In today’s global market, sourcing a reliable tire pressure gauge pump is crucial for businesses focused on maintaining vehicle safety and efficiency. However, international B2B buyers often face challenges in identifying quality products that meet diverse regional standards and customer expectations. This guide aims to empower procurement professionals by providing a comprehensive overview of tire pressure gauge pumps, including various types, their applications, supplier vetting processes, and cost considerations.

Understanding the nuances of tire pressure gauge pumps is essential for businesses in industries ranging from automotive services to logistics. By delving into the specific requirements for different markets—such as those in Africa, South America, the Middle East, and Europe—this guide offers actionable insights tailored to regional demands. Whether you’re based in Saudi Arabia or Brazil, you will learn how to evaluate suppliers effectively, ensuring that your investments lead to enhanced operational efficiency and customer satisfaction.

Furthermore, the guide will address the technological advancements in tire pressure gauge pumps, showcasing features that enhance usability and accuracy. With detailed comparisons of product specifications and market trends, you will be equipped to make informed purchasing decisions that align with your business goals. This resource serves as a vital tool for navigating the complexities of the global tire pressure gauge pump market, ultimately helping your business thrive in a competitive landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Tire Inflators | Accurate digital readouts, often with automatic shut-off | Automotive service centers, fleet maintenance | Pros: High accuracy, easy to use; Cons: Battery-dependent models may require frequent charging. |

| Analog Tire Pressure Gauges | Mechanical dial indicators, no batteries required | Workshops, garages, construction equipment | Pros: Durable and reliable; Cons: Less precise than digital models. |

| Portable Tire Inflators | Compact design, battery or vehicle-powered options | Roadside assistance, emergency kits | Pros: Easy to transport; Cons: Limited power and pressure output. |

| Heavy-Duty Tire Inflators | High PSI capabilities, robust construction | Trucking companies, off-road vehicle owners | Pros: Suitable for heavy-duty applications; Cons: Bulkier and more expensive. |

| Multi-Tire Inflation Systems | Simultaneous inflation for multiple tires | Fleet operations, racing teams | Pros: Saves time during tire maintenance; Cons: Higher initial investment. |

Digital tire inflators are characterized by their precise digital readouts, which provide accurate pressure measurements and often include features like automatic shut-off to prevent over-inflation. They are ideal for automotive service centers and fleet maintenance operations where accuracy and efficiency are critical. When considering a digital tire inflator, buyers should evaluate the power source (AC, DC, or battery), maximum PSI capabilities, and additional features such as built-in lighting or multiple nozzles. While they offer high accuracy and ease of use, battery-dependent models may require regular charging, which could lead to downtime.

Analog tire pressure gauges utilize mechanical dials to indicate tire pressure, making them a reliable choice for environments where electronic devices may be prone to failure. They are commonly used in workshops, garages, and with construction equipment due to their durability and simplicity. B2B buyers should consider the gauge’s pressure range, build quality, and ease of reading the dial. While analog gauges are generally less precise than their digital counterparts, they do not rely on batteries, making them a dependable option for consistent use in rugged conditions.

Portable tire inflators are designed for convenience, featuring compact designs that are easy to transport. They can be powered by either a vehicle’s power outlet or batteries, making them suitable for roadside assistance and emergency kits. B2B buyers should assess the inflator’s weight, maximum pressure output, and additional functionalities, such as built-in lights or adapters for inflating various items. Although portable models offer flexibility and ease of use, they may have limitations in terms of power and pressure output compared to larger, stationary inflators.

Heavy-duty tire inflators are built to handle high-pressure requirements, making them essential for trucking companies and off-road vehicle owners. They typically feature robust construction and high PSI capabilities, suitable for larger tires found on trucks and heavy machinery. When purchasing heavy-duty inflators, B2B buyers should evaluate the unit’s durability, maximum pressure capacity, and ease of use. While they excel in demanding applications, these inflators can be bulkier and more expensive, requiring a careful assessment of the return on investment for specific business needs.

Multi-tire inflation systems allow for the simultaneous inflation of multiple tires, significantly reducing maintenance time in fleet operations and racing teams. These systems are designed for efficiency and are often used in environments where quick turnaround times are essential. When considering a multi-tire inflation system, buyers should look at the system’s compatibility with existing equipment, maximum PSI, and ease of setup. Although they represent a higher initial investment, the time savings and increased productivity can justify the cost for businesses with significant tire maintenance needs.

| Industry/Sector | Specific Application of tire pressure gauge pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Routine tire maintenance and servicing | Ensures optimal vehicle performance and safety | Durability, accuracy, ease of use, and compatibility with various tire types |

| Transportation & Logistics | Fleet management for commercial vehicles | Reduces fuel consumption and extends tire life | Portable design, rapid inflation capabilities, and reliability under various conditions |

| Construction | Heavy machinery and equipment tire management | Enhances safety and operational efficiency | Heavy-duty construction, high PSI capability, and ruggedness for harsh environments |

| Agriculture | Tire pressure maintenance for farm equipment | Improves fuel efficiency and reduces downtime | Adaptability to various tire sizes, ease of transport, and battery-operated options |

| Sports & Recreation | Inflating tires for recreational vehicles | Enhances safety and performance in outdoor activities | Compact design, multi-purpose functionality, and quick inflation features |

In the automotive repair sector, tire pressure gauge pumps are essential tools for routine maintenance and servicing of vehicles. Mechanics utilize these pumps to ensure tires are inflated to the correct pressure, which is vital for vehicle safety and performance. An accurately inflated tire improves fuel efficiency, enhances handling, and extends tire lifespan, thereby reducing operational costs. When sourcing, businesses should prioritize pumps that are durable, easy to operate, and compatible with a wide range of tire types to meet diverse customer needs.

For companies in transportation and logistics, maintaining the proper tire pressure in commercial fleets is crucial. Tire pressure gauge pumps facilitate quick and efficient tire inflation, which helps to reduce fuel consumption and prolong tire life. This is particularly important in regions like Africa and South America, where long distances and rough terrains are common. When sourcing, businesses should consider pumps that are portable, capable of rapid inflation, and reliable under various environmental conditions to ensure uninterrupted operations.

In the construction industry, tire pressure gauge pumps are vital for managing the tires of heavy machinery and equipment. Ensuring that machinery operates with the correct tire pressure enhances safety and operational efficiency, reducing the risk of accidents and equipment failure. Construction firms should look for heavy-duty pumps that can handle high PSI levels and are rugged enough to withstand harsh job site conditions. Reliability and ease of transport are also key considerations for sourcing these tools.

Agricultural operations often rely on a variety of machinery, all of which require proper tire pressure for optimal performance. Tire pressure gauge pumps help farmers maintain the correct inflation levels, which can lead to improved fuel efficiency and reduced downtime during critical planting and harvesting seasons. Buyers in the agriculture sector should seek pumps that are adaptable to various tire sizes, easy to transport across fields, and possibly battery-operated for convenience in remote areas.

In the sports and recreation industry, tire pressure gauge pumps are used to inflate tires for recreational vehicles, including bicycles, ATVs, and trailers. Proper tire inflation is crucial for safety and performance during outdoor activities. Compact and multi-functional pumps are particularly valuable for recreational enthusiasts who require quick inflation and deflation capabilities. Buyers should consider sourcing pumps that are lightweight, portable, and equipped with features that cater to various recreational needs.

The Problem: Many B2B buyers, particularly those managing fleets or automotive workshops, face the challenge of inconsistent tire pressure measurements. A faulty or inaccurate tire pressure gauge pump can lead to either over-inflation or under-inflation of tires. This not only affects vehicle performance and fuel efficiency but also poses significant safety risks, especially in commercial settings where vehicle reliability is crucial. Buyers may find themselves frequently replacing gauges due to inaccuracy, resulting in increased operational costs and potential liability issues.

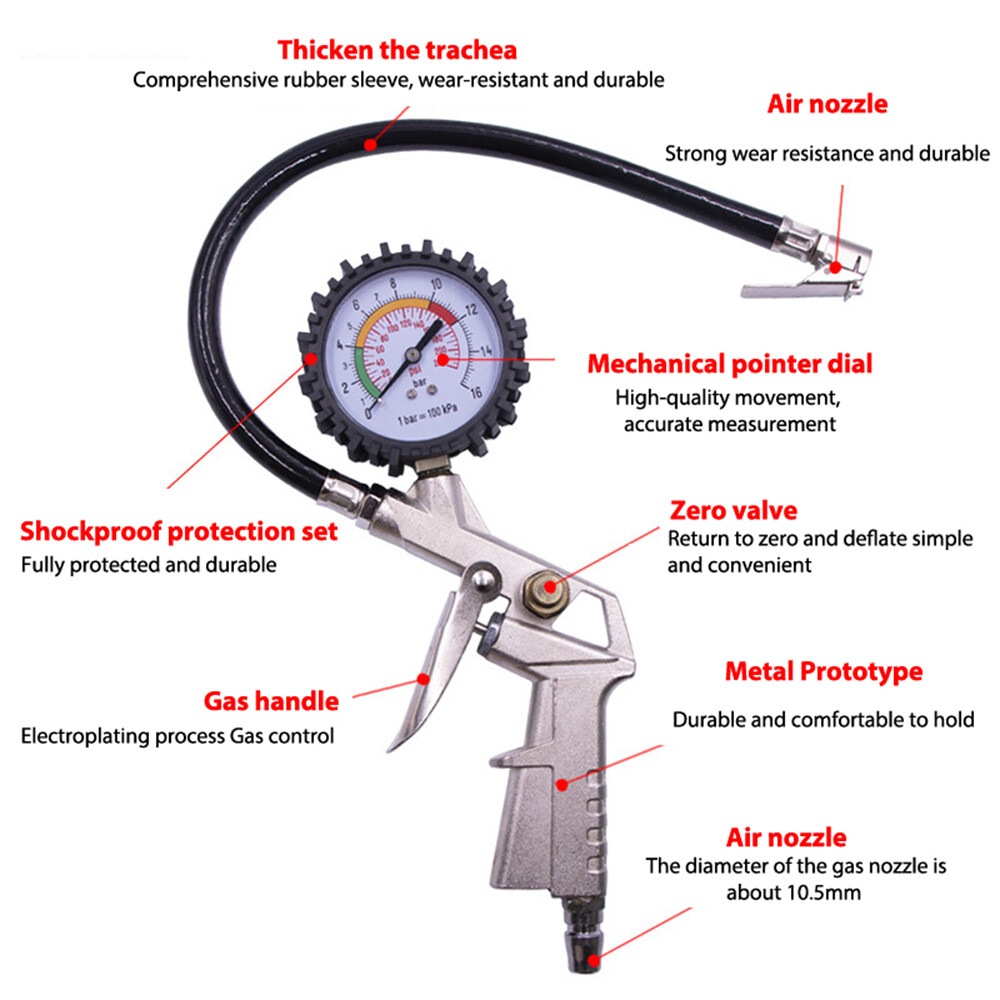

Illustrative image related to tire pressure gauge pump

The Solution: To combat this problem, B2B buyers should prioritize sourcing high-quality tire pressure gauge pumps from reputable manufacturers known for precision engineering. Implementing a standardized testing protocol for all inflators before use can help ensure accuracy. This may involve comparing readings against a certified standard gauge. Additionally, investing in digital inflators with built-in calibration features can help maintain measurement accuracy over time. Regular training for staff on the importance of accurate tire pressure management and the correct use of these tools will also enhance safety and operational efficiency.

The Problem: For businesses that rely on frequent tire maintenance, inefficiencies in tire inflation processes can lead to significant downtime and lost productivity. Many tire pressure gauge pumps may take too long to inflate tires, particularly those used in heavy-duty vehicles or in a busy workshop environment. This can frustrate employees and result in delays, ultimately affecting service delivery and customer satisfaction.

The Solution: To optimize tire inflation processes, buyers should consider investing in high-capacity tire pressure gauge pumps designed for rapid inflation and deflation. Products with higher PSI ratings can inflate tires more quickly, which is essential for businesses with large fleets. Additionally, employing portable or automated tire inflators can improve flexibility and reduce manual labor. Establishing a routine maintenance schedule for these tools will ensure they remain in top working condition, thereby minimizing downtime and enhancing overall efficiency.

Illustrative image related to tire pressure gauge pump

The Problem: B2B buyers often encounter difficulties when using tire pressure gauge pumps across different tire types and sizes. For example, a single pump may not adequately serve passenger vehicles, light trucks, and heavy machinery, leading to the need for multiple tools. This not only complicates inventory management but can also lead to costly delays when the appropriate tool is not readily available.

The Solution: To address this challenge, buyers should opt for versatile tire pressure gauge pumps that offer compatibility with a wide range of tire types and sizes. Look for models equipped with adjustable nozzles or multiple adapters to cater to various tire valves. Additionally, investing in a comprehensive tire inflation kit that includes different nozzles and extension hoses can streamline operations. Implementing a clear labeling and storage system for these tools ensures that staff can quickly access the appropriate equipment, reducing time spent searching for the right gauge and enhancing service efficiency.

When selecting materials for tire pressure gauge pumps, it’s crucial to consider factors such as durability, cost, and performance under various conditions. Here, we analyze four common materials used in tire pressure gauge pumps: aluminum, stainless steel, plastic, and rubber.

Aluminum is often favored for its lightweight and corrosion-resistant properties. With a temperature rating that can withstand moderate heat, aluminum is suitable for various environments. Its high strength-to-weight ratio makes it ideal for portable tire inflators, which are often used in diverse locations.

Pros: Aluminum is relatively inexpensive and easy to manufacture, allowing for cost-effective production. Its lightweight nature enhances portability, making it a preferred choice for consumer-grade tire inflators.

Illustrative image related to tire pressure gauge pump

Cons: While aluminum is resistant to corrosion, it can be prone to scratching and denting, which may affect the aesthetics and performance over time. Additionally, it may not perform as well under extreme pressure conditions compared to other metals.

For international buyers, particularly those in regions like Africa and the Middle East, aluminum’s lightweight nature can reduce shipping costs. However, compliance with local standards such as ASTM or DIN should be verified to ensure product safety and reliability.

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it a preferred material for high-pressure applications. It can withstand extreme temperatures and pressures, ensuring durability and longevity.

Pros: The robustness of stainless steel allows for reliable performance in harsh environments, making it suitable for industrial applications. Its resistance to rust and corrosion extends the lifespan of the product.

Cons: The primary drawback of stainless steel is its higher cost compared to aluminum and plastic. Manufacturing processes can also be more complex, requiring specialized equipment.

For B2B buyers in Europe and South America, stainless steel complies with stringent safety standards, making it an attractive option for high-end applications. However, its weight may increase shipping costs, which should be factored into the overall budget.

Plastic is a versatile material that is commonly used in the construction of tire pressure gauge pumps. It is lightweight and can be molded into complex shapes, which is beneficial for ergonomic designs.

Pros: The low cost of plastic makes it an attractive option for manufacturers, particularly for budget-friendly consumer products. Its resistance to corrosion and chemical damage is advantageous in various environments.

Cons: Plastic may not withstand high pressures as effectively as metals, limiting its use in heavy-duty applications. Additionally, it can degrade over time when exposed to UV light or extreme temperatures.

International buyers should consider the type of plastic used, as compliance with regulations regarding material safety is essential. In regions like Africa and Brazil, where environmental conditions can vary widely, selecting high-quality plastics can enhance product reliability.

Rubber is primarily used for seals and gaskets in tire pressure gauge pumps, providing essential flexibility and sealing capabilities. It can withstand a range of temperatures and pressures, making it suitable for various applications.

Pros: Rubber’s elasticity allows for a tight seal, preventing air leaks. Its cost-effectiveness and ease of manufacturing make it a popular choice for components that require flexibility.

Illustrative image related to tire pressure gauge pump

Cons: Rubber can degrade over time due to exposure to ozone, UV light, and extreme temperatures, which may necessitate more frequent replacements.

For B2B buyers, especially in the Middle East and Africa, sourcing high-quality rubber that meets international standards is crucial for ensuring long-term reliability. Understanding the specific rubber compounds used can help in making informed purchasing decisions.

| Material | Typical Use Case for tire pressure gauge pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body of portable tire inflators | Lightweight and corrosion-resistant | Prone to scratching and denting | Low |

| Stainless Steel | High-pressure applications | Exceptional strength and durability | Higher cost and complex manufacturing | High |

| Plastic | Consumer-grade inflators | Low cost and versatile | Limited pressure resistance and UV degradation | Low |

| Rubber | Seals and gaskets | Provides flexibility and tight sealing | Degrades over time with environmental exposure | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions about tire pressure gauge pumps, ensuring that they choose materials that align with their operational needs and compliance requirements.

The manufacturing process of tire pressure gauge pumps typically involves several critical stages, each designed to ensure the final product meets the required quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to tire pressure gauge pump

The manufacturing journey begins with the selection and preparation of raw materials. Common materials used in tire pressure gauge pumps include high-quality plastics, metals like aluminum or stainless steel, and rubber for seals and hoses. Each material is sourced based on its durability, resistance to corrosion, and ability to withstand pressure variations. Quality assurance starts at this stage, where suppliers must provide certifications confirming that materials meet international standards such as ISO 9001.

Once materials are prepared, they undergo the forming process, which involves shaping them into the necessary components. Techniques such as injection molding are prevalent for plastic parts, while metal components may be produced using processes like die casting or CNC machining. These techniques allow manufacturers to achieve precise dimensions and intricate designs, which are critical for the accurate functioning of the gauge. Regular checks during this stage ensure that components are within specified tolerances, reducing the likelihood of defects in the final product.

The assembly stage is where individual components come together to form the complete tire pressure gauge pump. This process often involves both manual labor and automated machinery, depending on the complexity and volume of production. Key components, such as the gauge, air hose, and inflation mechanism, must be assembled carefully to ensure proper functionality. Quality checkpoints during assembly, known as In-Process Quality Control (IPQC), are essential. These checks verify that each assembly step meets predefined criteria, minimizing the risk of issues that could affect performance.

Finishing processes, including surface treatment and packaging, are the final stages of manufacturing. Surface treatments may involve anodizing, painting, or applying anti-corrosive coatings to enhance durability and aesthetic appeal. Once finished, the products undergo Final Quality Control (FQC), where they are tested for functionality, accuracy, and durability before being packaged for shipment. This stage is crucial for ensuring that the product not only meets but exceeds customer expectations.

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for tire pressure gauge pumps, which require high precision and reliability. The QA system typically aligns with international standards such as ISO 9001, which outlines the criteria for a quality management system.

B2B buyers should be aware of various international certifications that may apply to tire pressure gauge pumps. The CE mark signifies compliance with European safety standards, while API certifications are relevant for products used in specific industrial applications. Ensuring that suppliers hold these certifications can provide confidence in the product’s safety and quality.

Quality control involves multiple checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) examines raw materials upon arrival to verify compliance with specifications. IPQC takes place during production, focusing on the assembly and functionality of components. Finally, FQC assesses the finished product to ensure it meets all performance and safety standards. This systematic approach to quality control helps mitigate risks associated with defects and performance failures.

Testing methods for tire pressure gauge pumps can include functional tests, pressure tests, and accuracy assessments. Functional tests ensure that the pump operates correctly under normal conditions, while pressure tests evaluate its ability to withstand specified pressure levels. Accuracy assessments measure the precision of the gauge, ensuring it provides reliable readings. These tests are crucial for establishing the credibility of the product and satisfying customer requirements.

Illustrative image related to tire pressure gauge pump

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are several strategies to consider:

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should request detailed audit reports, which should include findings from previous inspections and corrective actions taken. These audits can be performed by third-party organizations that specialize in quality assurance, providing an unbiased assessment of the supplier’s capabilities.

Buyers should prioritize suppliers with recognized certifications, as these demonstrate a commitment to quality. Requesting documentation that outlines the supplier’s quality management system and compliance with international standards can provide additional assurance. Regular updates and reports on quality metrics can also help maintain transparency between buyers and suppliers.

When sourcing tire pressure gauge pumps internationally, it’s important to understand the nuances of quality control that may vary by region. For example, regulations regarding product safety and environmental impact may differ significantly between countries. Buyers should ensure that suppliers can comply with local regulations in their respective markets, which may include obtaining specific certifications or undergoing additional testing.

In summary, the manufacturing processes and quality assurance practices for tire pressure gauge pumps are integral to delivering reliable and durable products. By understanding the various stages of manufacturing, recognizing the importance of quality control, and employing effective verification strategies, B2B buyers can make informed decisions when sourcing these essential tools. This diligence not only ensures product quality but also fosters long-term relationships with suppliers, ultimately benefiting all parties involved in the supply chain.

In the dynamic landscape of automotive maintenance, sourcing a reliable tire pressure gauge pump is essential for ensuring optimal tire performance and safety. This guide provides a practical checklist to assist B2B buyers in making informed procurement decisions, ensuring they select the best products that meet their operational needs and regional standards.

Illustrative image related to tire pressure gauge pump

Clearly outline the technical requirements for the tire pressure gauge pump you need. Consider factors such as maximum pressure capacity, accuracy levels, and whether you require digital or analog gauges. Understanding these specifications will help you narrow down options that align with your operational needs and the vehicles being serviced.

Evaluate whether the tire pressure gauge pump is compatible with your current tools and systems. Check for connections, power sources (AC, DC, or battery-operated), and any necessary adapters. Ensuring compatibility can streamline operations and reduce additional investment in new equipment.

Before committing to a supplier, conduct thorough due diligence. Request company profiles, product catalogs, and references from other businesses in your industry. Look for suppliers with a proven track record in reliability and quality, as these factors can significantly impact your operational efficiency.

Ensure that the products meet relevant international and local safety standards and certifications. This is particularly crucial for buyers in regions with stringent regulations, such as Europe and the Middle East. Check for certifications like CE marking or ISO standards, which indicate compliance with quality and safety requirements.

Request detailed quotes from multiple suppliers and compare pricing models, including bulk discounts and payment terms. Understanding the total cost of ownership, including shipping and potential duties, will help you make a financially sound decision. Look for suppliers who offer flexible payment options that align with your budgetary constraints.

Examine the warranty offered on the tire pressure gauge pump and the level of after-sales support provided by the supplier. A robust warranty can protect your investment, while responsive customer support can resolve issues quickly, minimizing downtime. Ensure you understand the warranty terms and what is covered.

Illustrative image related to tire pressure gauge pump

Whenever possible, request a trial or samples of the tire pressure gauge pumps you are considering. This allows you to assess their performance and usability in real-world conditions. Testing the equipment firsthand can reveal insights into quality, ease of use, and any potential issues that may arise during regular operation.

By following this checklist, B2B buyers can streamline their sourcing process for tire pressure gauge pumps, ensuring they select products that enhance operational efficiency and safety.

When sourcing tire pressure gauge pumps, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to tire pressure gauge pump

Materials: The choice of materials directly impacts the durability and performance of the pumps. Common materials like plastics, metals, and rubber are used, with quality variations affecting pricing. Higher-grade materials may lead to increased costs but can enhance the product’s longevity.

Labor: Labor costs vary by region and can significantly influence the final price. In countries with higher wage standards, labor costs are a larger portion of the overall expenditure. Outsourcing manufacturing to regions with lower labor costs can be a strategy for cost reduction.

Manufacturing Overhead: This encompasses costs related to utilities, rent, and equipment depreciation. Efficient manufacturing processes can minimize these overheads, allowing suppliers to offer competitive pricing.

Tooling: The initial investment in tooling for production can be significant. Custom designs will require specialized tools, increasing upfront costs. However, this can lead to tailored products that meet specific market demands.

Quality Control (QC): Implementing stringent QC processes ensures that the pumps meet industry standards and certifications. While this adds to the cost, it reduces the risk of returns and enhances customer satisfaction.

Logistics: Shipping and handling costs are essential considerations, especially for international buyers. Factors such as shipping methods, distances, and customs duties can add to the total cost.

Margin: Suppliers typically include a profit margin that reflects their business model and market conditions. Understanding the margin can aid buyers in negotiating better prices.

Several factors influence the pricing of tire pressure gauge pumps:

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounts. Suppliers are more willing to negotiate on pricing for larger orders, making it beneficial for buyers to assess their demand accurately.

Specifications and Customization: Unique specifications or custom branding can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

Materials and Quality Certifications: Products that meet international quality standards or possess certifications such as ISO are generally priced higher. Buyers in regions with strict regulations should factor in these costs.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record, while new entrants may offer lower prices to gain market share.

Incoterms: Understanding delivery terms can help buyers manage costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the final price by shifting responsibilities for shipping and insurance.

B2B buyers should employ several strategies to negotiate effectively:

Research and Comparison: Conduct thorough market research to understand prevailing prices. Comparing multiple suppliers can provide leverage in negotiations.

Total Cost of Ownership (TCO): Consider the long-term costs associated with the product, including maintenance, warranty, and potential replacements. A higher upfront cost may be justified by lower TCO.

Establish Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or improved service to loyal clients.

Be Transparent About Needs: Clearly communicate your requirements and expectations to suppliers. Transparency can lead to customized solutions that meet your needs without unnecessary costs.

For international buyers, particularly in Africa, South America, the Middle East, and Europe, several nuances should be considered:

Currency Fluctuations: Be mindful of currency exchange rates, as they can affect purchasing power and total costs.

Local Regulations: Familiarize yourself with import duties, taxes, and local regulations that may influence pricing.

Cultural Differences: Understanding cultural nuances can facilitate better communication and negotiation outcomes.

Buyers should note that the prices mentioned in various sources are indicative and can fluctuate based on market conditions. Engaging with suppliers to get tailored quotes will provide a clearer picture of costs specific to your needs. By understanding the cost structure and utilizing effective negotiation strategies, B2B buyers can secure the best deals on tire pressure gauge pumps.

In the tire maintenance industry, ensuring optimal tire pressure is crucial for vehicle performance, safety, and fuel efficiency. While tire pressure gauge pumps are widely used for this purpose, several alternative solutions exist that can also achieve effective tire inflation and monitoring. Understanding these alternatives can help international B2B buyers make informed decisions tailored to their operational needs.

| Comparison Aspect | Tire Pressure Gauge Pump | Digital Tire Inflator | Manual Hand Pump |

|---|---|---|---|

| Performance | Accurate pressure measurement; can inflate tires | Fast inflation; may include features like auto shut-off | Labor-intensive; slower inflation process |

| Cost | Moderate ($30-$70) | Higher ($50-$100) | Low ($10-$30) |

| Ease of Implementation | Simple; requires basic knowledge | User-friendly; often plug-and-play | Requires physical effort; less convenient |

| Maintenance | Minimal; check for leaks and calibrate | Regular checks needed; electrical components may fail | Low; generally durable but needs manual checks |

| Best Use Case | Regular vehicle maintenance | Quick roadside assistance or high-volume use | Emergency situations or casual use |

Digital tire inflators are designed for speed and convenience, often featuring automatic shut-off and built-in pressure gauges. They typically offer a higher PSI capacity than traditional gauge pumps, making them suitable for a variety of vehicles, including trucks and SUVs. However, their reliance on electrical components can lead to potential malfunctions, and they may require more frequent maintenance to ensure accuracy.

Illustrative image related to tire pressure gauge pump

Manual hand pumps are a cost-effective solution for tire inflation, especially in emergency situations. They are lightweight, portable, and require no electricity, making them ideal for remote areas. However, they demand physical effort and time to inflate tires, which can be a disadvantage in urgent scenarios. Moreover, the accuracy of pressure measurement may not be as reliable as digital options.

When selecting the right tire maintenance solution, B2B buyers should consider several factors, including the volume of tires needing maintenance, the typical operating environment, and the level of convenience required. For businesses that prioritize efficiency and rapid response, a digital tire inflator may be the best choice despite its higher initial cost. Conversely, for companies operating in remote locations with limited access to power, a manual hand pump could be the most practical option.

In conclusion, the choice between a tire pressure gauge pump, digital tire inflator, and manual hand pump ultimately hinges on specific operational needs and preferences. By evaluating performance, cost, ease of use, and maintenance requirements, B2B buyers can make a strategic decision that aligns with their business objectives and enhances overall tire maintenance efficiency.

Illustrative image related to tire pressure gauge pump

Understanding the essential technical properties of tire pressure gauge pumps is crucial for B2B buyers, as these specifications directly affect performance, reliability, and cost-effectiveness. Here are some critical specs to consider:

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates how much pressure the gauge can handle. Most tire pressure gauge pumps range from 100 to 200 PSI. For B2B buyers, selecting a pump with the appropriate PSI rating is vital, especially for heavy-duty applications like commercial vehicles or off-road machinery, where higher pressure is often required.

Accuracy tolerance refers to the permissible deviation from the true pressure measurement. A typical tolerance might be ±1-2 PSI. This specification is significant for B2B buyers, as accurate tire pressure measurements can prevent tire wear and improve fuel efficiency, leading to substantial cost savings in fleet operations.

The material used in constructing the tire pressure gauge pump affects durability and performance. Common materials include high-grade plastics, aluminum, and stainless steel. For international buyers, understanding material grades ensures that the product can withstand varying environmental conditions, such as extreme temperatures or humidity, particularly in regions like Africa and the Middle East.

Illustrative image related to tire pressure gauge pump

Tire pressure gauge pumps can be powered by various sources, including AC, DC, or battery. Understanding the power source is essential for B2B buyers who need to ensure compatibility with existing systems and the convenience of use in remote locations. For example, battery-operated pumps may be more advantageous for off-road applications.

The length and type of hose can influence the ease of use and flexibility of the pump. Longer hoses allow for better reach, especially in commercial settings where multiple tires may need inflating. Buyers should evaluate hose materials and fittings to ensure compatibility with their specific tire types and valve stems.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms that decision-makers should know:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire pressure gauge pumps, understanding OEM relationships can help buyers ensure they are sourcing high-quality, compatible products.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cost considerations. Knowing the MOQ helps in budgeting and planning for larger purchases.

Illustrative image related to tire pressure gauge pump

An RFQ is a document issued by a buyer to request pricing and availability for specific products. B2B buyers should be familiar with the RFQ process to obtain competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions.

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international trade. They clarify the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms is vital for avoiding misunderstandings and ensuring smooth transactions.

Warranty terms specify the duration and coverage of repairs or replacements for defects. B2B buyers should carefully review warranty conditions, as they can significantly impact the long-term cost of ownership and reliability of tire pressure gauge pumps.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their tire maintenance processes.

The tire pressure gauge pump market is witnessing significant growth driven by rising vehicle ownership, increased awareness of tire maintenance, and the push for fuel efficiency. With a global shift towards sustainability and eco-friendly practices, buyers are increasingly looking for products that help reduce fuel consumption and enhance tire longevity. This has led to a surge in the demand for high-precision inflators and digital gauges that provide accurate readings, thus preventing over-inflation or under-inflation.

Illustrative image related to tire pressure gauge pump

Emerging technologies such as IoT (Internet of Things) integration in tire pressure monitoring systems are becoming prevalent. These innovations enable real-time monitoring and can send alerts to drivers, promoting timely maintenance. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, sourcing products equipped with such technologies can enhance service offerings and customer satisfaction. Additionally, the rise of e-commerce platforms is making it easier for businesses to access a wider range of suppliers and products, optimizing procurement processes.

Moreover, the increasing trend of DIY vehicle maintenance among consumers is driving the demand for portable and user-friendly tire inflators. As more consumers prefer to manage tire pressure independently, international buyers should focus on product features such as portability, ease of use, and multifunctionality, including the ability to inflate various types of tires and sports equipment.

The environmental impact of manufacturing processes in the tire pressure gauge pump sector is gaining attention. As global consumers become more environmentally conscious, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes the use of recycled materials in manufacturing and reducing carbon footprints throughout the supply chain.

Illustrative image related to tire pressure gauge pump

Ethical sourcing is equally critical, as businesses face pressure to ensure their suppliers adhere to fair labor practices and environmentally responsible methods. Certifications such as ISO 14001 for environmental management and Fair Trade labels can help buyers identify suppliers committed to sustainability and ethical practices.

Investing in ‘green’ products not only aligns with corporate social responsibility goals but also appeals to end consumers who prefer eco-friendly options. B2B buyers should look for suppliers who offer transparent supply chains and can provide proof of sustainable practices, as this will enhance their brand reputation and customer loyalty.

The tire pressure gauge pump sector has evolved significantly over the past few decades. Initially, tire pressure gauges were mechanical devices that relied on analog readings, often leading to inaccuracies. The introduction of digital technology revolutionized the industry by providing precise measurements and ease of use.

As vehicle technology advanced, the integration of tire pressure monitoring systems (TPMS) became standard in many modern vehicles, further driving the demand for reliable and accurate tire pressure gauge pumps. This historical context underscores the importance of continuous innovation, positioning B2B buyers to focus on suppliers who are at the forefront of technological advancements in tire maintenance solutions.

Illustrative image related to tire pressure gauge pump

In summary, understanding the market dynamics, the significance of sustainability, and the historical evolution of the tire pressure gauge pump sector is crucial for international B2B buyers aiming to make informed sourcing decisions and enhance their competitive edge in the market.

How do I choose the right tire pressure gauge pump for my business needs?

Selecting the right tire pressure gauge pump involves considering several factors. First, assess the intended use—commercial or industrial—and the types of vehicles you’ll be servicing. Look for features like pressure range, durability, and ease of use. Digital gauges typically offer higher accuracy and ease of reading, while analog models may be more straightforward for basic applications. Additionally, consider your budget and whether you require any specific certifications or compliance with local regulations.

What is the best tire pressure gauge pump for high-volume applications?

For high-volume applications, consider pumps with a higher PSI rating and faster inflation speeds. Digital tire inflators, such as those with a capacity of 200 PSI, are ideal for quickly servicing multiple vehicles, particularly in commercial settings. Look for models that include features like automatic shut-off to prevent over-inflation and built-in pressure gauges for accuracy. Brands that are recognized for their reliability and performance in the market, such as JACO, are often recommended for such needs.

What factors should I consider when vetting suppliers for tire pressure gauge pumps?

When vetting suppliers, evaluate their reputation and experience in the industry. Check for reviews and testimonials from other B2B clients to gauge reliability. Additionally, inquire about their manufacturing processes, quality control measures, and product certifications. Assess their capacity for customization, response times for inquiries, and after-sales support. Ensure they can meet your volume needs and have a track record of timely deliveries, especially for international shipping.

What are the minimum order quantities (MOQs) for tire pressure gauge pumps?

MOQs can vary significantly by supplier and product type. Generally, established manufacturers may set MOQs ranging from 50 to 500 units, depending on the model and customization options. For smaller businesses, it’s advisable to discuss potential flexibility on MOQs with suppliers, as some may offer lower quantities for new customers or sample orders. Always clarify the MOQ upfront to avoid any unexpected costs or commitments.

What payment terms are commonly offered for international B2B purchases?

Payment terms can differ widely among suppliers, but common options include advance payment, 30/60/90-day terms, or letters of credit. Many suppliers require a deposit (often 30%) upon order confirmation, with the balance due before shipment. It’s essential to establish clear terms that protect both parties, especially when dealing with international transactions. Evaluate the payment methods accepted, such as bank transfers, credit cards, or online payment platforms, to ensure they align with your financial processes.

How can I ensure the quality of tire pressure gauge pumps before purchasing?

To ensure product quality, request samples from potential suppliers and conduct thorough testing. Check for accuracy in pressure readings and overall build quality. Additionally, ask about quality assurance processes, certifications, and warranty options. Engaging in third-party inspections or audits can also be beneficial, particularly for large orders. Establishing a clear communication line with the supplier about your quality expectations is crucial.

What shipping options are available for tire pressure gauge pumps, and how do I manage logistics?

Shipping options typically include air freight for faster delivery and sea freight for cost-effective bulk shipments. When managing logistics, consider factors like shipping time, costs, and the reliability of the shipping provider. Ensure that you understand the customs regulations of your destination country, including duties and taxes. Collaborating with logistics experts or freight forwarders can streamline the process and mitigate potential delays.

Are there customization options available for tire pressure gauge pumps?

Many suppliers offer customization options, including branding, color choices, and specific features tailored to your business needs. Discuss your requirements with potential suppliers, as some may have the capability to modify existing products or develop new ones to meet your specifications. Customization can enhance your brand identity and provide added value to your customers, making it an attractive option for B2B buyers.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Brands mentioned: Milton, Longacre, Astro, Matco. Features: Longacre offers analog and digital models, including temperature compensated ones. Astro inflators are priced around $80. Matco DT6 is a rebranded Astro 3018, priced at $90. Recommendations suggest that tire inflators should not be trusted to measure pressure accurately.

As the demand for reliable tire pressure gauge pumps continues to rise, strategic sourcing becomes imperative for international B2B buyers. Leveraging the insights gained from market trends, product features, and competitive pricing can significantly enhance procurement efficiency. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers who offer innovative features—such as digital displays and high PSI capabilities—while ensuring product durability and performance.

Investing in quality tire pressure gauge pumps not only ensures vehicle safety and optimal tire performance but also contributes to cost savings through improved fuel efficiency and extended tire life. Additionally, establishing strong relationships with manufacturers and distributors can open doors to advantageous pricing models and exclusive product offerings.

Looking ahead, the tire pressure gauge pump market is set to evolve with advancements in technology and sustainability. Buyers are encouraged to stay informed about emerging products and trends to make strategic decisions that align with their operational needs. By prioritizing quality and supplier reliability, international B2B buyers can position themselves for success in this dynamic marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.