In today’s rapidly evolving automotive landscape, sourcing high-quality car air pump compressor parts presents a significant challenge for international B2B buyers. The need for reliable inflation components is paramount, as they directly impact vehicle performance and safety. This comprehensive guide aims to equip you with the knowledge needed to navigate the complexities of the global market for car air pump compressor parts.

Throughout this guide, we will delve into various types of air pump components, their applications across different vehicle models, and the critical factors to consider when selecting suppliers. Additionally, we will explore effective strategies for vetting suppliers to ensure quality and reliability, as well as provide insights into cost considerations that can significantly affect your bottom line.

By addressing these key aspects, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Germany and Vietnam—to make informed purchasing decisions. Whether you are looking to optimize your inventory or ensure the longevity of your automotive systems, understanding the nuances of air pump compressor parts will enable you to enhance operational efficiency and deliver superior service to your clients.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressors | Compact, easy to transport, often powered by 12V or AC | Automotive repair shops, roadside assistance | Pros: Versatile, ideal for on-the-go inflation. Cons: Limited power compared to stationary models. |

| Onboard Air Compressors | Installed in vehicles, provides immediate air supply | Off-road vehicles, fleet management | Pros: Convenient for tire inflation during travel. Cons: Higher installation costs, may require maintenance. |

| Tire Inflator Kits | Includes various attachments for tire inflation, often manual | Tire shops, auto repair facilities | Pros: Cost-effective, suitable for small-scale operations. Cons: Slower inflation rates compared to electric models. |

| Air Compressor Parts | Components like hoses, gauges, and regulators for system optimization | Manufacturing, automotive service providers | Pros: Customizable, can improve existing systems. Cons: Requires technical knowledge for installation. |

| Heavy-Duty Air Compressors | High PSI capability, often with larger tanks for sustained use | Industrial applications, heavy machinery | Pros: High efficiency, suitable for demanding tasks. Cons: Higher cost and requires significant space. |

Portable air compressors are designed for convenience and ease of use. They are typically lightweight and powered by either a 12V car battery or standard AC outlet, making them ideal for mobile applications. B2B buyers, particularly those in automotive repair or roadside assistance, find these compressors beneficial for quick tire inflation and other pneumatic tasks. When purchasing, consider factors such as PSI ratings, air flow capacity, and compatibility with various attachments.

Onboard air compressors are permanently installed in vehicles, providing instant access to compressed air whenever needed. This feature is particularly useful for off-road vehicles and fleets that require reliable tire inflation during travel. Buyers should evaluate the compressor’s PSI output, ease of installation, and durability to ensure it meets their operational needs. While they offer convenience, the initial investment and potential maintenance requirements should be factored into purchasing decisions.

Tire inflator kits are essential for businesses that focus on tire maintenance and repair. These kits often come with multiple attachments, allowing for versatile inflation options. They are cost-effective and suitable for small-scale operations, such as local tire shops or automotive service centers. However, buyers should be aware of their slower inflation rates compared to electric models and ensure they select a kit that meets their specific operational demands.

Air compressor parts, including hoses, gauges, and regulators, play a crucial role in optimizing the performance of existing air systems. These components can enhance efficiency and reliability, making them vital for manufacturing and automotive service providers. Buyers must consider compatibility with their current systems and the technical expertise required for installation. Investing in high-quality parts can lead to significant long-term savings and improved operational performance.

Heavy-duty air compressors are designed for high-pressure applications and sustained use, making them ideal for industrial settings. They typically feature larger tanks and higher PSI capabilities, catering to demanding tasks such as powering heavy machinery or pneumatic tools. B2B buyers should assess the compressor’s specifications, including tank size and energy consumption, to ensure it aligns with their operational requirements. While these compressors can be a significant investment, their efficiency and durability often justify the cost.

| Industry/Sector | Specific Application of car air pump compressor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance | Enhances service efficiency and customer satisfaction | Quality, compatibility with various tire inflators, and durability. |

| Transportation & Logistics | Air suspension systems for heavy vehicles | Improves ride quality and safety for cargo transport | Pressure specifications, reliability under load, and ease of installation. |

| Manufacturing | Pneumatic tools and machinery operation | Increases productivity and reduces downtime | Sourcing from reputable suppliers, ensuring part compatibility, and availability of spares. |

| Outdoor Recreation & Sports | Inflating sports equipment and recreational vehicles | Facilitates quick and easy inflation for user convenience | Portability, power source options, and multi-functionality. |

| Construction | Compressed air for tools and equipment | Enhances operational efficiency on job sites | Robustness, pressure capacity, and compliance with safety standards. |

In automotive repair, car air pump compressor parts are essential for tire inflation and maintenance. They enable workshops to quickly service vehicles, ensuring tires are properly inflated for optimal performance. This not only boosts service efficiency but also enhances customer satisfaction as vehicles are returned in a safe and roadworthy condition. For international B2B buyers, sourcing high-quality, durable components that are compatible with various tire inflators is crucial to maintain operational standards.

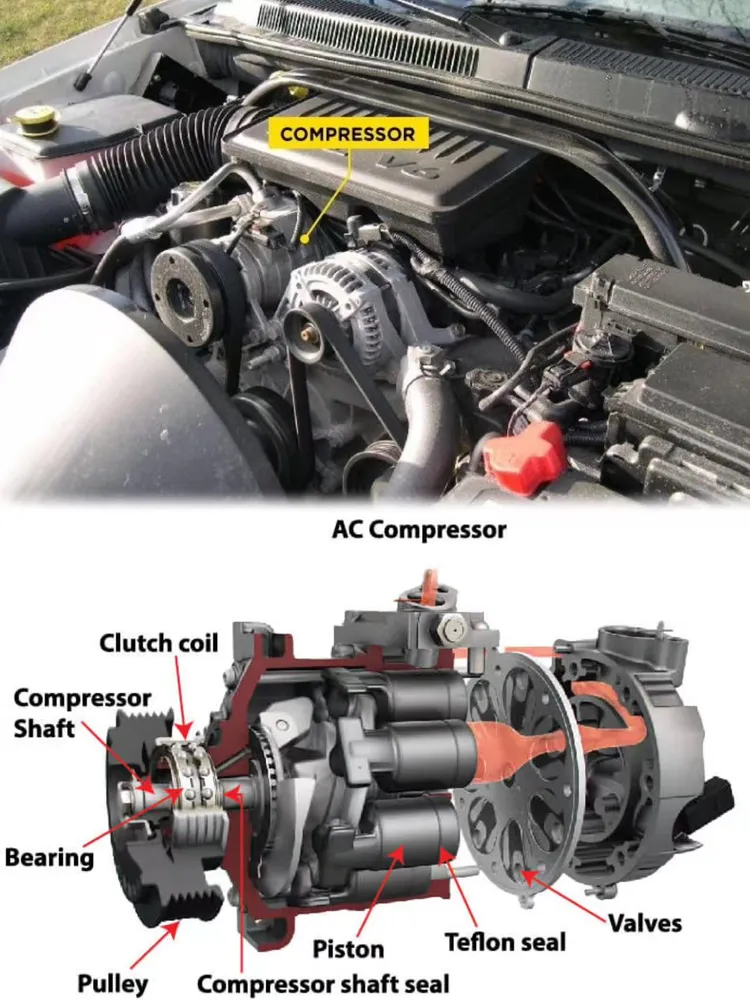

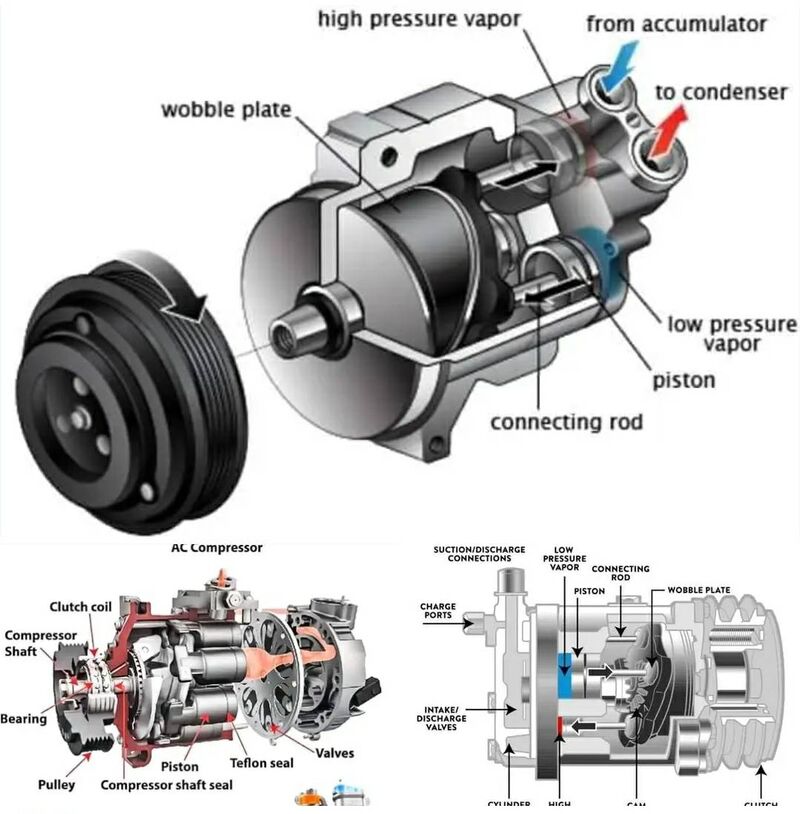

Illustrative image related to car air pump compressor parts

In the transportation and logistics sector, car air pump compressor parts are integral to air suspension systems in heavy vehicles. These components help maintain optimal ride quality, ensuring the safety of cargo during transit. The reliability of these parts under heavy loads is paramount, as any failure could lead to costly delays and potential damage. Buyers must consider pressure specifications and ease of installation when sourcing these components, especially in regions with varying vehicle standards.

Manufacturing industries rely heavily on pneumatic tools and machinery, which utilize car air pump compressor parts for operation. These components increase productivity by providing a steady supply of compressed air, reducing downtime caused by equipment failure. When sourcing, businesses should prioritize suppliers known for quality and reliability, ensuring that parts are compatible with existing machinery and readily available for maintenance needs.

In outdoor recreation, car air pump compressor parts are vital for inflating sports equipment, such as balls and inflatable boats, as well as recreational vehicles like ATVs. The convenience of quick inflation contributes to a better user experience. Buyers in this sector should focus on the portability of these components, as well as their power source options and multi-functionality, to cater to various outdoor activities.

In the construction industry, compressed air from car air pump compressor parts powers tools and equipment, enhancing operational efficiency on job sites. Reliable air supply is critical for tasks such as nail guns and pneumatic drills, where downtime can significantly impact project timelines. Buyers must ensure the robustness and pressure capacity of sourced components, along with compliance with safety standards, to maintain a productive work environment.

The Problem: Many B2B buyers face challenges in sourcing reliable and high-quality parts for car air pump compressors, particularly when dealing with multiple suppliers across different regions. Issues such as inconsistent quality, long lead times, and poor customer service can lead to significant operational inefficiencies and increased costs. This is especially pertinent in markets like Africa and South America, where access to dependable suppliers is limited, and the risk of counterfeit parts is high.

Illustrative image related to car air pump compressor parts

The Solution: To effectively source reliable air compressor parts, B2B buyers should prioritize establishing partnerships with reputable suppliers who have a proven track record. Conduct thorough research on potential suppliers, checking for certifications, customer testimonials, and case studies. Utilizing platforms that specialize in industrial parts procurement can streamline this process. Additionally, consider building a local inventory of essential parts to reduce lead times and ensure business continuity. When placing orders, specify the quality standards and certifications required, and request samples before bulk purchases to ensure compatibility and performance.

The Problem: Compatibility between new compressor parts and existing equipment is a frequent pain point for B2B buyers. Many buyers find themselves investing in new components that do not integrate seamlessly with their current systems, leading to performance issues and additional costs. This problem is exacerbated by the lack of standardized components across different manufacturers, making it difficult to find suitable replacements that meet specific operational requirements.

The Solution: To avoid compatibility issues, B2B buyers should undertake a comprehensive assessment of their existing equipment before sourcing new parts. This includes documenting specifications such as dimensions, pressure ratings, and connection types. When engaging with suppliers, provide this information upfront to ensure they can recommend compatible parts. Additionally, consider investing in modular components that offer flexibility and can be adapted to various systems. Establishing a relationship with a knowledgeable supplier can also provide valuable insights into compatibility and best practices for integration.

The Problem: Unplanned maintenance and extended downtime due to faulty or worn-out air compressor parts can significantly impact productivity and profitability. B2B buyers often struggle with predicting maintenance needs and managing inventory levels of spare parts, leading to operational disruptions. This is particularly critical in sectors where air compressors play a vital role in production processes, as even minor downtime can result in substantial financial losses.

The Solution: Implementing a proactive maintenance schedule can help mitigate downtime risks associated with air compressor parts. B2B buyers should work closely with suppliers to establish a regular maintenance routine that includes inspections, part replacements, and performance evaluations. Additionally, adopting predictive maintenance technologies can provide real-time data on equipment health, enabling timely interventions before failures occur. Keeping a well-organized inventory of fast-moving parts and consumables can also ensure that replacements are readily available when needed, minimizing the risk of extended operational interruptions. Lastly, training staff on basic maintenance practices can empower them to address minor issues before they escalate, further enhancing operational efficiency.

When selecting materials for car air pump compressor parts, it is crucial to consider the properties and performance characteristics of various materials. The right choice can significantly impact durability, efficiency, and overall product effectiveness. Below, we analyze four common materials used in the manufacturing of these components, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 150°C (302°F) and pressures of around 200 psi, making it suitable for various compressor applications. Its natural oxide layer provides additional protection against corrosion, which is particularly beneficial in humid or saline environments.

Pros: Aluminum is cost-effective and easy to machine, which simplifies the manufacturing process. It is also recyclable, aligning with sustainability goals.

Cons: While durable, aluminum can be less robust than steel under extreme conditions. It may not be suitable for high-pressure applications exceeding its limits.

Impact on Application: Aluminum’s compatibility with air and its corrosion resistance make it ideal for components such as housings and fittings. However, it may not be the best choice for parts exposed to harsh chemicals.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for aluminum quality, such as ASTM or ISO certifications, to guarantee performance.

Steel, particularly stainless steel, is renowned for its strength and durability. It can handle high temperatures (up to 400°C or 752°F) and pressures (up to 300 psi), making it suitable for heavy-duty applications. Its corrosion resistance is enhanced when treated or alloyed, which is essential for longevity.

Pros: Steel is highly durable and can be manufactured to meet stringent specifications, making it suitable for a wide range of applications.

Cons: Steel is heavier than aluminum, which may affect the overall weight of the compressor. It also tends to be more expensive and can be complex to machine.

Impact on Application: Steel’s robustness makes it ideal for critical components like valves and cylinders that require high pressure and temperature resistance.

Considerations for International Buyers: Buyers from Europe, especially Germany, should be aware of the DIN standards for steel quality to ensure compliance and performance.

Plastic materials, such as high-density polyethylene (HDPE) and polycarbonate, are increasingly used in air compressor components due to their lightweight and corrosion-resistant properties. They can typically withstand temperatures up to 80°C (176°F) and moderate pressure levels.

Pros: Plastics are generally less expensive and easier to mold, which can reduce manufacturing complexity and costs.

Cons: They may not be suitable for high-pressure applications and can degrade over time when exposed to UV light or extreme temperatures.

Illustrative image related to car air pump compressor parts

Impact on Application: Plastic is often used for non-structural components like housings and covers, where strength is less critical.

Considerations for International Buyers: Buyers should verify that plastics meet relevant safety and environmental standards in their regions, such as REACH in Europe.

Rubber is widely used for seals and gaskets due to its excellent elasticity and ability to form airtight seals. It can typically withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F) and moderate pressure levels.

Pros: Rubber provides superior sealing capabilities, preventing air leaks and enhancing compressor efficiency.

Illustrative image related to car air pump compressor parts

Cons: Rubber can degrade over time, especially when exposed to oils, chemicals, or extreme temperatures, which may necessitate more frequent replacements.

Impact on Application: Rubber is essential in applications requiring flexibility and sealing, such as in gaskets and O-rings.

Considerations for International Buyers: Buyers should ensure that rubber materials comply with local standards for durability and chemical resistance, particularly in industrial applications.

| Material | Typical Use Case for car air pump compressor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings, fittings | Lightweight, corrosion-resistant | Less robust under extreme conditions | Medium |

| Steel | Valves, cylinders | High strength and durability | Heavier, more complex to machine | High |

| Plastic | Non-structural components | Cost-effective, easy to mold | Limited pressure tolerance | Low |

| Rubber | Seals, gaskets | Excellent sealing capabilities | Degrades over time in harsh conditions | Medium |

This strategic material selection guide provides actionable insights for B2B buyers, enabling informed decisions that align with their operational needs and regional compliance requirements.

The manufacturing of car air pump compressor parts is a multi-faceted process that involves several crucial stages: material preparation, forming, assembly, and finishing. Each of these stages plays a significant role in determining the performance, reliability, and durability of the final product.

Illustrative image related to car air pump compressor parts

Material preparation is the first step in the manufacturing process. This stage involves selecting high-quality raw materials, such as metals (e.g., aluminum, steel) and plastics, which are essential for the structural integrity and functionality of compressor parts. Suppliers often source materials that comply with international standards to ensure quality. Once selected, the materials undergo various treatments, including heat treatment and surface coating, to enhance their properties, such as corrosion resistance and durability.

The forming stage utilizes various techniques to shape the prepared materials into specific components. Common methods include casting, machining, and stamping.

Each technique requires specialized equipment and skilled operators to ensure that the parts meet stringent specifications.

After forming, the components proceed to the assembly stage. This phase is critical as it determines how well the parts will work together in the final compressor.

The assembly process must also consider the ease of maintenance and repair, which can impact the long-term usability of the air pump systems.

Illustrative image related to car air pump compressor parts

The finishing stage enhances the aesthetic appeal and functional performance of the parts. This may include processes such as painting, coating, and polishing.

Finishing is often the last stage before parts are packaged and shipped, making it essential for ensuring that the final product meets customer expectations.

Quality assurance (QA) is a pivotal aspect of the manufacturing process for car air pump compressor parts. International standards, such as ISO 9001, provide frameworks for establishing effective quality management systems.

Understanding these standards helps B2B buyers gauge a supplier’s commitment to quality and regulatory compliance.

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

Illustrative image related to car air pump compressor parts

By implementing these checkpoints, manufacturers can identify and rectify issues early in the production process, reducing the risk of defects in final products.

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps:

Conduct Audits: Regular audits of the supplier’s facilities can provide insights into their manufacturing and quality control practices. Buyers should look for adherence to international standards.

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection records and compliance certifications.

Engage Third-Party Inspectors: Independent inspections can offer an unbiased evaluation of the supplier’s quality control measures and product quality.

Evaluate Certifications: Confirm that the supplier holds relevant certifications and that they are up-to-date. This includes ISO certifications and any industry-specific qualifications.

Review Customer Feedback: Checking references and reviews from other customers can provide additional assurance regarding a supplier’s reliability and quality.

International B2B buyers must navigate various nuances when it comes to quality control, especially in regions with different regulatory landscapes.

By being proactive in understanding these nuances, buyers can better ensure that they receive high-quality products that meet their specific needs.

Illustrative image related to car air pump compressor parts

In conclusion, the manufacturing processes and quality assurance for car air pump compressor parts are complex yet critical to delivering reliable and efficient products. By understanding the key stages of manufacturing, relevant quality standards, and how to verify supplier practices, B2B buyers can make informed decisions that enhance their operational success.

Sourcing car air pump compressor parts requires a strategic approach to ensure quality, compatibility, and value for your investment. This guide provides a step-by-step checklist tailored for international B2B buyers, helping you navigate the complexities of procurement while minimizing risks and maximizing efficiency.

Before initiating your search, outline the technical specifications required for your air pump compressor parts. This includes understanding the pressure ratings, sizes, materials, and compatibility with existing systems. A clear definition helps streamline your sourcing process and ensures you receive parts that meet your operational needs.

Conduct thorough research to identify potential suppliers specializing in air pump compressor parts. Use industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors. This step is vital to ensure you have a diverse pool of suppliers to choose from.

Verify that your shortlisted suppliers hold relevant certifications and quality standards, such as ISO 9001 or CE marking. This step is critical for ensuring that the parts meet international quality and safety standards, which can significantly impact your operations.

Before making bulk purchases, request samples of the air pump compressor parts to assess quality and compatibility. This hands-on evaluation allows you to identify any potential issues before finalizing your order, thereby reducing the risk of costly mistakes.

Once you have evaluated the quality of the samples, compare the pricing and payment terms from different suppliers. While cost is important, also consider factors such as warranty, after-sales support, and delivery timelines, which can affect the overall value of your purchase.

Engage in negotiations with your chosen supplier to secure the best possible terms. Focus on price, delivery schedules, and any additional services they may offer, such as technical support or extended warranties. Effective negotiation can lead to significant cost savings and better service.

After reaching an agreement that meets your needs, ensure that all terms are documented in a formal contract. This contract should outline all specifications, pricing, delivery schedules, and warranties. A clear agreement protects both parties and helps prevent misunderstandings in the future.

By following this checklist, you can effectively navigate the sourcing process for car air pump compressor parts, ensuring that you make informed decisions that align with your business objectives.

When sourcing car air pump compressor parts, understanding the cost structure is essential for making informed purchasing decisions. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The quality and type of materials used directly impact costs. For example, stainless steel components may be more expensive than plastic alternatives but offer greater durability and performance.

Labor: Labor costs vary significantly by region. Countries with lower labor costs, such as Vietnam, may present a more attractive sourcing option for international buyers. However, consider the trade-offs in quality and reliability.

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Manufacturers in regions with higher overhead costs will likely have higher prices.

Tooling: The initial investment in tooling can be significant, especially for custom parts. If a buyer requires specialized components, the tooling costs may be amortized over larger order volumes to reduce per-unit pricing.

Quality Control: Effective QC processes ensure that parts meet specifications and standards. Investing in robust QC can increase costs but also reduce the risk of defective products, which is crucial for maintaining brand reputation.

Logistics: Transportation costs can vary widely based on the shipping method, distance, and Incoterms. International shipping from manufacturers in Asia to buyers in Africa or Europe may incur additional fees, impacting total costs.

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin expectations of different suppliers can help buyers negotiate better deals.

Several factors influence pricing for car air pump compressor parts, which B2B buyers should consider when negotiating contracts:

Illustrative image related to car air pump compressor parts

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to lower per-unit costs due to economies of scale. Buyers should strive to meet MOQ requirements to benefit from reduced pricing.

Specifications and Customization: Customized parts or those with specific specifications often come at a premium. Buyers should balance the need for customization with cost considerations.

Quality and Certifications: Parts that meet international quality standards or certifications may command higher prices. However, these investments can lead to long-term savings by reducing failure rates and warranty claims.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

Incoterms: Understanding the terms of delivery and shipping responsibilities can significantly impact total costs. Buyers should negotiate Incoterms that minimize unexpected expenses.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in sourcing. Here are actionable tips:

Negotiate Effectively: Always approach negotiations with a clear understanding of the market rates and your budget constraints. Establish a relationship with suppliers to facilitate better terms.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential downtime costs. Sometimes, investing in higher-quality parts can lead to lower long-term expenses.

Stay Informed About Pricing Nuances: Prices can fluctuate due to economic conditions, currency exchange rates, and supply chain disruptions. Keeping abreast of these factors can help in timing purchases effectively.

Evaluate Multiple Suppliers: Don’t settle for the first quote. Compare multiple suppliers to understand market pricing better and leverage competition to negotiate better deals.

Conduct Due Diligence: Before finalizing a supplier, perform background checks and request samples. This ensures that the supplier meets your quality standards and reduces the risk of future issues.

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple sources to obtain the most accurate and current pricing information.

In the automotive industry, car air pump compressor parts play a crucial role in maintaining tire pressure and ensuring optimal vehicle performance. However, there are alternative solutions and technologies that can also achieve similar results. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and application needs.

| Comparison Aspect | Car Air Pump Compressor Parts | Portable Electric Tire Inflators | CO2 Tire Inflators |

|---|---|---|---|

| Performance | Reliable for continuous use; can inflate multiple tires quickly. | Generally effective but may require longer inflation times for larger tires. | Quick inflation; suitable for emergency situations. |

| Cost | Moderate initial investment; ongoing maintenance costs. | Lower upfront costs; may require replacement over time. | Higher upfront costs for the CO2 canisters; no maintenance required. |

| Ease of Implementation | Requires installation and integration into the vehicle’s system. | Simple plug-and-play operation; very user-friendly. | No installation needed; easy to use with minimal setup. |

| Maintenance | Requires regular maintenance and part replacements to ensure efficiency. | Minimal maintenance; typically requires battery checks. | No maintenance; CO2 cartridges need to be replaced as they are used. |

| Best Use Case | Ideal for workshops and commercial fleets needing consistent tire inflation. | Suitable for personal use and occasional roadside assistance. | Best for emergency situations or outdoor adventures where quick inflation is needed. |

Portable electric tire inflators are compact devices that can easily be stored in a vehicle for emergency use. They are typically powered by the car’s battery or a wall outlet. The main advantage of these inflators is their user-friendly design, allowing even non-technical users to operate them without any hassle. However, they may take longer to inflate larger tires compared to dedicated compressor systems, making them less ideal for high-demand commercial applications.

CO2 tire inflators utilize pressurized carbon dioxide cartridges to quickly inflate tires. They are particularly favored in emergency scenarios due to their speed and portability. The significant advantage of CO2 inflators is that they require no maintenance and can be used without the need for electrical power. However, the ongoing cost of replacing CO2 cartridges can add up, and they may not be suitable for frequent use, particularly in a commercial setting where continuous tire inflation is necessary.

When considering which solution to adopt, B2B buyers must evaluate their specific needs, including the volume of tire inflations required, budget constraints, and the intended use case. For businesses with high-volume tire maintenance, investing in car air pump compressor parts may be the most effective solution. Conversely, for occasional users or those needing a portable solution, a portable electric tire inflator or CO2 tire inflator may suffice.

Ultimately, assessing the trade-offs between performance, cost, and maintenance will guide buyers in selecting the most suitable tire inflation solution for their operations. Understanding these alternatives not only enhances operational efficiency but also ensures that businesses remain responsive to their customers’ needs.

Understanding the technical specifications of car air pump compressor parts is crucial for B2B buyers. These specifications not only determine the performance and durability of the components but also impact the overall efficiency of air systems. Here are some essential properties to consider:

Material Grade

The material grade of compressor parts, such as aluminum, stainless steel, or high-density plastic, directly affects their strength, weight, and corrosion resistance. For example, stainless steel is often preferred for components exposed to moisture due to its durability. Choosing the right material ensures longevity and reduces the need for frequent replacements, which is vital for maintaining operational efficiency.

Pressure Rating

This specification indicates the maximum pressure a compressor part can handle, typically measured in PSI (pounds per square inch). High-pressure ratings are essential for applications requiring robust performance, such as in heavy-duty vehicles or off-road equipment. B2B buyers must match the pressure ratings of components with their specific applications to avoid failures that could lead to costly downtime.

Flow Rate

The flow rate, measured in cubic feet per minute (CFM), defines how much air the compressor can deliver. This is critical for applications needing rapid inflation or powering pneumatic tools. A higher flow rate translates to better performance and efficiency, making it a key consideration for buyers looking to optimize their systems.

Tolerance

Tolerance refers to the allowable deviation from a specified dimension. Precise tolerances are vital for ensuring that parts fit together correctly and function as intended. This is particularly important in high-performance applications where even small discrepancies can lead to inefficiencies or equipment failure.

Temperature Range

Understanding the operational temperature range of compressor parts is essential for ensuring reliability in various climates. Parts designed to withstand extreme temperatures will perform better in adverse conditions, reducing the risk of overheating and subsequent failures.

Compatibility

Compatibility with existing systems and components is crucial for seamless integration. B2B buyers should verify that parts meet industry standards and are compatible with OEM specifications to ensure proper functionality and support.

Navigating the B2B landscape requires familiarity with industry terminology. Here are some common trade terms that are essential for effective communication and decision-making:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of a vehicle or equipment. Understanding OEM parts is vital as they often guarantee compatibility and quality, making them a preferred choice for many buyers.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers gauge their purchasing requirements and manage inventory effectively. This is particularly important for businesses looking to maintain cost-efficiency in procurement.

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. Crafting a clear and detailed RFQ can lead to better pricing and terms, making it a key step in the procurement process.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risks, and logistics, which is crucial for successful transactions.

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for planning inventory and ensuring timely delivery of parts, which is critical for maintaining operational efficiency.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of a product. Knowing the warranty terms can help buyers make informed decisions and assess the risk associated with purchasing specific parts.

By comprehending these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance operational efficiency and ensure the longevity of their car air pump compressor systems.

The global market for car air pump compressor parts is experiencing significant growth, driven by rising vehicle ownership and increasing demand for efficient inflation solutions. As automotive markets expand in regions like Africa and South America, the need for reliable air compressor components is escalating. Furthermore, technological advancements are reshaping the sector, with innovations such as integrated pressure management systems and enhanced material durability becoming crucial. B2B buyers are increasingly focused on sourcing parts that not only meet performance standards but also facilitate seamless integration into existing systems.

Another emerging trend is the shift towards digital platforms for sourcing. E-commerce and online marketplaces are transforming how buyers access and procure parts, allowing for greater transparency and competitive pricing. In regions like Europe and the Middle East, where regulations on product quality and safety are stringent, suppliers that can demonstrate compliance and offer traceable supply chains are gaining a competitive edge. Additionally, the emphasis on customer service and after-sales support is becoming paramount, as buyers seek reliable partnerships that extend beyond the initial transaction.

Sustainability is increasingly influencing purchasing decisions in the car air pump compressor parts sector. B2B buyers are recognizing the environmental impact of their sourcing choices, particularly in terms of resource consumption and waste generation. The demand for ‘green’ certifications and eco-friendly materials is on the rise, as companies strive to enhance their corporate social responsibility profiles. Suppliers that can provide transparent information about their sourcing practices, such as the use of recyclable materials or energy-efficient manufacturing processes, are likely to attract conscientious buyers.

Ethical sourcing is also critical in maintaining a positive brand reputation. Buyers are more inclined to partner with manufacturers that adhere to fair labor practices and demonstrate a commitment to social responsibility. As consumers become more aware of the implications of their purchases, B2B companies that prioritize ethical supply chains will not only comply with regulatory demands but also enhance their market positioning. This shift towards sustainability is not merely a trend; it represents a fundamental change in how businesses operate and engage with their supply chains.

The car air pump compressor parts market has evolved significantly over the decades, transitioning from basic mechanical components to sophisticated systems that integrate advanced technology. Initially, air pumps were purely mechanical devices, but as automotive technology advanced, so did the complexity and functionality of compressor parts. The introduction of electronic controls and smart technology has revolutionized the sector, allowing for features such as automatic pressure regulation and real-time monitoring.

Furthermore, globalization has played a pivotal role in shaping the supply chain landscape. International trade agreements and improved logistics have facilitated easier access to a wider range of components from different regions, enabling buyers to source competitively priced parts without compromising on quality. As the market continues to innovate and adapt, understanding these historical shifts will be crucial for B2B buyers aiming to navigate the complexities of sourcing in today’s dynamic environment.

How do I select the right air pump compressor parts for my needs?

Choosing the right air pump compressor parts involves assessing your specific requirements, including the intended application, air pressure needs, and compatibility with existing equipment. Start by evaluating the type of compressor you are using, whether it’s portable or stationary. Consult product specifications, and consider components such as hoses, gauges, and pressure regulators. Engaging with suppliers who offer expert advice can also help ensure you select high-quality parts that optimize performance and efficiency.

What are the common issues with car air pump compressor parts, and how can I address them?

Common issues with car air pump compressor parts include air leaks, insufficient pressure, and component wear. To address these problems, regularly inspect parts for signs of damage or wear, such as cracks or corrosion. Ensure all connections are secure to prevent air leaks, and replace worn components promptly to maintain optimal performance. Implementing a routine maintenance schedule can help identify potential issues early, reducing downtime and repair costs.

What are the key factors to consider when vetting suppliers for air pump compressor parts?

When vetting suppliers, consider their reputation, product quality, and customer service. Look for suppliers with positive reviews and proven experience in the industry. Request samples to assess the quality of their parts, and inquire about their manufacturing processes and quality assurance measures. Additionally, evaluate their ability to provide timely delivery and support, as these factors are crucial for maintaining your operations.

What are the typical minimum order quantities (MOQs) for air pump compressor parts?

Minimum order quantities for air pump compressor parts can vary significantly based on the supplier and the type of component. Generally, MOQs can range from a few pieces for standard items to several hundred for specialized parts. It’s essential to discuss MOQs with potential suppliers early in the negotiation process to ensure they align with your purchasing needs and inventory management strategies.

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront payments, partial payments upon order confirmation, and net 30 or 60 terms. Be sure to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment systems. Additionally, consider negotiating terms that offer protection against currency fluctuations and ensure timely delivery of goods.

How can I ensure the quality of the air pump compressor parts I purchase?

To ensure quality, request certification documents from your suppliers, such as ISO certifications or compliance with international standards. Conduct thorough research on the supplier’s manufacturing processes and quality control measures. Additionally, consider implementing a quality assurance protocol that includes regular inspections and testing of received parts to verify they meet your specifications and performance expectations.

What logistics considerations should I keep in mind when importing air pump compressor parts?

Logistics considerations for importing parts include shipping methods, customs regulations, and lead times. Choose a shipping method that balances cost and speed, such as air freight for urgent orders or sea freight for bulk shipments. Be aware of customs duties and tariffs in your destination country, and ensure all necessary documentation is in order to avoid delays. Collaborating with experienced logistics partners can streamline the process and mitigate potential issues.

Can I customize air pump compressor parts to suit my specific requirements?

Many suppliers offer customization options for air pump compressor parts, allowing you to tailor components to your specific requirements. This could include changes in size, material, or specific features like pressure ratings or fittings. Discuss your needs with potential suppliers, and inquire about their capabilities and lead times for custom orders. Customization can enhance performance and compatibility with your existing systems, providing a significant advantage in your operations.

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Airmoto Tire Inflator Portable Air Compressor – Cordless Air Pump for Car Tires: Brand New, $129.00, Buy It Now, +$6.95 delivery, Located in United States, 580 sold. 20″ Car Tire Valve Connect Air Inflator Pump Extension Hose Tube Adapter Parts: Brand New, $10.98 or Best Offer, Free delivery, Located in United States, Free returns. Air Compressor Case for DEWALT 20V MAX Tire Inflator DCC020IB – Wa…

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Spare Parts For Tire Inflators | Tameson.com

Domain: alltopusa.com

Registered: 2022 (3 years)

Introduction: [{‘name’: ‘Air Compressor Kit Dual Cylinder w/LCD Control Panel’, ‘price’: ‘$215.99 USD’, ‘original_price’: ‘$269.99 USD’, ‘psi’: ‘150PSI’, ‘flow_rate’: ‘12.35 ft³/Min’, ‘power’: ’12V DC’}, {‘name’: ‘Air Compressor Kit w/LCD Control Panel’, ‘price’: ‘$151.99 USD’, ‘original_price’: ‘$189.99 USD’, ‘psi’: ‘150PSI’, ‘flow_rate’: ‘7.06 ft³/Min’, ‘power’: ’12V DC’}, {‘name’: ‘Air Compressor Kit Dual Cy…

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: {“products”:[{“name”:”Hose Coupling Dust Cap”,”sku”:”0740113″,”price”:”$3.95″},{“name”:”Digital Tire Inflator”,”sku”:”ARB601″,”price”:”$63.85″,”original_price”:”$70.95″},{“name”:”Twin Motor Onboard 12V Air Compressor”,”sku”:”CKMTA12″,”price”:”$593.95″,”original_price”:”$659.95″},{“name”:”Pump Up Kit”,”sku”:”171302V2″,”price”:”$89.95″,”original_price”:”$99.95″},{“name”:”Hose Coupling US STD JIC-4″,…

In today’s competitive market, strategic sourcing of car air pump compressor parts is essential for maximizing efficiency and performance. By selecting high-quality components that integrate seamlessly with existing systems, B2B buyers can ensure reliability and durability, which are critical for maintaining operational standards. The emphasis on premium materials and innovative features—such as multi-tire pressure management and automatic moisture drainage—can significantly enhance the user experience and operational efficiency.

Furthermore, sourcing from reputable suppliers not only guarantees product quality but also fosters long-term partnerships that can yield beneficial terms and conditions. As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local demands and preferences will be crucial for successful procurement strategies.

Looking ahead, B2B buyers are encouraged to leverage digital platforms for sourcing and procurement, which offer access to a wider range of suppliers and parts. By staying informed about emerging trends and technologies, businesses can position themselves to capitalize on opportunities in the car air pump compressor parts market. Embrace strategic sourcing as a pathway to driving growth and enhancing operational efficiency in your organization.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to car air pump compressor parts

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.