In the dynamic landscape of transportation, sourcing a reliable semi tire inflator can pose significant challenges for international B2B buyers. With the critical role that properly inflated tires play in ensuring vehicle safety and operational efficiency, selecting the right inflator becomes paramount. This guide delves into the various types of semi tire inflators available in the market, their specific applications across different terrains and climates, and essential considerations for supplier vetting. Additionally, we will discuss cost factors and performance metrics that influence purchasing decisions.

For businesses operating in regions such as Africa, South America, the Middle East, and Europe—where road conditions and regulations can vary widely—understanding the nuances of tire inflators is crucial. This guide aims to empower B2B buyers by providing actionable insights that facilitate informed purchasing decisions. Whether you are in Nigeria seeking durable equipment for rough terrains or in Germany looking for high-performance solutions, our comprehensive overview will help you navigate the complexities of the global market. By equipping yourself with the right knowledge, you can ensure that your fleet remains operational and safe, ultimately enhancing your bottom line.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| On-Board Air Supply Inflators | Utilizes the truck’s existing air supply; often includes glad-hand attachments. | Fleet maintenance, remote tire servicing. | Pros: Convenient, no extra power source needed. Cons: Limited by truck’s air capacity. |

| Portable Tire Inflators | Compact, electric or battery-operated; easy to transport. | Emergency roadside assistance, small fleet operations. | Pros: Versatile, can be used anywhere. Cons: Battery life may limit usage. |

| Automatic Tire Inflation Systems | Automated systems that maintain tire pressure; can be integrated into fleet management. | Large fleets, logistics companies. | Pros: Reduces manual labor, ensures optimal tire pressure. Cons: Higher initial investment. |

| Manual Tire Inflation Kits | Basic kits with air hoses, gauges, and manual pumps; no automation. | Small businesses, independent operators. | Pros: Cost-effective, straightforward. Cons: Labor-intensive, requires operator skill. |

| Digital Tire Inflators | Equipped with digital gauges for precise inflation; often feature programmable settings. | Fleet operations, tire shops. | Pros: Accurate readings, user-friendly. Cons: More expensive than analog options. |

On-board air supply inflators harness the air supply already present in a truck, making them ideal for fleets that prioritize efficiency in remote locations. These systems typically come with attachments such as glad-hand connectors, allowing for quick and easy inflation without additional equipment. B2B buyers should consider the capacity of the truck’s air system, as this will dictate the inflator’s effectiveness in high-demand scenarios.

Portable tire inflators are compact, making them perfect for emergency situations or on-the-go applications. They can be electric or battery-operated, providing flexibility for various environments. Businesses that require quick responses, such as roadside assistance services, will find these inflators particularly beneficial. However, considerations around battery life and the need for recharging should be factored into purchasing decisions.

Automatic tire inflation systems are sophisticated solutions designed to maintain optimal tire pressure without manual intervention. These systems are particularly advantageous for large fleets, as they can integrate with fleet management software to ensure consistency across all vehicles. While the initial investment may be higher, the long-term savings from improved fuel efficiency and reduced tire wear can justify the cost, making them a valuable asset for logistics companies.

Manual tire inflation kits are straightforward and cost-effective, making them suitable for small businesses or independent operators. These kits typically include basic components like air hoses, gauges, and manual pumps. While they require more labor and skill to operate effectively, they provide a reliable solution for businesses that may not have the budget for more advanced systems. B2B buyers should evaluate their operational needs and consider the trade-off between cost and convenience.

Digital tire inflators offer enhanced accuracy with digital gauges and programmable settings, making them ideal for fleet operations and tire shops. The precision of these inflators can lead to better tire maintenance, improved safety, and reduced fuel costs. Although they come at a higher price point compared to manual options, the benefits of accuracy and ease of use can make them a worthwhile investment for businesses focused on efficiency and reliability.

| Industry/Sector | Specific Application of Semi Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | On-site tire inflation for freight trucks | Reduces downtime and enhances fleet efficiency | Durable materials, compatibility with truck air systems |

| Construction | Tire maintenance for heavy machinery | Ensures operational safety and equipment uptime | Pressure capacity, hose length, and attachment types |

| Agriculture | Inflation for agricultural vehicles | Maximizes productivity and reduces tire wear | Weather resistance, portability, and ease of use |

| Mining | Tire inflation for mining trucks | Minimizes operational delays and maintenance costs | Heavy-duty construction, high-pressure capability |

| Oil & Gas | Tire inflation for drilling rigs | Enhances safety and reduces the risk of tire failure | Robustness, all-weather performance, and attachment versatility |

In the transportation and logistics sector, semi tire inflators are crucial for maintaining the tire pressure of freight trucks. These inflators utilize the truck’s on-board air supply, allowing for quick inflation in remote locations. This capability minimizes downtime during hauls, ensuring that fleets operate at maximum efficiency. International buyers, particularly from regions with challenging terrains like Africa and South America, should prioritize inflators that are durable and compatible with their specific truck models.

The construction industry relies heavily on heavy machinery, which often operates in rugged conditions. Semi tire inflators are employed to maintain optimal tire pressure for vehicles like bulldozers and excavators. This maintenance is vital for ensuring safety and preventing equipment malfunctions that can lead to costly delays. Buyers in Europe and the Middle East should consider inflators with high-pressure capabilities and robust materials that can withstand harsh environments.

In agriculture, tire inflation for tractors and harvesters is essential for maximizing productivity. Properly inflated tires reduce soil compaction and enhance fuel efficiency, leading to cost savings. Semi tire inflators designed for agricultural use must be portable and easy to operate in various weather conditions. Buyers from regions with diverse climates, such as Nigeria and Brazil, should seek inflators that offer flexibility and durability.

The mining industry often operates large trucks that require constant tire maintenance due to the rough terrain. Semi tire inflators are used to inflate tires quickly, minimizing operational delays caused by tire issues. This capability is essential for maintaining a steady workflow and reducing overall maintenance costs. Buyers should focus on heavy-duty inflators that can handle high-pressure requirements and provide reliable performance in extreme conditions.

Illustrative image related to semi tire inflator

In the oil and gas sector, tire inflation for drilling rigs is critical for ensuring operational safety. Semi tire inflators help maintain tire pressure, reducing the risk of blowouts and improving vehicle handling. Given the often remote locations of drilling sites, inflators must be robust and capable of operating in various weather conditions. International buyers should look for models that offer versatility in attachments and have a proven track record of durability.

The Problem:

B2B buyers often face challenges in maintaining optimal tire pressure for their semi-trucks, which is critical for safety and fuel efficiency. Inconsistent tire pressure can lead to increased fuel consumption, reduced tire lifespan, and a higher risk of blowouts. This is particularly concerning for logistics companies operating in regions with extreme weather fluctuations, such as Africa or the Middle East, where temperatures can vary significantly. Moreover, traditional tire inflators may not be equipped to handle the demands of heavy-duty trucks, leading to further complications.

The Solution:

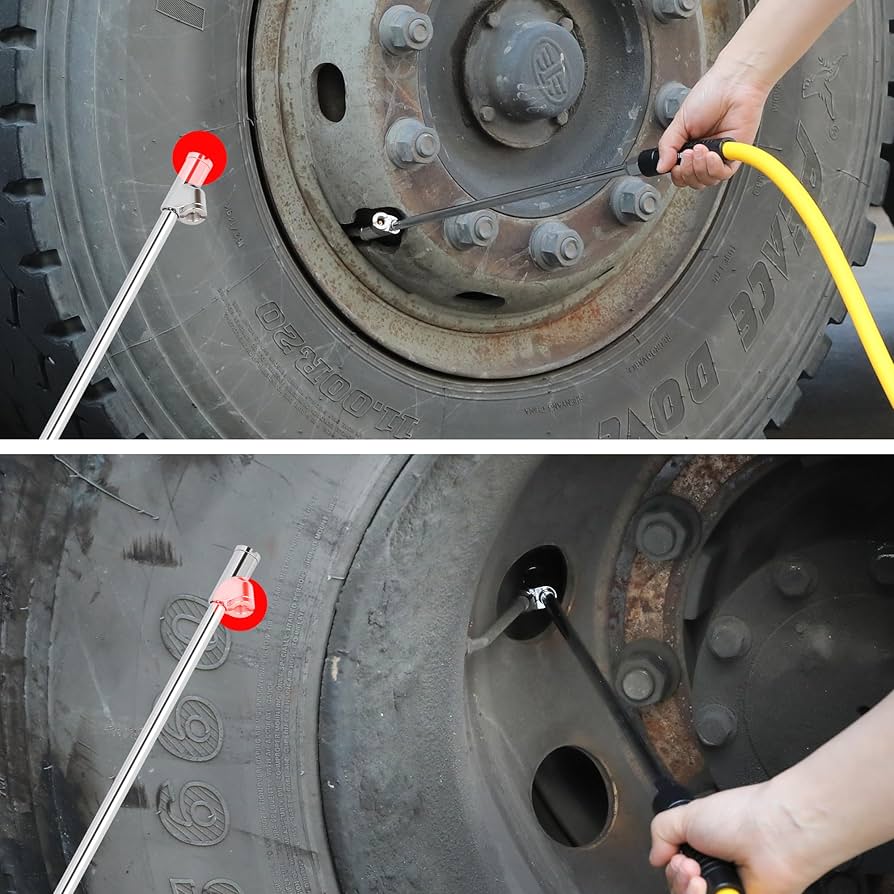

To address this issue, buyers should invest in high-quality semi tire inflators that provide accurate pressure readings and can withstand varying weather conditions. Look for inflators with a built-in pressure gauge and digital readouts to ensure precise monitoring. Additionally, consider sourcing inflators that utilize your truck’s on-board air supply, such as those with a glad-hand attachment, which simplifies the inflation process. Regular training for staff on tire maintenance and the proper use of inflators can also enhance safety and efficiency. Implementing a routine tire pressure check schedule can significantly mitigate risks and ensure that all tires are operating at optimal levels.

The Problem:

Logistics operations often require tire maintenance in remote areas where access to conventional service stations is limited. This can lead to downtime, which is costly in the transportation industry. For example, a logistics company in South America might find itself stranded with a flat tire and no nearby facilities for inflation, affecting delivery schedules and customer satisfaction. The lack of effective tools to inflate tires on-site exacerbates the problem.

The Solution:

Investing in portable semi tire inflators specifically designed for remote use is crucial. Select inflators that are lightweight, easy to handle, and feature long hoses, such as 50-foot options, enabling access to tires even on the farthest reaches of a trailer. Additionally, consider inflators that operate in extreme temperatures, ensuring functionality regardless of the environment. Training staff to use these tools effectively and developing a contingency plan for tire issues in remote locations can help minimize downtime and ensure that operations continue smoothly.

The Problem:

Companies managing fleets of semi-trucks often struggle with the compatibility of tire inflators across different truck models. Variations in tire valve types, pressure requirements, and equipment specifications can lead to inefficiencies and wasted resources. For instance, a logistics company in Germany may find that one inflator works well with certain truck models but fails with others, creating frustration and prolonging maintenance times.

The Solution:

To alleviate these complications, it is advisable to standardize equipment across the fleet. When sourcing semi tire inflators, choose models that come with various attachments compatible with different tire valves. This will ensure that all vehicles can be serviced without the need for multiple inflators. Additionally, consider investing in a comprehensive tire management system that tracks tire pressure and maintenance schedules across the fleet. This proactive approach not only streamlines operations but also enhances safety and reduces the risk of tire-related incidents on the road. Regular training sessions can further equip staff with the knowledge to handle diverse equipment efficiently.

When selecting materials for semi tire inflators, it’s essential to consider their properties, advantages, disadvantages, and how they align with the needs of international B2B buyers. This analysis focuses on four common materials: rubber, PVC, hybrid polymers, and aluminum.

Key Properties: Rubber is known for its excellent elasticity and flexibility, making it suitable for a wide range of temperatures. It can typically handle pressures up to 300 psi, depending on the formulation.

Illustrative image related to semi tire inflator

Pros & Cons: The durability of rubber is a significant advantage, as it can withstand wear and tear from various environmental conditions. However, it can be prone to degradation from ozone exposure and UV radiation, which may limit its lifespan. Additionally, rubber can be cost-effective but may require more complex manufacturing processes.

Impact on Application: Rubber is compatible with air and can handle various media, making it suitable for tire inflation. However, its susceptibility to environmental factors can be a concern in regions with extreme weather conditions.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure that the rubber used complies with local standards for durability and safety. In Europe, adherence to ASTM or DIN standards is essential for quality assurance.

Illustrative image related to semi tire inflator

Key Properties: PVC (Polyvinyl Chloride) is lightweight and resistant to corrosion, with a pressure rating that can also reach up to 300 psi.

Pros & Cons: The primary advantage of PVC is its cost-effectiveness and ease of manufacturing. However, PVC can become rigid in cold temperatures, impacting flexibility. It is less durable than rubber, particularly in extreme conditions, which may lead to a shorter lifespan.

Impact on Application: PVC is compatible with air but may not perform well in high-temperature applications. It is suitable for general-purpose use but may not be ideal for heavy-duty scenarios.

Considerations for International Buyers: Buyers should be aware of the environmental impact of PVC and consider alternatives if sustainability is a priority. Compliance with local regulations regarding material safety is also crucial.

Key Properties: Hybrid polymers, such as those used in Flexzilla products, offer exceptional flexibility across a broad temperature range (-40°F to 140°F) and can withstand pressures up to 300 psi.

Pros & Cons: These materials provide superior durability and resistance to kinking, making them easier to handle. However, they may come at a higher cost compared to traditional materials like rubber and PVC.

Illustrative image related to semi tire inflator

Impact on Application: Hybrid polymers are ideal for use in diverse climates, ensuring consistent performance in both hot and cold environments. Their flexibility allows for easy storage and handling.

Considerations for International Buyers: Buyers in Europe and South America may appreciate the advanced technology behind hybrid polymers, which often meet stringent environmental and safety standards. Ensuring compliance with ASTM or JIS standards is advisable.

Key Properties: Aluminum is lightweight, corrosion-resistant, and can handle high pressures, making it a robust choice for components like air chucks and fittings.

Pros & Cons: The primary advantage of aluminum is its durability and resistance to corrosion, which extends the life of the inflator. However, aluminum can be more expensive than rubber or PVC and may require specialized manufacturing processes.

Impact on Application: Aluminum is suitable for high-pressure applications and can withstand extreme conditions, making it perfect for heavy-duty tire inflators.

Considerations for International Buyers: Buyers should consider the cost implications of aluminum components and ensure that they meet local standards for material safety and performance.

| Material | Typical Use Case for Semi Tire Inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General-purpose tire inflation | Excellent durability and elasticity | Prone to degradation from UV/ozone | Medium |

| PVC | Budget-friendly inflators | Cost-effective and lightweight | Becomes rigid in cold temperatures | Low |

| Hybrid Polymers | Heavy-duty tire inflators | Superior flexibility and durability | Higher cost compared to PVC/rubber | High |

| Aluminum | High-pressure fittings and components | Corrosion-resistant and durable | More expensive and complex to manufacture | High |

This strategic material selection guide provides essential insights for B2B buyers in various regions, ensuring they make informed decisions tailored to their specific needs and compliance requirements.

The manufacturing process for semi tire inflators involves several critical stages that ensure product quality, reliability, and performance. Understanding these stages can empower B2B buyers to make informed decisions about their suppliers and the products they choose.

The initial stage in manufacturing semi tire inflators begins with material selection. Common materials include high-quality rubber for hoses, aluminum or steel for fittings, and durable polymers for components designed to withstand varying environmental conditions. The selection of materials is crucial, as they must endure high pressures and temperatures while maintaining flexibility and durability.

Illustrative image related to semi tire inflator

The preparation process may involve cutting, molding, and treating these materials to meet specific performance standards. For instance, hoses are often designed to remain flexible in extreme temperatures ranging from -40°F to 140°F, ensuring usability across diverse climates. This phase also includes sourcing materials from reputable suppliers to guarantee quality and compliance with international standards.

Once materials are prepared, the next stage is forming and assembly. This stage includes processes like extrusion for hoses and precision machining for metal components. The hose is typically manufactured through extrusion, where raw rubber is shaped into a flexible tube.

After forming, the assembly process begins. This involves attaching fittings, connectors, and any additional accessories such as air chucks and gauges. Quality assurance is integrated into this stage through the use of jigs and fixtures that ensure components fit together precisely, reducing the risk of leaks or failures.

Illustrative image related to semi tire inflator

The finishing stage involves various techniques to enhance the durability and aesthetic appeal of semi tire inflators. This may include surface treatments such as coating, painting, or applying anti-abrasion materials to hoses. These treatments not only improve resistance to wear but also provide a weatherproof barrier.

Additionally, this stage may involve testing the final product for visual defects and ensuring it meets the specified standards before packaging. Proper labeling is also crucial, as it informs users about the product’s specifications, safety instructions, and compliance certifications.

Quality assurance (QA) is an essential aspect of the manufacturing process that guarantees the reliability and safety of semi tire inflators. B2B buyers should be aware of relevant international and industry-specific standards that suppliers must adhere to.

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements. For semi tire inflators, adherence to this standard ensures that the manufacturing processes are efficient and that products meet quality benchmarks.

Additionally, CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For buyers in Africa and South America, certifications such as API (American Petroleum Institute) may also be relevant, particularly for products used in industrial applications.

The manufacturing process of semi tire inflators incorporates several quality control (QC) checkpoints to ensure that every product meets established standards.

IQC is the first checkpoint, where raw materials are inspected upon arrival. This involves verifying that materials meet specifications and are free from defects. Suppliers should provide certificates of conformity or test reports to substantiate the quality of their materials.

IPQC occurs during the manufacturing stages, where ongoing inspections are performed. This may involve measuring dimensions, checking for leaks in assembled products, and assessing the quality of surface treatments. Employing statistical process control (SPC) techniques can help identify variations in the manufacturing process, allowing for timely corrections.

FQC is the last checkpoint before products are packaged and shipped. This stage includes thorough testing of the final product under various conditions to ensure it performs as expected. Common testing methods include pressure testing, durability assessments, and functionality tests to confirm that the inflators can operate under the specified conditions.

For international B2B buyers, verifying the quality control measures of suppliers is vital to ensure they receive reliable products.

Conducting supplier audits can provide insights into their manufacturing processes and quality assurance practices. Buyers should request access to the supplier’s quality management system documentation, including their ISO certifications, inspection reports, and corrective action records.

Engaging third-party inspection services can further validate the supplier’s quality control measures. These independent entities conduct comprehensive assessments and provide unbiased reports, offering buyers peace of mind regarding product quality.

Illustrative image related to semi tire inflator

B2B buyers from different regions, such as Africa, South America, the Middle East, and Europe, may face unique challenges when sourcing semi tire inflators. Understanding local regulations, import standards, and compliance requirements is crucial.

Each region may have specific compliance requirements that products must meet to be legally sold. For instance, buyers in Europe must ensure that products meet CE marking requirements, while those in Africa may need to consider local safety standards. Understanding these nuances can help buyers avoid regulatory pitfalls and ensure smooth import processes.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for semi tire inflators is essential for B2B buyers. By focusing on material selection, manufacturing techniques, quality standards, and verification methods, buyers can confidently source reliable products that meet their operational needs.

When sourcing a semi tire inflator, it is essential to approach the process systematically to ensure you acquire a high-quality product that meets your operational needs. This guide outlines the critical steps to consider, helping you make informed decisions that align with your business objectives.

Illustrative image related to semi tire inflator

Before engaging with suppliers, clearly outline the technical requirements of the semi tire inflator you need. Consider factors such as the maximum working pressure, hose length, and compatibility with existing equipment.

– Key Specifications to Consider:

– Maximum PSI (e.g., 300 PSI is typical for heavy-duty applications).

– Hose material and length (e.g., durable, flexible materials like hybrid polymers are ideal).

Understanding current trends and innovations in tire inflators can give you a competitive edge. Review industry publications, attend trade shows, and participate in forums to gather insights on the latest technologies and best practices.

– Focus Areas:

– Look for advancements in materials that enhance durability and flexibility.

– Identify features that improve usability, such as quick-connect fittings or automatic shut-off valves.

Thoroughly vet suppliers to ensure they meet your quality and reliability standards. Request detailed company profiles, product catalogs, and customer testimonials to assess their credibility.

– Questions to Ask:

– What certifications do they hold (e.g., ISO, CE)?

– Can they provide references from other businesses in your region or industry?

Illustrative image related to semi tire inflator

Once you have shortlisted potential suppliers, request product samples. Testing the inflators in real-world conditions is crucial to ensure they perform as expected.

– Testing Considerations:

– Check for ease of use and efficiency in inflating tires.

– Assess the durability of the materials under various environmental conditions.

Engage in negotiations to secure the best pricing and terms. Consider bulk purchase discounts, warranty provisions, and after-sales support.

– Negotiation Tips:

– Be clear about your budget constraints and volume requirements.

– Inquire about additional services, such as training or maintenance support.

Ensure that the products meet relevant local and international safety standards. Compliance is not only a legal requirement but also critical for ensuring the safety of your operations.

– Compliance Checkpoints:

– Review safety certifications and compliance documentation.

– Ensure the inflator is suitable for the specific environmental conditions of your operational areas.

Once you’ve made your selection, establish a clear communication plan with your supplier. This ensures you can address any issues that arise and maintain a steady supply chain.

– Communication Strategies:

– Set regular check-ins to discuss performance and any necessary adjustments.

– Utilize project management tools to keep track of orders and delivery schedules.

By following these steps, you can confidently navigate the procurement process for a semi tire inflator, ensuring that your investment aligns with your operational needs and enhances your overall efficiency.

When sourcing semi tire inflators, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

Materials: The quality and type of materials used significantly impact the cost. Durable hoses, robust air chucks, and high-quality gauges ensure longevity and performance, but they also raise the base price. Products made from advanced polymers, like the Flexzilla hose, typically command a higher price due to their superior flexibility and durability.

Labor: Manufacturing labor costs can vary widely based on the region and the complexity of the assembly process. In regions with lower labor costs, such as parts of South America and Africa, the overall manufacturing expense may be reduced, potentially leading to lower pricing for buyers.

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, impacting the final price of the inflators.

Tooling: The cost of molds and machinery used in the production of semi tire inflators can be significant, especially for custom designs or high-volume orders. Initial tooling costs are usually absorbed over larger production runs, so they are a critical consideration for bulk buyers.

Quality Control (QC): Implementing stringent quality control measures ensures product reliability but adds to the overall cost. Buyers should inquire about the QC processes in place and their impact on pricing.

Logistics: Shipping and handling costs can vary significantly based on distance, mode of transport, and weight. International buyers should factor in these costs, especially when sourcing from different continents.

Margin: Supplier margins will vary based on brand positioning and market competition. Established brands may have higher margins due to perceived value and brand loyalty.

Several factors influence the pricing of semi tire inflators, including:

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to discounts. Negotiating MOQs can yield significant savings for businesses looking to stock inventory.

Specifications and Customization: Customized products or those with advanced specifications generally come at a premium. Buyers should weigh the necessity of such features against the additional costs.

Materials: The choice of materials directly impacts pricing. High-performance materials may reduce long-term costs due to lower replacement rates.

Quality and Certifications: Products with certifications (like ISO or CE) may be priced higher but can offer peace of mind regarding performance and safety standards.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more, but they often provide better support and warranty services.

Incoterms: Understanding shipping terms (like FOB or CIF) is crucial for international transactions as they determine who bears the cost and risk at various stages of shipping.

Negotiation Strategies: Building a relationship with suppliers can lead to better pricing and terms. Leverage your purchasing power by discussing long-term agreements or multiple product purchases.

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider maintenance, durability, and replacement cycles to determine the true value of an inflator.

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and taxes that may affect overall costs. It’s essential to factor these into your budget.

Research Local Regulations: Different regions may have specific regulations regarding tire inflators. Ensure compliance to avoid unexpected costs or delays.

Request Samples: Before committing to a large order, request samples to assess quality and performance. This can help in making an informed decision and can also be a negotiation point.

When sourcing semi tire inflators, buyers should remain vigilant about the various cost components and price influencers. Understanding these factors will empower B2B buyers to negotiate effectively and make informed purchasing decisions that align with their operational needs. Prices can vary widely based on the aforementioned elements, so it’s advisable to seek multiple quotes and conduct thorough research before finalizing any agreements.

In the realm of tire maintenance, particularly for heavy-duty vehicles like semi-trucks, ensuring optimal tire pressure is critical for safety, efficiency, and cost management. While semi tire inflators are a common solution, various alternative methods and technologies exist that can also effectively address the need for tire inflation. This section evaluates these alternatives, helping B2B buyers make informed decisions based on their specific operational requirements.

| Comparison Aspect | Semi Tire Inflator | Portable Air Compressor | On-board Air Supply System |

|---|---|---|---|

| Performance | Fast inflation with high PSI capability | Moderate inflation speed | Continuous supply, high efficiency |

| Cost | Moderate initial investment | Varies widely, generally lower | Higher installation cost |

| Ease of Implementation | Easy to use, requires minimal setup | Requires storage space | Permanent installation required |

| Maintenance | Low maintenance, occasional checks | Regular maintenance needed | Minimal, but system checks necessary |

| Best Use Case | Remote tire inflation needs | General use, DIY applications | Fleet management, constant use |

Portable air compressors serve as a versatile solution for tire inflation. These devices are generally more affordable than semi tire inflators, making them attractive for businesses operating on a tighter budget. However, their performance can be inconsistent; they may take longer to inflate tires compared to dedicated inflators. Moreover, while portable compressors are easy to use, they require adequate storage space and may need regular maintenance to ensure optimal functioning. They are best suited for general use, particularly in situations where mobility is paramount.

An on-board air supply system is integrated directly into a truck, allowing for immediate tire inflation without the need for additional equipment. This system provides a continuous supply of air, making it highly efficient for fleets that require frequent tire maintenance. However, the installation cost is considerably higher than both semi tire inflators and portable air compressors. Maintenance is also minimal, although regular system checks are necessary to prevent issues. This solution is particularly beneficial for companies managing large fleets or operating in remote areas where access to external inflation tools may be limited.

When selecting a tire inflation solution, B2B buyers must consider their specific operational needs, budget constraints, and the environments in which they operate. Semi tire inflators offer a reliable and efficient option for remote inflation needs, while portable air compressors provide flexibility and affordability for general applications. On-board air supply systems, while more costly, offer unmatched efficiency for fleet management. Ultimately, the decision should align with the operational demands and long-term goals of the business, ensuring that the chosen solution enhances productivity and safety on the road.

When selecting a semi tire inflator, understanding its technical specifications is crucial for ensuring efficiency and reliability in operations. Here are some essential properties to consider:

Material Composition

– Definition: The material used in the construction of the inflator, typically a blend of polymers or rubber.

– Importance: High-quality materials, such as those that offer abrasion resistance and flexibility, are vital for durability and performance in various climates. This ensures that the inflator can withstand harsh environmental conditions, which is especially relevant for buyers in regions with extreme weather variations.

Maximum Working Pressure (MWP)

– Definition: The highest pressure at which the inflator can operate safely, usually measured in pounds per square inch (psi).

– Importance: An inflator with a higher MWP (e.g., 300 psi) allows for faster inflation and the ability to handle larger tires or multiple tires simultaneously. This is particularly beneficial for fleet operators who require efficiency and reliability in their operations.

Hose Length and Diameter

– Definition: The length and internal diameter of the air hose connected to the inflator.

– Importance: A longer hose (e.g., 50 feet) allows for greater reach, essential for accessing tires on larger vehicles or trailers. The diameter (e.g., 3/8 inch) affects airflow and inflation speed, making it a critical specification for timely tire maintenance.

Temperature Range

– Definition: The range of temperatures within which the inflator can operate effectively.

– Importance: An inflator that remains functional in extreme temperatures (from -40°F to 140°F) ensures consistent performance regardless of environmental conditions. This is particularly important for international buyers who may encounter varied climates.

Kink Resistance

– Definition: The ability of the hose to resist kinking under pressure.

– Importance: A hose that does not kink is easier to handle and reduces downtime during inflation. This property enhances operational efficiency, making it an essential consideration for fleet maintenance.

Attachment Types

– Definition: The types of fittings and connectors available for the inflator, such as glad-hand attachments and air chucks.

– Importance: Compatibility with different truck systems is crucial for seamless integration into existing maintenance processes. Understanding the attachment types ensures that the inflator can be used across various fleet vehicles.

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some commonly used terms in the semi tire inflator market:

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding whether a product is OEM ensures that buyers receive high-quality, reliable components that meet original specifications, which is crucial for maintaining fleet integrity.

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget effectively, especially for international transactions where shipping costs can significantly impact overall expenses.

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specified products or services.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating informed decision-making in procurement processes.

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping and freight.

– Importance: Familiarity with Incoterms helps buyers understand their responsibilities concerning shipping, insurance, and tariffs, which is crucial for international trade, especially for buyers in diverse regions like Africa and South America.

Lead Time

– Definition: The amount of time from placing an order to receiving the product.

– Importance: Understanding lead times is critical for inventory management and planning, particularly in industries where downtime can lead to significant losses.

Warranty Terms

– Definition: The conditions under which a product can be returned or repaired at no cost to the buyer.

– Importance: Knowing warranty terms provides assurance of product quality and reliability, essential for long-term investments in fleet maintenance equipment.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right semi tire inflator that meets their operational needs effectively.

The semi tire inflator market is currently experiencing significant growth driven by several global factors. Firstly, the expansion of the logistics and transportation sectors in regions like Africa, South America, the Middle East, and Europe is increasing the demand for reliable tire inflation solutions. As trucking fleets expand, the need for efficient tire maintenance becomes critical to minimize downtime and enhance safety.

Emerging technologies are transforming the landscape of tire inflators. Internet of Things (IoT) integration is enabling advanced monitoring systems that provide real-time data on tire pressure, helping fleet managers maintain optimal tire health and improve fuel efficiency. Additionally, the trend towards automation is leading to the development of smart inflators that can automatically adjust pressure based on sensor feedback. This trend is particularly relevant for international B2B buyers looking for innovative solutions that enhance operational efficiency.

Market dynamics are also influenced by regional variations. For example, buyers in Africa may prioritize cost-effectiveness and durability due to challenging road conditions, while European buyers may focus on advanced technology and sustainability features. Understanding these regional nuances is crucial for B2B buyers to make informed sourcing decisions.

Sustainability has become a vital consideration for B2B buyers in the semi tire inflator market. The environmental impact of manufacturing processes and the materials used in inflators is increasingly under scrutiny. Buyers are now looking for products that not only perform well but also minimize their ecological footprint.

Ethical sourcing practices are essential for companies aiming to enhance their brand reputation and meet consumer expectations. Buyers should consider suppliers who demonstrate commitment to ethical labor practices and environmental stewardship. Utilizing materials that are recyclable or produced through sustainable methods can also be beneficial. Certifications such as ISO 14001 (Environmental Management) and Cradle to Cradle can provide assurance of a supplier’s commitment to sustainability.

As regulations around environmental impact tighten globally, B2B buyers must prioritize suppliers who can demonstrate compliance with these standards. This proactive approach not only mitigates risks but also positions companies as leaders in sustainability within their respective markets.

Illustrative image related to semi tire inflator

The evolution of the semi tire inflator market can be traced back to the early days of trucking when manual inflation methods were the norm. As the trucking industry grew, the need for more efficient and reliable tire maintenance solutions became apparent. The introduction of pneumatic systems revolutionized tire inflation, allowing for quicker and more consistent pressure management.

Over the years, advancements in materials science have led to the development of more durable and flexible inflator hoses, capable of withstanding extreme conditions. The recent focus on technology integration has further transformed the market, with the rise of smart inflators equipped with sensors and connectivity features. These innovations not only enhance the functionality of inflators but also align with the growing demand for automation and efficiency in the logistics sector.

Understanding this historical context provides valuable insights into current trends and future directions in the semi tire inflator market, guiding B2B buyers in making strategic sourcing decisions.

How do I select the right semi tire inflator for my fleet needs?

Choosing the right semi tire inflator requires assessing the specific needs of your fleet. Consider factors such as the types of vehicles you operate, the average tire size, and the typical conditions your vehicles encounter. Look for inflators that can handle high-pressure requirements (at least 300 psi), offer durability against harsh weather, and have attachments compatible with your truck’s air supply system. Additionally, ensure the inflator kit includes essential components like a glad-hand attachment and air chuck for ease of use.

What features should I prioritize in a semi tire inflator?

When sourcing a semi tire inflator, prioritize features such as maximum working pressure, hose length, and material durability. A robust maximum pressure rating (around 300 psi) is crucial for heavy-duty applications. Opt for hoses made from flexible materials that can withstand extreme temperatures and resist kinking. Also, consider the length of the hose; longer hoses (50-60 feet) provide better reach, especially for dual-axle trailers. Lastly, look for a kit that includes essential attachments like glad-hand connectors and air chucks for versatility.

What are the typical payment terms for international purchases of tire inflators?

Payment terms for international purchases can vary widely depending on the supplier and your negotiated agreement. Common terms include letters of credit, advance payments, or net payment terms (e.g., net 30, net 60). It’s advisable to establish clear terms upfront and verify if the supplier offers payment flexibility, especially for larger orders. Additionally, consider using secure payment methods to protect your transaction and reduce the risk of fraud.

How can I ensure the quality of the semi tire inflators I purchase?

To ensure quality, conduct thorough research on potential suppliers. Check for certifications, industry standards compliance, and customer reviews. Request product samples to assess material quality and functionality before placing a bulk order. Additionally, inquire about the manufacturer’s quality assurance processes, warranty policies, and after-sales support. Engaging with suppliers who have a proven track record can significantly mitigate risks associated with product quality.

What are the minimum order quantities (MOQs) typically required by suppliers?

Minimum order quantities (MOQs) can vary greatly among suppliers, ranging from as low as 10 units to several hundred. It’s essential to clarify MOQs during your initial discussions to align your purchasing strategy with supplier capabilities. If your needs are lower than the MOQ, consider negotiating terms or collaborating with other buyers to meet the requirement. Some suppliers may offer flexibility on MOQs, especially for established relationships or larger contracts.

What logistics considerations should I keep in mind when importing semi tire inflators?

Logistics plays a crucial role in the successful import of semi tire inflators. Consider factors such as shipping methods (air vs. sea), transit times, customs clearance processes, and potential tariffs. Ensure you understand the regulations governing the importation of such products in your destination country. Collaborating with a reliable freight forwarder can streamline the logistics process, helping to navigate complexities such as documentation and compliance, ultimately reducing delays.

Can I customize the semi tire inflator to meet specific needs?

Many suppliers offer customization options for semi tire inflators, allowing you to tailor the product to your specifications. Customizations may include hose lengths, attachment types, or branding options. When considering customization, discuss your specific requirements with potential suppliers to understand the feasibility, lead times, and any additional costs involved. Custom products can enhance operational efficiency, ensuring the inflators meet your exact needs.

What are the best practices for maintaining semi tire inflators?

Regular maintenance is essential to prolong the lifespan of your semi tire inflators. Inspect the hoses and connections periodically for signs of wear or damage, and replace any faulty components immediately. Store inflators in a cool, dry place to prevent material degradation caused by extreme temperatures. Additionally, ensure that all attachments are cleaned and stored properly after use. Implementing these best practices can help ensure that your inflators remain functional and reliable for your fleet’s needs.

Domain: flexzilla.com

Registered: 2008 (17 years)

Introduction: Product Name: Truck Tire Inflator Kits

SKU: HGH2-FZ

Length: 50ft (also available in 60ft)

Overview: The Flexzilla truck tire inflator kits utilize a truck’s on-board air supply to inflate tires in remote situations.

Material: Flexible Hybrid Polymer, which offers extreme flexibility and durability.

Features:

– Universal glad-hand attachment for easy connection to truck air supply.

– Extreme all-…

Domain: myteeproducts.com

Registered: 2003 (22 years)

Introduction: Truck Tire Inflation Kit 3/8″ ID with Air Chuck & Gladhand; SKU: MP-TTIK; Regular Price: $31.99; Special Price: $27.09 (15% Off); Free shipping eligible over $199.99; Includes: 3/8″ x 50′ Hose, Glad Hand Attachment, 30° Dual Air Chuck; Maximum Working Pressure: 300 lbs per Square Inch; Weight: 5.75 lbs; Color: Orange; Availability: In stock.

Domain: tiresupplynetwork.com

Registered: 2018 (7 years)

Introduction: Inflation Tools Collection: 84 products including Air Chucks, Inflators, Gauges, and Accessories. Featured products include: 1. Dill Breast Cancer Awareness Pink Air Pressure Pencil Gauge (20-90 psi) – $5.00 2. Haltec Truck Pencil Air Gauge (20-120 psi) – $4.99 3. Haltec Pencil Air Gauge (5-45 psi for Air-Liquid Tires) – $5.99 4. Xtra Seal Standard Passenger Pencil Air Pressure Gauge (10-50 psi) -…

Domain: thetruckersreport.com

Registered: 2003 (22 years)

Introduction: This company, Portable Air Compressors – Top Recommendations for Truck Tires, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: kentool.com

Registered: 1998 (27 years)

Introduction: Heavy Duty Truck Tire Inflation Kit, SKU: 26050, Length: 50 ft. (15.24m), Male Fittings: 1/4” Brass, Max Pressure: 300 psi, Inside Diameter: 3/8” (9.2mm), Glad Hand attaches to heavy-duty air brake equipped trucks, quick inflation with straight-on dual foot chuck.

In the competitive landscape of logistics and transportation, the strategic sourcing of semi tire inflators emerges as a critical investment for businesses aiming to enhance operational efficiency and safety. By selecting high-quality tire inflation kits, such as those utilizing durable materials and advanced features, companies can ensure consistent tire performance, reduce downtime, and ultimately lower operational costs.

B2B buyers should prioritize suppliers who offer reliable products that can withstand diverse climate conditions, especially in regions like Africa and South America, where environmental challenges can impact equipment performance. Moreover, understanding the importance of universal attachments, such as glad-hand fittings, can further streamline tire maintenance processes in remote locations.

As we look to the future, the demand for innovative tire inflator solutions is expected to grow. International buyers are encouraged to explore partnerships with manufacturers that emphasize sustainability and technological advancements in their product offerings. Investing in strategic sourcing today will not only enhance tire management but also position businesses for success in an evolving market. Make informed decisions and elevate your operational capabilities by choosing the right tire inflation solutions for your fleet.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to semi tire inflator