliers must ensure that materials meet industry standards for safety and performance.

Once the materials are prepared, they undergo various forming techniques. Aluminum components are typically produced through processes such as extrusion or machining, which provide precise dimensions and surface finishes. Plastic parts may be created using injection molding, allowing for intricate designs that meet specific functional requirements. Each technique is chosen based on the component’s design and required performance characteristics.

After forming, the components are assembled. This stage requires careful attention to detail, as proper assembly is crucial for the inflator’s performance. Automated assembly lines may be used for efficiency, but manual assembly is also common, especially for quality-critical components. This ensures that every inflator meets the specified design and functionality.

Finally, the inflators undergo finishing processes, including surface treatment and coating to enhance durability and aesthetics. Anodizing aluminum can provide additional corrosion resistance, while quality control checks ensure that all components are assembled correctly and function as intended. This stage often includes the application of branding elements and packaging for distribution.

Quality assurance (QA) is a vital aspect of the manufacturing process for Airshot Tubeless Tire Inflators. It ensures that the final product meets international standards and customer expectations.

To maintain high-quality production, manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer has established processes for consistently delivering quality products. Additionally, certifications such as CE mark and API (American Petroleum Institute) standards may apply depending on the market and use case.

Quality control is integrated into the manufacturing process at various checkpoints, including:

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials upon arrival. Suppliers are assessed based on their ability to provide materials that meet specified standards.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each stage adheres to quality standards. This may involve measuring dimensions, assessing surface finishes, and ensuring proper assembly techniques.

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted. This includes functional testing, pressure testing, and visual inspections to confirm that the inflators perform as expected and meet safety standards.

Manufacturers utilize various testing methods to validate the performance and safety of the Airshot Tubeless Tire Inflator. Common testing techniques include:

Pressure Testing: This involves subjecting the inflator to high pressures to ensure it can withstand operational conditions without failure. It is a critical test for safety and functionality.

Functional Testing: Each inflator is tested to confirm it performs as designed, including the ability to inflate tires efficiently and maintain pressure.

Durability Testing: Components may undergo stress tests to simulate long-term use, ensuring that they can withstand wear and tear over time.

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are several methods to assess supplier quality:

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes, quality management systems, and adherence to international standards. This helps buyers identify potential risks and areas for improvement.

Quality Reports: Requesting documentation of quality control procedures and test results can give buyers confidence in the supplier’s commitment to quality. Suppliers should be able to provide detailed reports on IQC, IPQC, and FQC processes.

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality. This is particularly important for international buyers who may not have direct oversight of the manufacturing process.

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances when sourcing Airshot Tubeless Tire Inflators:

Regulatory Compliance: Each region may have different regulatory requirements that impact product quality. Understanding these regulations is essential for compliance and market entry.

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality and performance. Buyers must communicate their specific requirements clearly to avoid misunderstandings.

Logistics and Supply Chain Considerations: International shipping can introduce risks that affect product quality, such as exposure to extreme temperatures or humidity. Buyers should ensure that suppliers have robust packaging and shipping practices to mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance practices associated with the Airshot Tubeless Tire Inflator is crucial for B2B buyers. By focusing on quality at every stage, from material preparation to final inspection, suppliers can deliver a product that meets the high standards expected in today’s competitive markets.

This guide serves as a comprehensive checklist for B2B buyers interested in procuring the Airshot Tubeless Tire Inflator. This tool is essential for efficient tire inflation, particularly in markets where quick and reliable solutions are necessary. The following steps will help you ensure that you choose the right product and supplier for your needs.

Understanding the specifications you need is crucial before making a purchase. The Airshot Tubeless Tire Inflator requires a floor pump capable of reaching 120-160 psi for optimal performance. Make sure to consider compatibility with Presta valves and any necessary adapters for your operations.

Not all suppliers are created equal, especially in international markets. Look for companies with a proven track record in distributing high-quality bicycle accessories. Check their online reviews, ask for references, and evaluate their customer service responsiveness.

Ensure that the Airshot you are considering is an original product. Counterfeit items may not perform as expected and could lead to customer dissatisfaction. Request documentation of certifications and quality assurance processes from the supplier to validate the product’s authenticity.

Illustrative image related to airshot tubeless tire inflator

Pricing can vary significantly among suppliers, so it’s important to compare costs. Make sure to factor in shipping fees, customs duties, and delivery times, especially for international orders. Look for suppliers that offer bulk purchase discounts or flexible payment options to enhance your procurement strategy.

After-sales support is vital for maintenance and troubleshooting. Inquire about warranty terms and the availability of spare parts, such as valve core adapters or filling valves. Reliable customer support can save you time and money in case of any issues with the product.

Stay informed about the cycling market trends in your target regions, such as Africa, South America, the Middle East, and Europe. Understanding local demand for tubeless tire solutions will help you make informed purchasing decisions and optimize your inventory levels.

Illustrative image related to airshot tubeless tire inflator

Before committing to a large order, consider making a smaller trial purchase. This allows you to evaluate the product’s performance and the supplier’s reliability firsthand. Gather feedback from your team on usability and effectiveness to ensure it meets your operational standards.

By following this checklist, you will be well-equipped to make an informed purchasing decision regarding the Airshot Tubeless Tire Inflator, ensuring that it meets your business needs while delivering value to your customers.

When analyzing the cost structure for the Airshot tubeless tire inflator, several key components must be considered. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The Airshot inflator is constructed from high-quality aluminum and components designed for durability. The cost of raw materials can fluctuate based on market demand, impacting overall pricing. Buyers should consider sourcing materials that offer a balance between quality and cost-effectiveness to ensure longevity and reliability.

Labor: Labor costs can vary significantly depending on the region of production. In countries with lower labor costs, manufacturers can offer more competitive pricing. However, this may come at the expense of quality if not managed properly. It’s essential to evaluate the skill level and training of the workforce involved in production to ensure consistent quality.

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing for better pricing strategies. Buyers should inquire about the manufacturer’s operational efficiencies as they can directly impact product pricing.

Tooling: The cost of specialized equipment and tooling required for production can be substantial. This is especially relevant for customized orders or variations of the Airshot inflator. Understanding the tooling costs can help buyers gauge the feasibility of their specific requirements.

Quality Control: Ensuring that products meet safety and performance standards requires investment in quality control measures. This may involve testing, inspections, and certifications. Buyers should consider the importance of these factors in their sourcing decisions, as high-quality products can reduce the total cost of ownership.

Logistics: Shipping and handling costs can significantly affect the final price. Factors such as distance, mode of transport, and Incoterms will play a role in determining logistics expenses. Buyers should assess the total logistics costs, especially when sourcing from international suppliers.

Margin: Manufacturers will typically apply a markup to cover their costs and achieve profitability. Understanding typical margins in the industry can help buyers negotiate better deals.

Several price influencers can affect the overall cost of sourcing the Airshot tubeless tire inflator:

Illustrative image related to airshot tubeless tire inflator

Volume/MOQ: Larger order quantities often result in lower per-unit costs due to economies of scale. Buyers should assess their demand forecasts to negotiate minimum order quantities (MOQs) effectively.

Specs/Customization: Custom features or specifications can lead to increased costs. Buyers should weigh the benefits of customization against potential price hikes.

Materials: The choice of materials can significantly affect pricing. Opting for premium materials may enhance durability but will also increase costs. Buyers should consider their target market’s expectations when selecting materials.

Quality/Certifications: Products with higher certifications and quality assurances may command higher prices. International buyers should consider the value of these certifications in their markets.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better service and product assurance.

Incoterms: Understanding the Incoterms can help buyers manage shipping risks and costs effectively. Incoterms dictate the responsibilities of buyers and sellers, impacting the final landed cost.

Negotiation: Engage in open discussions with suppliers about pricing, payment terms, and potential discounts for bulk orders. Building a good relationship can lead to more favorable terms.

Cost-Efficiency: Consider the total cost of ownership rather than just the upfront cost. A cheaper initial price may lead to higher long-term costs due to durability issues or increased maintenance needs.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and taxes that can affect overall costs. Understanding local market conditions in regions like Africa, South America, the Middle East, and Europe is essential for effective budgeting.

Supplier Evaluation: Conduct thorough due diligence on potential suppliers. Look for reviews, certifications, and case studies to ensure they can meet your quality and delivery requirements.

Trial Orders: If possible, place small trial orders to assess product quality and supplier reliability before committing to larger volumes.

The prices and cost components outlined are indicative and subject to change based on market conditions, supplier negotiations, and other external factors. Always conduct thorough market research and supplier evaluations to ensure the best sourcing decisions for your business needs.

When it comes to inflating tubeless tires, the Airshot Tubeless Tire Inflator has garnered attention for its efficiency and user-friendly design. However, B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, should consider other viable alternatives that may fit their specific requirements. This comparison aims to provide insights into the performance, cost, ease of implementation, maintenance, and best use cases for the Airshot and its alternatives.

| Comparison Aspect | Airshot Tubeless Tire Inflator | CO2 Inflators | Electric Tire Pumps |

|---|---|---|---|

| Performance | High pressure, rapid inflation; effectively seats tire beads | Quick inflation but limited to small tires; can be inconsistent | Moderate pressure; suitable for multiple applications but slower than Airshot |

| Cost | $82 USD | $20 – $50 USD per unit (plus recurring CO2 costs) | $30 – $100 USD |

| Ease of Implementation | Simple, tool-free setup; requires a track pump | Very easy, single-use, no setup required | Plug-and-play; requires charging or a power source |

| Maintenance | Low; durable materials and components | Very low; replace CO2 cartridges as needed | Moderate; requires regular checks and maintenance |

| Best Use Case | Ideal for bike shops and enthusiasts needing consistent performance | Great for emergency situations and lightweight setups | Suitable for home use and multiple vehicles |

CO2 inflators are popular for their portability and ease of use. They allow users to quickly inflate a tire using compressed CO2 cartridges. However, while they are effective for emergency situations, they may not provide enough force to seat the tire bead properly on larger or stubborn tires. Additionally, the ongoing cost of purchasing CO2 cartridges can add up over time. Their best use case is for cyclists on the go who need a lightweight solution for quick fixes.

Electric tire pumps offer a convenient alternative, particularly for those who may not have access to a track pump. They can inflate a variety of tires, from bicycles to cars, making them versatile. However, their performance can be slower compared to the Airshot, particularly for tubeless tires that require higher pressure to seat beads effectively. Maintenance can also be more demanding, as they need regular checks and charging. Electric pumps are best suited for home use where users require a multi-functional tool.

Illustrative image related to airshot tubeless tire inflator

Selecting the appropriate tire inflation solution depends on the specific needs of the buyer. For businesses focused on high-performance tire installations, such as bike shops, the Airshot Tubeless Tire Inflator stands out for its efficiency and reliability. Alternatively, if portability and emergency readiness are paramount, CO2 inflators may be the better choice. For those seeking a versatile solution for various tire types, electric pumps could be the ideal fit. By carefully assessing performance, cost, and usage scenarios, B2B buyers can make informed decisions that align with their operational requirements.

The Airshot Tubeless Tire Inflator is constructed from high-grade aluminum, which offers a combination of lightweight durability and resistance to corrosion. This is crucial for B2B buyers as it ensures the product can withstand the rigors of frequent use, particularly in environments where exposure to moisture and varying temperatures is common. The choice of material impacts the product’s lifespan and performance, making it a critical consideration for businesses seeking reliable inflators.

The inflator is designed to operate within a pressure range of 120 to 160 PSI. This specification is vital for professional users, as it indicates the inflator’s capability to seat tires effectively without the risk of equipment failure. Understanding this pressure rating allows businesses to ensure that their inflator is compatible with the specific tire types and sizes they deal with, thereby enhancing operational efficiency.

The Airshot Tubeless Tire Inflator is compatible with both Presta and Schrader valves, making it a versatile tool for different types of bicycles. This feature is particularly important for B2B buyers who may cater to a diverse clientele with varying bike specifications. The ability to adapt to different valve types reduces the need for multiple tools and streamlines the tire inflation process, ultimately saving time and resources.

The inflator includes a quick release valve that allows for the rapid discharge of air. This design feature is essential for efficiently seating tire beads, which can be a challenging process. For businesses, this means reduced labor time and improved customer satisfaction, as tires can be inflated quickly and effectively. The quick release mechanism also enhances user experience, making it a valuable selling point.

The compact and lightweight design of the Airshot Tubeless Tire Inflator makes it easy to transport, whether for on-the-go repairs or use in a workshop setting. For B2B buyers, this portability is a significant advantage, as it allows for flexible usage scenarios, from mobile repair services to stationary setups. The ability to easily move the inflator can facilitate better service delivery and enhance operational versatility.

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of the Airshot Tubeless Tire Inflator, understanding OEM relationships can help businesses ensure they are sourcing high-quality components and products. This is critical for maintaining brand integrity and product reliability.

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for the Airshot Tubeless Tire Inflator is essential for inventory planning and cost management. This term helps businesses gauge the feasibility of stocking the product based on demand and financial constraints.

Illustrative image related to airshot tubeless tire inflator

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For companies looking to purchase the Airshot Tubeless Tire Inflator in bulk, issuing an RFQ allows them to compare prices and terms from different suppliers, ensuring they secure the best deal possible.

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and delivery timelines. Understanding Incoterms is crucial for B2B buyers from various regions, as they help clarify shipping obligations and costs associated with importing the Airshot Tubeless Tire Inflator.

Warranty terms specify the conditions under which a product can be repaired or replaced. For businesses investing in the Airshot Tubeless Tire Inflator, comprehending warranty terms is vital for risk management. It ensures that they are protected against defects and can maintain operational efficiency without incurring unexpected costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the Airshot Tubeless Tire Inflator, ultimately enhancing their business operations and customer service capabilities.

The global market for tubeless tire inflators, particularly the Airshot model, is experiencing significant growth driven by increased adoption of tubeless tire systems among cyclists and automotive users. This trend is particularly evident in regions like Africa, South America, the Middle East, and Europe, where cycling is gaining popularity both as a sport and a means of transportation. B2B buyers in these markets are increasingly looking for reliable, easy-to-use solutions that streamline tire maintenance, reducing dependency on traditional workshops and air compressors.

Emerging technologies are playing a crucial role in sourcing trends. For example, the integration of digital platforms for procurement and logistics is allowing buyers to access a wider range of suppliers, compare prices effectively, and read reviews from other businesses. Furthermore, the demand for durable and high-quality components is growing, with an emphasis on products that can withstand varying environmental conditions. This is particularly relevant for international buyers in regions like Saudi Arabia and Brazil, where temperature extremes can impact product performance.

Additionally, sustainability is becoming a focal point in purchasing decisions. B2B buyers are increasingly prioritizing products that minimize environmental impact, which can influence brand loyalty and market positioning. As such, suppliers that demonstrate a commitment to quality and sustainability are likely to gain a competitive edge.

Sustainability in the airshot tubeless tire inflator sector is a critical consideration for B2B buyers. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, making ethical sourcing paramount. Buyers are increasingly concerned with the materials used in production, the carbon footprint of transportation, and the overall sustainability of the supply chain.

The Airshot tubeless tire inflator is constructed from high-quality aluminum, a material that is not only durable but also recyclable. This aspect appeals to environmentally conscious buyers who are looking for products that can contribute to their sustainability goals. Additionally, suppliers who offer certifications for their products, such as ISO 14001 for environmental management, can provide added assurance to buyers regarding their commitment to sustainable practices.

By prioritizing ethical sourcing, businesses can not only enhance their brand reputation but also attract a growing segment of consumers who value sustainability. This shift is particularly prominent in markets across Europe and the Middle East, where government regulations and consumer preferences are increasingly aligned with environmental responsibility.

The Airshot tubeless tire inflator emerged as a solution to the common challenges faced by cyclists when mounting tubeless tires. Traditionally, cyclists relied on bulky air compressors, which could be cumbersome and inconvenient. The Airshot revolutionized this process by introducing a compact, easy-to-use inflator that can be charged with a standard track pump, allowing users to achieve the necessary pressure to seat tire beads without the need for specialized equipment.

Since its introduction, the Airshot has gained traction among both amateur and professional cyclists, becoming a staple in bike maintenance kits. Its design reflects an understanding of the market’s needs—namely, reliability, portability, and ease of use. As the cycling community continues to embrace tubeless technology for its benefits, such as reduced weight and improved puncture resistance, the Airshot tubeless tire inflator is poised to maintain its position as a leading product in this niche market.

How do I solve issues with inflating tubeless tires using the Airshot tubeless tire inflator?

To resolve inflation issues with the Airshot, ensure that the rim and tire are clean and free from debris. If the tire does not bead properly, apply soapy water to the bead area to facilitate seating. Make sure the air valve is closed before pressurizing the Airshot with a floor pump to the recommended pressure of 120-160 psi. If problems persist, check that the valve core is clean and free of obstructions, and consider removing it temporarily to enhance airflow.

What is the best method for using the Airshot tubeless tire inflator effectively?

The best method involves first mounting the tire loosely on the rim and applying soapy water to the bead. Attach the Airshot to the valve, ensuring the air valve is closed, then pump it to the required pressure. Open the air valve quickly to release a burst of air that seats the tire bead against the rim. After the bead is seated, you may need to use a standard pump to achieve the desired tire pressure. Always ensure the components are in good condition before use.

What are the payment terms for purchasing Airshot tubeless tire inflators in bulk?

Payment terms can vary by supplier but typically include options such as upfront payment, net 30, or net 60 days for larger orders. It’s advisable to discuss terms directly with your supplier to negotiate favorable conditions that suit your cash flow. Some suppliers may also offer discounts for early payments or larger order quantities, so be sure to inquire about these possibilities when placing a bulk order.

What is the minimum order quantity (MOQ) for Airshot tubeless tire inflators?

The minimum order quantity for Airshot inflators can vary based on the distributor or manufacturer. Generally, MOQs may range from 50 to 100 units for bulk purchases. It’s essential to communicate with your supplier to confirm their specific MOQ requirements, as this can also influence pricing and shipping arrangements. Understanding these details can help you better plan your inventory and budget.

How can I vet suppliers for Airshot tubeless tire inflators?

Vetting suppliers involves checking their credentials, reviews, and history in the industry. Look for suppliers with a proven track record in B2B sales, ideally with experience in your region. Request references and evaluate their responsiveness and customer service quality. Additionally, consider visiting their facilities if possible, or conducting a video call to assess their operations and confirm their ability to meet your needs.

What quality assurance measures should I expect with the Airshot tubeless tire inflator?

Quality assurance for the Airshot includes rigorous testing of materials and components to ensure durability and functionality. Look for suppliers that provide certifications or compliance with international quality standards. Inquire about their warranty policy and any guarantees they offer for product performance. Regular quality checks during production and before shipment can also be indicators of a reliable supplier.

What logistics options are available for shipping Airshot inflators internationally?

International shipping options for Airshot inflators typically include air freight, sea freight, and express courier services. The choice depends on your budget, urgency, and the destination country. Discussing logistics with your supplier can help you determine the most cost-effective and timely shipping method. Additionally, consider customs clearance processes and any tariffs that may apply to ensure smooth delivery to your location.

Can I customize the Airshot tubeless tire inflator for my brand?

Yes, many suppliers offer customization options for the Airshot tubeless tire inflator, including branding with your logo or specific color schemes. Customization can enhance brand visibility and create a unique selling proposition. Discuss your requirements with the supplier to understand the minimum order quantities and lead times associated with custom orders, as well as any additional costs involved in the process.

Domain: airshot.bike

Introduction: Airshot Tubeless Tyre Inflator: Regular price $82.00 USD. Easy to use, tool-free operation from garage, van, or track. Compatible with Presta valves; includes adapter for valve stem. Made with high-quality components for durability. Sustainable design, eliminates need for CO2 cylinders. Spare filling valve: Regular price $7.00 USD, made with high-quality materials for durability. Valve Core Adapte…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Airshot tire inflator is designed for seating tubeless tires. Users report it works well for various tire sizes, including 38 mm gravel and 26×2.2 MTB tires. It may require some additional techniques, such as using soapy water or pre-inflating with a tube, for stubborn tires. The product is praised for its effectiveness, reliability, and ease of use, making tire mounting less stressful and time-co…

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “AIRSHOT 1.15L Tubeless Tire Inflator Pump”, “Brand”: “Monte Carlo”, “GTIN”: “0797776068203”, “UPC”: “0797776068203”, “eBay Product ID”: “14012570058”, “Price”: “$68.99”, “Shipping”: “Free shipping”, “Returns”: “No returns, but backed by eBay Money back guarantee”, “Condition”: “New”, “Power Source”: “Electric Corded”, “Sport/Activity”: “Cycling”, “Maximum Working Pressure”: “11 b…

Domain: exploringwild.com

Registered: 2018 (7 years)

Introduction: Product Name: Airshot Tubeless Tire Inflator

Price: $64.99

Material: Aluminum

Valve Type: Presta (ideally with removable core, but not required)

Volume: 1.15 liters

Key Features:

– Compact and portable

– Works with existing floor pump

– No power required

– Simple and durable

– Takes the hassle out of installing tubeless tires

– Allows for quick tire installation with a satisfying “POP” sound when…

Domain: merlincycles.com

Registered: 1997 (28 years)

Introduction: Airshot Tubeless Tyre Inflator

– Developed for hassle-free inflation of tubeless tyres without a compressor

– Pressurized using an ordinary track pump

– Rapid but controlled air release via a release tap

– Maximum pressure: 160 Psi

– Quick and easy tubeless tyre seating

– Uses standard pump to charge

– Quick high volume air shot to seat tyre

– Weight: 0.620 kg

– Dimensions: 39.5 x 11 x 8 cm

– Avai…

Domain: thebikesettlement.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Airshot Tubeless Tyre Inflator”, “category”: “Bicycle Accessories”, “sub_category”: “Pumps & Puncture Repair”, “type”: “Floor Pumps”, “features”: [“Quick inflation of tubeless tyres”, “Lightweight and portable design”, “Compatible with Presta and Schrader valves”, “Easy to use with a simple one-step process”], “usage”: “Ideal for mountain bikers and road cyclists who use tubeless…

As the demand for efficient and reliable solutions in the cycling industry continues to grow, the Airshot tubeless tire inflator stands out as a premier choice for international B2B buyers. Its ease of use, compatibility with various valve types, and commitment to sustainability make it an indispensable tool for both individual cyclists and bike shops. By strategically sourcing the Airshot, businesses can enhance their service offerings, reduce dependency on costly compressor systems, and improve customer satisfaction by empowering users to tackle tubeless tire installations independently.

Investing in high-quality products like the Airshot not only positions your business favorably in a competitive market but also supports the transition towards more sustainable practices in the cycling sector. With the global cycling community expanding rapidly across regions such as Africa, South America, the Middle East, and Europe, now is the opportune moment to secure a reliable supply chain for this essential product.

Illustrative image related to airshot tubeless tire inflator

Embrace the opportunity to elevate your product lineup and meet the growing demand for tubeless tire solutions. Connect with suppliers today to ensure you are well-equipped to serve your customers effectively and efficiently in the evolving marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.