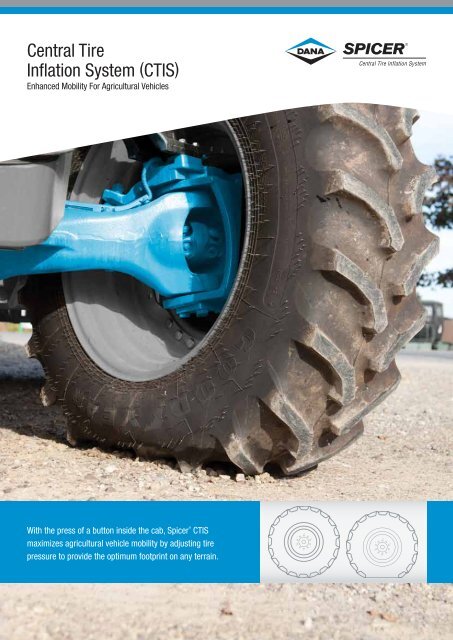

In an increasingly competitive global market, sourcing a reliable Central Tire Inflation System (CTIS) is crucial for businesses looking to enhance vehicle performance and operational efficiency. Many organizations, particularly those in challenging environments such as agriculture, construction, and military operations, face the pressing challenge of maintaining optimal tire pressure to prevent costly downtimes and ensure safety. This comprehensive guide delves into the various types of CTIS available, their applications across different sectors, and key factors to consider when vetting suppliers.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe—such as Vietnam and Saudi Arabia—will find actionable insights on navigating the complexities of sourcing CTIS. By exploring aspects such as cost implications, technological advancements, and installation requirements, this guide empowers decision-makers to make informed purchasing choices. Additionally, it highlights the long-term benefits of investing in a high-quality CTIS, including reduced fuel consumption, enhanced tire longevity, and improved vehicle mobility in diverse terrains.

Ultimately, this resource aims to equip businesses with the knowledge needed to optimize their fleet operations, mitigate risks, and achieve significant savings in both time and costs, ensuring they remain competitive in a dynamic market landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Military CTIS | High durability, remote diagnostics, emergency modes | Defense and military vehicles | Pros: Enhanced safety, reliability in combat. Cons: Higher initial investment. |

| Agricultural CTIS | Soil compaction reduction, optimized for varying terrain | Agricultural machinery | Pros: Increases crop yield, reduces soil damage. Cons: Limited to agricultural applications. |

| Commercial Vehicle CTIS | Flexibility in pressure adjustment, fuel efficiency | Construction, logistics, transport | Pros: Lower operating costs, improved vehicle lifespan. Cons: Requires regular maintenance. |

| Off-Road CTIS | Adaptability for extreme terrains, low-pressure operation | Off-road vehicles, mining equipment | Pros: Maximizes traction, minimizes tire damage. Cons: May not be suitable for urban environments. |

| Integrated CTIS | All-in-one system with real-time monitoring capabilities | Heavy-duty trucks, fleet management | Pros: Comprehensive control, reduces downtime. Cons: Potential complexity in installation. |

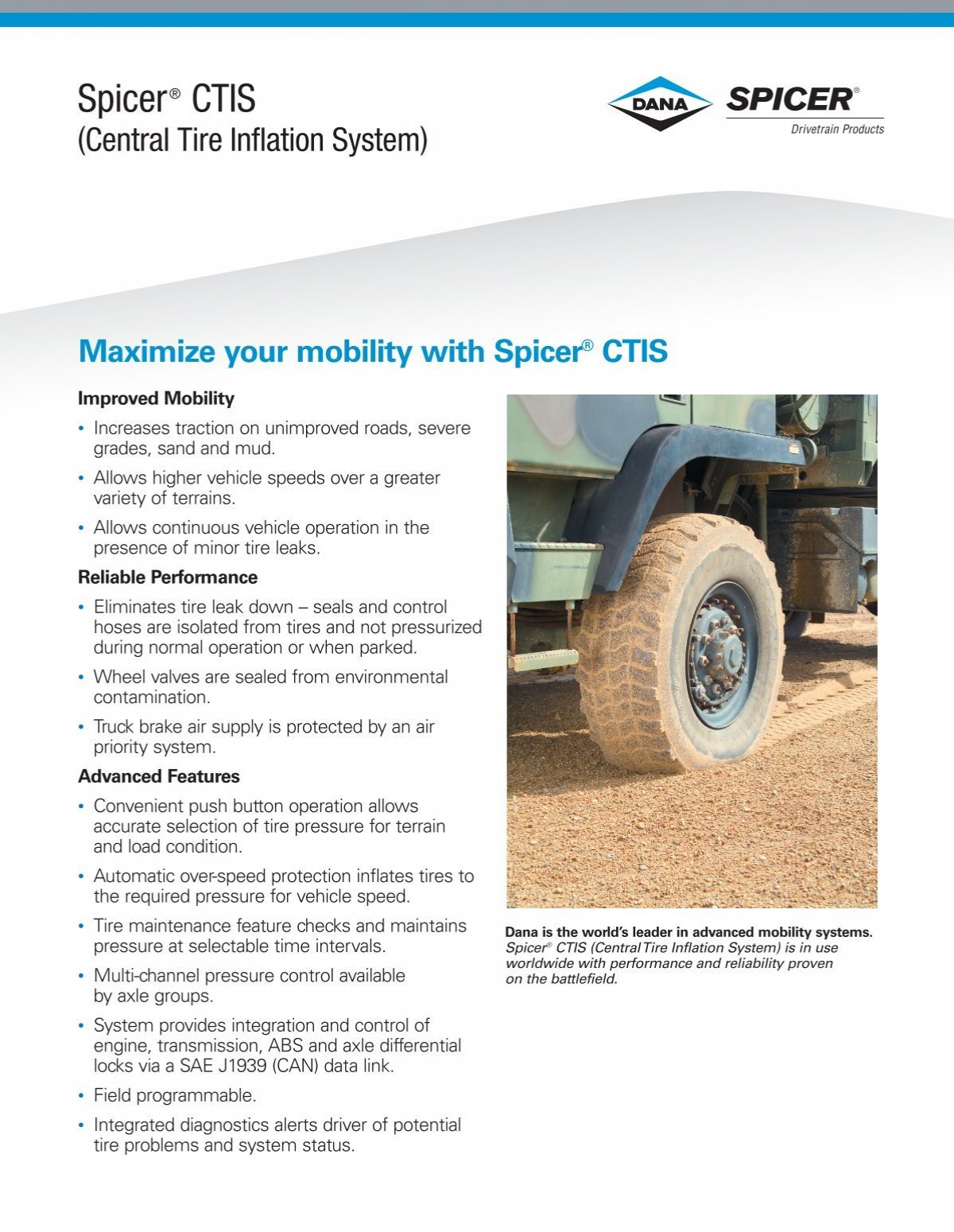

Military Central Tire Inflation Systems (CTIS) are engineered for high durability and reliability, crucial for defense applications. They feature advanced remote diagnostics and emergency modes to ensure operational safety in combat scenarios. B2B buyers in the defense sector should consider the initial investment against the system’s ability to enhance vehicle mobility and safety in challenging environments, making it a critical component for military logistics.

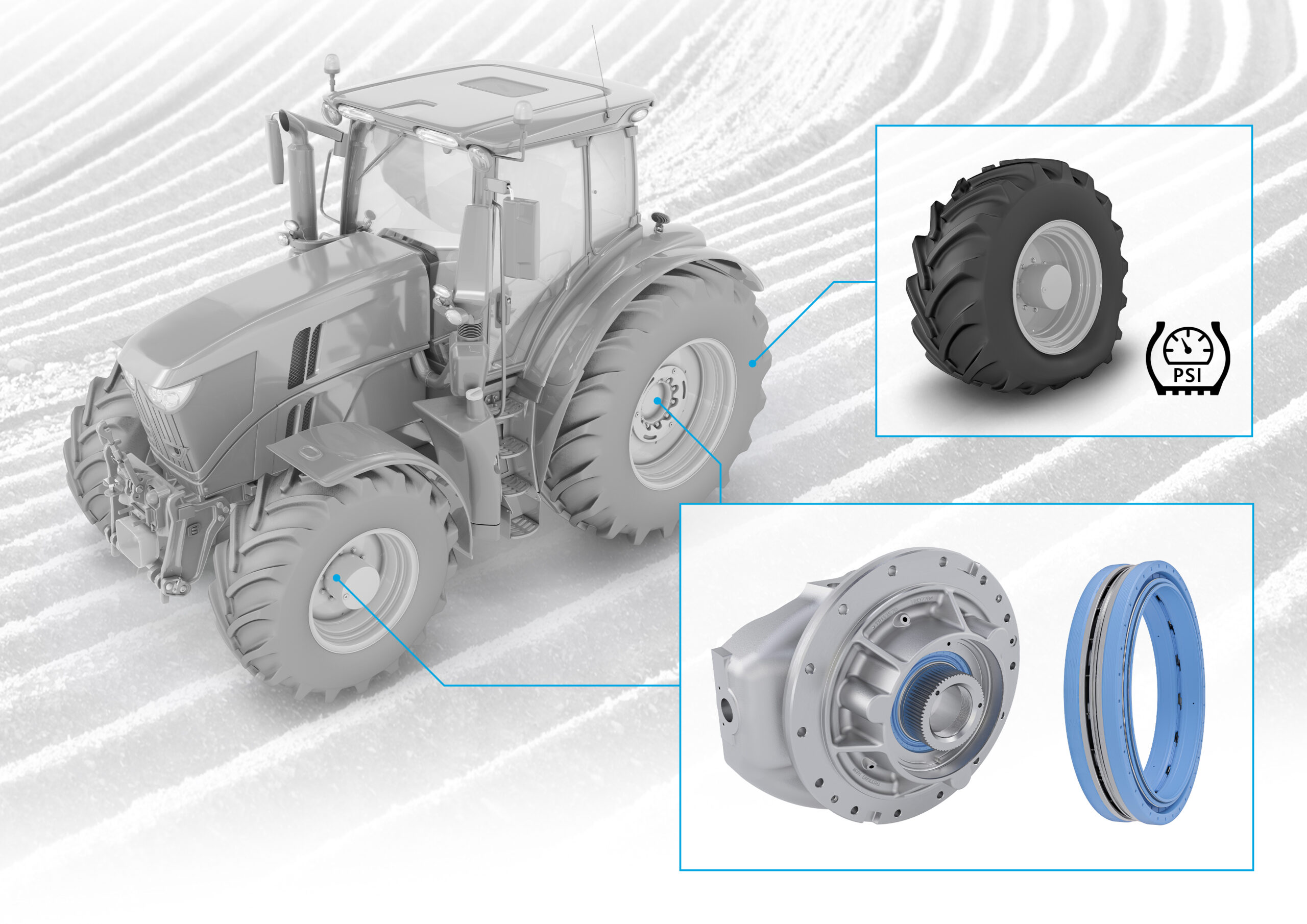

Agricultural CTIS is specifically designed to address the unique needs of farming equipment, focusing on soil compaction reduction. By allowing for tire pressure adjustments based on terrain, this system enhances traction and minimizes ground damage, which can significantly impact crop yields. Buyers in the agricultural sector should evaluate the long-term benefits of increased productivity against the investment costs, particularly in regions where soil health is a priority.

Commercial Vehicle CTIS provides flexibility in tire pressure management, optimizing fuel efficiency and extending tire life across various applications, including construction and logistics. The system’s ability to adapt to load variations and terrain types results in lower operating costs and improved vehicle performance. B2B buyers should weigh the potential savings in fuel and maintenance against the need for regular system upkeep, making it a strategic investment for fleet operators.

Off-Road CTIS is designed for vehicles operating in extreme conditions, allowing them to function effectively at low tire pressures. This adaptability maximizes traction and minimizes tire damage, crucial for mining and off-road applications. Buyers should consider the system’s performance advantages in rugged environments while assessing its limitations in urban settings, ensuring it meets their operational requirements.

Integrated CTIS combines tire inflation control with real-time monitoring, providing comprehensive oversight for heavy-duty trucks and fleet management. This system reduces downtime by alerting operators to tire issues before they become critical. B2B buyers should evaluate the complexity of installation and maintenance against the benefits of enhanced operational efficiency and reduced tire-related disruptions, making it a valuable asset for fleet operators.

Illustrative image related to ctis central tire inflation system

| Industry/Sector | Specific Application of ctis central tire inflation system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Precision farming vehicles for crop management | Enhances traction, reduces soil compaction, increases crop yields | Compatibility with existing machinery; ease of installation and maintenance |

| Military | All-terrain military vehicles for defense operations | Improves mobility in challenging terrains, enhances vehicle safety | Reliability in harsh conditions; integrated diagnostics for real-time monitoring |

| Construction | Heavy machinery in construction sites | Reduces tire wear, lowers fuel consumption, enhances vehicle uptime | Customization options for different vehicle types; support for emergency repairs |

| Mining | Haul trucks and equipment in mining operations | Maximizes tire lifespan, reduces operational costs, improves safety | Robustness against extreme conditions; availability of spare parts and service support |

| Transportation | Freight and logistics vehicles operating in diverse terrains | Optimizes fuel efficiency, minimizes downtime, improves load management | Compliance with international standards; supplier reliability for ongoing support |

In the agricultural sector, the CTIS is employed in precision farming vehicles to optimize tire pressure based on varying load and terrain conditions. This system addresses the challenge of soil compaction, which can adversely affect crop yields by up to 30%. By maintaining the optimal tire pressure, farmers can enhance traction, reduce fuel consumption, and improve the overall efficiency of their operations. Buyers in this sector should consider compatibility with existing machinery and the ease of installation and maintenance when sourcing CTIS solutions.

For military vehicles, the CTIS is crucial for maintaining mobility in diverse and challenging environments. It allows for real-time adjustments to tire pressure, which is essential for navigating rough terrains and avoiding immobilization due to tire leaks. This technology enhances vehicle safety and ensures that soldiers can escape threats effectively. International buyers in defense sectors should prioritize reliability in harsh conditions and look for integrated diagnostic features that provide real-time monitoring of tire health.

In the construction industry, the CTIS is integrated into heavy machinery to improve operational efficiency. By allowing for precise tire pressure adjustments, it reduces tire wear and enhances fuel consumption, ultimately leading to lower operational costs. Additionally, minimizing downtime caused by tire malfunctions keeps construction projects on schedule. Buyers should seek customization options that cater to different vehicle types and ensure that suppliers offer robust support for emergency repairs.

In mining, the CTIS is essential for haul trucks and other heavy equipment operating in extreme conditions. It maximizes tire lifespan by maintaining optimal pressure, thus reducing operational costs and improving safety on-site. The ability to adjust tire pressure based on terrain is vital for navigating uneven surfaces and heavy loads. When sourcing CTIS for mining applications, buyers should focus on the system’s robustness against harsh environments and the availability of spare parts and service support.

Illustrative image related to ctis central tire inflation system

In the transportation sector, the CTIS enhances the performance of freight and logistics vehicles that operate across varied terrains. By optimizing tire pressure, it improves fuel efficiency and minimizes vehicle downtime, which is critical for maintaining delivery schedules. The system also aids in better load management, ensuring that vehicles perform optimally regardless of the conditions. Buyers in this sector should ensure that the CTIS complies with international standards and that the supplier is reliable for ongoing support and maintenance.

The Problem: Many B2B buyers in industries like construction, agriculture, and logistics face the challenge of maintaining optimal tire pressure across varying terrain. Drivers often encounter situations where they need to adjust tire pressure for off-road conditions or heavy loads, but doing this manually is time-consuming and prone to error. Such inconsistencies can lead to reduced traction, increased tire wear, and ultimately, higher operational costs. For instance, a construction company may find its vehicles stuck in muddy conditions due to under-inflated tires, causing delays and additional costs.

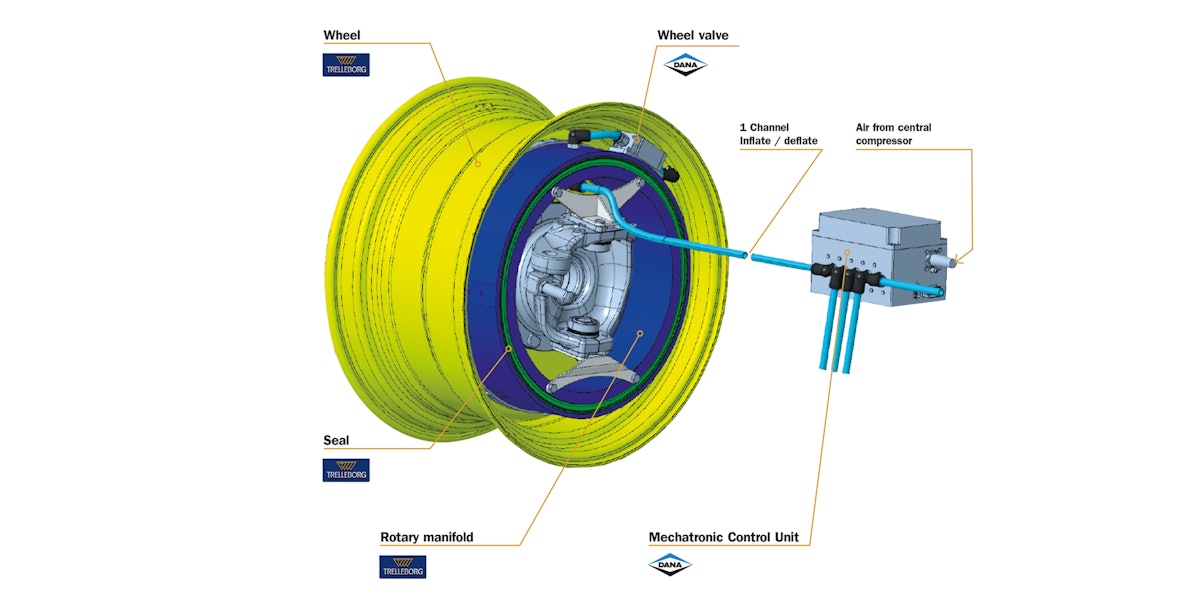

The Solution: Implementing a Central Tire Inflation System (CTIS) can significantly enhance operational efficiency. This system allows drivers to adjust tire pressures with the push of a button from inside the cab, adapting to the terrain in real-time. When sourcing a CTIS, buyers should consider systems that feature automatic pressure adjustments based on load and terrain type, like those offered by leading manufacturers. Additionally, buyers should ensure that the system includes integrated diagnostics to monitor tire health continuously. Training drivers on the system’s functionality will ensure they can respond quickly to changing conditions, thereby reducing downtime and improving vehicle mobility.

The Problem: Downtime caused by tire malfunctions, such as punctures or leaks, can severely impact the bottom line for businesses relying on transportation. For example, a logistics company might experience significant delays in deliveries due to a truck being immobilized from a minor tire issue. The lack of immediate alerts or monitoring systems can lead to escalating problems before they are addressed, ultimately affecting customer satisfaction and increasing operational costs.

The Solution: A CTIS equipped with an automatic emergency mode can be a game-changer. This feature not only alerts drivers to potential tire issues but also allows for immediate adjustments to maintain optimal pressure, even in the event of a minor leak. When evaluating CTIS options, buyers should look for systems that provide integrated diagnostics, which alert operators about tire conditions and system status. This proactive approach reduces downtime as it enables drivers to respond promptly to issues before they escalate. Furthermore, routine maintenance and inspections should be scheduled to ensure the CTIS is functioning optimally, which can prevent larger problems from occurring.

The Problem: Rising fuel costs are a significant concern for many businesses, particularly those in sectors like transportation and agriculture, where fuel efficiency directly impacts profitability. Improper tire pressure can lead to increased rolling resistance, which in turn drives up fuel consumption. A logistics company operating a fleet of trucks may find that fluctuating tire pressures are leading to higher than necessary fuel expenses, affecting their overall budget and competitive edge.

The Solution: Utilizing a CTIS can effectively address fuel efficiency concerns by maintaining optimal tire pressure at all times. By allowing for real-time adjustments based on load and terrain, CTIS helps minimize fuel consumption and reduce tire wear. When selecting a CTIS, businesses should prioritize systems that provide continuous pressure monitoring and can be integrated with existing fleet management software. This integration enables data analysis, allowing companies to track fuel efficiency trends and make informed decisions about their operations. Furthermore, training staff on the importance of maintaining optimal tire pressure through the CTIS can help instill a culture of efficiency within the organization, ultimately leading to cost savings and improved performance.

Illustrative image related to ctis central tire inflation system

When selecting materials for Central Tire Inflation Systems (CTIS), it is crucial to consider their properties, advantages, and limitations. The performance and reliability of CTIS systems directly impact vehicle mobility, operational costs, and overall efficiency. Below is an analysis of four common materials used in CTIS components.

Key Properties: Aluminum alloys are lightweight, have excellent corrosion resistance, and can withstand moderate pressure and temperature variations. They typically have a tensile strength ranging from 70 to 700 MPa, making them suitable for various applications.

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, which contributes to fuel efficiency and overall vehicle performance. However, they can be more expensive than steel and may require additional treatments to enhance their strength and durability, particularly in demanding environments.

Impact on Application: Aluminum alloys are compatible with various media, including air and hydraulic fluids, making them ideal for CTIS applications. However, their performance may degrade at high temperatures, which should be considered in extreme conditions.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards for aluminum alloys, such as ASTM B221 or DIN 1725. Additionally, the availability of aluminum components may vary based on local manufacturing capabilities.

Illustrative image related to ctis central tire inflation system

Key Properties: High-strength steel offers exceptional tensile strength, often exceeding 600 MPa, and can handle high pressures and temperatures. It also exhibits good fatigue resistance, making it suitable for heavy-duty applications.

Pros & Cons: The primary advantage of high-strength steel is its durability and cost-effectiveness, especially for larger components. However, it is heavier than aluminum, which can negatively impact fuel efficiency. Additionally, it may require corrosion-resistant coatings to prevent rust in harsh environments.

Impact on Application: High-strength steel is compatible with air and other fluids used in CTIS systems. Its robustness makes it ideal for components exposed to high stresses, such as valves and connectors.

Considerations for International Buyers: Buyers should consider compliance with international standards such as ASTM A992 or JIS G3106. In regions with high humidity or corrosive environments, additional protective measures may be necessary.

Illustrative image related to ctis central tire inflation system

Key Properties: Polyurethane is a versatile polymer known for its excellent abrasion resistance, flexibility, and ability to withstand a wide range of temperatures (-30°C to +80°C). It is often used in seals and gaskets within CTIS systems.

Pros & Cons: The main advantage of polyurethane is its ability to form tight seals, preventing leaks and maintaining pressure. However, it can be less durable than metals in high-stress applications and may degrade under UV exposure.

Impact on Application: Polyurethane is compatible with air and many hydraulic fluids, making it suitable for seals in CTIS systems. Its flexibility allows it to accommodate variations in pressure without compromising performance.

Considerations for International Buyers: Buyers should check for compliance with standards like ASTM D412 for tensile strength and ASTM D624 for tear resistance. In regions with high UV exposure, selecting UV-stabilized formulations may be necessary.

Key Properties: Brass is a copper-zinc alloy known for its excellent corrosion resistance and machinability. It can withstand moderate pressures and has good thermal conductivity.

Pros & Cons: The primary advantage of brass is its resistance to corrosion, particularly in humid environments, making it ideal for fittings and connectors. However, it is generally more expensive than steel and may not be suitable for high-pressure applications.

Illustrative image related to ctis central tire inflation system

Impact on Application: Brass is compatible with air and various fluids, making it suitable for CTIS applications. Its ability to resist corrosion enhances the longevity of components in challenging environments.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B36 for brass tubes and fittings. In regions with strict regulations on copper alloys, such as Europe, understanding local compliance requirements is crucial.

| Material | Typical Use Case for ctis central tire inflation system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Lightweight components like valves and housings | Excellent corrosion resistance | Higher cost than steel | High |

| High-Strength Steel | Heavy-duty components like frames and brackets | Exceptional durability | Heavier, may require coatings | Medium |

| Polyurethane | Seals and gaskets for pressure maintenance | Tight seals, flexibility | Less durable under stress | Medium |

| Brass | Fittings and connectors | Corrosion resistance | Higher cost, limited pressure use | High |

This strategic material selection guide provides essential insights for international B2B buyers, aiding in the informed decision-making process regarding CTIS components tailored to their specific operational needs and environmental conditions.

The manufacturing process of Central Tire Inflation Systems (CTIS) involves several critical stages to ensure high-quality and reliable systems suitable for various applications, including military, agriculture, and commercial vehicles.

The first stage in the manufacturing process is material preparation, where high-quality raw materials are selected based on the specifications needed for durability and performance. Common materials include high-strength metals for valves and tubing, durable plastics for housing components, and specialized rubber for seals and gaskets. The selection of these materials is crucial as they must withstand extreme environmental conditions, such as high temperatures, humidity, and abrasive terrains.

Following material preparation, the forming process takes place. This includes techniques such as machining, injection molding, and stamping to create the individual components of the CTIS. Machining is often used for precision parts like valves and fittings, ensuring a tight fit and reliable operation. Injection molding is typically employed for plastic parts, allowing for intricate designs that enhance functionality while keeping production costs manageable.

Once the components are formed, the assembly process begins. This is a critical stage where precision and attention to detail are paramount. Automated assembly lines may be used for high-volume production, incorporating robotics to ensure consistency and reduce human error. Manual assembly is often necessary for complex systems, where skilled technicians ensure that each component is correctly installed and tested. Quality checks are integrated throughout the assembly process to catch any defects early on.

The finishing stage involves several techniques to enhance the performance and longevity of the CTIS. This may include surface treatments such as anodizing, powder coating, or painting, which provide corrosion resistance and improve aesthetic appeal. Additionally, final assembly includes fitting all components together, followed by comprehensive testing to ensure the system operates correctly under various conditions.

Quality assurance (QA) is a vital aspect of the manufacturing process for CTIS, ensuring that the systems meet international standards and customer expectations.

Manufacturers of CTIS typically adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards assures buyers that the manufacturer has a systematic approach to managing quality, ensuring consistent product performance. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may apply depending on the application of the CTIS.

Illustrative image related to ctis central tire inflation system

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Common testing methods include:

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control measures of CTIS suppliers.

Buyers should request detailed quality control reports and audit results from potential suppliers. These documents should outline compliance with international standards, results from quality checks, and any corrective actions taken in response to issues. Regular audits by third-party organizations can also provide an unbiased assessment of a supplier’s quality management practices.

Engaging third-party inspection services can provide additional assurance regarding the quality of CTIS products. These inspections can verify that the manufacturing processes and final products meet agreed-upon specifications and standards. Buyers can arrange for inspections at various stages of production, including pre-shipment inspections, to ensure that the products conform to the required quality levels.

International B2B buyers must be aware of specific nuances in quality control that can affect their purchasing decisions.

By comprehensively understanding the manufacturing processes and quality assurance measures in CTIS production, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

In the competitive landscape of B2B procurement, acquiring a Central Tire Inflation System (CTIS) requires a strategic approach. This guide is designed to assist international buyers in navigating the complex sourcing process to ensure they select the right system for their operational needs.

Establishing clear technical specifications is crucial as it aligns your operational requirements with the capabilities of the CTIS. Consider factors such as vehicle types, load capacities, and the types of terrain you will encounter. This clarity will help you communicate effectively with suppliers and ensure that the system meets your needs.

Different CTIS models offer varying functionalities. Key features to consider include:

– Automatic pressure adjustments: Look for systems that can adapt tire pressure based on load and terrain automatically.

– Diagnostic alerts: Ensure the system provides real-time feedback on tire health and pressure levels.

These features are essential for enhancing vehicle mobility and reducing downtime due to tire issues.

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, including their experience in providing CTIS solutions. Look for:

– Case studies: Examples of successful implementations in your industry can provide insight into a supplier’s capabilities.

– References: Speak with other buyers in similar regions or sectors to gauge satisfaction and reliability.

Ensure that the CTIS you are considering complies with relevant industry standards and regulations. This may include safety certifications and environmental considerations. Compliance is crucial for avoiding potential legal issues and ensuring that the system operates reliably in your specific market conditions.

After-sales support is a critical factor in ensuring the longevity and effectiveness of your CTIS. Investigate the warranty terms offered by suppliers, including:

– Duration and coverage: A longer warranty may indicate greater confidence in the product’s reliability.

– Availability of technical support: Ensure the supplier can provide prompt assistance and maintenance services as needed.

Once you have identified potential suppliers, issue RFPs to gather detailed proposals. This process allows you to compare pricing, features, and service levels. Ensure that your RFP includes specific criteria based on the previous steps to facilitate meaningful comparisons.

Illustrative image related to ctis central tire inflation system

Finally, conduct a comprehensive cost-benefit analysis of the proposals received. Consider not just the initial purchase price but also:

– Operational savings: Evaluate how the CTIS can reduce tire wear and improve fuel efficiency.

– Long-term ROI: Assess the potential for reduced downtime and increased productivity, which can significantly impact your bottom line.

By following this checklist, B2B buyers can make informed decisions when sourcing a Central Tire Inflation System, ultimately enhancing operational efficiency and reducing costs in the long run.

When sourcing Central Tire Inflation Systems (CTIS), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The core materials used in CTIS, such as high-quality rubber for seals, durable metals for valves, and electronic components for control systems, significantly impact costs. High-grade materials enhance durability and performance, especially in demanding environments.

Labor: Skilled labor is essential for the assembly and installation of CTIS. The complexity of the system requires trained technicians, which adds to the overall labor costs. This is particularly relevant in regions with varying labor costs.

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help in minimizing these overhead costs.

Tooling: Custom tooling for specific vehicle applications can increase initial costs. However, investing in proper tooling can lead to better precision and efficiency in production, potentially lowering costs over time.

Quality Control (QC): Rigorous QC processes are necessary to ensure reliability and performance, particularly for systems used in critical applications like military and emergency vehicles. Investing in quality checks can prevent costly failures and recalls.

Logistics: Transportation costs, including shipping and handling, can vary based on the location of suppliers and buyers. International shipping can be particularly expensive, so it’s essential to factor in these logistics costs when sourcing CTIS.

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market positioning and the competitive landscape.

Several factors influence the pricing of CTIS, which buyers should consider:

Volume/MOQ: The minimum order quantity (MOQ) significantly affects pricing. Larger orders typically yield better per-unit pricing, making it beneficial for businesses with high demand.

Specifications/Customization: Custom features tailored to specific vehicle types or operational requirements can increase costs. Buyers should balance the need for customization with budget constraints.

Materials: Premium materials may come at a higher price but can offer better performance and longevity, thus providing a better Total Cost of Ownership (TCO).

Quality and Certifications: Systems that comply with international standards or come with certifications (e.g., ISO, military specifications) may carry a premium price but can assure buyers of reliability and quality.

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge more due to their proven track record.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

To maximize value when sourcing CTIS, buyers should consider the following strategies:

Negotiation: Engage suppliers in negotiations to secure better pricing, especially for bulk orders or long-term contracts. Leverage competitive quotes from multiple suppliers to strengthen your bargaining position.

Cost-Efficiency: Look beyond initial costs to assess the Total Cost of Ownership. Evaluate long-term savings from enhanced fuel efficiency and reduced downtime due to tire issues.

Pricing Nuances for International B2B Buyers: Be aware of currency fluctuations, tariffs, and local regulations when sourcing from international suppliers. This understanding can help in budgeting accurately and avoiding unexpected costs.

Research and Network: Attend industry conferences and trade shows to connect with suppliers and gain insights into pricing trends and innovations in CTIS technology.

Request Samples: Before making a large purchase, request samples to evaluate the quality and performance of the CTIS. This can prevent costly mistakes and ensure you are investing in a reliable product.

Prices for Central Tire Inflation Systems can vary widely based on numerous factors, including geographic location, supplier, and specific system configurations. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Illustrative image related to ctis central tire inflation system

As businesses increasingly seek to optimize vehicle performance and reduce operational costs, understanding alternative solutions to the Central Tire Inflation System (CTIS) becomes essential. This analysis will compare CTIS with two viable alternatives: traditional manual tire inflation systems and automatic tire pressure monitoring systems (TPMS). Each solution presents unique advantages and challenges, making it critical for B2B buyers to evaluate their specific needs against these alternatives.

| Comparison Aspect | Ctis Central Tire Inflation System | Manual Tire Inflation System | Automatic Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Performance | Adjusts pressure dynamically for optimal traction and stability | Requires manual adjustment, less responsive | Monitors pressure but does not adjust it automatically |

| Cost | Higher initial investment but reduces long-term costs | Low initial cost but higher long-term operational costs | Moderate cost; ongoing monitoring may incur expenses |

| Ease of Implementation | Requires professional installation | Easy to implement; no special tools needed | Installation can be complex depending on vehicle type |

| Maintenance | Low maintenance with built-in diagnostics | Requires regular checks and manual adjustments | Low maintenance; alerts for pressure issues but no adjustments |

| Best Use Case | Ideal for off-road, military, and heavy-duty vehicles | Suitable for light-duty vehicles and occasional use | Best for fleet management where monitoring is critical |

Manual tire inflation systems offer a straightforward approach to maintaining tire pressure. They are typically less expensive to install and operate, making them attractive for light-duty vehicles or applications where tire pressure changes are infrequent. However, they require drivers to physically check and adjust tire pressure, which can lead to human error and inconsistent tire performance. In demanding environments, such as construction or off-road applications, the inability to adjust pressure on-the-fly may lead to reduced vehicle mobility and increased tire wear.

Automatic tire pressure monitoring systems (TPMS) serve as an advanced alternative by providing real-time tire pressure data to drivers. This system allows for proactive monitoring, alerting users to potential issues before they become significant problems. However, TPMS does not adjust tire pressure automatically, which means that while it can help prevent tire damage, it cannot provide the immediate performance benefits of a CTIS. Additionally, installation can be more complex and costly, especially for older vehicles not originally designed for such systems.

When selecting a tire inflation solution, B2B buyers should carefully assess their operational needs, vehicle types, and budget constraints. For businesses that operate in challenging terrains or require maximum vehicle performance, the CTIS offers unparalleled benefits despite its higher initial costs. Alternatively, businesses with lighter operational demands may find manual systems sufficient, while those focused on monitoring may lean towards TPMS. Ultimately, the choice hinges on balancing upfront investment with long-term operational efficiency and vehicle performance requirements.

Illustrative image related to ctis central tire inflation system

Understanding the critical specifications of a Central Tire Inflation System (CTIS) can significantly influence purchasing decisions for B2B buyers. Here are some essential technical properties to consider:

Pressure Range

The pressure range of a CTIS typically spans from 10 to 100 psi. This range is crucial because it allows for adjustments based on varying terrain and load conditions. For example, lower pressures can enhance traction on soft ground, while higher pressures can improve fuel efficiency on highways. B2B buyers should ensure the system meets the specific requirements of their operational environment.

Response Time

The response time indicates how quickly the system can adjust tire pressure. High-performance CTIS units can respond within seconds to changing conditions. This rapid adjustment is essential for maintaining optimal vehicle performance and safety, particularly in industries like agriculture or defense, where terrain can change abruptly.

Durability and Environmental Resistance

The materials used in CTIS components, such as sealed wheel valves and robust tubing, are designed to withstand harsh conditions. Properties such as corrosion resistance and temperature tolerance are vital for ensuring the longevity of the system. Buyers should evaluate the materials to ensure they can endure the specific environmental challenges faced in their operations, such as extreme temperatures or exposure to chemicals.

Diagnostic Capabilities

Integrated diagnostic features are a significant advantage of modern CTIS technologies. These systems can continuously monitor tire pressure and alert drivers to potential issues like leaks or low pressure. This capability reduces downtime and maintenance costs, making it a key consideration for B2B buyers focused on operational efficiency.

Control Mechanism

The control mechanism, often a push-button interface or a digital display, allows for easy adjustments from within the vehicle. This user-friendly design is particularly important for operators who may need to make quick decisions in the field. Ensuring that the control system is intuitive can enhance driver confidence and safety.

Weight

The weight of the CTIS system can affect vehicle performance, particularly in military and agricultural applications where payload capacity is critical. Lightweight systems contribute to better fuel efficiency and maneuverability, making it important for buyers to consider the weight specifications relative to their vehicle type.

Familiarity with industry jargon is crucial for effective communication and negotiation in the procurement process. Here are some common terms related to CTIS:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that may be marketed by another manufacturer. In the context of CTIS, purchasing from an OEM often ensures compatibility and quality assurance, which are crucial for operational reliability.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for companies looking to implement CTIS across multiple vehicles.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers. This document usually outlines specific requirements, including technical specifications and quantities, enabling suppliers to provide accurate pricing.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and manage logistics effectively, especially when sourcing from international suppliers.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and ensuring that vehicles are equipped with CTIS promptly, minimizing operational delays.

Warranty and Support

Warranty terms and after-sales support are critical considerations when purchasing CTIS. Buyers should clarify the duration and coverage of warranties, as well as the availability of technical support, to ensure long-term satisfaction and performance of the system.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance vehicle performance and operational efficiency in demanding environments.

The Central Tire Inflation System (CTIS) sector is witnessing significant growth driven by several global factors. Increasing demand for enhanced vehicle performance in various terrains, particularly in industries such as agriculture, defense, and construction, is pushing manufacturers to innovate and offer advanced tire management solutions. International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are increasingly focused on systems that provide flexibility, reliability, and operational efficiency.

Illustrative image related to ctis central tire inflation system

Emerging technologies such as IoT-enabled tire monitoring and automation are transforming traditional CTIS solutions. These innovations allow for real-time tire pressure adjustments based on load and terrain, which not only enhances vehicle mobility but also reduces operational costs. Additionally, the rising awareness of fuel efficiency and environmental impact is prompting organizations to adopt CTIS technologies that minimize fuel consumption and tire wear.

Market dynamics are also influenced by regulatory requirements, particularly in regions with strict environmental standards. This is leading to a demand for CTIS solutions that comply with sustainability initiatives while offering robust performance. For B2B buyers, understanding these trends is crucial for sourcing the right products that align with their operational needs and sustainability goals.

Sustainability is becoming a central theme in the sourcing strategies of B2B buyers within the CTIS sector. The environmental impact of tire management systems is significant, as improper tire pressure can lead to increased fuel consumption, higher greenhouse gas emissions, and accelerated road wear. Consequently, companies are increasingly seeking CTIS solutions that optimize tire pressure to reduce these negative impacts.

Illustrative image related to ctis central tire inflation system

Ethical sourcing plays a pivotal role as well. Buyers are prioritizing suppliers who adhere to sustainable practices, such as using recycled materials or environmentally friendly manufacturing processes. Certifications like ISO 14001 (Environmental Management) are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. B2B buyers are encouraged to evaluate their supply chains for ethical practices, ensuring that their sourcing decisions align with their corporate social responsibility (CSR) goals.

Furthermore, companies that adopt ‘green’ certifications and materials in their CTIS solutions not only enhance their brand reputation but also attract eco-conscious clients. This shift towards sustainability and ethical sourcing reflects a broader trend in B2B markets, where corporate responsibility is now a key driver of purchasing decisions.

The evolution of the Central Tire Inflation System (CTIS) can be traced back to its origins in military applications during the 1980s. Initially designed to enhance mobility and performance in challenging terrains, CTIS technology has since expanded into various commercial sectors, including agriculture and construction.

Over the years, advancements in technology have significantly improved the functionality and reliability of CTIS. Today’s systems offer automated pressure adjustments, integrated diagnostics, and remote operation capabilities, all of which enhance vehicle performance while reducing the risk of tire-related issues. This evolution has not only increased the operational efficiency of vehicles equipped with CTIS but has also made these systems more accessible to a broader range of industries, solidifying their role in modern vehicle management.

As the demand for sustainable and efficient tire management continues to grow, the CTIS sector is poised for further innovation, ensuring that it meets the ever-evolving needs of B2B buyers worldwide.

How do I solve tire pressure issues in remote locations?

To effectively address tire pressure issues in remote areas, consider implementing a Central Tire Inflation System (CTIS). This system allows for real-time adjustments to tire pressure from within the vehicle, optimizing performance based on varying terrain and load conditions. It significantly reduces the risks associated with tire malfunctions, such as punctures or leaks, by maintaining optimal pressure levels. Additionally, the integrated diagnostics feature alerts drivers to potential tire problems, enhancing safety and operational efficiency in challenging environments.

What is the best CTIS for heavy-duty vehicles operating in harsh terrains?

The Spicer Central Tire Inflation System (CTIS) is highly recommended for heavy-duty vehicles navigating harsh terrains. Designed for maximum mobility and reliability, this system allows drivers to adjust tire pressure based on specific load and terrain requirements, ensuring optimal traction and reducing wear. The push-button operation simplifies use, while features like sealed wheel valves and automatic emergency modes enhance performance and safety. This system has been extensively tested in military applications, proving its effectiveness in demanding conditions.

What are the key benefits of using a Central Tire Inflation System for my fleet?

Implementing a CTIS can provide numerous benefits for your fleet, including improved fuel efficiency, extended tire life, and enhanced vehicle mobility. By maintaining optimal tire pressure, the system reduces soil compaction and minimizes tire wear, leading to lower operating costs. Moreover, the ability to adjust tire pressure on-the-fly enhances safety and reduces downtime associated with tire-related issues. This is particularly beneficial in industries such as construction, agriculture, and defense, where vehicle performance is critical.

How can I vet suppliers of Central Tire Inflation Systems internationally?

To vet suppliers of CTIS internationally, start by researching their reputation and reliability in the market. Look for manufacturers with a proven track record and positive customer reviews. Verify their certifications and compliance with international standards, which can indicate quality assurance practices. Additionally, consider reaching out to past clients for references. It’s also beneficial to request product samples or detailed specifications to evaluate the quality of their systems before making a commitment.

What customization options are available for CTIS?

Most manufacturers of Central Tire Inflation Systems offer customization options tailored to specific vehicle requirements and operational needs. Customizations may include varying valve types, control interfaces, and pressure settings to accommodate different terrains and loads. It’s essential to communicate your specific needs to the supplier to ensure the CTIS is optimized for your fleet’s unique conditions. Collaborating closely with the manufacturer during the design phase can result in a more effective and efficient system.

What is the minimum order quantity (MOQ) for purchasing CTIS?

The minimum order quantity for Central Tire Inflation Systems can vary significantly by supplier and the specific system required. Generally, manufacturers may require a MOQ ranging from a few units to several dozen, depending on production capabilities and inventory levels. It’s advisable to discuss your fleet size and future needs with potential suppliers, as some may offer flexibility in MOQs for larger contracts or ongoing partnerships.

What payment terms should I expect when sourcing CTIS internationally?

Payment terms for international sourcing of Central Tire Inflation Systems typically include options such as upfront payment, net 30/60/90 days, or letters of credit, depending on the supplier’s policies and your negotiation. Ensure to clarify these terms during initial discussions to avoid misunderstandings later. Additionally, consider using secure payment methods that protect both parties, especially when dealing with international transactions.

How does logistics factor into the procurement of CTIS?

Logistics is a crucial component of procuring Central Tire Inflation Systems, particularly for international buyers. Factors to consider include shipping methods, lead times, and customs clearance processes. Collaborate with your supplier to understand their shipping capabilities and ensure they can meet your delivery timelines. Additionally, plan for potential delays by factoring in customs regulations in your country, which may impact delivery schedules. Establishing a reliable logistics partner can streamline this process and help mitigate risks associated with international shipping.

Domain: spicerparts.com

Registered: 2004 (21 years)

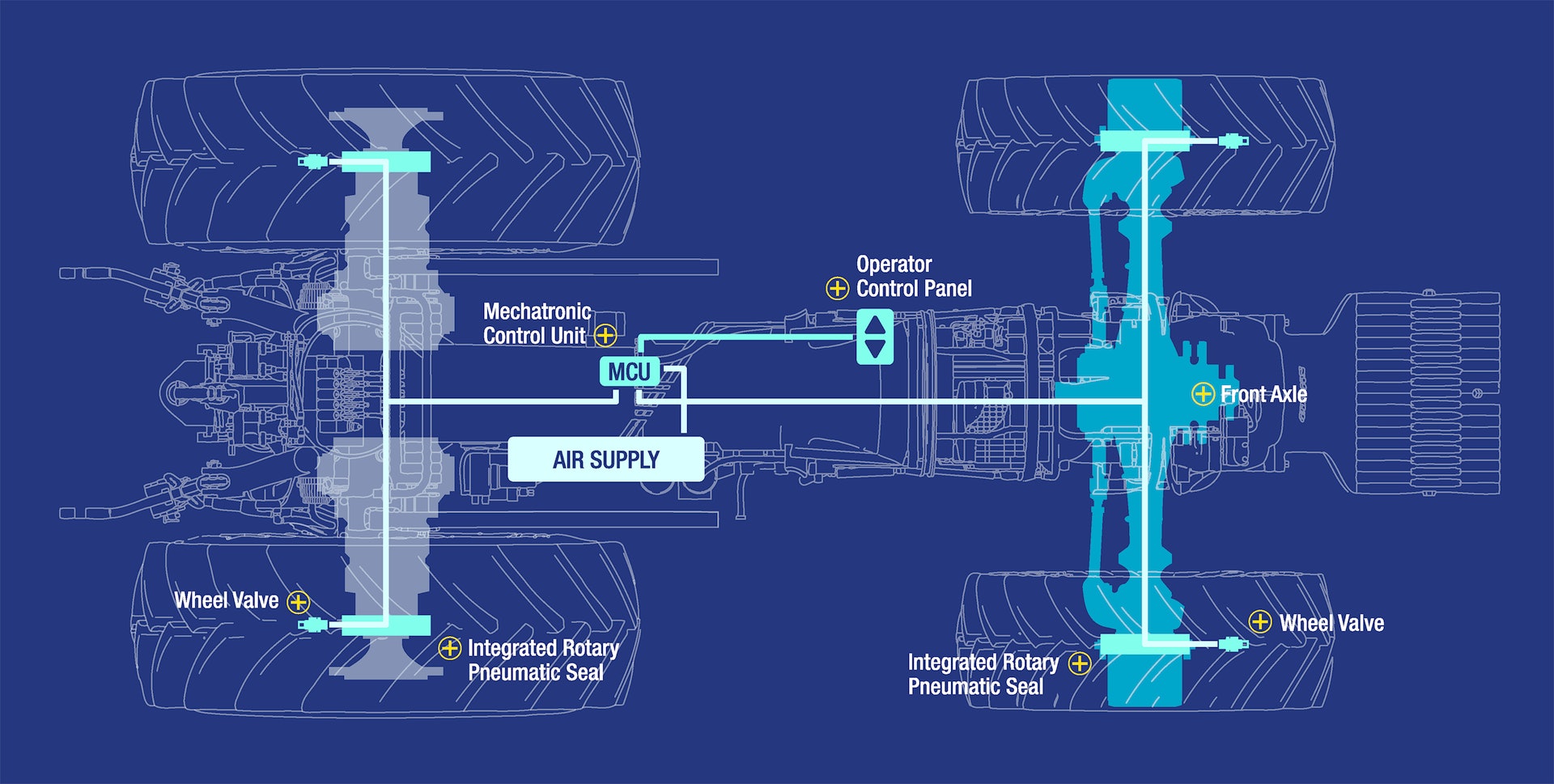

Introduction: Product Name: Central Tire Inflation System (CTIS™) – Axle

Key Features:

– Automatic emergency mode to handle leaks

– Allows adjustment of tire pressure based on vehicle load

– Enhances traction, tire life, and fuel consumption

– Convenient push-button operation for optimum pressure selection

– Integrated diagnostics for tire problems and system status

– Reduces downtimes associated with tire mal…

Domain: ftl.technology

Introduction: Central Tire Inflation System (CTIS) allows precise tire pressure adjustment on the move, enhancing vehicle mobility and performance in demanding conditions. Key features include:

– Adjusts tire pressure to improve traction, eliminate tire leaks, and reduce soil compaction.

– Provides remote operation from within the vehicle cab.

– Continuously checks and maintains optimum tire pressure.

– Red…

Domain: dana.com

Registered: 1993 (32 years)

Introduction: Central Tire Inflation System (CTIS) enhances mobility for government defense and vocational vehicles. Key features include: reliability and performance for military applications, improved all-wheel drive performance, maximum mobility, full diagnostics, a ‘limp home’ feature for disabled vehicles, complete mobility optimization, remote wheel-end venting, sealed wheel valves to prevent contaminatio…

Domain: business.michelinman.com

Registered: 2001 (24 years)

Introduction: Central Tire Inflation System (CTIS) allows farmers to adjust tire pressure on demand from the driver’s seat. It uses sensors, valves, and a control unit to optimize tire pressure for different terrains, improving driving conditions. Key advantages include:

– Up to 4% increase in productivity due to improved traction.

– Up to 10% fuel savings in field use when adjusting tire pressure.

– Up to 3…

Domain: ntstiresupply.com

Registered: 2007 (18 years)

Introduction: Central Tire Inflation Systems (CTIS) help combat soil compaction, a major profit stealer for farmers. Key benefits include optimizing tire pressure for different tasks: low pressure for field work to maximize traction and minimize compaction, and high pressure for safe road travel. The systems consist of three main components: Air Supply (compressor), Air Control (in-cab controller, air distribut…

In conclusion, the Central Tire Inflation System (CTIS) represents a significant advancement in optimizing vehicle performance across various terrains, making it an essential investment for international B2B buyers. Key takeaways highlight the system’s ability to enhance tire longevity, improve fuel efficiency, and reduce operational costs. The adaptability of CTIS technology to different load conditions and terrains ensures that vehicles maintain optimum performance, whether in agriculture, military, or construction applications.

Strategic sourcing of CTIS not only guarantees access to cutting-edge technology but also aligns with the growing demand for sustainable and efficient operations in emerging markets like Africa, South America, the Middle East, and Europe. By proactively addressing tire maintenance and performance issues, businesses can significantly reduce downtime and enhance overall productivity.

As you consider integrating CTIS into your fleet, remember that this technology is not just about inflation; it’s about maximizing mobility and ensuring your operations are future-ready. We encourage you to engage with trusted suppliers and explore the latest innovations in CTIS to empower your business for the challenges ahead.

Illustrative image related to ctis central tire inflation system

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.