In the fast-paced world of global commerce, sourcing a reliable air pump can be a daunting task for B2B buyers. Whether you are looking for high-performance tire inflators for automotive needs or versatile pumps for recreational applications, the challenge lies in identifying products that meet rigorous quality standards while remaining cost-effective. This guide serves as a comprehensive resource, addressing various types of air pumps and their specific applications, supplier vetting processes, and pricing strategies.

By offering insights into the diverse functionalities of air pumps, we aim to equip international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—with the knowledge necessary to make informed purchasing decisions. Understanding the nuances of product specifications, such as maximum pressure capabilities and portability features, is crucial for optimizing your procurement strategy.

In addition to product evaluations, this guide will delve into the importance of supplier reliability and the impact of after-sales support on long-term partnerships. By the end of this guide, you will be well-prepared to navigate the complexities of the air pump market, ensuring that your organization can maintain operational efficiency and meet customer demands effectively.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Tire Inflators | Compact design, battery-operated, often includes pressure gauges | Automotive maintenance, roadside assistance | Pros: Easy to transport, quick inflation. Cons: Limited battery life for heavy use. |

| Industrial Air Compressors | High-capacity, continuous duty operation, often stationary | Manufacturing, construction, automotive | Pros: High efficiency, suitable for heavy-duty tasks. Cons: Requires significant space and power supply. |

| Electric Air Pumps | Plug-in models with high PSI output, often feature automatic shut-off | Home use, sports equipment inflation | Pros: Consistent performance, easy to use. Cons: Dependence on power source limits portability. |

| Hand Pumps | Manual operation, lightweight, typically lower pressure output | Small-scale applications, camping | Pros: No power needed, portable. Cons: Labor-intensive, slower inflation rates. |

| High-Pressure Air Pumps | Designed for specialized applications, can reach high PSI levels | Industrial equipment maintenance, tire shops | Pros: High performance, versatile. Cons: Higher cost, may require specialized training to operate. |

Portable tire inflators are compact, battery-operated devices designed for quick inflation of vehicle tires. They often come equipped with built-in pressure gauges and multiple power options, making them ideal for roadside assistance or automotive maintenance. B2B buyers should consider their portability and ease of use, especially for businesses that require rapid response to tire issues. While they are convenient for light to moderate use, it’s essential to evaluate their battery life and inflation speed to ensure they meet operational demands.

Industrial air compressors are robust machines designed for continuous operation in demanding environments. They are typically stationary and provide high-capacity air supply for various applications, including manufacturing and construction. B2B buyers must consider the compressor’s efficiency, power requirements, and maintenance needs. While they excel in performance and can handle heavy-duty tasks, they require a significant investment and dedicated space, making them suitable for larger operations with consistent air supply needs.

Electric air pumps are plug-in models known for their consistent performance and high PSI output. They often feature automatic shut-off mechanisms, enhancing user convenience and safety during inflation tasks. Commonly used in home settings and for inflating sports equipment, these pumps are suitable for businesses that require frequent, reliable inflation without the need for portability. Buyers should weigh the benefits of ease of use against the limitations of dependence on a power source, which can restrict mobility.

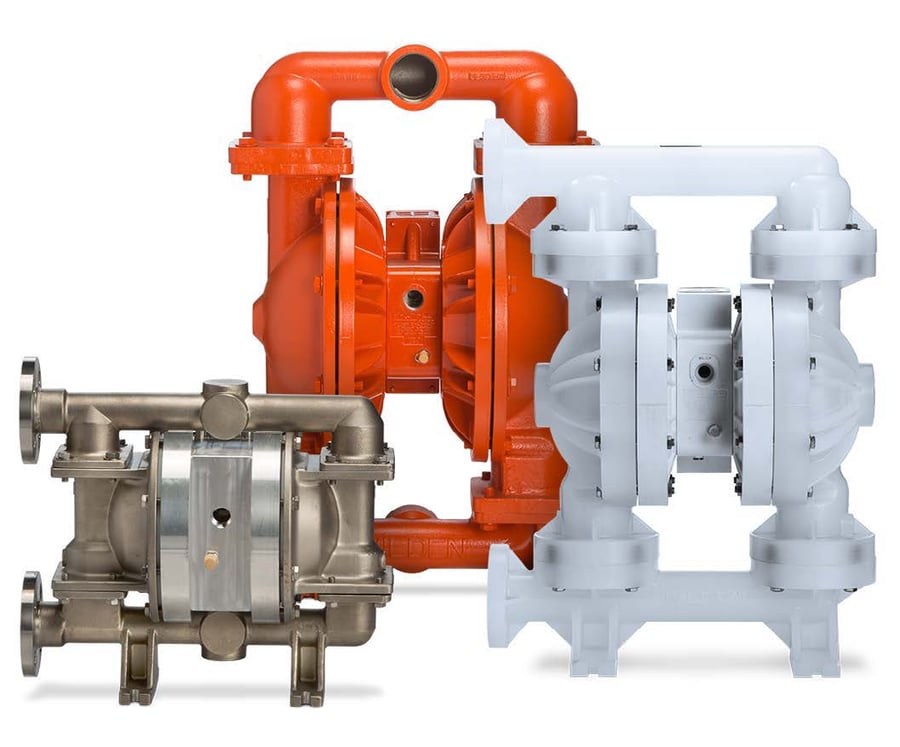

Illustrative image related to good air pump

Hand pumps are lightweight and manually operated, making them ideal for small-scale applications, such as camping or emergency use. Their portability and lack of power requirements allow for use in remote locations. However, B2B buyers should recognize that while hand pumps are cost-effective and easy to carry, they require physical effort and are slower in inflating tires compared to powered options. Their suitability lies in situations where convenience and simplicity are prioritized over speed and efficiency.

High-pressure air pumps are designed to handle specialized applications that require significant PSI levels, such as industrial equipment maintenance and tire shop operations. These pumps deliver exceptional performance and versatility, making them valuable assets for businesses needing to inflate high-pressure systems. However, buyers should consider the higher upfront costs and potential need for specialized training to operate these pumps effectively. Their investment is justified in settings where high performance is critical to operational success.

| Industry/Sector | Specific Application of good air pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tire Inflation for Fleet Maintenance | Enhances vehicle safety and fuel efficiency | Look for high PSI capabilities, portability, and durability. |

| Manufacturing | Pneumatic Tool Operation | Increases efficiency in assembly lines | Ensure compatibility with existing tools and energy sources. |

| Agriculture | Crop Spraying and Fertilizer Application | Optimizes resource use and improves yield | Assess air pressure consistency and adaptability to terrain. |

| Construction | Concrete Compaction and Air Supply | Ensures structural integrity and project timelines | Evaluate pressure control and ease of transport on-site. |

| Healthcare | Medical Equipment Operation | Supports critical patient care equipment | Focus on reliability, portability, and compliance with standards. |

In the automotive sector, good air pumps are essential for tire inflation during fleet maintenance. Regularly maintaining proper tire pressure enhances vehicle safety and improves fuel efficiency, leading to significant cost savings. B2B buyers should prioritize pumps that can achieve high PSI levels, are portable for easy use, and demonstrate durability to withstand frequent use. Additionally, the availability of power options (battery or direct connection) is crucial for operations in remote areas.

In manufacturing, good air pumps are integral for operating pneumatic tools, which are widely used in assembly lines. These pumps provide the necessary air pressure to power tools such as drills, wrenches, and riveters, thus increasing operational efficiency and productivity. Buyers in this sector should ensure compatibility with existing pneumatic systems and consider energy source requirements. A focus on the pump’s reliability and maintenance needs can also help minimize downtime.

Illustrative image related to good air pump

In agriculture, good air pumps are utilized for crop spraying and fertilizer application. They help optimize the distribution of chemicals and nutrients, ensuring better resource use and potentially increasing crop yields. Buyers from this sector must assess the pump’s ability to maintain consistent air pressure and its adaptability to various terrains. Furthermore, considering the pump’s capacity for different types of applications, such as spraying or aeration, can enhance operational effectiveness.

In construction, good air pumps are vital for concrete compaction and providing air supply for various tools. Properly compacted concrete ensures structural integrity and adherence to project timelines, making reliable air pumps a critical investment. Buyers should evaluate features such as pressure control and portability, as construction sites often require equipment that can be easily transported. Additionally, assessing the pump’s performance under varying environmental conditions is essential for consistent results.

In healthcare, good air pumps support the operation of critical medical equipment, including ventilators and oxygen concentrators. The reliability of these pumps can directly impact patient care and outcomes, making them a priority for medical facilities. B2B buyers should focus on sourcing pumps that meet stringent regulatory standards and offer portability for use in different medical settings. Additionally, understanding the pump’s maintenance requirements can ensure uninterrupted operation in high-stakes environments.

The Problem: Many B2B buyers managing fleets face the challenge of maintaining optimal tire pressure across multiple vehicles. This can lead to increased fuel consumption, uneven tire wear, and potential safety hazards. For instance, a logistics company operating in regions with varying climates may find that fluctuations in temperature cause significant changes in tire pressure, resulting in the need for frequent checks and adjustments. Moreover, traditional tire inflators may not be readily available or may lack the necessary specifications to handle the demands of heavy-duty vehicles.

The Solution: To overcome this issue, B2B buyers should invest in high-quality, versatile air pumps designed for fleet operations. Look for models with integrated digital pressure gauges and automatic shut-off features, which allow for precise inflation without the risk of over-inflation. Additionally, consider sourcing cordless inflators that can operate on rechargeable batteries for added convenience, especially in remote locations. Regularly train staff on the importance of tire maintenance and the proper usage of air pumps, ensuring they understand how to monitor tire pressure effectively and use the equipment efficiently. Establishing a routine maintenance schedule will also help mitigate pressure-related issues, thus prolonging the lifespan of tires and enhancing fuel efficiency.

The Problem: For companies operating in remote areas, the accessibility of air pumps can be a significant hurdle. Situations may arise where a vehicle becomes stranded due to a flat tire, and the nearest service station is miles away. This can lead to downtime, affecting productivity and customer satisfaction. Additionally, buyers may encounter air pumps that are bulky or difficult to transport, complicating the situation further.

The Solution: To address this pain point, B2B buyers should seek compact and portable air pumps that offer high performance without sacrificing convenience. Opt for models that come with multi-functional capabilities, such as the ability to inflate not only vehicle tires but also sports equipment or inflatable goods. Ensure these pumps are lightweight and come with a durable carrying case for easy transport. It’s also beneficial to choose inflators with both battery and vehicle power options, providing flexibility in various environments. Implementing a training program for staff on how to use these portable pumps efficiently will also enhance responsiveness in emergency situations, reducing downtime and ensuring swift resolutions.

The Problem: B2B buyers often face the frustration of inconsistent performance from their air pumps. Issues like prolonged inflation times, inaccurate pressure readings, or equipment failure can lead to operational disruptions. This is especially critical for businesses reliant on timely deliveries, as delays caused by faulty equipment can impact customer trust and profitability.

Illustrative image related to good air pump

The Solution: To ensure reliability and consistency, it is crucial for B2B buyers to conduct thorough research before purchasing air pumps. Prioritize brands with strong reputations for quality and customer service. Look for pumps that have undergone rigorous testing and come with warranties or guarantees. Incorporate feedback from other businesses in your industry to identify models that have proven effective under similar conditions. Regular maintenance and calibration of the air pumps should also be part of your operational procedures, allowing for timely identification of potential issues before they affect performance. Additionally, consider investing in a fleet of air pumps to ensure that if one unit fails, others are readily available, minimizing the risk of operational delays.

When selecting materials for air pumps, it’s essential to consider their properties, advantages, and limitations, especially for international B2B buyers. The choice of material can significantly influence the pump’s performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of air pumps.

Aluminum is a popular choice for air pump components due to its lightweight and high strength-to-weight ratio. It has excellent thermal conductivity, which helps in dissipating heat generated during operation. Aluminum also exhibits good corrosion resistance, particularly when anodized, making it suitable for various environments.

Pros: The lightweight nature of aluminum enhances portability, which is crucial for mobile air pumps. Its durability ensures a long lifespan, and its recyclability aligns with sustainability goals.

Cons: While aluminum is generally cost-effective, high-quality grades can be expensive. Additionally, it may not withstand extreme temperatures as well as some other metals, which could limit its applications in high-temperature environments.

Impact on Application: Aluminum is compatible with various media, including air and gases, making it versatile for different air pump designs.

Considerations for International Buyers: Buyers in regions with strict environmental regulations, such as Germany, may prefer aluminum due to its recyclability. Compliance with standards like DIN can also be a factor in material selection.

Steel is another common material used in air pumps, particularly for components that require high strength and durability. It has a high tensile strength and can withstand significant pressure, making it ideal for heavy-duty applications.

Pros: Steel’s robustness allows for use in high-pressure environments, and its cost-effectiveness makes it a popular choice for manufacturers.

Illustrative image related to good air pump

Cons: Steel is heavier than aluminum, which can affect portability. It is also susceptible to corrosion, requiring protective coatings or treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel is suitable for applications involving high-pressure air, such as industrial air pumps used in manufacturing and construction.

Considerations for International Buyers: Buyers from regions with high humidity or corrosive environments, such as parts of South America and the Middle East, should prioritize corrosion-resistant coatings on steel components to ensure longevity.

Illustrative image related to good air pump

Plastics, particularly high-performance polymers, are increasingly used in air pump manufacturing due to their lightweight and corrosion-resistant properties. They can be molded into complex shapes, allowing for innovative designs.

Pros: The use of plastic can significantly reduce the weight of air pumps, enhancing portability. Additionally, plastics are generally resistant to corrosion, making them suitable for various environments.

Cons: While plastics can be cost-effective, they may not withstand high temperatures or pressures as well as metals. This limitation can restrict their use in heavy-duty applications.

Impact on Application: Plastic components are ideal for low-pressure applications, such as small portable air pumps for inflating tires and recreational equipment.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant safety and performance standards, particularly in Europe, where regulations can be stringent.

Composite materials, which combine two or more materials to achieve superior properties, are gaining traction in air pump design. They can offer the best of both worlds—strength and weight reduction.

Pros: Composites can be engineered to provide excellent strength-to-weight ratios and enhanced resistance to temperature and corrosion. This versatility makes them suitable for various applications.

Cons: The manufacturing process for composites can be complex and costly, potentially leading to higher prices for the end product.

Illustrative image related to good air pump

Impact on Application: Composites are particularly useful in specialized air pumps that require high performance in extreme conditions, such as aerospace applications.

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of composite materials, especially in regions where budget constraints are significant, such as parts of Africa and South America.

| Material | Typical Use Case for good air pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable air pumps for consumer use | Lightweight and corrosion-resistant | May not withstand extreme temperatures | Medium |

| Steel | Industrial air pumps for heavy-duty use | High strength and cost-effective | Heavier and prone to corrosion | Low |

| Plastic | Small, low-pressure air pumps | Lightweight and moldable | Limited high-temperature and pressure resistance | Low |

| Composite | Specialized high-performance air pumps | Superior strength-to-weight ratio | Complex and costly to manufacture | High |

This analysis provides B2B buyers with a comprehensive overview of material options for air pumps, enabling informed decisions based on specific application requirements and regional considerations.

Manufacturing a high-quality air pump involves several critical stages, each contributing to the overall performance and reliability of the final product. Understanding these stages can help B2B buyers assess the capabilities and practices of potential suppliers.

Illustrative image related to good air pump

The manufacturing process begins with material preparation, which involves sourcing high-grade materials that meet specific standards. Common materials include durable plastics, metals such as aluminum or steel, and rubber for seals and hoses. Suppliers typically conduct thorough assessments of material quality to ensure compliance with international standards.

Before production, materials undergo various treatments, including cutting, shaping, and surface treatment to enhance durability and performance. For example, metals may be coated to prevent corrosion, while plastics may be reinforced to withstand high pressures. This stage is crucial, as the quality of raw materials directly impacts the pump’s efficiency and longevity.

The forming stage involves shaping the prepared materials into components that will make up the air pump. Techniques such as injection molding, extrusion, and machining are commonly employed.

Injection Molding: This method is often used for plastic components, allowing for complex shapes and designs with precision. It is highly efficient for mass production, making it a cost-effective choice for manufacturers.

Extrusion: Used for creating hoses and other continuous components, extrusion ensures uniformity in shape and thickness, which is essential for performance.

Machining: For metal parts, precision machining is employed to achieve the necessary tolerances. This is particularly important for components that must fit together tightly to prevent air leaks.

These techniques ensure that all parts of the pump are produced with high accuracy, contributing to the overall quality of the final product.

Once the components are formed, the next step is assembly. This stage can vary significantly depending on the complexity of the air pump design. Automated assembly lines are often used for high-volume production, ensuring consistency and efficiency. However, manual assembly may be employed for more intricate pumps that require detailed attention.

During assembly, components are meticulously joined, often with the use of adhesives, screws, or welding. Quality checks are typically conducted at this stage to ensure that each assembly meets specified standards. A well-assembled air pump should operate smoothly, with no signs of air leakage or mechanical failure.

Illustrative image related to good air pump

The finishing stage enhances the aesthetic and functional qualities of the air pump. This may include surface treatments like painting, anodizing, or applying protective coatings. These processes not only improve the appearance but also add an extra layer of protection against environmental factors such as moisture and UV rays.

Additionally, final testing is performed during this stage to ensure the pump meets performance specifications, such as pressure capacity and flow rate. These tests are critical for ensuring that the pump can withstand the conditions it will face in real-world applications.

Quality assurance (QA) is essential in the manufacturing of air pumps, as it ensures that products meet both safety and performance standards. International buyers should be aware of various QA practices and certifications that indicate a manufacturer’s commitment to quality.

ISO 9001 is one of the most recognized quality management standards worldwide. It outlines requirements for a quality management system (QMS) that helps organizations ensure they consistently meet customer and regulatory requirements. For air pump manufacturers, adherence to ISO 9001 signifies a commitment to quality in every aspect of production.

Illustrative image related to good air pump

Additionally, industry-specific standards such as CE marking in Europe, which indicates compliance with health and safety standards, and API (American Petroleum Institute) standards for pumps used in oil and gas applications, are also critical. These certifications ensure that the pumps can be safely used in their intended environments.

Quality control (QC) checkpoints are vital throughout the manufacturing process. Common checkpoints include:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are tested for quality to catch any defects early. This may include checks for dimensional accuracy and performance metrics.

Final Quality Control (FQC): Before the pumps are packaged and shipped, they undergo rigorous testing to confirm that they meet all performance specifications. This is the last opportunity to identify and rectify any issues.

These checkpoints are crucial for maintaining high-quality standards and ensuring customer satisfaction.

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some effective strategies:

Buyers can request quality audits from potential suppliers. These audits provide insight into the manufacturer’s quality management systems and processes. Suppliers should be willing to share their ISO certifications and any internal QC reports that detail their testing and inspection processes.

Furthermore, buyers can conduct site visits to observe the manufacturing process firsthand. This not only allows for direct observation of QC practices but also fosters a relationship with the supplier.

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct comprehensive inspections at various stages of production, offering unbiased assessments of product quality. This is particularly valuable for international buyers who may not have the resources to conduct on-site evaluations.

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality assurance. Different regions may have varying standards and regulatory requirements, making it essential to ensure compliance with local laws.

Additionally, cultural differences may influence communication and expectations regarding quality. Establishing clear agreements and understanding local practices can help mitigate misunderstandings and ensure a smoother procurement process.

In conclusion, understanding the manufacturing processes and quality assurance practices for air pumps is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing processes, and rigorous quality control, buyers can make informed decisions and choose suppliers that meet their quality standards.

In the competitive landscape of B2B procurement, sourcing a reliable air pump requires careful consideration of various factors. This checklist will guide you through the essential steps to ensure you select a high-quality air pump that meets your operational needs.

Establishing clear technical specifications is vital for your procurement process. Determine the required pressure range, flow rate, and power source (e.g., battery-operated, electric, or manual). This helps to narrow down options that align with your specific applications, whether for automotive, industrial, or recreational use.

Conduct thorough market research to understand the available air pumps and their features. Identify leading brands and their product offerings, focusing on those that have a strong reputation for reliability and performance. This step will provide insight into industry standards and innovations that could benefit your procurement.

Illustrative image related to good air pump

Before making any commitments, it’s crucial to vet suppliers thoroughly. Request company profiles, product catalogs, and references from buyers in similar industries or regions. This due diligence ensures that you are dealing with reputable suppliers who can meet your quality and service expectations.

Understanding the after-sales support and warranty policies is essential for a long-term investment. Inquire about the availability of spare parts, service agreements, and customer support channels. A reliable warranty indicates the manufacturer’s confidence in their product and can save you costs on potential repairs or replacements.

Whenever possible, request samples or demonstrations of the air pumps you are considering. This allows you to evaluate the product’s performance, usability, and build quality in real-world conditions. A hands-on assessment can provide insights that specifications alone may not reveal.

Once you have identified a suitable supplier and product, engage in pricing negotiations. Discuss bulk order discounts, payment terms, and delivery schedules. Effective negotiation can significantly impact your overall procurement costs and operational efficiency.

Before concluding the deal, ensure all terms are clearly outlined in the purchase agreement. Confirm product specifications, delivery timelines, and warranty details. A well-defined contract protects both parties and lays the groundwork for a successful business relationship.

By following this practical sourcing guide, you will be well-equipped to make informed decisions in procuring a high-quality air pump that meets your business needs.

The cost structure for sourcing a good air pump is multifaceted, encompassing several critical components. Materials form the base of the cost structure, typically comprising high-quality plastics, metals, and electronic components. The choice of materials directly impacts durability and performance, which can influence the final pricing.

Labor costs are another significant factor, particularly in regions where labor rates vary. In countries with lower labor costs, manufacturers may offer competitive pricing, but it’s essential to consider the trade-off between cost and quality.

Manufacturing overhead includes expenses related to utilities, rent, and equipment maintenance, which can vary based on location and operational efficiency. Tooling costs for specialized molds or machinery can also be considerable, particularly for customized designs or high-volume production runs.

Illustrative image related to good air pump

Quality Control (QC) processes ensure that products meet specified standards, adding another layer of expense. Manufacturers must invest in testing and inspection procedures to maintain quality, especially for products intended for international markets where compliance with safety and performance certifications is crucial.

Logistics costs, including shipping, warehousing, and customs duties, can significantly affect overall pricing. International buyers should be aware of these expenses, as they can vary greatly depending on the shipping method and distance.

Lastly, the margin is the profit that manufacturers aim to achieve. This margin can vary based on competition, market demand, and perceived value.

Several factors influence the pricing of air pumps. Volume and Minimum Order Quantity (MOQ) are critical; larger orders typically result in reduced per-unit costs due to economies of scale. Customization requests can also lead to increased costs, as tailored solutions often require additional resources and time.

The specifications and quality of the air pump play a significant role in pricing. Higher quality pumps with advanced features, such as built-in pressure gauges or rapid inflation capabilities, will generally command a higher price. Certifications for safety and performance can also affect costs, as compliant products often require additional testing and documentation.

Supplier factors such as reputation, reliability, and financial stability can influence pricing. Established suppliers may charge a premium for their perceived value, while new entrants may offer lower prices to gain market share.

Lastly, Incoterms—the international commercial terms—affect pricing by determining who is responsible for shipping costs, insurance, and import duties. Buyers should carefully consider these terms to understand their total cost exposure.

When negotiating prices, buyers should be prepared to discuss volume discounts and be flexible with order quantities to achieve better pricing. Understanding the Total Cost of Ownership (TCO) is crucial; consider not just the purchase price but also maintenance, warranty, and potential replacement costs over the product’s lifespan.

Buyers should also be aware of pricing nuances when sourcing internationally, especially from regions like Africa, South America, the Middle East, and Europe. Currency fluctuations can impact costs, so locking in prices or negotiating in a stable currency can mitigate risks.

Furthermore, consider the lead time for delivery, as longer shipping times can lead to increased costs if expedited shipping is needed. Lastly, building a strong relationship with suppliers can lead to better pricing, priority service, and improved communication, which are invaluable for successful international transactions.

Prices for air pumps can vary widely based on the factors discussed. It’s advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

In the realm of air inflation solutions, the choice of a “good air pump” can significantly impact operational efficiency and cost-effectiveness for businesses. However, it’s crucial for B2B buyers to explore alternative solutions that may offer distinct advantages depending on specific operational needs. This analysis compares a traditional air pump with two viable alternatives: electric inflators and CO2 inflators. Each solution has unique features that cater to different use cases, performance requirements, and budget constraints.

| Comparison Aspect | Good Air Pump | Electric Inflator | CO2 Inflator |

|---|---|---|---|

| Performance | Reliable for various applications | Quick inflation, good for tires | Instant inflation for small items |

| Cost | Moderate ($50 – $100) | Varies ($30 – $150) | Higher long-term cost ($10 per cartridge) |

| Ease of Implementation | Simple setup, requires manual effort | Plug-and-play, user-friendly | Requires cartridges, limited refills |

| Maintenance | Low maintenance, durable | Minimal, check power source | Low, but requires cartridge replacement |

| Best Use Case | General tire inflation and equipment | Tire maintenance for vehicles | Emergency inflation for sports equipment |

Electric inflators are becoming increasingly popular due to their speed and efficiency. They can inflate tires and other inflatable items quickly, making them ideal for automotive and recreational use. The primary advantage is their ease of use; simply plug them into a power source and start inflating. However, electric inflators can be limited by their reliance on a power outlet, making them less versatile in remote locations. Additionally, while their initial costs can be competitive, ongoing electricity costs should be considered.

CO2 inflators are specialized devices that utilize pressurized carbon dioxide cartridges to achieve rapid inflation. They are particularly favored in cycling and sporting applications where weight and size are critical. The main advantage of CO2 inflators is their ability to provide instant inflation without the need for a power source. However, they can become costly over time due to the need for replacement cartridges, and they are generally not suitable for larger items like car tires. B2B buyers should consider whether the convenience of portability outweighs the long-term expenses associated with cartridge replacements.

When selecting the best air inflation solution, B2B buyers must carefully assess their specific requirements. A good air pump may be the most versatile option for general use, while electric inflators excel in speed and convenience for tire maintenance. Conversely, CO2 inflators serve well in niche markets such as cycling but can incur higher long-term costs. By understanding the strengths and weaknesses of each alternative, businesses can make informed decisions that align with their operational objectives and budget considerations, ensuring optimal performance in their air inflation needs.

When evaluating air pumps for commercial use, several technical properties are essential to ensure optimal performance, durability, and suitability for specific applications. Below are critical specifications that B2B buyers should consider:

Illustrative image related to good air pump

Maximum Pressure Rating (PSI)

– This specification indicates the highest pressure the pump can achieve, measured in pounds per square inch (PSI). For applications involving automotive tires, a pump with a maximum PSI of at least 80 is advisable, particularly for heavy-duty vehicles. Understanding the PSI requirements helps ensure that the pump meets the demands of specific tasks, enhancing both efficiency and safety.

Duty Cycle

– The duty cycle refers to the ratio of operational time to resting time, typically expressed as a percentage. A pump with a higher duty cycle can operate for longer periods without overheating, which is crucial for high-demand environments. Selecting a pump with an appropriate duty cycle can reduce downtime and maintenance costs, making it a vital consideration for businesses that rely on continuous operation.

Power Source

– Air pumps can be powered by various sources, including AC power, DC power from car batteries, or rechargeable batteries. Understanding the power requirements is essential for ensuring compatibility with existing infrastructure. A versatile power source can enhance the pump’s usability across different environments, from workshops to remote job sites.

Inflation Speed

– This property measures how quickly the pump can inflate a tire or other inflatables, often quantified in liters per minute (LPM) or similar metrics. Faster inflation speeds can significantly reduce downtime, especially in commercial settings where time efficiency is critical. Evaluating inflation speed helps businesses choose a pump that aligns with their operational needs.

Material and Build Quality

– The materials used in the construction of an air pump impact its durability and performance. Common materials include high-grade plastics, metals, and rubber components. Assessing the build quality can help predict the pump’s longevity and resistance to wear, particularly in rugged environments. A well-constructed pump can lead to reduced replacement costs and improved reliability.

Pressure Gauge Type

– The type of pressure gauge, whether analog or digital, affects the ease of monitoring inflation progress. Digital gauges typically offer greater accuracy and ease of reading, which can enhance user experience and reduce the risk of over-inflation. Selecting a pump with a quality gauge can improve operational safety and efficiency.

Navigating the procurement process requires familiarity with industry jargon and trade terms. Here are some essential terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM status of a pump can provide insights into its quality and compatibility with existing equipment. Buyers often prefer OEM products for their reliability and warranty support.

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management. Buyers should assess whether the MOQ aligns with their purchasing needs to avoid excess stock or increased costs.

RFQ (Request for Quotation)

– An RFQ is a formal document soliciting price quotes from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices, terms, and conditions across multiple vendors, ensuring they secure the best deal.

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost implications, which are critical in cross-border transactions.

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the product. This term is vital for planning and inventory management. Understanding lead times can help businesses ensure they have the necessary equipment when needed, minimizing potential operational disruptions.

Warranty Period

– The warranty period specifies the duration for which a product is covered against defects or malfunctions. A comprehensive warranty can provide peace of mind and protect against unforeseen repair costs, making it an important factor in decision-making.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting air pumps, ultimately enhancing their operational efficiency and product reliability.

The global good air pump market is witnessing significant growth driven by rising demand across various industries, including automotive, construction, and recreational sectors. Factors such as increased vehicle ownership in emerging markets like Africa and South America, coupled with a surge in e-commerce, are fueling the need for efficient tire inflation solutions. Additionally, the ongoing transition towards electric vehicles (EVs) is likely to create new opportunities in the air pump sector, as these vehicles often require specialized inflators for their unique tire specifications.

Emerging B2B technology trends are influencing sourcing strategies as well. Automation and IoT integration are becoming more prevalent, allowing businesses to monitor tire pressure remotely and optimize maintenance schedules. Buyers are increasingly seeking suppliers who can provide data-driven insights into product performance, enhancing decision-making capabilities. Furthermore, the growth of online marketplaces is reshaping traditional sourcing methods, enabling buyers from regions like the Middle East and Europe to access a broader range of products and suppliers.

Market dynamics are also characterized by increased competition, leading to innovation in product design and functionality. For instance, the introduction of compact, battery-operated inflators with features like built-in pressure gauges and multiple charging options is appealing to international B2B buyers who prioritize convenience and efficiency. As the market evolves, understanding these trends will be crucial for buyers aiming to make informed procurement decisions.

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the good air pump sector. The environmental impact of manufacturing processes and the materials used in air pumps is under scrutiny, prompting buyers to seek suppliers who demonstrate a commitment to reducing their carbon footprint. This includes adopting eco-friendly manufacturing practices and utilizing recyclable or biodegradable materials in product design.

Buyers are increasingly interested in suppliers that hold certifications for sustainable practices, such as ISO 14001 for environmental management or certifications from organizations like the Forest Stewardship Council (FSC). These certifications can provide assurance that the products are produced responsibly, aligning with the values of environmentally conscious consumers and businesses.

Moreover, ethical supply chains are essential for building trust and fostering long-term relationships between buyers and suppliers. Transparency in sourcing materials, fair labor practices, and adherence to local regulations are key factors that B2B buyers should consider when evaluating potential suppliers. By prioritizing sustainability and ethical sourcing, buyers not only contribute to environmental preservation but also enhance their brand reputation in a competitive marketplace.

The history of air pumps can be traced back to the late 19th century, when the first hand-operated pumps were developed for inflating bicycle tires. These early models were simple and manual, requiring significant physical effort. As the automotive industry grew in the early 20th century, the demand for more efficient and convenient tire inflation solutions led to the development of foot-operated pumps and, eventually, electric inflators.

By the late 20th century, advancements in technology paved the way for portable air pumps, making them accessible to everyday consumers. The introduction of battery-operated and cordless models revolutionized the market, catering to the needs of a more mobile population. Today, the good air pump sector continues to evolve, with innovations in digital pressure gauges, smart connectivity, and compact designs, reflecting the changing demands of B2B buyers across various industries.

Understanding this evolution is crucial for international B2B buyers, as it highlights the trajectory of product development and the increasing importance of technology and convenience in purchasing decisions. As the sector progresses, buyers must stay informed about historical trends to anticipate future innovations and align their sourcing strategies accordingly.

How do I choose the right air pump for my business needs?

Choosing the right air pump involves assessing your specific requirements, such as the type of tires or equipment you need to inflate, the frequency of use, and your operational environment. For instance, if you require a portable solution for multiple vehicles, a cordless or compact inflator might be ideal. Consider the pump’s maximum pressure capabilities, flow rate, and any additional features like built-in pressure gauges or USB ports. Consulting with suppliers about your application can also provide insights into the best options available for your business.

What is the best air pump for commercial vehicle maintenance?

For commercial vehicle maintenance, a high-capacity air pump, such as the Viair 88P, is recommended due to its robust design and ability to inflate larger tires quickly. It can handle high pressures and is well-suited for trucks and SUVs. However, if portability is crucial, the AstroAI Cordless Tire Inflator offers an excellent balance of performance and convenience, allowing for easy use in various locations without needing a power source. Evaluate the specific demands of your fleet to determine the best fit.

What are the key features to look for in a high-quality air pump?

Key features to consider include maximum pressure capacity, inflation speed, portability, and ease of use. A digital pressure gauge can enhance accuracy, while features like automatic shut-off and multiple power options (battery, 12V adapter) increase convenience. Durability is also important, especially for industrial applications; consider pumps made from high-quality materials that can withstand heavy use. Additional features such as built-in lights or adapters for various inflatables may also be beneficial.

What factors should I consider when vetting suppliers for air pumps?

When vetting suppliers, consider their experience in the industry, product range, and reputation. Request references or case studies from previous clients to gauge reliability and customer service. Verify certifications and compliance with international quality standards, especially if you are importing goods. It’s also prudent to assess their logistics capabilities, lead times, and whether they offer customization options to meet your specific needs. Conducting a thorough background check can help mitigate risks.

What is the minimum order quantity (MOQ) for air pumps from international suppliers?

The minimum order quantity (MOQ) for air pumps can vary widely among suppliers, often ranging from 50 to 500 units depending on the manufacturer and product type. It’s essential to discuss your requirements with potential suppliers to understand their MOQ policies and negotiate terms that align with your purchasing strategy. Some suppliers may be willing to accommodate smaller orders, especially if you’re a new customer or seeking a trial order before committing to larger quantities.

What payment terms are commonly offered by air pump suppliers?

Payment terms vary by supplier but typically include options like upfront payment, a deposit with the balance due upon delivery, or net terms (e.g., net 30 or net 60 days). It’s crucial to clarify these terms before finalizing an order, especially for international transactions where currency exchange rates and transfer fees may apply. Consider using secure payment methods such as letters of credit or escrow services to protect your investment during the transaction.

How can I ensure the quality of the air pumps I purchase?

To ensure quality, request samples from potential suppliers to evaluate performance and durability firsthand. Review product specifications and certifications to confirm compliance with international standards. Establishing a quality assurance process, including periodic inspections during production and before shipment, can help mitigate risks. Building a relationship with your supplier and maintaining open communication can also facilitate quality control and timely resolution of any issues.

What logistics considerations should I keep in mind when importing air pumps?

When importing air pumps, consider shipping methods, costs, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure your supplier has experience with international shipping and can provide necessary documentation, such as bills of lading and customs declarations. Be aware of import duties and taxes in your country to avoid unexpected costs. Finally, establish a reliable logistics partner to manage the supply chain effectively.

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Tire Inflators: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power Cordless Tire Inflator – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX Tire Inflator – Built for lifetime usage and ownership. 5. Milwaukee M18 Cordless Tire Inflator – Robust and powerful with four different memory settings….

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Royobi air pump with a 4ah 18v battery – reliable and portable.

2. EPAUTO air pump – plugs into cigarette lighter, available on Amazon.

3. VIAIR 12v cigarette lighter air pump – recommended for its convenience.

4. Ryobi, Milwaukee, and Harbor Freight brands – known for their battery-operated air pumps.

5. Dewalt air compressor – rechargeable battery or car plug option.

6. Milwaukee air pump – f…

In the evolving landscape of air pump sourcing, international B2B buyers must prioritize efficiency, reliability, and adaptability. The recent evaluations highlight that top-performing air pumps, such as the AstroAI Cordless Tire Inflator, not only deliver superior performance but also incorporate user-friendly features that cater to diverse needs—from compact designs for personal vehicles to robust options for trucks and SUVs. Strategic sourcing involves selecting products that ensure optimal operational performance while being cost-effective.

For buyers in regions like Africa, South America, the Middle East, and Europe, it is crucial to understand the local market demands and regulatory standards that influence purchasing decisions. Investing in high-quality air pumps can lead to reduced maintenance costs, improved safety, and enhanced customer satisfaction.

Looking ahead, the air pump market is poised for innovation, with advancements in technology promising even more efficient solutions. As you consider your sourcing strategy, engage with reputable suppliers who offer comprehensive product support and insights into the latest trends. By doing so, you will position your business for sustainable growth and success in a competitive landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.