In the dynamic world of motorcycle maintenance, sourcing the best motorcycle tire inflator is crucial for ensuring safety and performance on the road. Flat tires can halt journeys unexpectedly, causing inconvenience and potential loss of revenue for businesses relying on two-wheeled transport. This guide addresses the challenges faced by international B2B buyers in sourcing reliable tire inflators, providing a comprehensive overview of various types, applications, and essential features to consider.

From portable electric inflators to manual pumps, this resource covers a spectrum of products tailored to meet the diverse needs of markets across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany. Buyers will find insights on supplier vetting processes, allowing them to identify trustworthy manufacturers and distributors. Additionally, the guide offers detailed cost analyses to help businesses budget effectively while maximizing quality and performance.

By equipping B2B buyers with actionable insights and in-depth product comparisons, this guide empowers them to make informed purchasing decisions. Whether you are looking to enhance your product offerings or ensure your fleet remains operational, understanding the nuances of motorcycle tire inflators is essential for success in today’s competitive landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Tire Inflators | Fast inflation, powered by battery or motorcycle outlet | Motorbike dealerships, repair shops | Pros: Quick inflation, user-friendly; Cons: Can be bulky, may require power source. |

| Hand Pumps | Manual operation, lightweight, portable | Emergency roadside kits, touring riders | Pros: No power needed, durable; Cons: Labor-intensive, slower inflation. |

| CO2 Inflators | Compact, uses CO2 cartridges for quick inflation | Off-road and adventure biking | Pros: Extremely portable, rapid inflation; Cons: Limited number of uses, cartridge costs. |

| Mini Compressors | Compact design, suitable for both motorcycle and car tires | Small workshops, personal use | Pros: Versatile, good for various tire types; Cons: Limited power, may overheat. |

| Heavy-Duty Air Compressors | High-capacity, designed for frequent use | Professional garages, fleet maintenance | Pros: Durable, fast inflation; Cons: Expensive, requires significant space. |

Electric tire inflators are favored for their speed and convenience. They connect to a motorcycle’s battery or a power outlet, allowing for rapid tire inflation. Suitable for B2B applications in motorbike dealerships and repair shops, these inflators can significantly reduce downtime for customers. Buyers should consider power requirements, noise levels, and size when purchasing, as some models can be quite bulky and may generate considerable noise during operation.

Hand pumps are a traditional choice for tire inflation, known for their simplicity and reliability. They require no power source, making them ideal for emergency roadside kits or for riders who prefer a lightweight option. While they are labor-intensive and take longer to inflate tires, their durability and ease of use can be appealing for B2B buyers looking for cost-effective solutions. When purchasing, consider factors such as weight, ease of operation, and inflation speed.

CO2 inflators are designed for quick tire inflation using pre-filled cartridges, making them incredibly portable and ideal for off-road and adventure biking. Their compact size allows for easy storage in riding gear or small toolkits. However, B2B buyers should be aware of the cost associated with purchasing replacement cartridges and the limited number of uses per cartridge. They are best suited for businesses that cater to adventure riders who prioritize weight and space savings.

Mini compressors are compact and versatile, capable of inflating both motorcycle and car tires. They are well-suited for small workshops or personal use, providing a balance between power and portability. When selecting a mini compressor, B2B buyers should consider its inflation rate, duty cycle, and ease of storage. While they may not handle heavy-duty tasks, their adaptability makes them a valuable addition to any toolkit.

Heavy-duty air compressors are designed for frequent use, making them ideal for professional garages and fleet maintenance operations. These compressors can handle larger volumes of air and provide rapid inflation, which is critical for businesses that require quick turnaround times. However, they tend to be more expensive and require more space. B2B buyers must evaluate their specific needs, including budget and available space, when considering heavy-duty options.

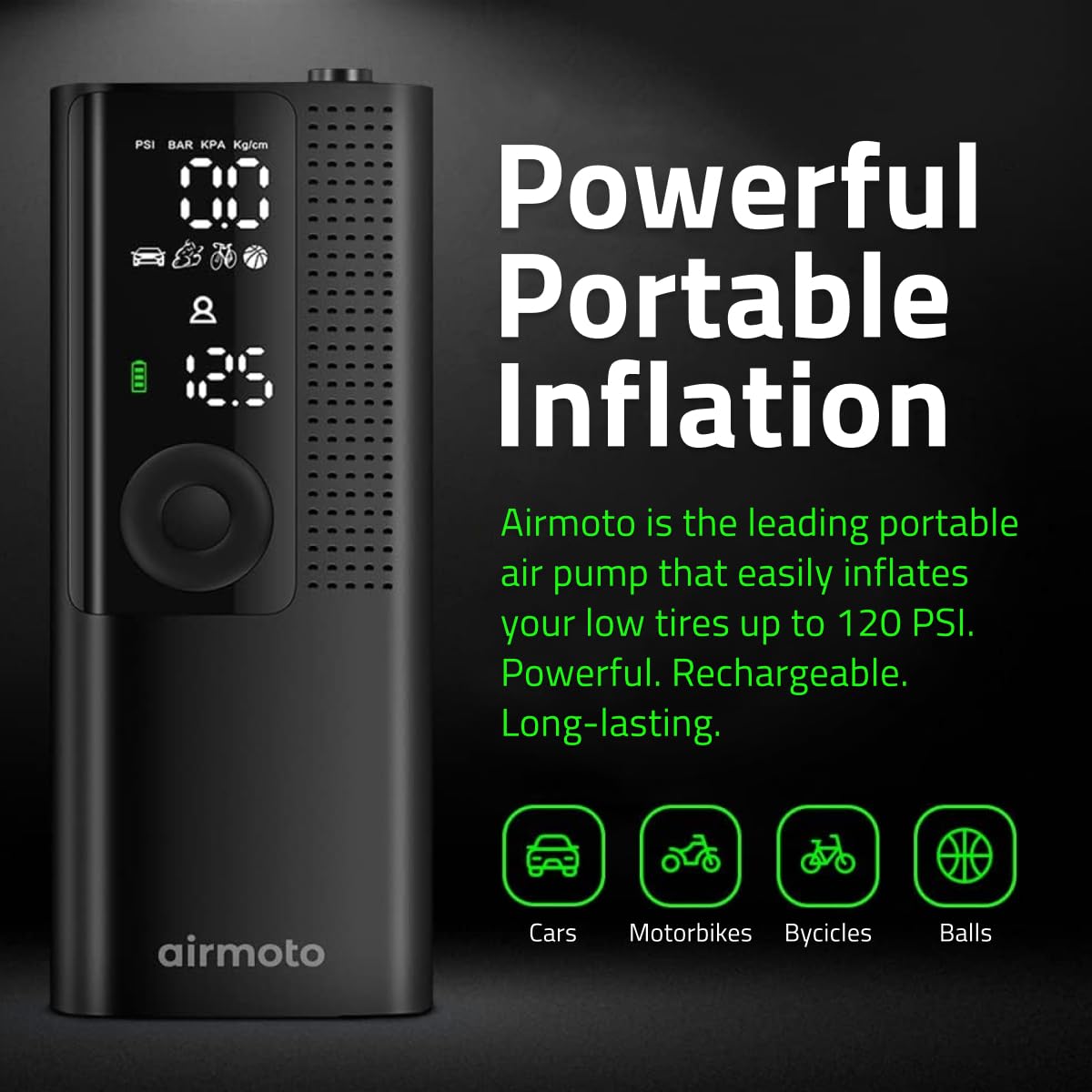

Illustrative image related to best motorcycle tire inflator

| Industry/Sector | Specific Application of best motorcycle tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Quick tire repairs on delivery motorcycles and scooters | Minimizes downtime, ensuring timely deliveries and maintaining customer satisfaction | Durability, portability, and compatibility with various power sources |

| Tourism & Adventure | Essential equipment for guided motorcycle tours | Enhances safety and reliability for tour operators, improving customer experience | Compact design, ease of use, and reliable inflation speed |

| Emergency Services | Tire maintenance for emergency response motorcycles | Ensures operational readiness, allowing quick response in critical situations | Robustness, fast inflation capabilities, and lightweight design |

| Motorcycle Dealerships | Pre-delivery checks and customer service for newly sold motorcycles | Increases customer satisfaction through prompt service and reliable maintenance | Accuracy of pressure gauges and ease of integration into service processes |

| Recreational Vehicle Rentals | Maintenance of rental motorcycles and ATVs during peak seasons | Reduces operational costs by minimizing tire-related breakdowns | Versatility for different tire types and ease of storage |

In the transportation and logistics sector, motorcycle tire inflators are crucial for delivery services using two-wheeled vehicles. These inflators allow for quick tire repairs, ensuring that delivery personnel can address flat tires on the go. By minimizing downtime, businesses can maintain their schedules and enhance customer satisfaction. When sourcing inflators, companies should consider factors such as durability, portability, and compatibility with various power sources to ensure reliability in diverse environments, especially in regions like Africa and South America where road conditions may be challenging.

For tourism and adventure companies that offer guided motorcycle tours, having a reliable tire inflator is essential. These devices enhance safety by allowing tour guides to quickly address tire issues, thus preventing potential accidents during rides. This reliability improves the overall customer experience, leading to higher satisfaction and repeat business. B2B buyers in this sector should prioritize compact designs and ease of use, as these features are vital for quick roadside repairs in remote locations across Europe and the Middle East.

Emergency services rely on motorcycles for quick response times in urban settings. A tire inflator ensures that these vehicles are always ready for action, providing the ability to perform rapid tire maintenance when needed. This capability is vital for maintaining operational readiness in critical situations. When sourcing inflators, emergency service providers should look for robust models that offer fast inflation capabilities while being lightweight for easy transport, particularly in regions with varying terrain and climate conditions.

Motorcycle dealerships utilize tire inflators for pre-delivery checks and ongoing customer service. Ensuring that motorcycles are delivered with properly inflated tires enhances customer satisfaction and reduces the likelihood of post-purchase complaints. For dealerships, accuracy in pressure gauges and ease of integration into service processes are key considerations. Sourcing high-quality inflators that can withstand frequent use is crucial for maintaining operational efficiency in competitive markets, particularly in Europe where customer expectations are high.

In the recreational vehicle rental industry, tire inflators are essential for maintaining motorcycles and ATVs, especially during peak rental seasons. These tools help reduce operational costs by minimizing the risk of tire-related breakdowns, which can lead to dissatisfied customers and lost revenue. Buyers in this sector should seek inflators that are versatile enough to handle different tire types and are easy to store, ensuring they are always ready for use in various rental scenarios across diverse geographic regions.

Illustrative image related to best motorcycle tire inflator

The Problem: B2B buyers often face the dilemma of ensuring that their motorcycle tire inflators remain functional in remote or rugged terrains. Imagine a scenario where a fleet of delivery motorcycles is operating in a rural area, and one of the inflators fails due to poor construction or improper handling. This not only halts operations but can lead to costly delays and dissatisfied customers. Additionally, the harsh environmental conditions, such as extreme temperatures or dust, can exacerbate the wear and tear on inflators, making reliability a critical concern.

The Solution: To mitigate these challenges, buyers should prioritize sourcing inflators that are specifically designed for durability and reliability in extreme conditions. Look for inflators with robust, metal construction and features such as heat resistance and waterproofing. Brands that offer warranties or guarantees on their products can provide added peace of mind. Furthermore, implementing a routine maintenance schedule can enhance the lifespan of inflators. This includes regular checks for wear, ensuring proper storage in protective cases, and training staff on correct usage techniques to prevent damage during transportation.

The Problem: Inconsistent tire pressure can lead to safety issues and increased fuel consumption, which are crucial for businesses that rely on a fleet of motorcycles. A common pain point for B2B buyers is the lack of accurate gauges on inflators, resulting in either over-inflation or under-inflation of tires. This not only affects the performance and safety of the motorcycles but can also lead to premature tire wear, increasing overall operational costs.

Illustrative image related to best motorcycle tire inflator

The Solution: Buyers should invest in inflators that come equipped with high-quality, integrated pressure gauges that provide accurate readings. When sourcing inflators, consider models that allow for preset pressure settings, which can streamline the inflation process and ensure consistency. It’s also advisable to conduct regular calibration checks on the inflators to maintain accuracy. Additionally, providing training for staff on the importance of monitoring tire pressure and how to use the inflators effectively can further enhance safety and efficiency.

The Problem: When dealing with tire issues on the road, time is of the essence. B2B buyers often find that bulky or complicated inflators can create delays in roadside assistance scenarios, impacting service delivery. For instance, a motorcycle delivery service may experience a flat tire during a busy delivery period, and if the inflator is difficult to operate or cumbersome to carry, it can lead to extended downtime.

The Solution: To address this issue, buyers should look for compact and lightweight inflators that are user-friendly. Opt for models that feature ergonomic designs and straightforward operation, allowing for quick setup and inflation. Inflators with integrated storage for power cables and hoses can also minimize clutter and enhance portability. Providing staff with hands-on training on the quickest methods to deploy and operate the inflators can reduce the time spent on roadside repairs. Additionally, consider investing in inflators that can be powered by the motorcycle’s battery or have dual power options, ensuring they are ready for use in various situations.

When selecting materials for motorcycle tire inflators, it is crucial to consider their properties, advantages, and limitations. The performance of the inflator is heavily influenced by the materials used, which can affect durability, cost, and suitability for specific applications. Here, we analyze four common materials used in the construction of motorcycle tire inflators.

Aluminum is a popular choice for the body of motorcycle tire inflators due to its lightweight and corrosion-resistant properties. It typically has a temperature rating of up to 150°C and can handle pressures exceeding 100 psi, making it suitable for high-performance applications.

Pros: Aluminum is durable, lightweight, and resistant to rust, which is essential for outdoor use. Its manufacturing process is relatively straightforward, allowing for cost-effective production.

Cons: While aluminum is strong, it can be prone to dents and scratches, which may compromise its aesthetic appeal and structural integrity over time. Additionally, it may not be as cost-effective as some other materials.

Impact on Application: Aluminum is compatible with various media, including air and CO2, making it versatile for different types of tire inflators.

Illustrative image related to best motorcycle tire inflator

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure that aluminum inflators comply with local corrosion resistance standards, as humidity and salt exposure can affect performance.

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is often used for components such as housings and hoses in motorcycle tire inflators. These plastics typically withstand temperatures up to 80°C and pressures around 50 psi.

Pros: Plastic is lightweight, cost-effective, and resistant to corrosion and chemicals, making it ideal for various environments. It can also be molded into complex shapes, allowing for innovative designs.

Illustrative image related to best motorcycle tire inflator

Cons: The main drawback is that plastic may not withstand high temperatures and pressures as effectively as metals. It can also become brittle over time, especially when exposed to UV light.

Impact on Application: Plastic is suitable for non-pressurized components but may not be ideal for high-stress parts of the inflator.

Considerations for International Buyers: Buyers should verify that the plastic used meets international standards like ASTM for safety and durability, especially in regions with extreme weather conditions.

Steel is often utilized for components requiring high strength, such as the inflator’s motor casing or pressure chambers. It can handle high temperatures (up to 300°C) and pressures, making it suitable for robust applications.

Pros: Steel is extremely durable and resistant to wear and tear, providing a long service life. It can also be treated for corrosion resistance, enhancing its longevity.

Cons: The main disadvantage is its weight, which can make the inflator cumbersome. Additionally, the manufacturing process for steel can be more complex and costly compared to aluminum or plastic.

Impact on Application: Steel is ideal for high-pressure applications but may require additional design considerations to mitigate weight issues.

Considerations for International Buyers: Buyers in Europe, particularly in Germany, should ensure that steel components comply with DIN standards for quality and safety.

Rubber is commonly used for seals and hoses in tire inflators due to its flexibility and ability to maintain a good seal under pressure. It can typically handle temperatures ranging from -40°C to 100°C.

Illustrative image related to best motorcycle tire inflator

Pros: Rubber is excellent for creating airtight seals and can absorb vibrations, enhancing the inflator’s performance. It is also relatively inexpensive.

Cons: Rubber can degrade over time, especially when exposed to ozone or UV light, which may lead to leaks or failures.

Impact on Application: Rubber is essential for components that require flexibility and sealing capabilities but may need to be replaced periodically.

Illustrative image related to best motorcycle tire inflator

Considerations for International Buyers: Buyers should check for compliance with international standards regarding rubber materials, particularly in regions with harsh climates.

| Material | Typical Use Case for best motorcycle tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body and structural components | Lightweight and corrosion-resistant | Prone to dents and scratches | Medium |

| Plastic | Housings and non-pressurized parts | Cost-effective and moldable | Limited temperature and pressure resistance | Low |

| Steel | Motor casing and pressure chambers | High durability and strength | Heavy and complex manufacturing | High |

| Rubber | Seals and hoses | Excellent sealing capabilities | Degrades over time | Low |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on performance requirements and regional considerations.

The manufacturing process of motorcycle tire inflators involves several critical stages, ensuring that the final product meets both performance and safety standards.

The first stage in the manufacturing process is material preparation. High-quality materials such as durable plastics, metals, and rubber are sourced from reputable suppliers. Manufacturers often perform a thorough analysis of raw materials to ensure they meet necessary specifications for strength, flexibility, and heat resistance. This stage may also include the procurement of electrical components such as motors, gauges, and power cords, which must comply with international electrical safety standards.

Once materials are prepared, the next step is forming. This involves shaping the raw materials into specific components of the inflator. Key techniques include injection molding for plastic parts, metal stamping for structural components, and extrusion for hoses. Advanced manufacturers may utilize computer numerical control (CNC) machines to achieve precision in forming components, which is crucial for the inflator’s performance and longevity.

The assembly stage brings together all the formed components. This process often requires skilled labor and may be supplemented by automation for efficiency. During assembly, manufacturers follow strict guidelines to ensure that each unit is constructed correctly. This includes attaching the motor to the housing, integrating the power supply, and ensuring that all hoses and valves are properly connected.

The final stage of manufacturing is finishing. This can involve several processes such as surface treatment, painting, and quality marking. Finishing not only enhances the aesthetic appeal of the product but also protects it against environmental factors like corrosion and wear. Manufacturers may also include final assembly inspections to verify that the product meets all design specifications before packaging.

Quality assurance (QA) is essential in the manufacturing process of motorcycle tire inflators. It ensures that each product meets international standards and customer expectations for performance and safety.

Manufacturers typically adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This standard helps organizations ensure consistent quality and improvement in their processes. Additionally, industry-specific certifications like CE marking (indicating compliance with European health and safety standards) or API standards (for products used in the petroleum and natural gas industry) may be relevant, depending on the inflator’s design and intended use.

The quality control process usually involves several checkpoints, including:

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival at the manufacturing facility. Materials that do not meet specifications are rejected, ensuring only high-quality inputs are used in production.

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor critical parameters. This may include checking dimensions, electrical connections, and assembly integrity. Real-time feedback allows for immediate corrections, minimizing defects.

Final Quality Control (FQC): After assembly, the finished inflators undergo comprehensive testing. This includes performance tests (e.g., pressure output, noise levels) and safety checks (e.g., electrical safety). Each unit is evaluated against established benchmarks to ensure it meets quality standards.

Testing methods employed in the QA process for motorcycle tire inflators can vary but typically include:

Illustrative image related to best motorcycle tire inflator

Functional Testing: Each inflator is tested to ensure it operates as intended. This involves inflating a tire to a specified pressure within a given timeframe.

Durability Testing: Inflators are subjected to stress tests to evaluate their performance under extreme conditions, such as prolonged use or exposure to high temperatures.

Electrical Safety Testing: Electrical components are tested for insulation resistance and grounding to prevent electrical hazards.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital to ensuring product reliability.

Conducting supplier audits is one effective way to assess a manufacturer’s quality control practices. Buyers should consider both scheduled and surprise audits to get a comprehensive view of the manufacturing processes and quality management systems in place. Key areas to focus on during audits include adherence to international standards, the effectiveness of quality checkpoints, and the overall cleanliness and organization of the manufacturing facility.

Buyers should request access to quality control reports, which should provide insights into the testing methods used, results from various quality checkpoints, and any corrective actions taken for non-conformities. This documentation can give buyers confidence in the supplier’s commitment to quality.

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the quality of the products being produced. These inspections can be particularly valuable for buyers who may not have the resources to conduct comprehensive audits themselves.

International buyers should be aware of regional differences in quality standards and certifications. For instance, while CE marking is crucial for products sold in Europe, different regions may have other requirements. Understanding these nuances can help buyers navigate the complexities of international trade and ensure compliance with local regulations.

Additionally, cultural differences may impact communication and expectations regarding quality. Establishing clear lines of communication and setting mutual quality standards can help mitigate misunderstandings and ensure that both parties are aligned on quality expectations.

By understanding the manufacturing processes and quality assurance practices involved in producing motorcycle tire inflators, B2B buyers can make informed decisions, ensuring that they procure reliable products that meet the demands of their markets.

This sourcing guide provides a structured approach for B2B buyers seeking the best motorcycle tire inflators. Selecting the right inflator is essential not only for ensuring the safety and performance of motorcycles but also for enhancing customer satisfaction and operational efficiency. The following checklist outlines critical steps to help you make informed procurement decisions.

Establishing clear technical specifications is the first step in your procurement process. Consider the types of motorcycles your customers use and their tire sizes, as different inflators have varying pressure ratings and capabilities. Important parameters include maximum psi, power source compatibility, and whether the inflator can handle both motorcycle and car tires.

Evaluate the size and weight of the inflators to ensure they meet your operational needs. Compact, lightweight models are preferable for on-the-go applications, especially in regions where space is a premium. Consider storage options and whether the inflator will fit within the standard storage compartments of motorcycles.

Performance is crucial when selecting an inflator. Look for metrics such as inflation time, maximum pressure, and duty cycle (the ratio of operational time to rest time). A reliable inflator should quickly restore tire pressure, minimizing downtime for your customers.

Given that many inflators operate at high decibels, noise levels should be a consideration, especially for customers sensitive to sound. Choose models that balance performance with quieter operation to enhance user experience. Look for specifications that indicate noise levels, typically measured in dBA.

Before finalizing your purchase, ensure that suppliers have the necessary certifications and quality assurance standards in place. A reputable supplier should offer warranties that reflect the product’s reliability and durability.

Illustrative image related to best motorcycle tire inflator

Thoroughly vet potential suppliers to ensure they can meet your business needs. Request detailed company profiles, product catalogs, and case studies from other buyers within your industry. This step helps you assess supplier reliability and their ability to deliver products on time.

Once you have identified potential suppliers, engage in negotiations to secure the best pricing and payment terms. Consider bulk purchase discounts, shipping costs, and return policies. Transparent communication during this phase can lead to a more favorable long-term partnership.

By following this checklist, you can systematically evaluate and select the best motorcycle tire inflators for your business, ensuring you meet both your operational needs and those of your customers.

Illustrative image related to best motorcycle tire inflator

Understanding the cost structure of motorcycle tire inflators is crucial for B2B buyers seeking to source these products effectively. The primary cost components include:

Materials: Raw materials such as plastic, rubber, and metal significantly influence the overall cost. Higher quality materials typically yield better performance and durability, which can justify a higher price point.

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs might offer competitive pricing but may also compromise on quality. Conversely, manufacturers in regions with higher wages often provide better craftsmanship.

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient production processes can help minimize overhead costs, impacting the final pricing.

Tooling: The initial cost of tooling for production can be substantial, particularly for custom designs. This one-time cost can be spread across larger production volumes, making it essential to consider the minimum order quantity (MOQ).

Quality Control (QC): Investing in quality control processes ensures product reliability and safety. However, this can add to the manufacturing cost. Certifications like ISO or CE can also influence pricing, as they require compliance with stringent quality standards.

Logistics: Transportation and warehousing costs are integral, especially for international shipments. Factors such as distance, shipping methods, and customs duties can significantly affect overall costs.

Margin: Manufacturers and suppliers typically add a profit margin to cover their operational costs and risks. Understanding standard margins in the industry can aid buyers in negotiating better deals.

Several factors can influence the pricing of motorcycle tire inflators, including:

Volume/MOQ: Larger orders often lead to lower unit prices. Buyers should negotiate MOQs that align with their inventory needs to optimize costs.

Specifications and Customization: Customized products or unique specifications can lead to increased costs. Buyers should weigh the benefits of customization against their budget constraints.

Materials Quality and Certifications: Higher quality materials and compliance with international certifications can increase costs but also enhance product value and reliability.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record and customer service.

Incoterms: Understanding Incoterms is vital for international transactions, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help avoid unexpected costs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. A well-structured negotiation can lead to significant savings.

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the inflators, including maintenance, warranty services, and potential replacements. A lower upfront cost might not always translate to lower overall costs.

Research Market Prices: Conduct thorough market research to understand the pricing landscape. This knowledge will empower buyers during negotiations and help identify fair pricing.

Stay Informed on Pricing Nuances: Be aware of the fluctuations in material costs, labor rates, and geopolitical factors that may affect pricing. This insight can help in making timely purchasing decisions.

Leverage Technology for Sourcing: Utilize online platforms and trade shows to connect with multiple suppliers. This allows for better comparison of prices and product offerings.

In conclusion, understanding the cost structure, pricing influencers, and best practices for negotiation can significantly benefit B2B buyers in sourcing motorcycle tire inflators effectively. By focusing on these aspects, businesses can make informed decisions that align with their operational needs and budget constraints.

When it comes to maintaining motorcycle tire pressure, selecting the right inflator is essential for safety and performance. While electric motorcycle tire inflators are popular for their convenience and efficiency, there are several alternative solutions worth considering. This analysis will compare the ‘best motorcycle tire inflator’ against two viable alternatives: manual hand pumps and CO2 inflator kits. Each option has unique benefits and drawbacks, making it crucial for B2B buyers to evaluate which solution aligns best with their operational needs.

| Comparison Aspect | Best Motorcycle Tire Inflator | Manual Hand Pump | CO2 Inflator Kit |

|---|---|---|---|

| Performance | Quick inflation, up to 150 psi in minutes | Slower, requires manual effort | Fast but limited to a few uses |

| Cost | $30 – $165 | $10 – $30 | $20 – $50 per kit |

| Ease of Implementation | Plug and play, requires power source | Requires physical effort | Simple setup, no power needed |

| Maintenance | Minimal, but may require checks | Low, few moving parts | Low, but cartridges need replacement |

| Best Use Case | Long rides, varied tire sizes | Emergency roadside inflation | Quick fixes for small punctures |

Manual hand pumps are a classic solution for inflating motorcycle tires. They are typically lightweight, portable, and inexpensive, making them a favorite among riders who prefer a no-frills approach. While they are effective for emergency situations, the performance is significantly slower compared to electric inflators. Riders must exert physical effort, which can be exhausting, especially during a roadside repair. However, manual pumps have the advantage of being maintenance-free and can be used without any power source, making them reliable in remote areas.

CO2 inflator kits are another alternative that provides a quick and effective way to inflate tires. These kits typically come with a CO2 cartridge and a nozzle that attaches directly to the tire valve. The inflation process is rapid, allowing for quick fixes, especially for small punctures. However, the primary drawback is the limited number of uses; once the CO2 cartridge is expended, it must be replaced. Additionally, while these kits are compact and easy to carry, they may not deliver sufficient pressure for larger tires or multiple inflations. They are best suited for emergency situations where speed is crucial.

For B2B buyers in the motorcycle industry, selecting the appropriate tire inflation solution hinges on specific operational requirements and use cases. The ‘best motorcycle tire inflator’ offers rapid inflation and versatility for various tire sizes, making it ideal for longer journeys. In contrast, manual hand pumps provide a reliable, low-cost solution for emergency situations, while CO2 inflator kits excel in delivering quick fixes for minor punctures. Evaluating factors such as cost, ease of use, and maintenance will help buyers determine which solution best meets their needs in diverse riding conditions and environments.

When selecting a motorcycle tire inflator, understanding its essential technical properties is crucial for B2B buyers. Here are several key specifications that can significantly impact performance and usability:

Maximum Pressure Rating (PSI)

– This specification indicates the highest pressure the inflator can achieve, typically measured in pounds per square inch (PSI). A higher PSI allows the inflator to effectively inflate a variety of tires, including those on motorcycles and cars. For B2B buyers, this means the inflator can serve multiple purposes, making it a versatile investment for workshops and fleets.

Power Consumption (Amps)

– Power consumption is measured in amperes (amps) and indicates how much electrical current the inflator requires to operate. Knowing the amperage helps buyers ensure compatibility with their power sources, whether they are battery-operated or plug-in models. This specification is critical in regions where power supply stability may vary.

Duty Cycle

– The duty cycle defines how long the inflator can operate before it needs to cool down. For example, a 10-minute on and 10-minute off duty cycle allows for sustained use without overheating. Understanding this specification is essential for businesses that may need to inflate multiple tires in succession, ensuring efficiency in operations.

Inflation Speed

– Measured in PSI per minute, inflation speed indicates how quickly the inflator can fill a tire. A faster inflation speed reduces downtime, which is particularly valuable in commercial settings where time is of the essence. Buyers should consider this property to improve operational efficiency.

Size and Weight

– The physical dimensions and weight of the inflator affect its portability and storage options. A compact and lightweight model is easier to transport, making it ideal for mobile repair services or for inclusion in motorcycle kits. Buyers must evaluate their storage capabilities and transportation needs when selecting an inflator.

Material Durability

– The materials used in the construction of the inflator influence its longevity and reliability. High-quality materials such as reinforced plastics or metals can withstand harsh conditions, making the inflator suitable for use in diverse environments. B2B buyers should prioritize durability to minimize replacement costs.

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some commonly used terms relevant to motorcycle tire inflators:

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, OEM suppliers often provide components that are integrated into branded products. Understanding OEM relationships can lead to better sourcing options for buyers.

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory management and purchasing decisions. Buyers should negotiate MOQs to align with their budget and storage capabilities.

RFQ (Request for Quotation)

– An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes detailed specifications and quantities required. B2B buyers should prepare comprehensive RFQs to receive accurate and competitive pricing from manufacturers.

Incoterms (International Commercial Terms)

– Incoterms are predefined commercial terms that dictate the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, reducing the risk of misunderstandings. Buyers should familiarize themselves with relevant Incoterms to ensure smooth transactions.

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for inventory planning and ensuring that operations run smoothly. B2B buyers should consider lead times when negotiating with suppliers to avoid stockouts.

Warranty Period

– The warranty period defines the duration during which a product is covered for defects or malfunctions. A longer warranty period can indicate higher product quality and provide peace of mind for B2B buyers. Understanding warranty terms is essential for assessing the overall value of an inflator.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing the best motorcycle tire inflators, ultimately enhancing their operational efficiency and customer satisfaction.

The motorcycle tire inflator market is experiencing significant growth, driven by an increase in motorcycle ownership and a growing awareness of the importance of tire maintenance. Global trends indicate a rising preference for portable, user-friendly, and efficient inflators that cater to both recreational and professional riders. In regions such as Africa, South America, the Middle East, and Europe, the demand for reliable tire inflators is amplified by the expanding motorcycle tourism sector and the need for quick roadside assistance.

Technological advancements are reshaping the landscape, with electric inflators gaining traction due to their ease of use and speed. B2B buyers are increasingly looking for products that combine performance with compact design, as space-saving devices are essential for riders who travel long distances. Moreover, the integration of smart technology, such as digital pressure gauges and automatic shut-off features, is becoming a standard expectation.

Emerging B2B sourcing trends include the adoption of direct-to-consumer models, which provide manufacturers with greater control over branding and customer experience. Additionally, e-commerce platforms are facilitating easier access to a wider range of products, allowing international buyers to source inflators from diverse markets. Understanding these dynamics is crucial for B2B buyers aiming to navigate the competitive landscape effectively.

Sustainability is increasingly becoming a priority in the motorcycle tire inflator market, as consumers and businesses alike are more aware of environmental impacts. For B2B buyers, sourcing inflators that are produced using sustainable materials can enhance brand reputation and align with the growing consumer preference for eco-friendly products. This includes the use of recyclable materials in packaging and the incorporation of energy-efficient manufacturing processes.

Ethical supply chains are also paramount, particularly for international buyers who must ensure compliance with global labor standards. Companies that can demonstrate a commitment to ethical practices are likely to gain a competitive edge. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance credibility and appeal to socially conscious consumers.

Furthermore, the market is witnessing a rise in products that minimize waste, such as durable inflators designed for longevity and repairability. Offering inflators that feature replaceable parts can reduce overall waste and promote a circular economy, which is increasingly attractive to B2B buyers focused on sustainability.

Illustrative image related to best motorcycle tire inflator

The motorcycle tire inflator market has evolved significantly over the past few decades. Initially dominated by manual pumps, the introduction of electric inflators revolutionized tire maintenance for riders, offering faster and more efficient inflation. The 1990s saw the emergence of portable electric inflators, designed for ease of use and compact storage, catering to the growing motorcycle tourism sector.

As technology advanced, features such as digital pressure gauges and automatic shut-off mechanisms became standard, enhancing user experience and safety. The recent trend towards smart technology integration, such as app connectivity for monitoring tire pressure, reflects the ongoing evolution of consumer expectations. This historical context is essential for B2B buyers, as it highlights the importance of innovation and adaptability in selecting products that meet the demands of modern riders.

How do I choose the right motorcycle tire inflator for my business needs?

Selecting the right motorcycle tire inflator involves considering several factors such as inflator type (electric or manual), maximum pressure capabilities, size, and portability. Evaluate the specific requirements of your market, including the types of motorcycles commonly used and the typical tire sizes. Additionally, assess the ease of use, durability, and warranty options provided by manufacturers. It’s also wise to read reviews and conduct trials to ensure that the inflator meets your operational standards and customer expectations.

What is the best motorcycle tire inflator for high-pressure tires?

For high-pressure tires, look for inflators that can reach at least 150 psi, such as the BikeMaster Portable Mini-Air Compressor or the CyclePump Expedition Tire Inflator. These models offer robust performance and quick inflation times, making them suitable for various tire types. Ensure that the inflator you choose has a solid warranty and is backed by reliable customer service, as this adds value to your purchase and enhances your reputation among buyers.

What are the key features to consider when sourcing motorcycle tire inflators?

When sourcing motorcycle tire inflators, key features to consider include power source options (battery or AC), maximum pressure, inflation time, portability, and included accessories like hoses and connectors. Additionally, assess the noise levels during operation, as quieter models may be preferred in certain markets. Investigate the build quality and materials used, as these factors can influence durability and performance under various conditions.

How can I vet suppliers for motorcycle tire inflators effectively?

To vet suppliers effectively, start by researching their reputation in the industry, including customer reviews and feedback. Request references from other businesses that have sourced products from them. Evaluate their manufacturing capabilities, quality assurance processes, and compliance with international standards. Additionally, consider their responsiveness and willingness to provide samples, as this can indicate their commitment to customer satisfaction.

What are the typical minimum order quantities (MOQs) for motorcycle tire inflators?

Minimum order quantities (MOQs) for motorcycle tire inflators can vary widely depending on the manufacturer and the specific model. Generally, MOQs can range from 50 to several hundred units. Always inquire about MOQs before placing an order, as this can impact your inventory management and cash flow. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s beneficial to negotiate terms that suit your business needs.

What payment terms should I expect when importing motorcycle tire inflators?

Payment terms for importing motorcycle tire inflators typically range from 30% to 50% upfront, with the balance due upon shipment or delivery. Common payment methods include bank transfers, letters of credit, or payment platforms like PayPal. It’s essential to clarify these terms during negotiations to avoid any misunderstandings. Additionally, consider discussing potential discounts for early payment or larger orders, which can improve your overall purchasing strategy.

How do I ensure quality assurance (QA) for motorcycle tire inflators?

To ensure quality assurance for motorcycle tire inflators, request detailed specifications and certifications from your supplier. Implement a quality control process that includes inspecting samples before bulk orders and conducting regular audits of the manufacturing facilities. Additionally, establish clear communication channels for addressing any defects or issues that may arise post-purchase. Collaborating with suppliers who have a robust QA system in place can significantly reduce risks associated with product quality.

What logistics considerations should I keep in mind when sourcing motorcycle tire inflators internationally?

When sourcing motorcycle tire inflators internationally, consider shipping costs, delivery times, and customs regulations. Research the most efficient shipping methods that balance cost and speed, such as air freight for urgent needs or sea freight for bulk orders. Be aware of import duties and taxes that may apply, as these can affect your overall expenses. Collaborating with a logistics provider familiar with international trade can streamline the process and mitigate potential challenges.

Domain: roadrunner.travel

Introduction: [{‘name’: ‘Aerostich Mini Compressor’, ‘price’: ‘$47’, ‘time_to_inflate’: ‘6:25’, ‘maximum_temperature’: ‘115° F’, ‘power_connection’: ‘6’ cord, alligator clips, cigarette plug, and ring connectors’, ‘accessories’: ‘Carrying case, power connectors, pump; optional $85 Compact Tire Repair Kit available.’}, {‘name’: ‘BestRest CyclePump’, ‘price’: ‘$100’, ‘time_to_inflate’: ‘6:30’, ‘maximum_temperatur…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. AntiGravity Batteries ADV Micro-Start Tire Inflator & Air Pump – Compact, works off SAE connector, suitable for airing up from 15psi to 22psi. 2. Certified 12V Top Off Portable Air Compressor – $20 plug-in compressor, modified for SAE plug, packs small, reliable power if the bike runs. 3. CO2 cartridges and small bicycle pump – alternative inflation method. 4. MotoPumps – Made in the USA, robus…

Domain: revzilla.com

Registered: 2006 (19 years)

Introduction: This company, RevZilla – Top Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: lexin-moto.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Lexin P5 Portable Tire Pump”, “features”: {“battery_size”: “5000 mAH Lithium Ion Cell”, “pressure_range”: “2-150 PSI”, “charging”: “USB-A Output for Mobile Device Charging”, “cooling”: “Internal Cooling Fan”, “hose”: “Heat and Abrasion Protected Threaded Filling Trachea”}, “warranty”: “Two-Year Hassle-Free Warranty”, “applications”: [“Motorcycle Tires”, “Car Tires”, “Bicycle Tire…

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 1. Aerostich Mini Compressor – Price: $53, Weight: 1lb, 0.9oz, PSI after 90 seconds: 14psi, Features: Comes in a protective case, designed to be hung from the bike.

2. Microstart Tire Inflator (New) – Price: $29.99, Weight: 0lb, 12.3oz, PSI after 90 seconds: 14psi, Features: On-board light and pressure gauge, short air hose.

3. Microstart Tire Inflator (Old, 2018) – PSI after 90 seconds: 1psi, aft…

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Fanttik – X8 Air Compressor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the competitive landscape of motorcycle tire inflators, strategic sourcing emerges as a pivotal factor for B2B buyers seeking to maximize both efficiency and value. By understanding the nuances of various inflator models, such as their power sources, inflation speeds, and durability, businesses can make informed purchasing decisions that align with their operational needs. The insights from our comprehensive guide highlight the importance of selecting inflators that not only meet the immediate requirements of tire inflation but also provide reliability in diverse environments, particularly in regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to best motorcycle tire inflator

Investing in high-quality motorcycle tire inflators ensures that businesses can maintain operational continuity and enhance customer satisfaction by minimizing downtime on the road. As you consider your procurement strategies, prioritize products that demonstrate robustness and versatility, which are critical in varying terrains and conditions.

Looking ahead, the demand for reliable motorcycle tire inflators is set to grow, driven by increasing motorcycle ownership and adventure tourism. Seize this opportunity to source strategically, ensuring your inventory is equipped with the best solutions available. Engage with reputable suppliers and leverage the insights from this guide to enhance your competitive edge in the marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.